Box folding mechanism

A technology of folding box and jacking mechanism, which is applied in the direction of packaging, etc., can solve the problems of needing a lot of manpower, unfavorable long-term use, and low position accuracy, and achieve the effect of high folding efficiency, small occupied space, and high folding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

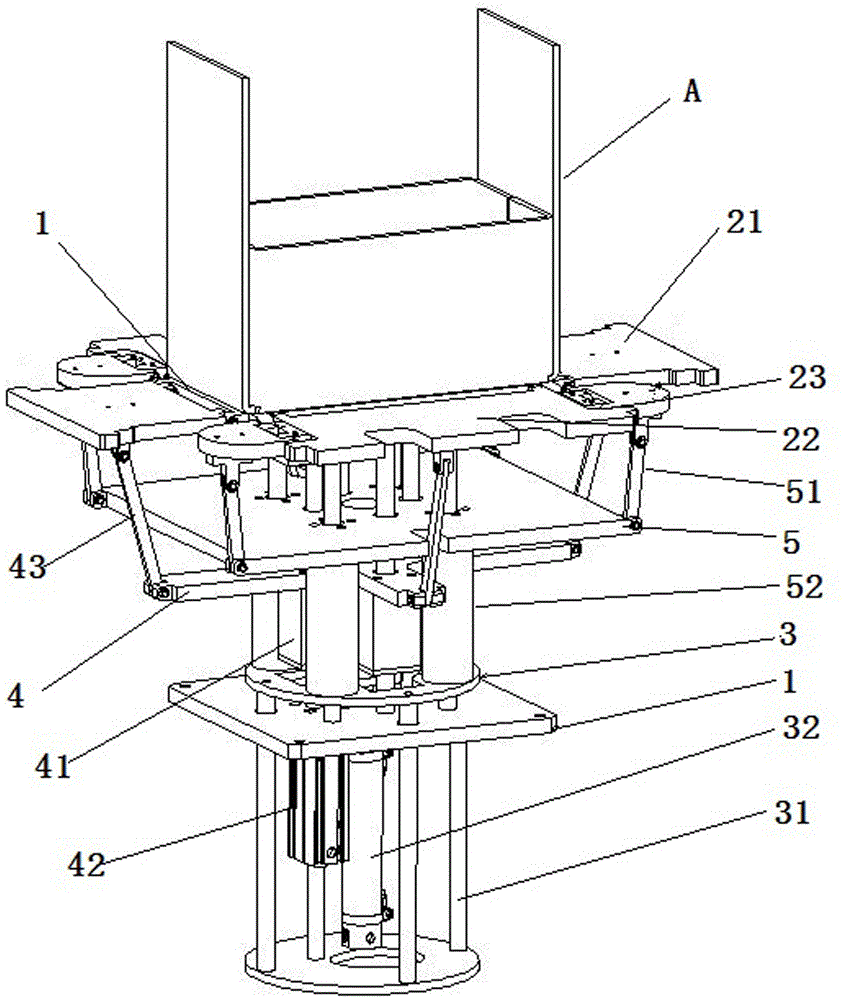

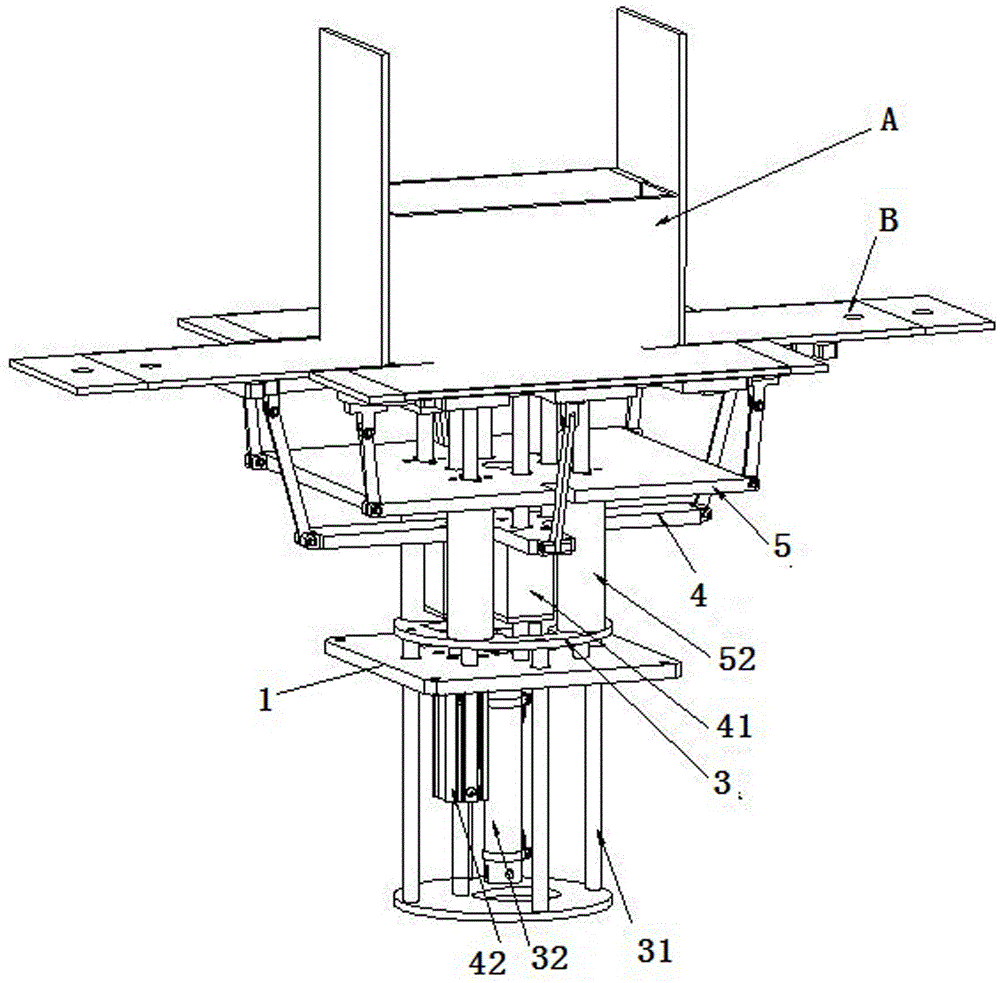

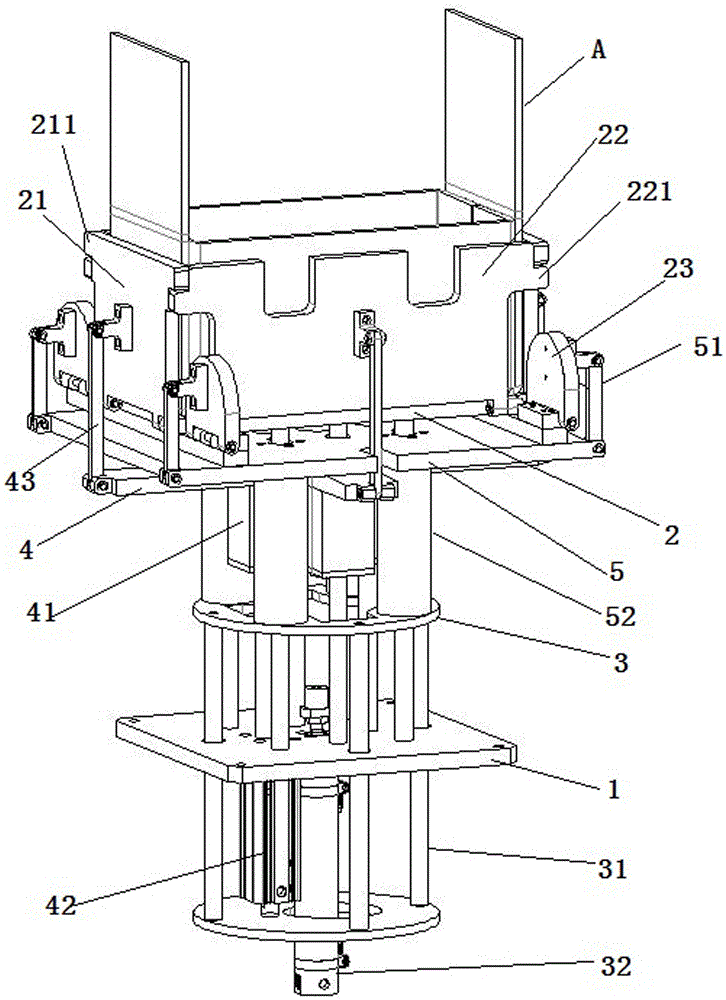

[0017] Aiming at the above-mentioned technical solution, a preferred embodiment is given and described in detail with reference to the drawings. see Figure 1 to Figure 3 , The folding box mechanism of the present invention mainly includes a frame, a folding platform, a folding plate, a folding ear plate, a folding plate lifting mechanism, a folding ear plate lifting mechanism and a pressing mechanism, wherein.

[0018] rack, not shown in the figure. A fixed substrate 1 is fixedly installed on the frame. A folding platform 2 is fixedly installed on the frame above the fixed base plate 1 . The folding platform is a square platform for placing the cut flat cardboard. In this embodiment, the folded planar cardboard is marked as A, and the unfolded planar cardboard is marked as B. A pair of short folding plates 21 and a pair of long folding plates 22 are respectively hinged on opposite sides of the folding platform. The short and long folding panels are at the same level as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com