Patents

Literature

43 results about "EAR FOLDING" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The breed's distinctive folded ears are produced by an incompletely dominant gene that affects the cartilage of the ears, causing the ears to fold forward and downward, giving a cap-like appearance to the head. Smaller, tightly folded ears set in a cap-like fashion are preferred to a loose fold and larger ear.

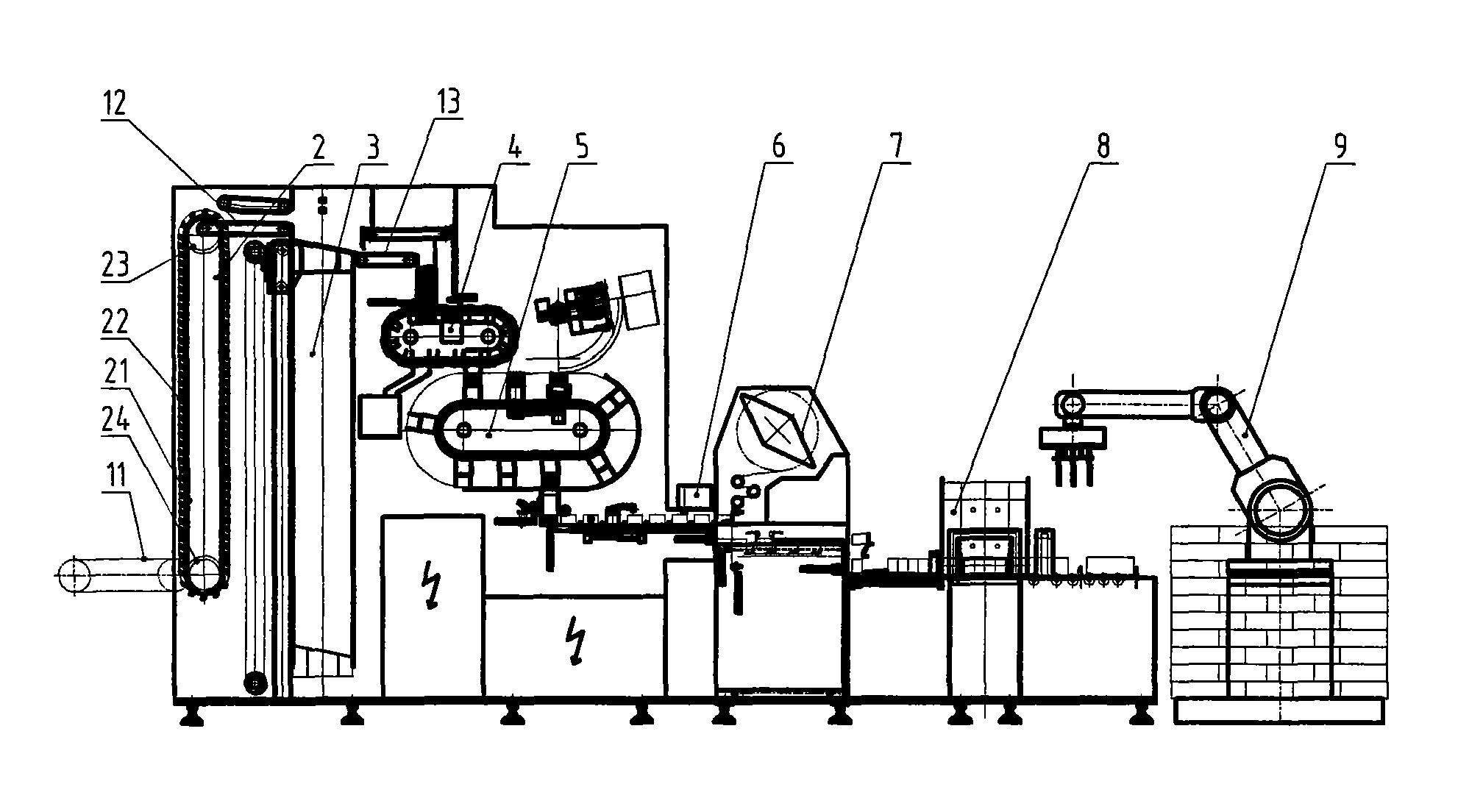

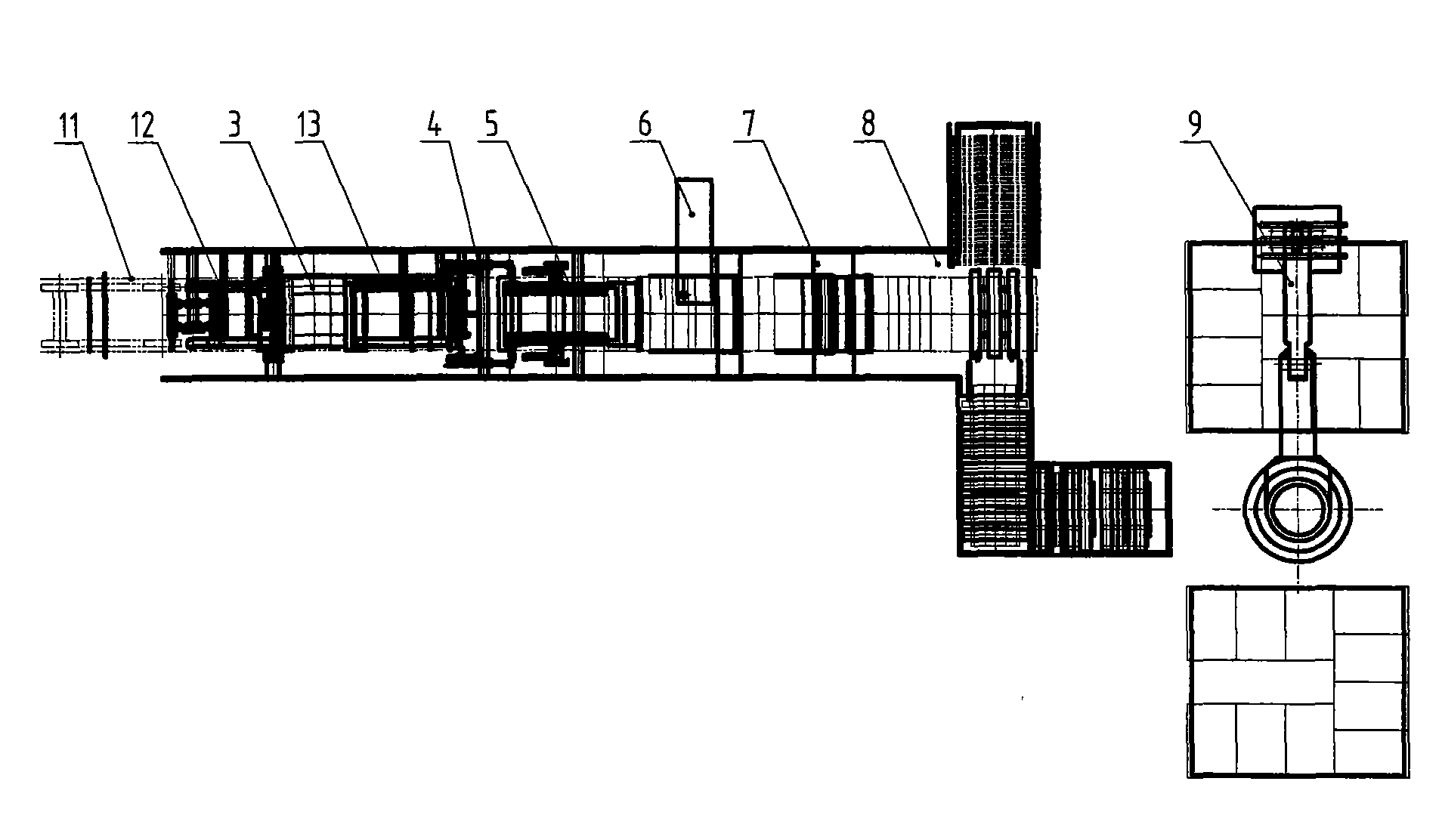

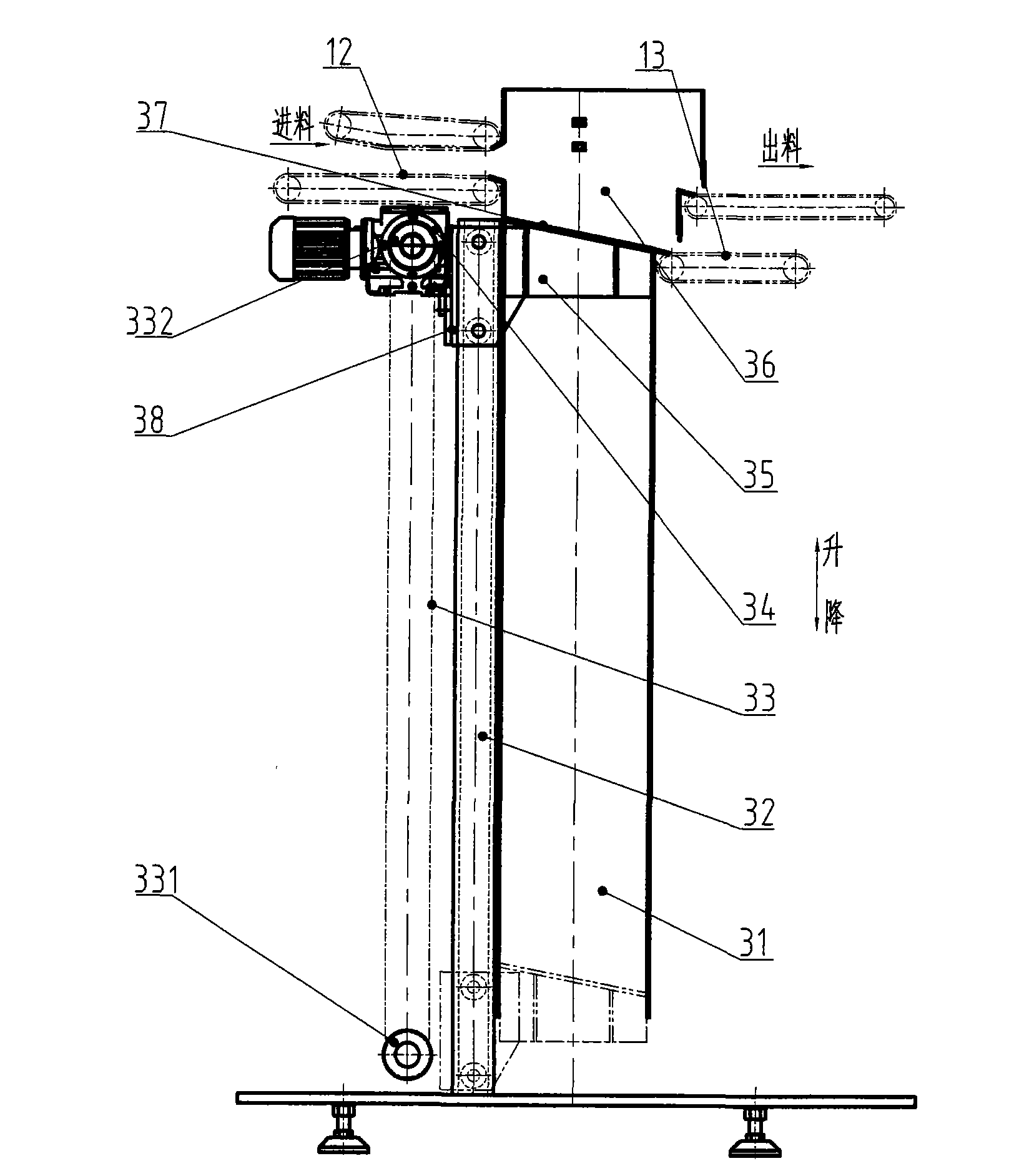

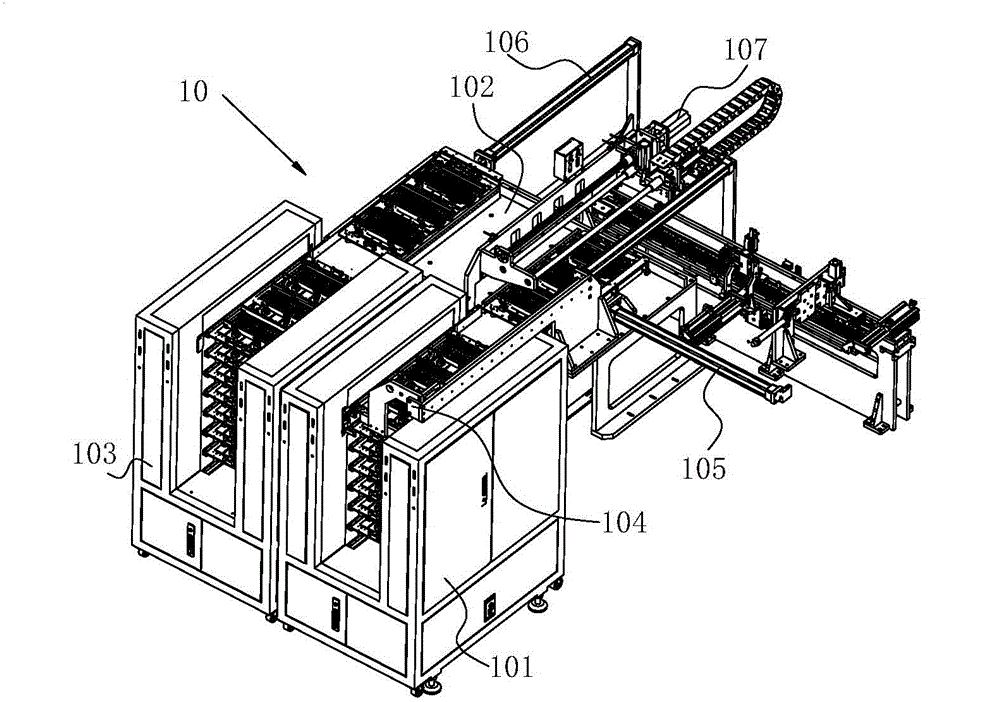

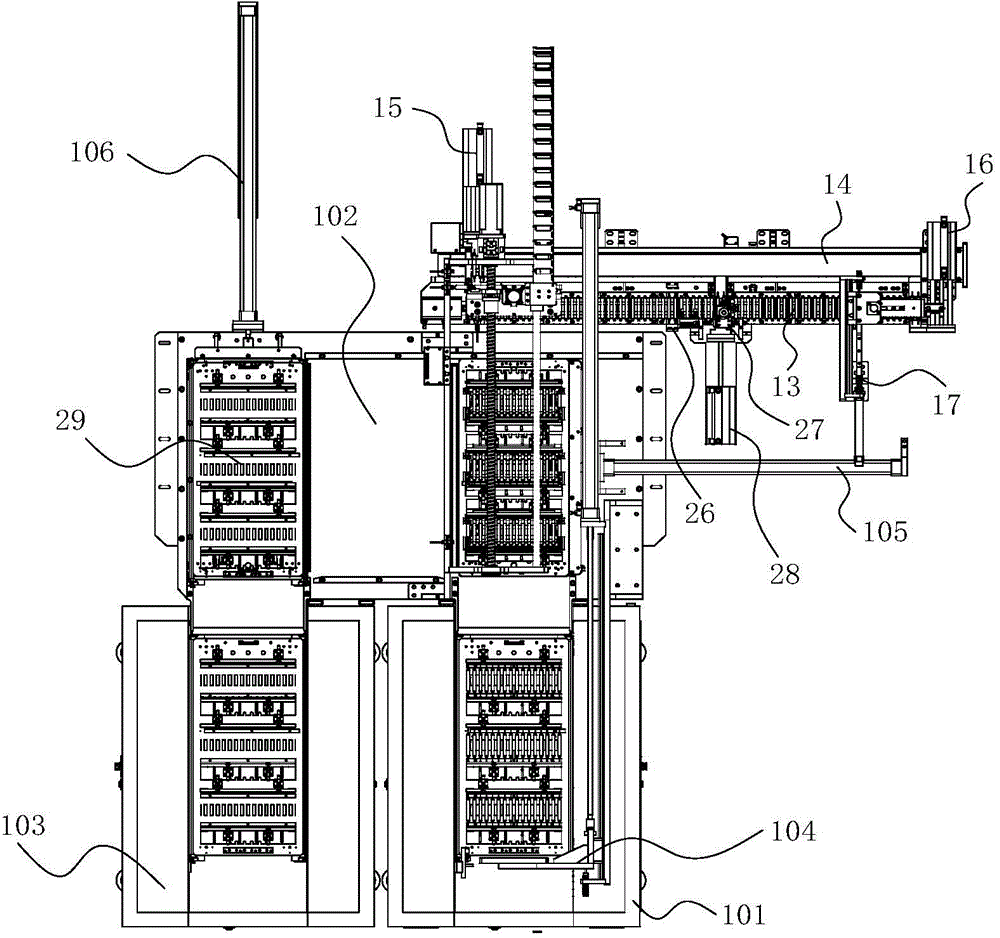

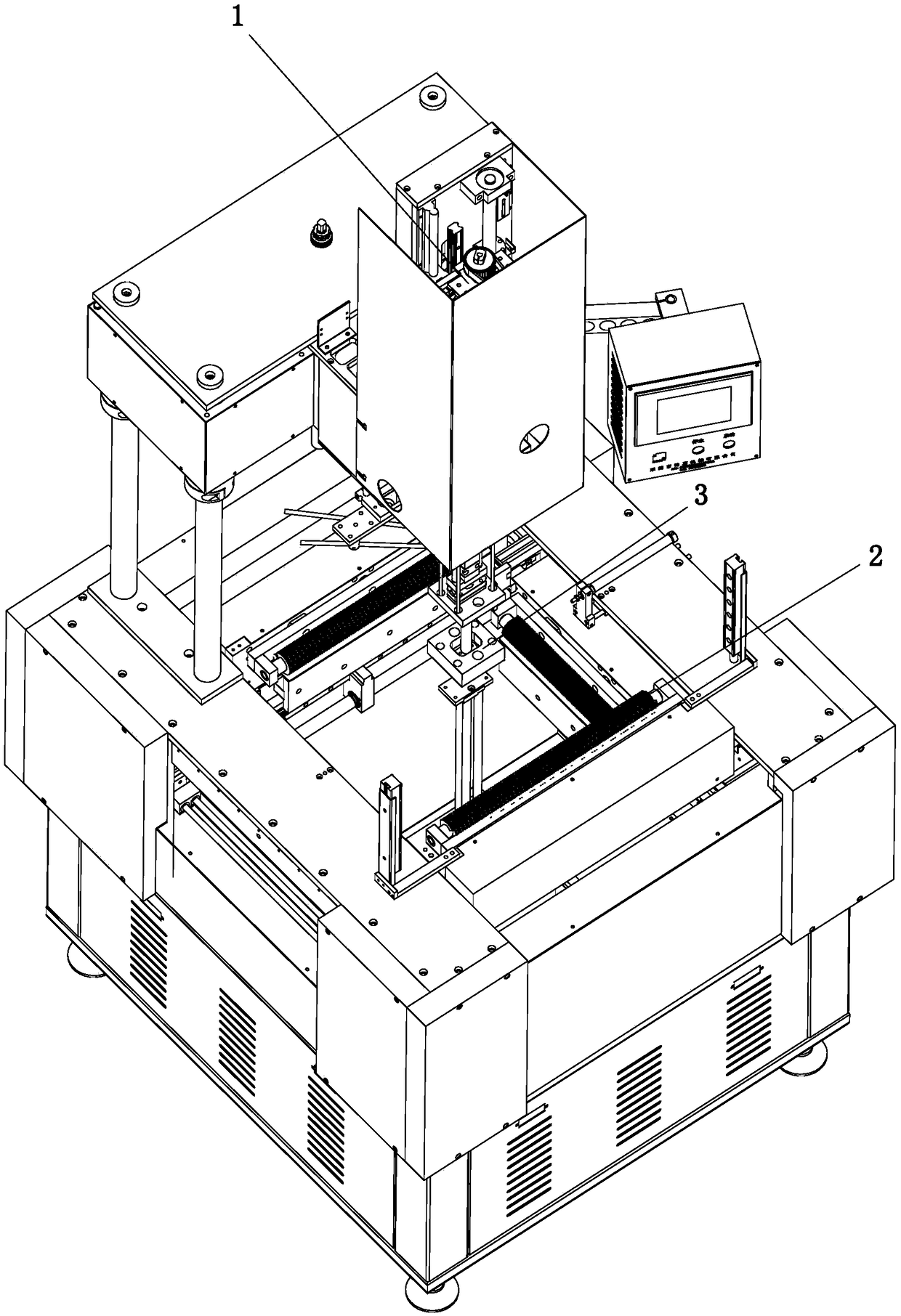

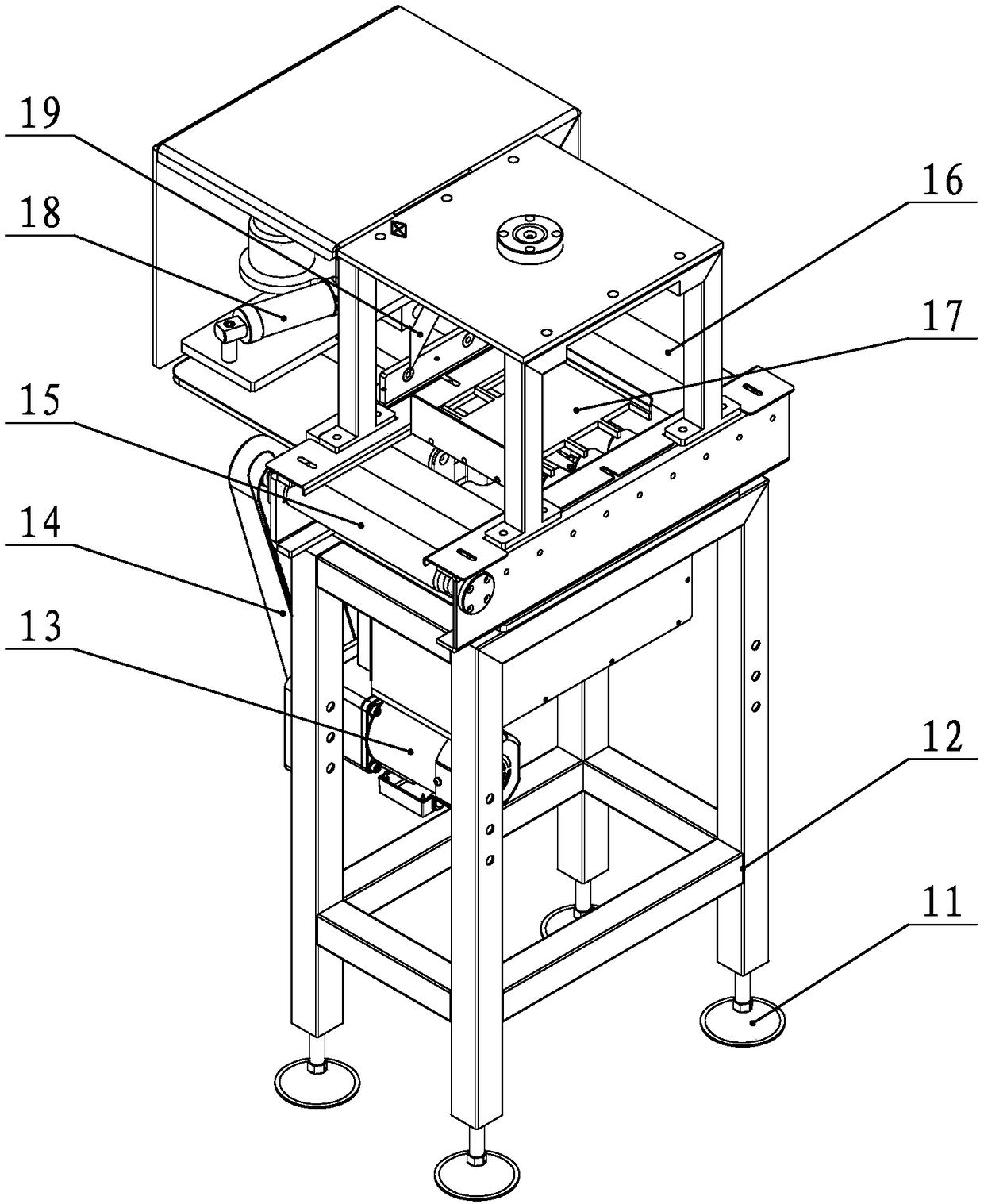

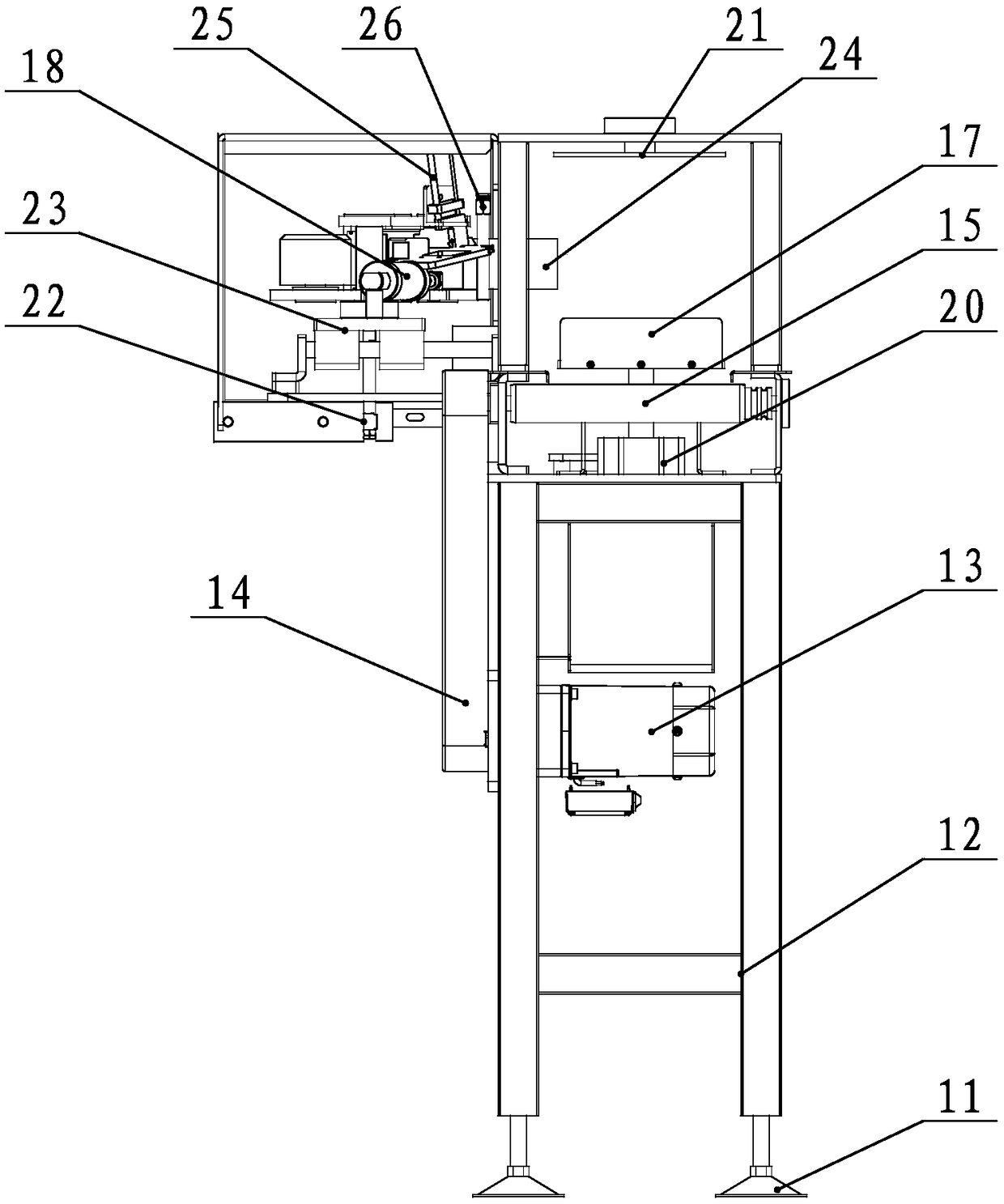

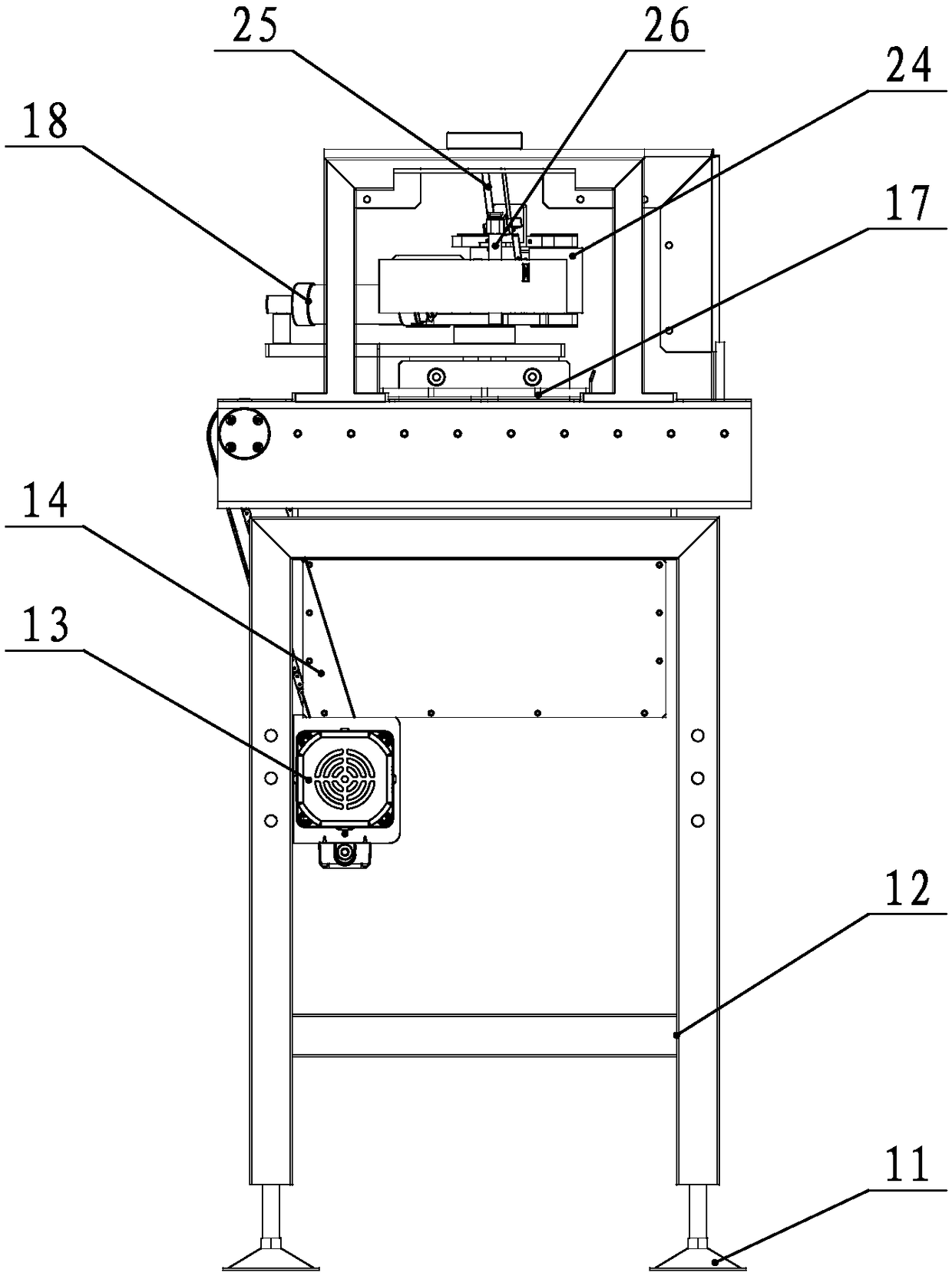

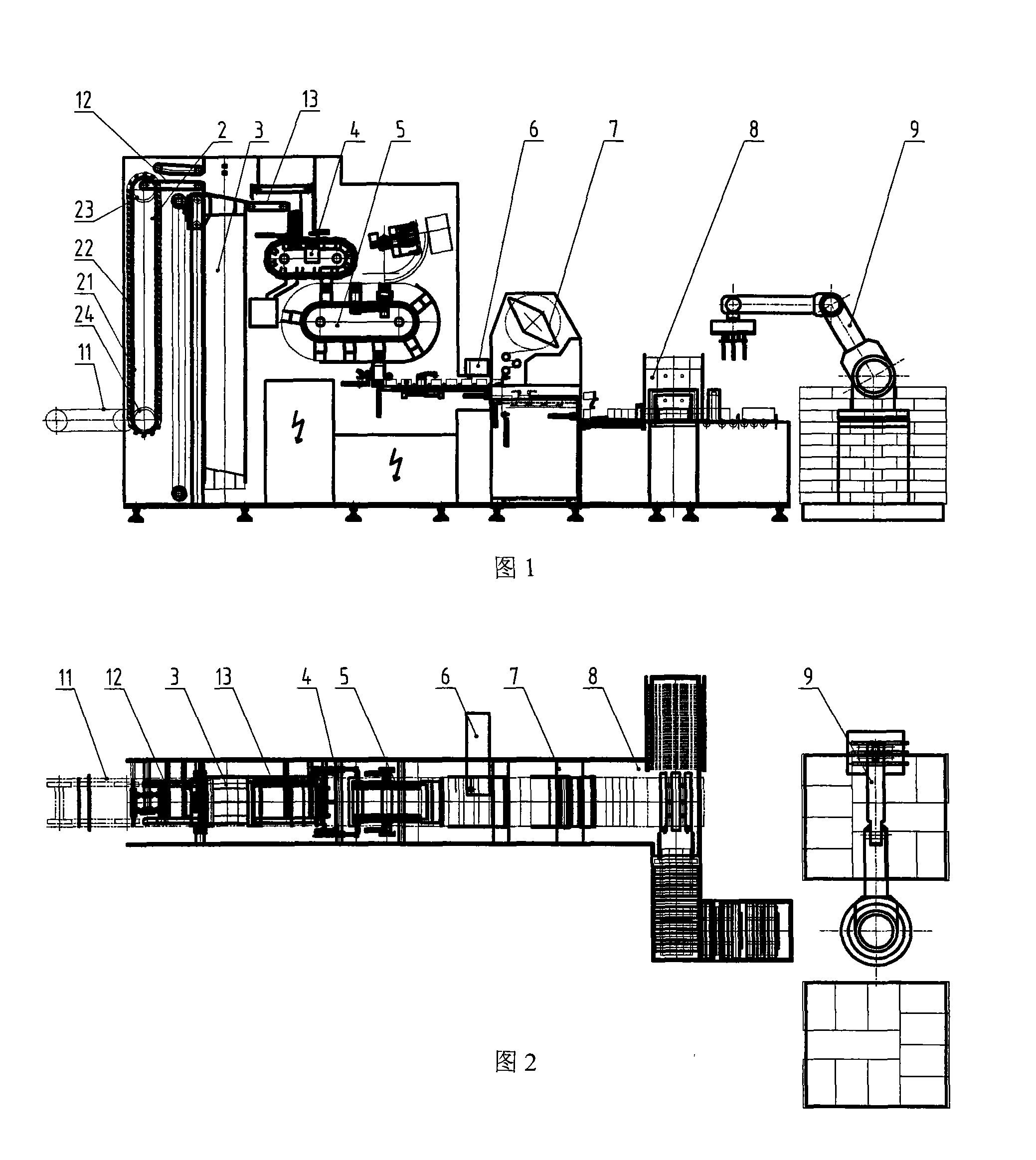

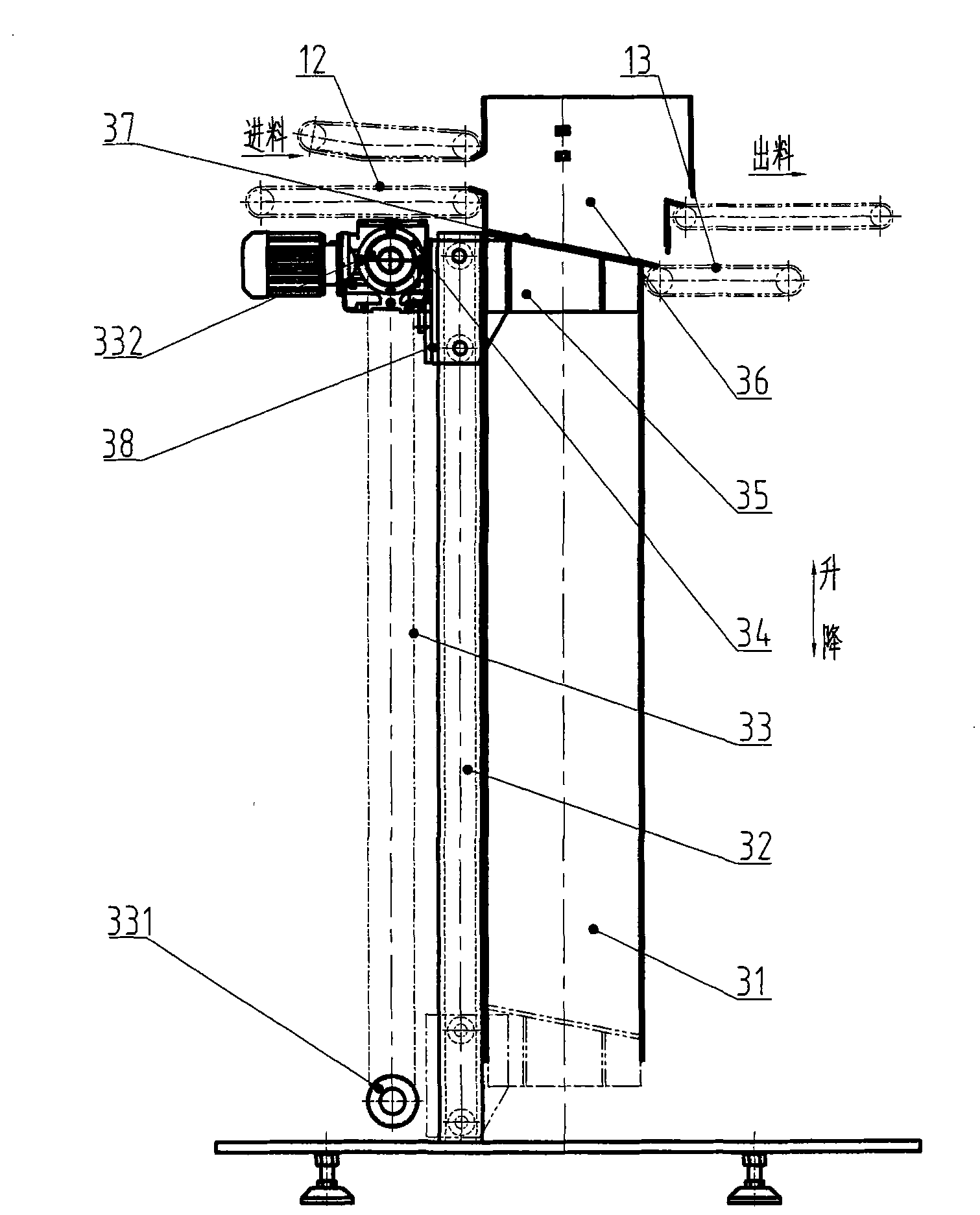

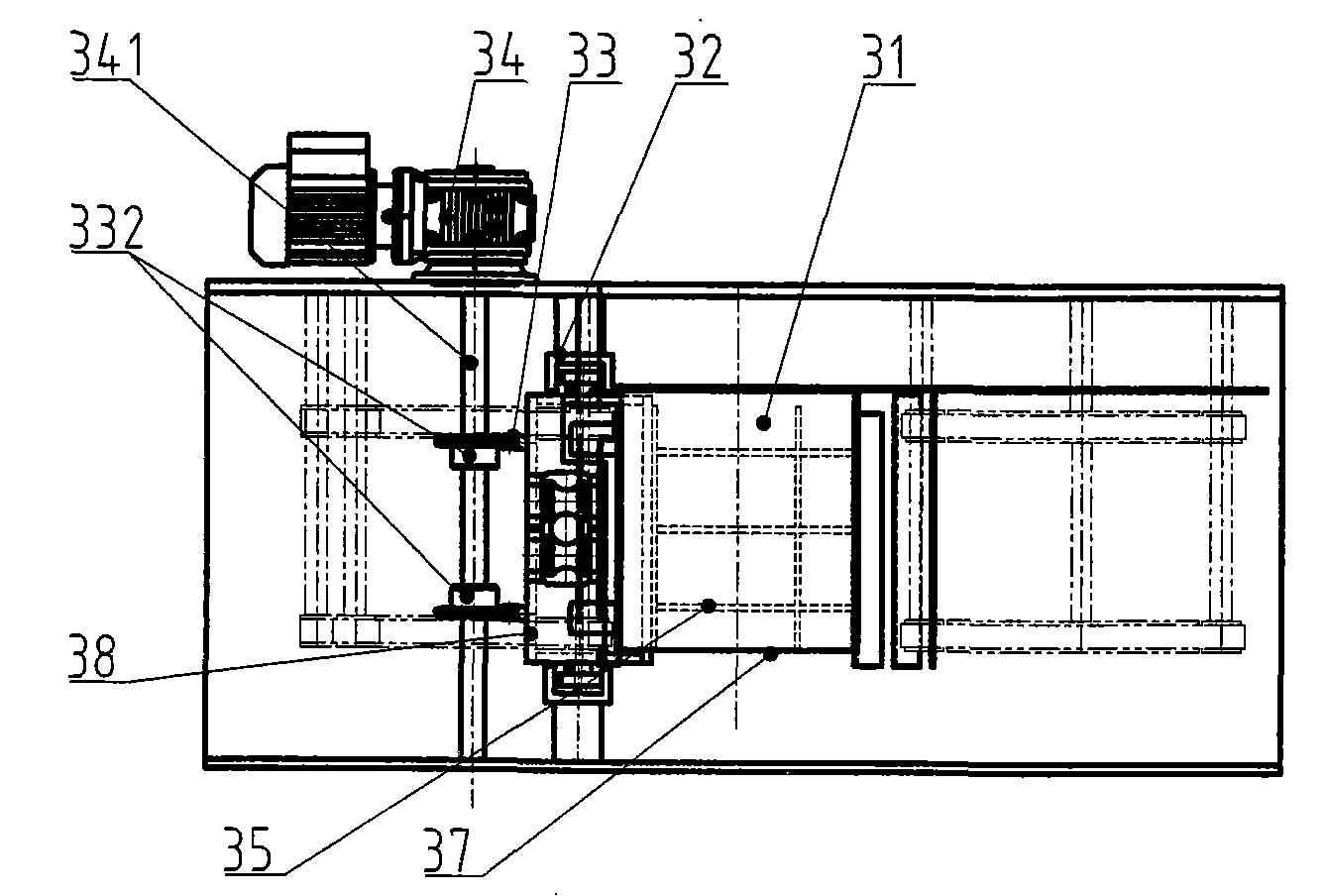

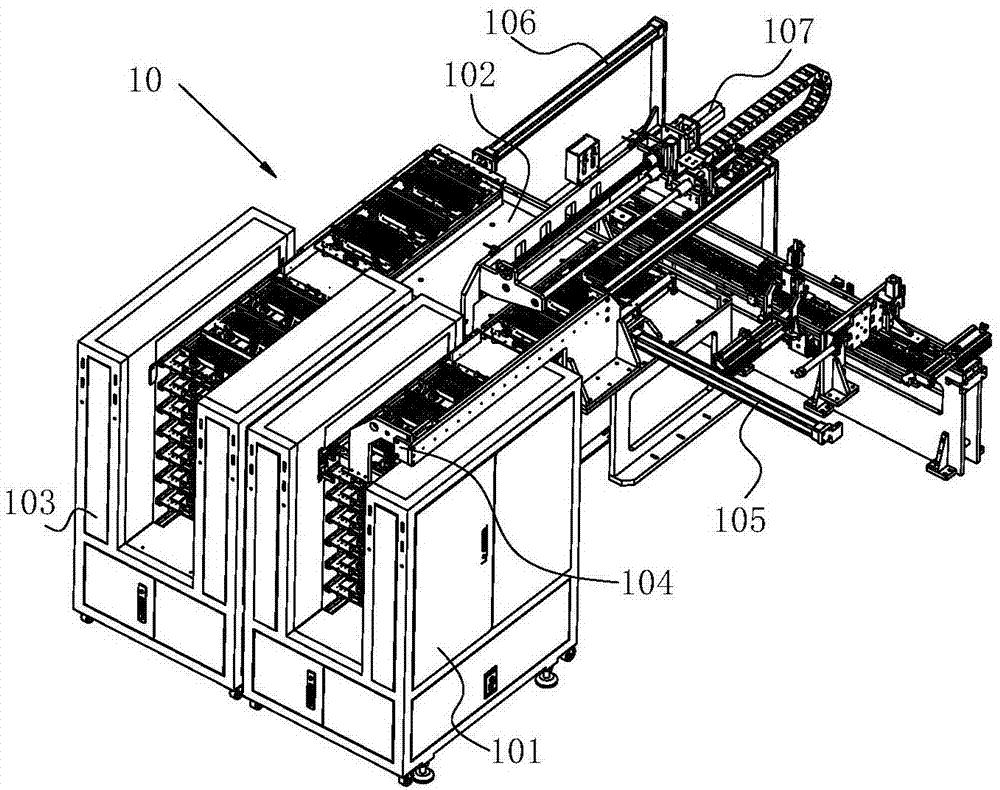

Automatic packaging machine

InactiveCN101525056AReduce laborQuality improvementWrapper twisting/gatheringSolid materialEngineeringManufacturing line

The invention provides an automatic packaging machine, comprising a conveying mechanism. The automatic packaging machine is characterized by also comprising a lifter, a storing machine, a sub-boxing weigher and a boxing and packaging machine. The materials to be packaged are conveyed by the lifter to the storing machine for temporary storage so as to maintain continuous normal operation of production lines and packaging lines, or the materials are conveyed directly to another conveyer by the storage machine, then conveyed into a material-collecting box of the sub-boxing weigher, subpackaged into a material box by a discharging channel of the lower part of the material-collecting box, weighed, measured and conveyed into a charging box of the boxing and packaging machine; packaging box paper is placed on the materials by a paper box supply mechanism, firstly box edge folding, edge ear folding and edge end folding of the packaging box paper are finished, then the rest box edge folding and edge end folding are finished in the discharging process of separation of the materials from the charging box, thus realizing full automatic sub-boxing, measuring, boxing and packaging of materials, reducing the labor of workers to a greater degree, improving working efficiency and enhancing level and quality of products. The boxing and packaging machine has compact structure and reasonable layout and does not occupy space.

Owner:KUNMING DINGCHENG TECH

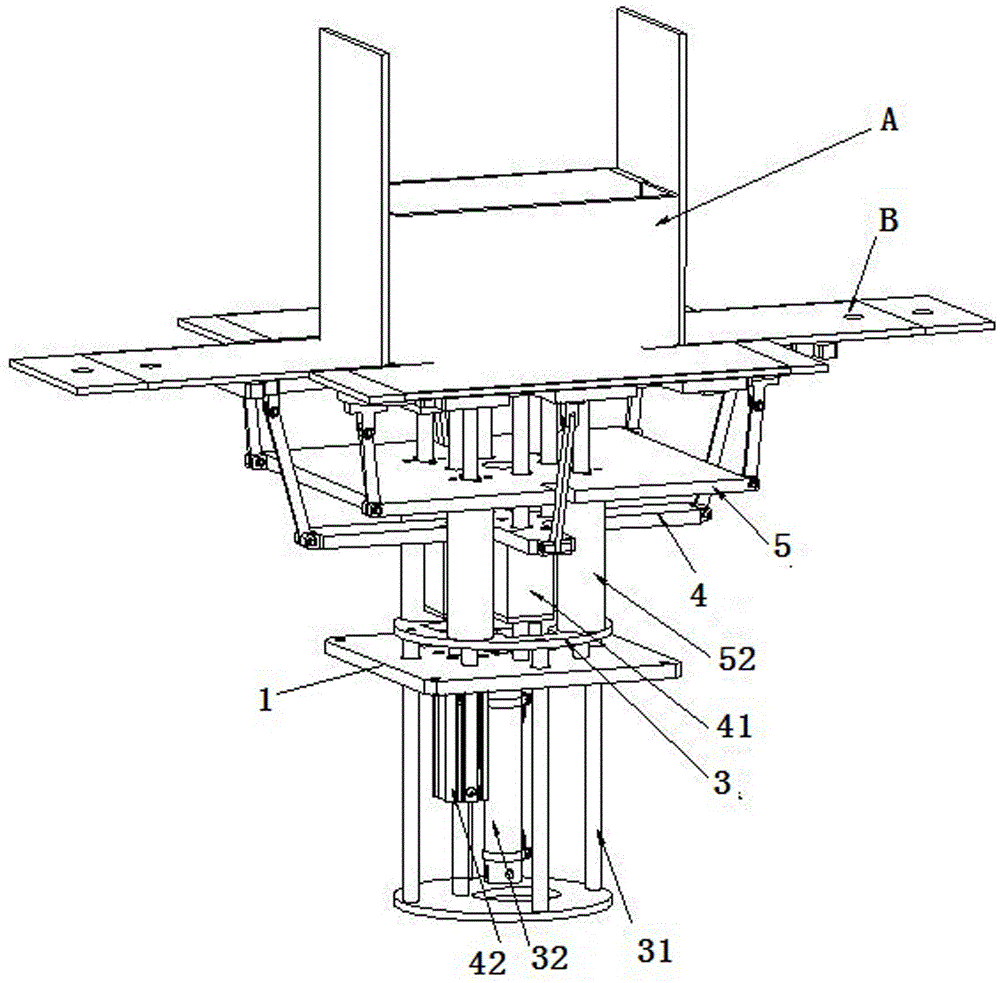

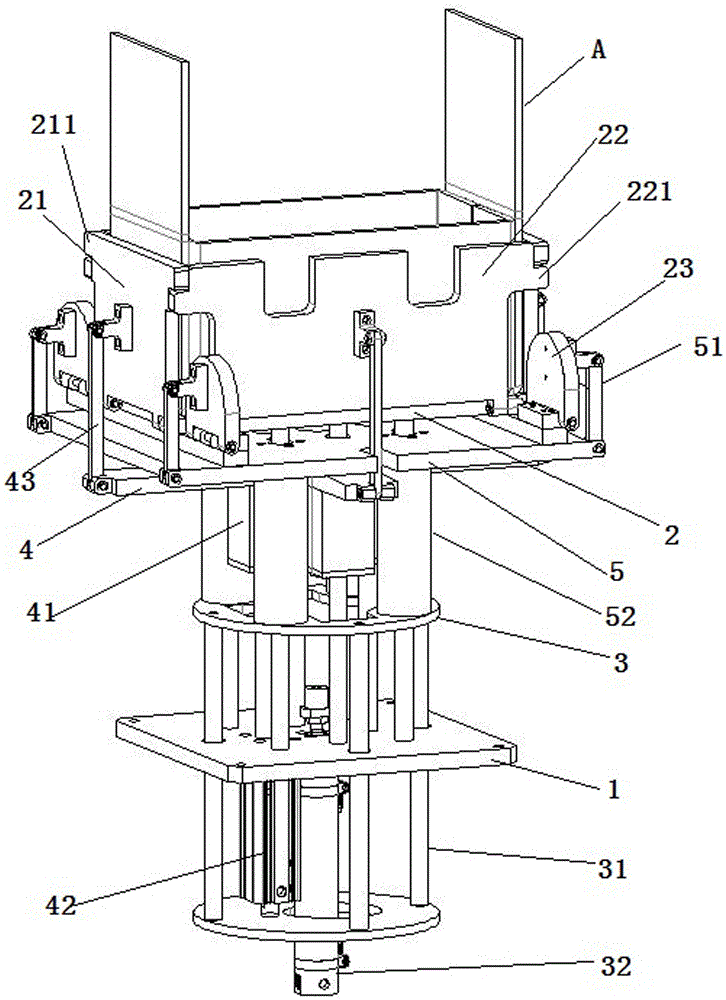

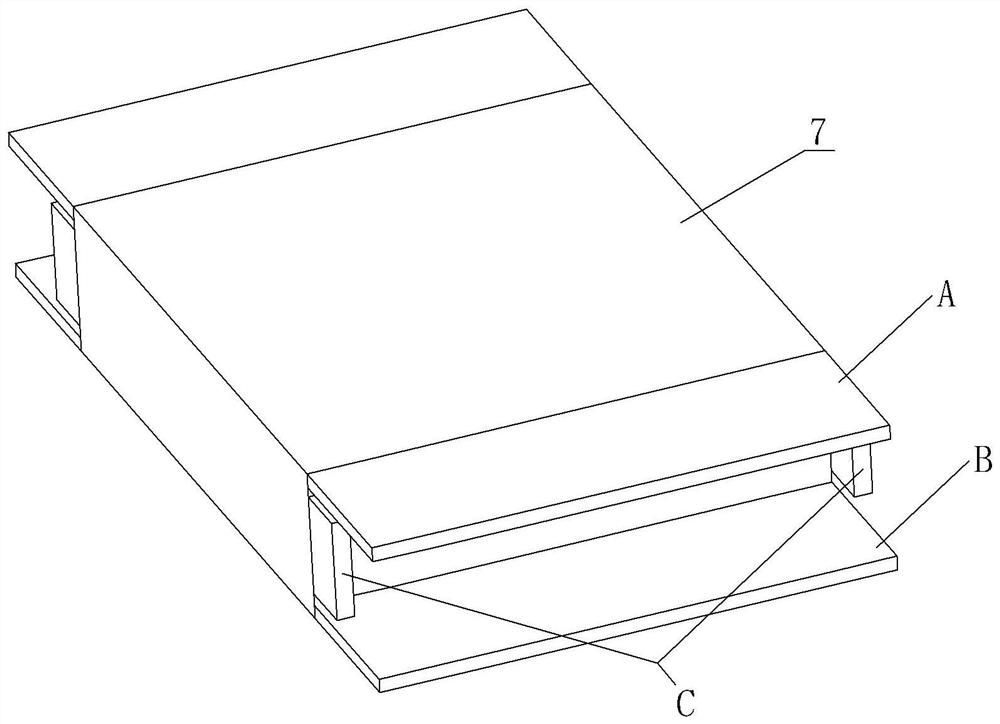

Box folding mechanism

The invention relates to a box folding mechanism. The box folding mechanism comprises a rack, wherein a square folding platform is fixed on the rack, two groups of folding plates are separately hinged to two opposite sides of the folding platform, and ear folding plates are separately hinged to the rack at two opposite sides of one group of folding plates; a folding plate jacking mechanism and an ear folding plate jacking mechanism are separately arranged on the rack below the folding platform, the folding plates are movably connected with the folding plate jacking mechanism separately through links, and the ear folding plates are movably connected with the ear folding plate jacking mechanism separately through links, two pressing mechanisms are further arranged on the rack above the folding platform, one pressing mechanism is used for pressing ear folding parts of carton boards, and the other pressing mechanism is used for pressing carton boards parts, which do not need folding, located on the folding platform. According to the box folding mechanism, all corners of each cut planar carton board can be automatically folded as required according to box folding requirements. The folding efficiency is high, the folding quality is high, and the space occupied by the box folding mechanism is small.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

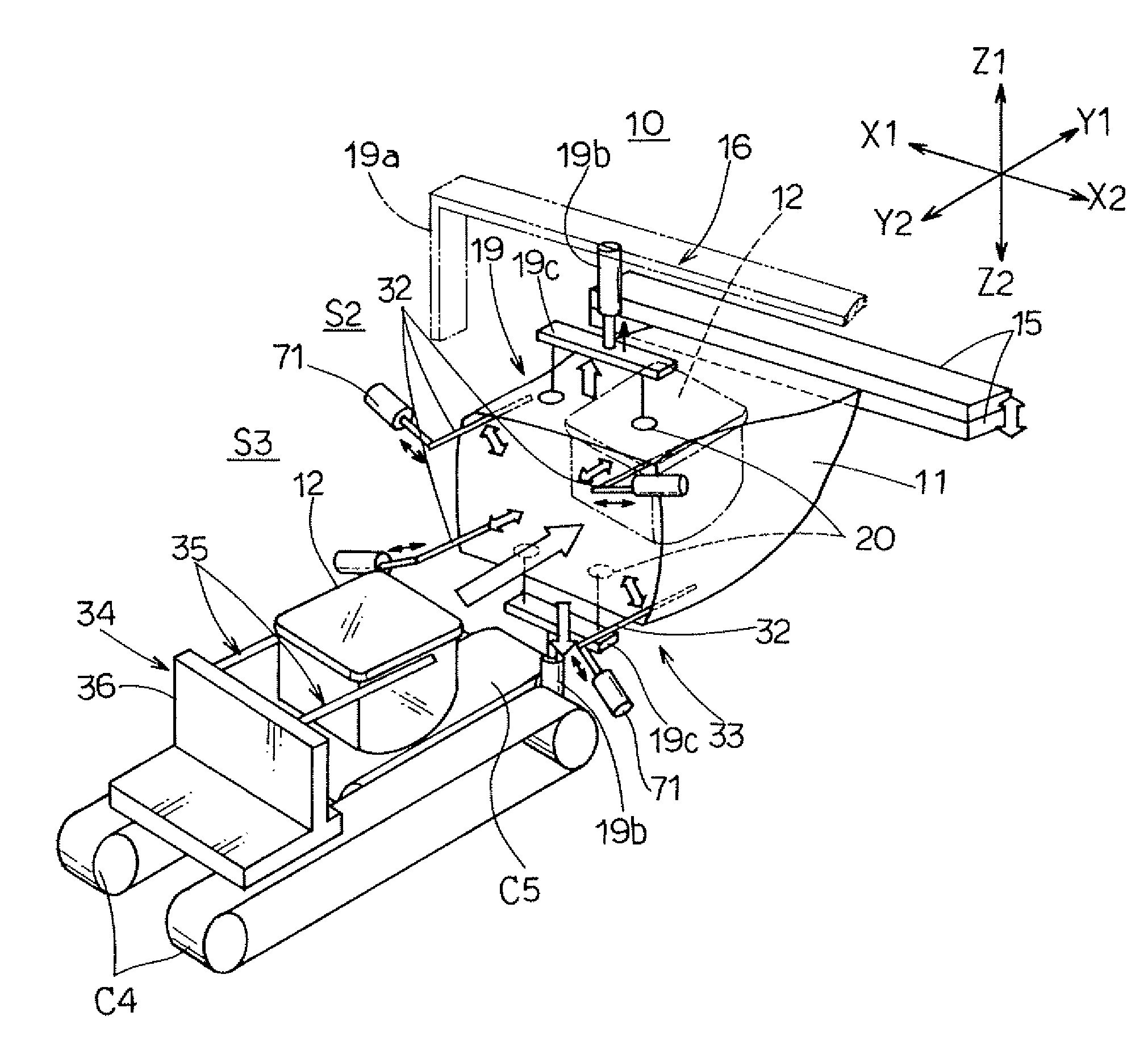

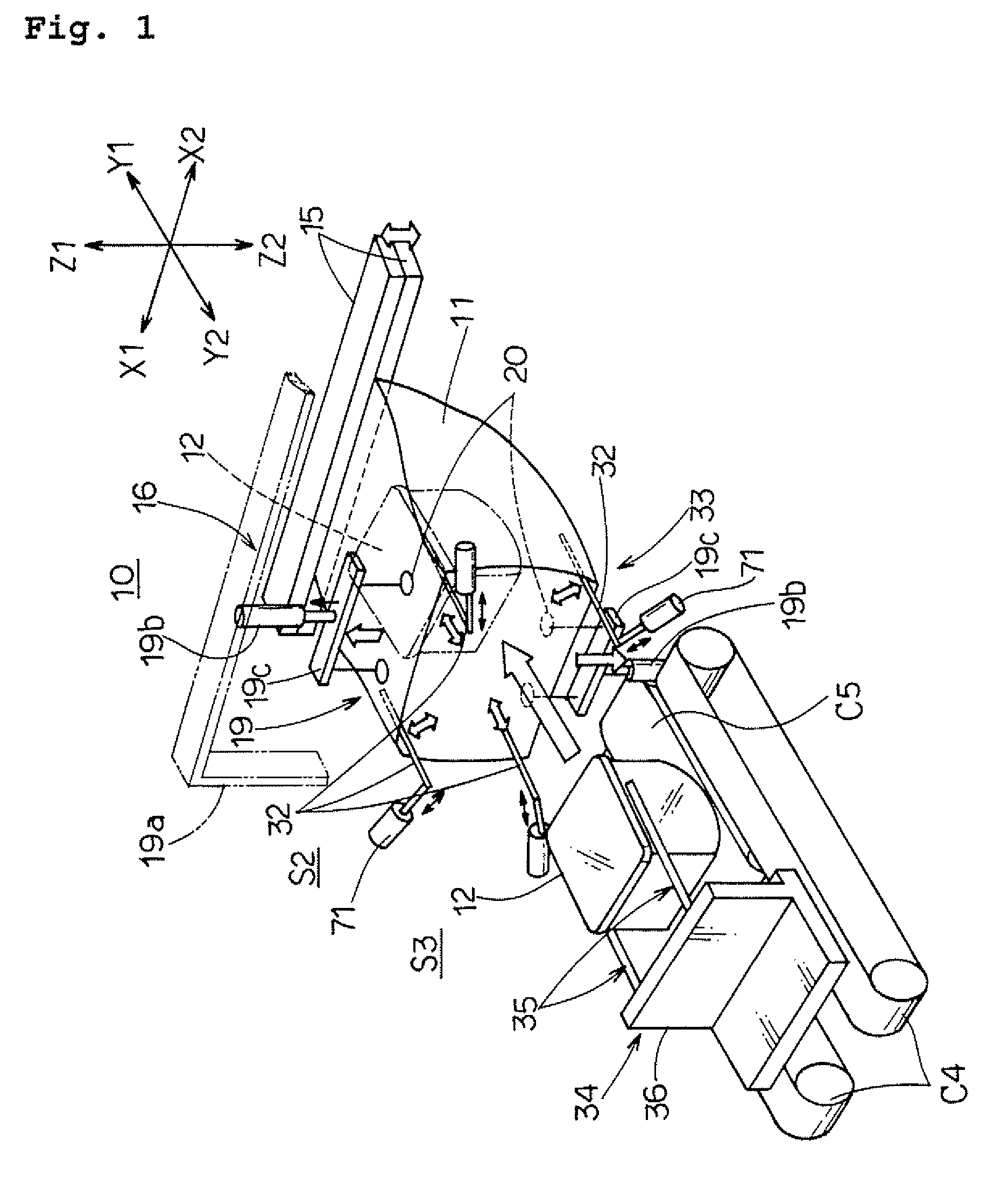

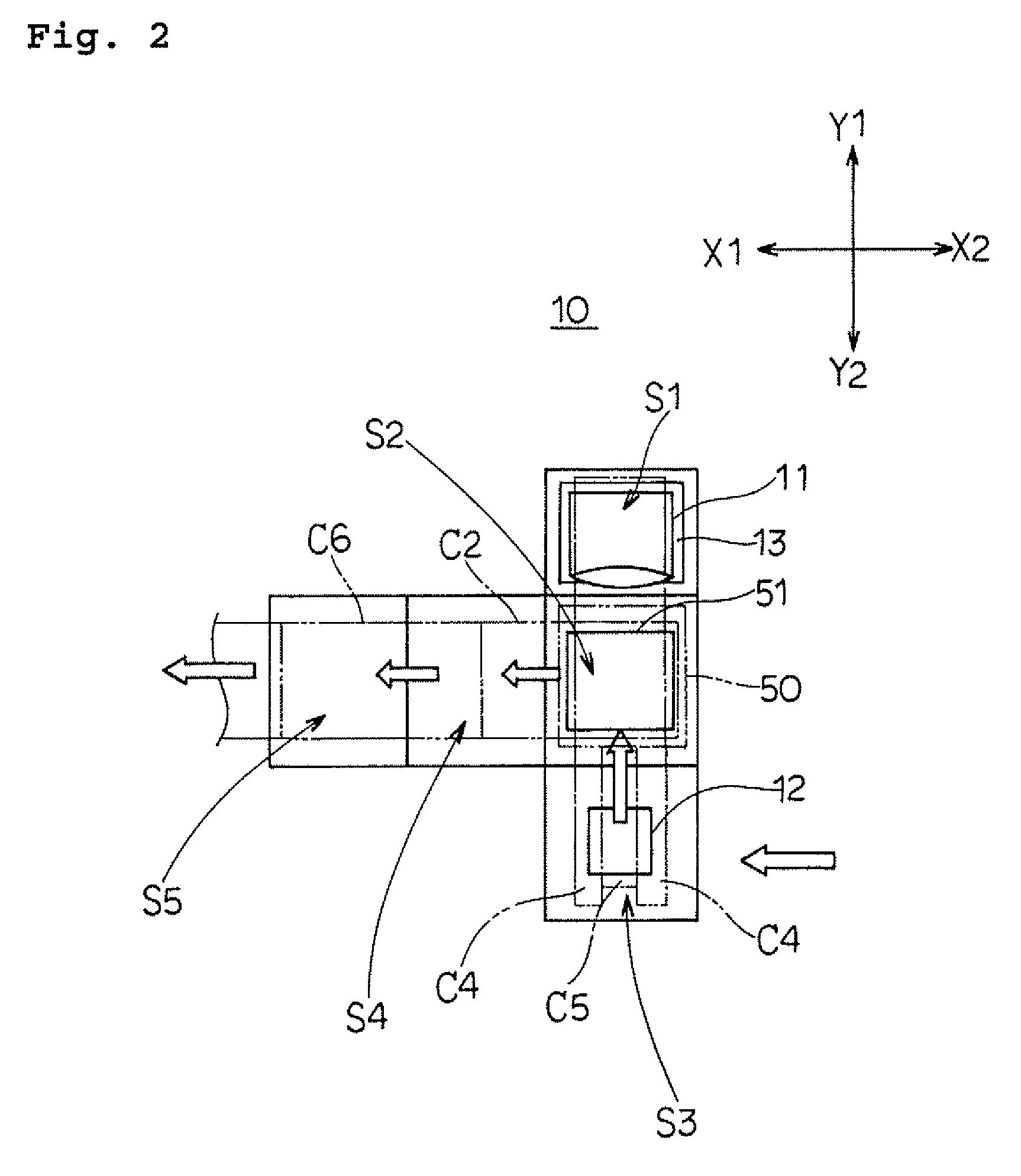

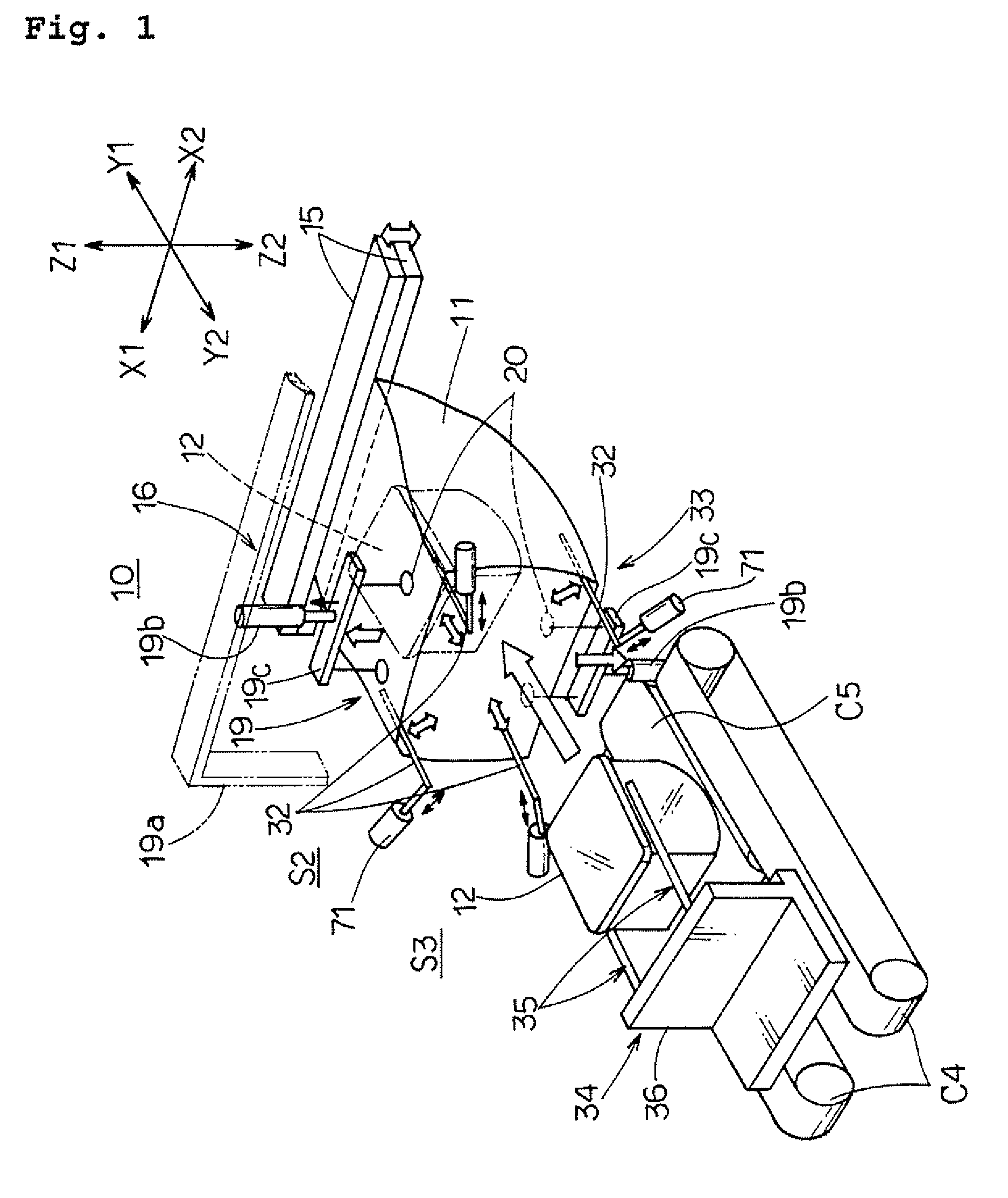

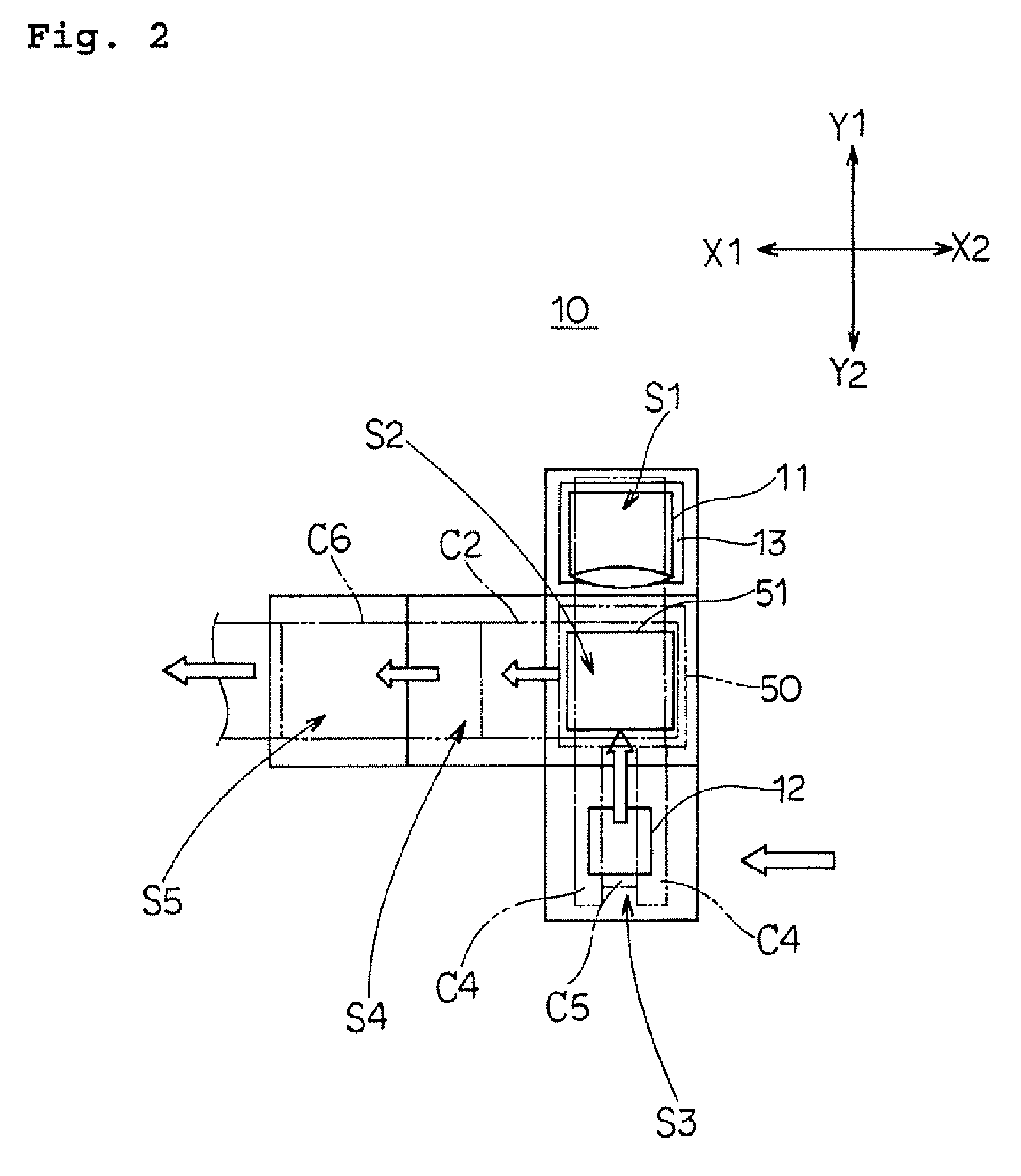

Container packaging apparatus

ActiveUS7290382B2Quality improvementForming accuratelyWrapping material feeding apparatusWrapper folding/bending apparatusEngineeringEAR FOLDING

A wafer case is inserted into a packaging bag, and an ear folding and shaping bar is pressed against a root of each corresponding triangular ear portion, making a folding back line in each triangular ear portion. Each of the triangular ear portions is folded back over a container side surface by a bag rear end ear folder. The folding operation for each of the triangular ear portions is performed precisely and smoothly.

Owner:SUMCO CORP

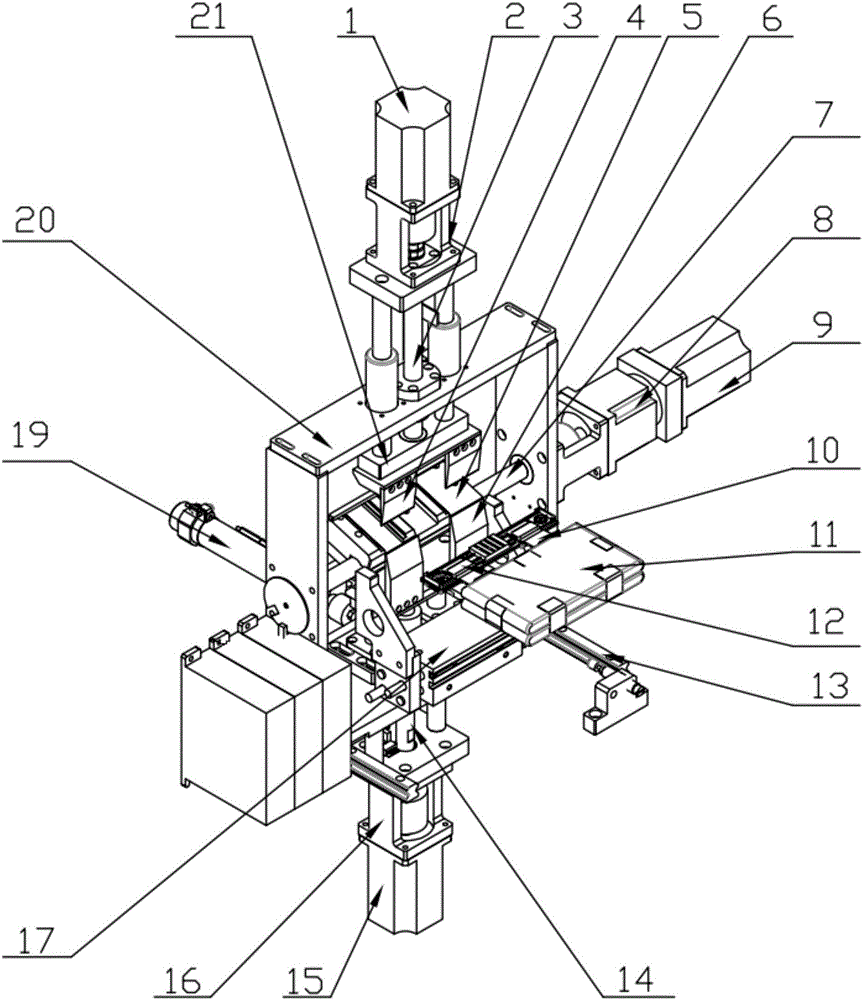

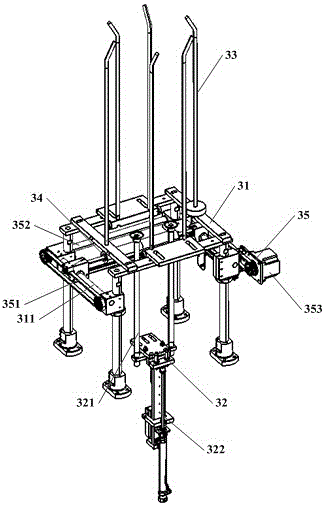

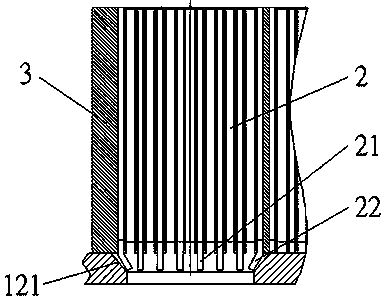

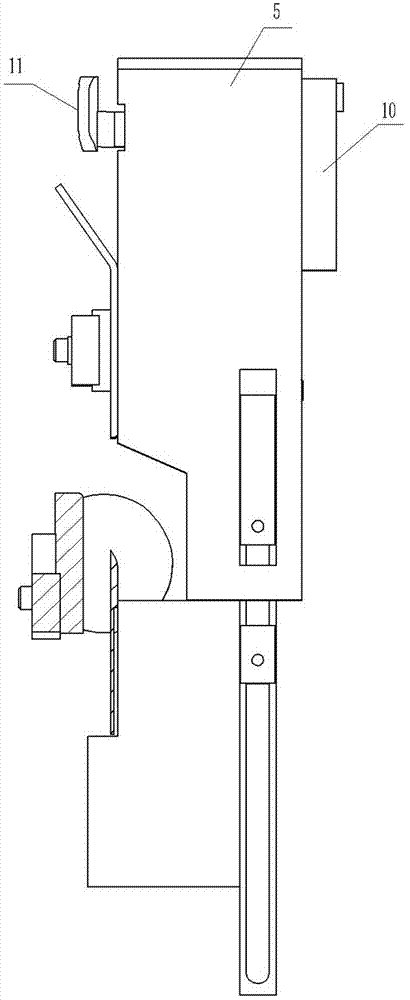

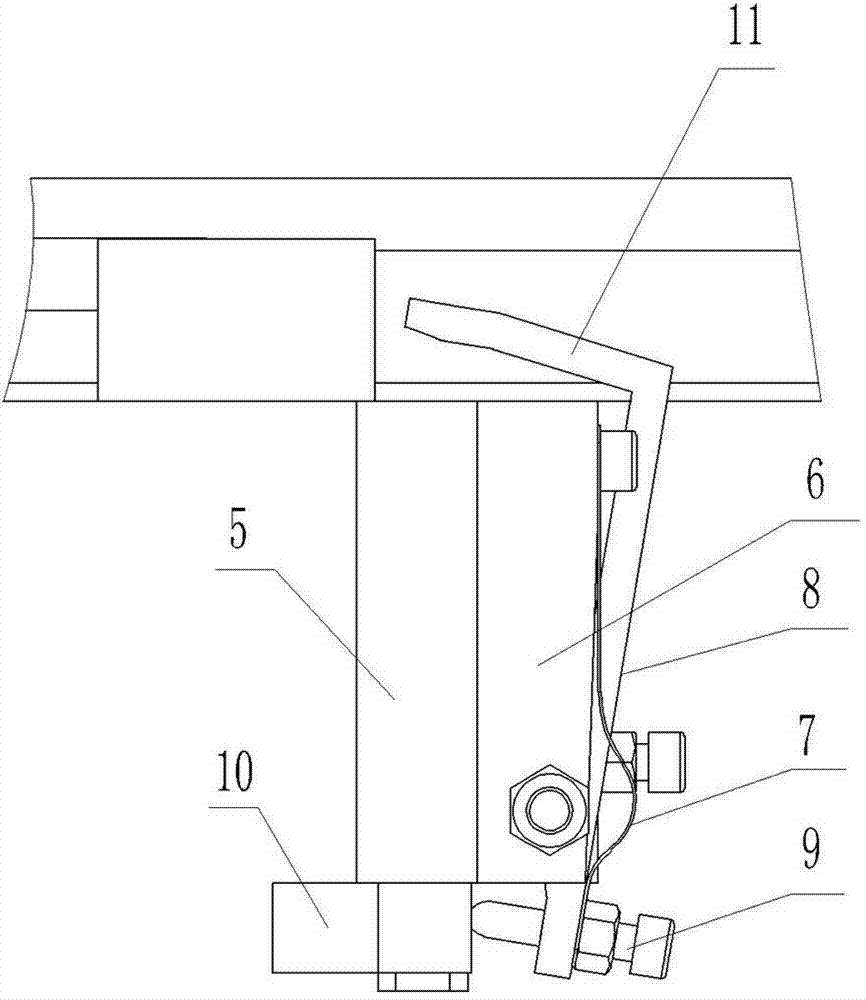

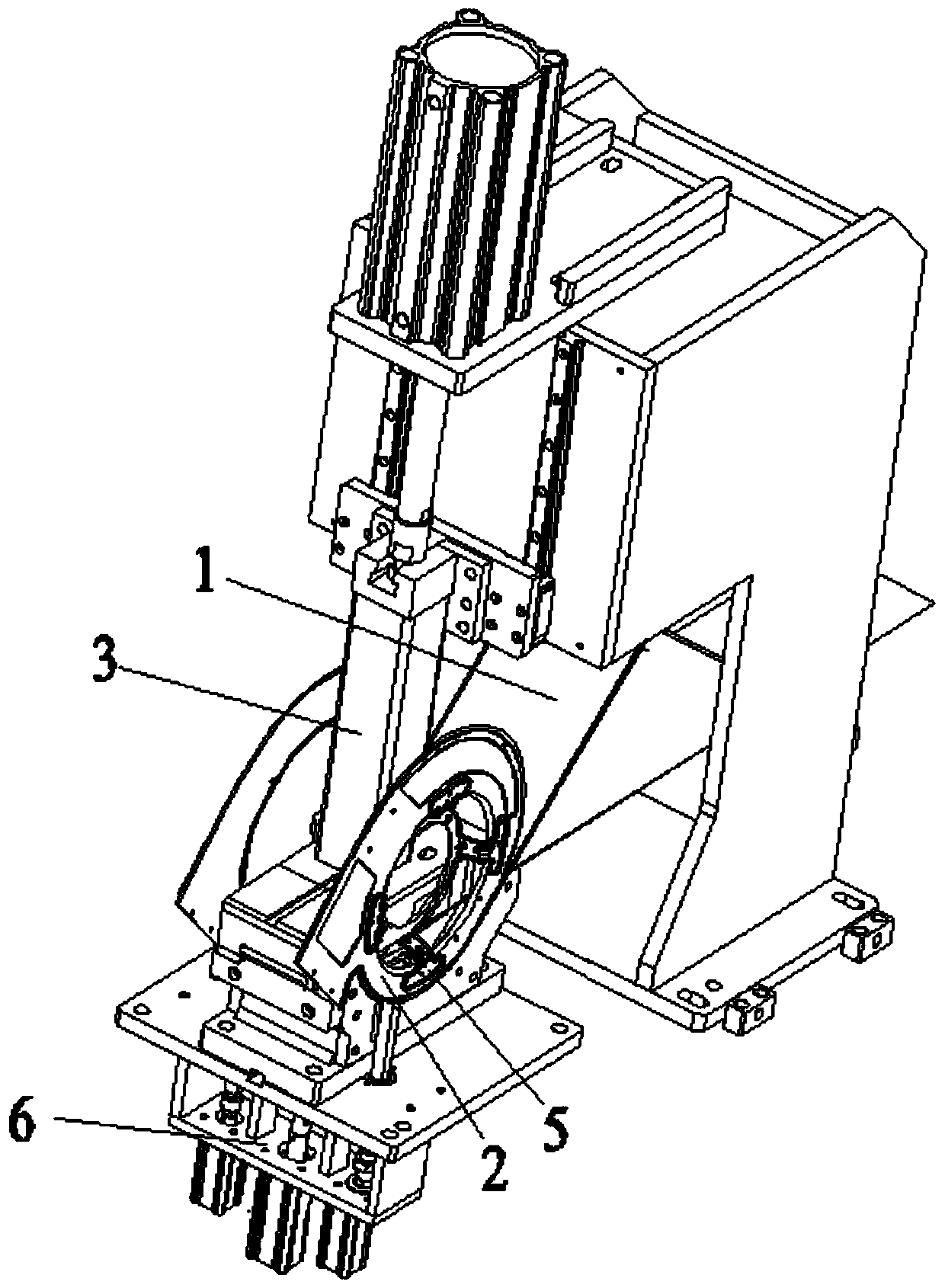

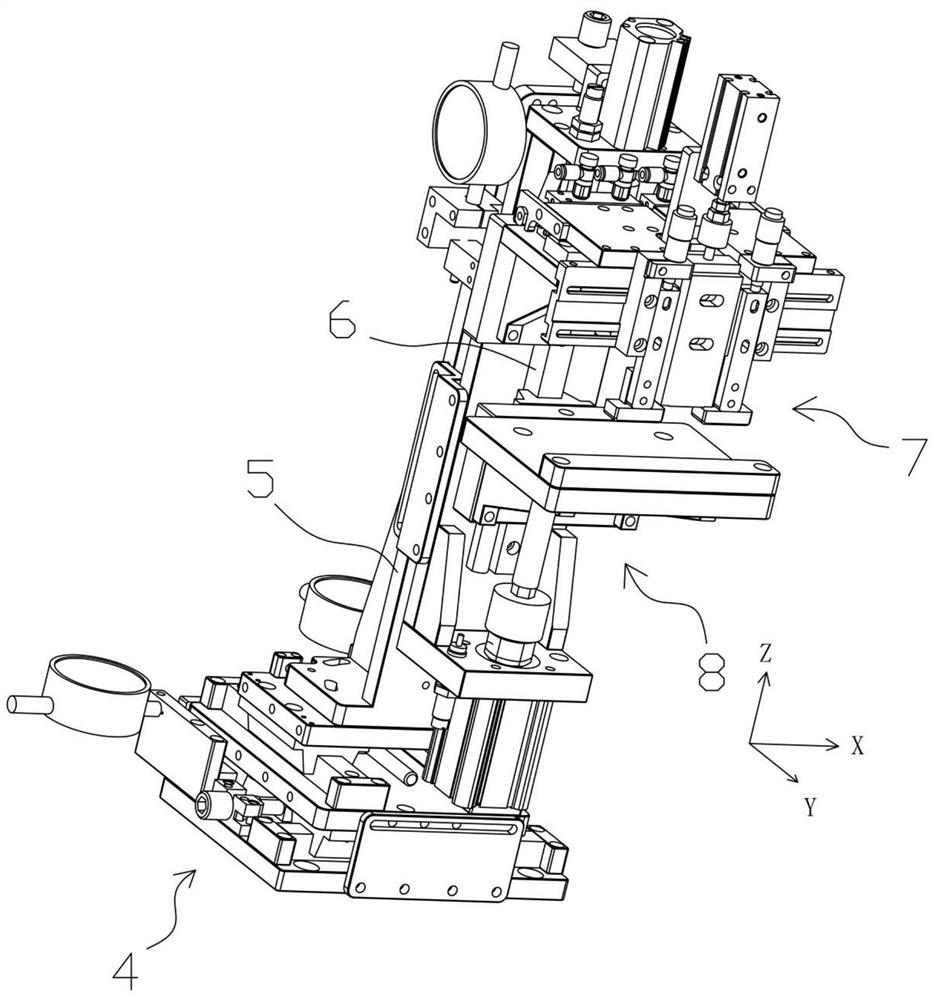

Automatic power battery pole ear bending mechanism and work method thereof

InactiveCN106583508ARapid BendingImprove automationPrimary cell manufactureFinal product manufactureElectricityPower battery

The invention relates to an automatic power battery pole ear bending mechanism which comprises a framework workbench, an upward-folding motor fixedly arranged on the upper side of the framework workbench, a downward-folding motor fixedly arranged on the lower side of the framework workbench, an upward-folding pole ear block in drive connection with the upward-folding motor and a downward-folding pole ear block in drive connection with the downward-folding motor; the automatic power battery pole ear bending mechanism furthermore comprises a rotary motor fixedly arranged on the left side or right side of the framework workbench and a cover plate rotation device in drive connection with the rotary motor; the downward-folding pole ear block is provided with vertically-upward lower inserting pieces, the upward-folding pole ear block is provided with vertically-downward upper inserting pieces, and the lower inserting pieces and the upper inserting pieces are arranged oppositely and are staggered by a preset distance in the horizontal direction; and the automatic power battery pole ear bending mechanism furthermore comprises a control device, and the control device is electrically connected with the upward-folding motor, the downward-folding motor and the rotary motor. By means of the automatic power battery pole ear bending mechanism, a power battery pole ear can be rapidly bent and formed, automation of folding of the pole ear and bending of various pole ears are greatly improved, it is beneficial to improvement of quality of pole-ear-folding products, equipment production efficiency is improved, and the equipment cost is lowered.

Owner:GEESUN AUTOMATION TECH

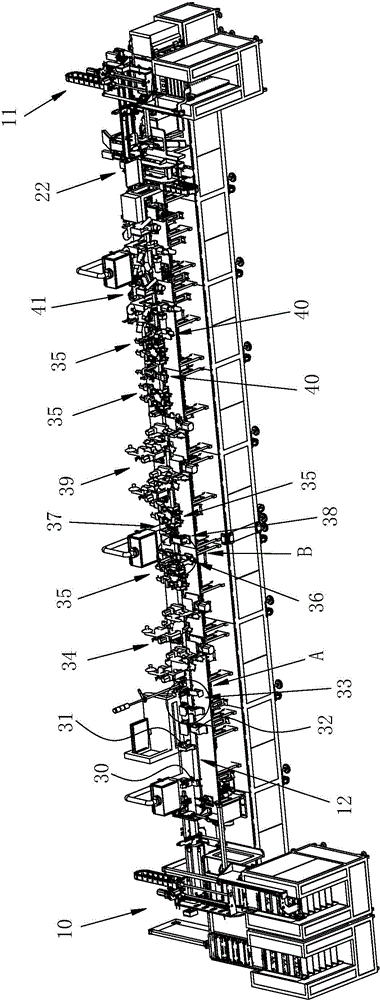

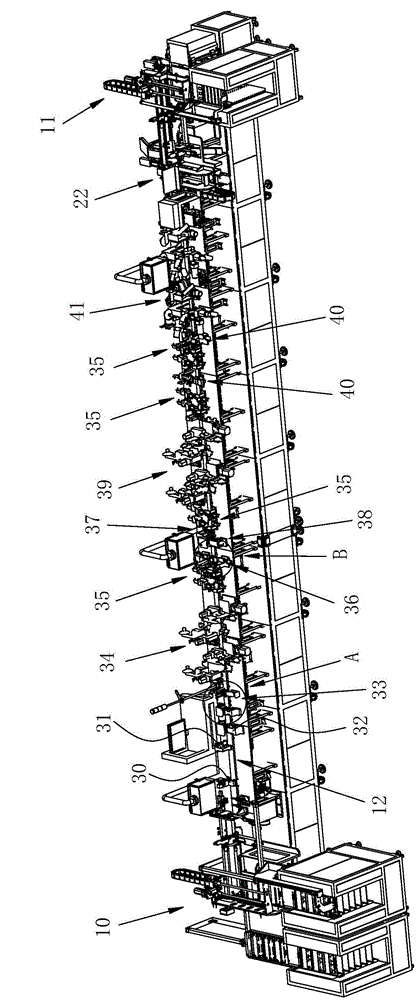

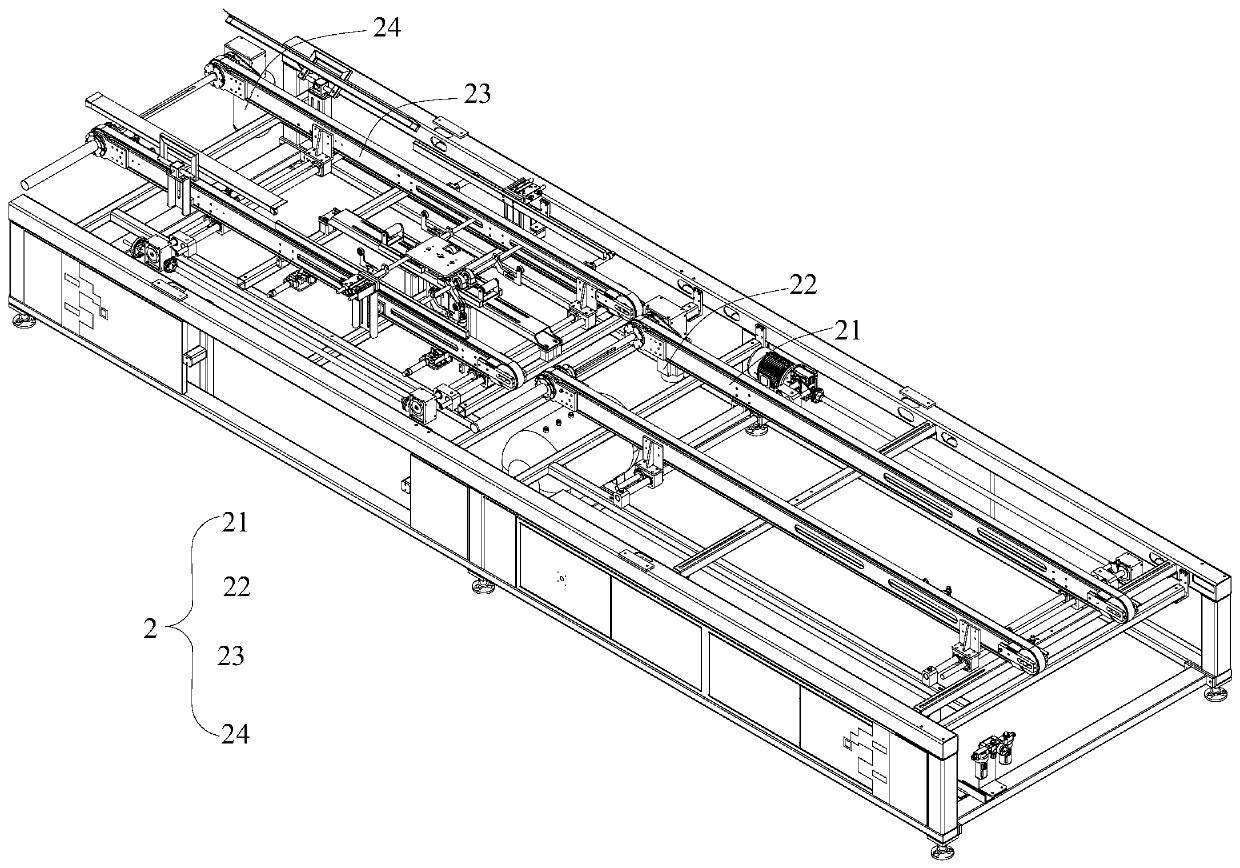

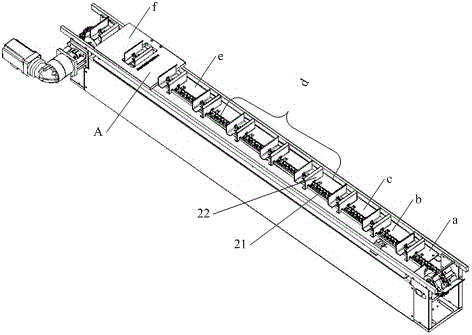

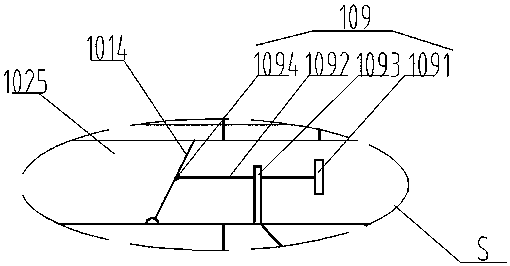

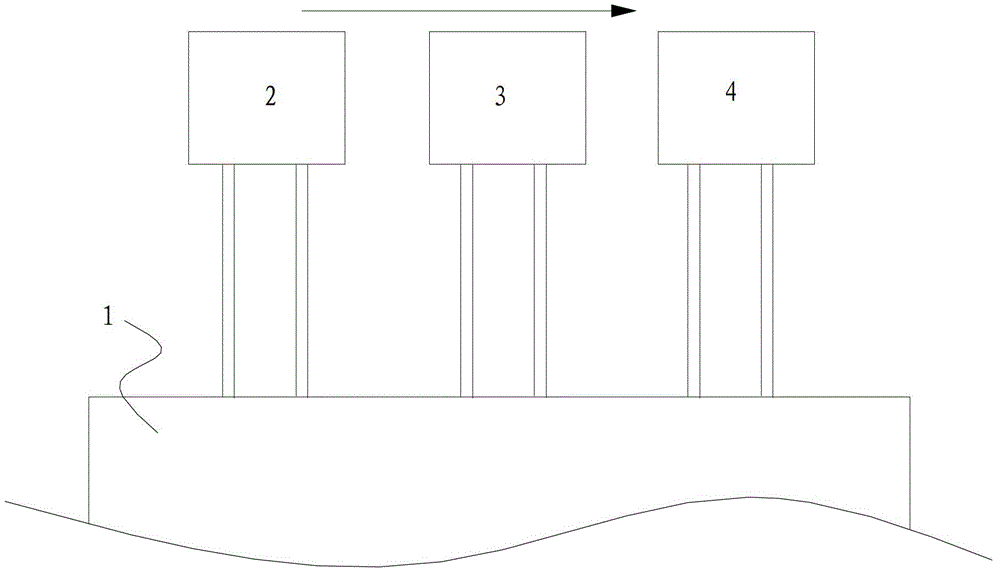

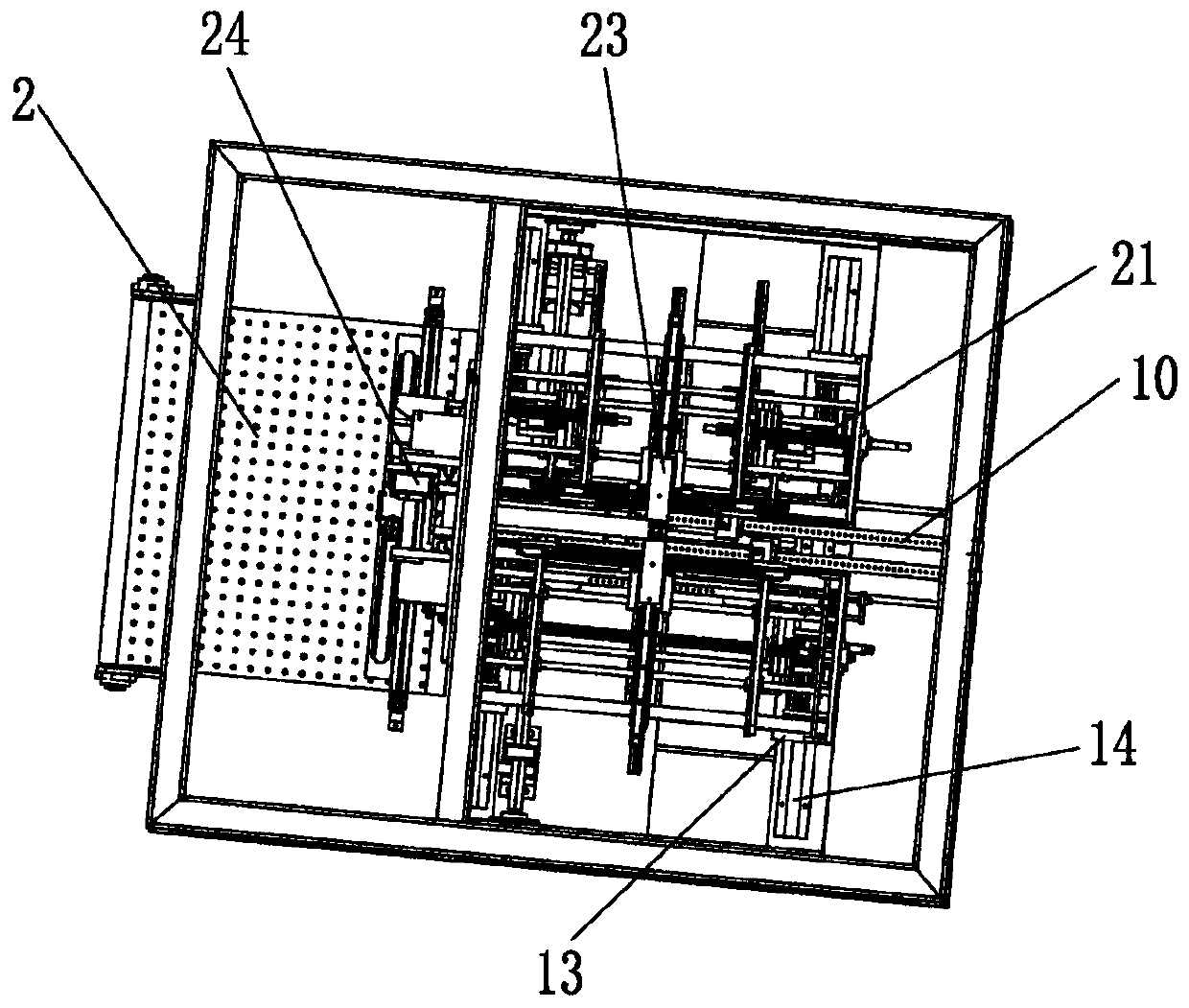

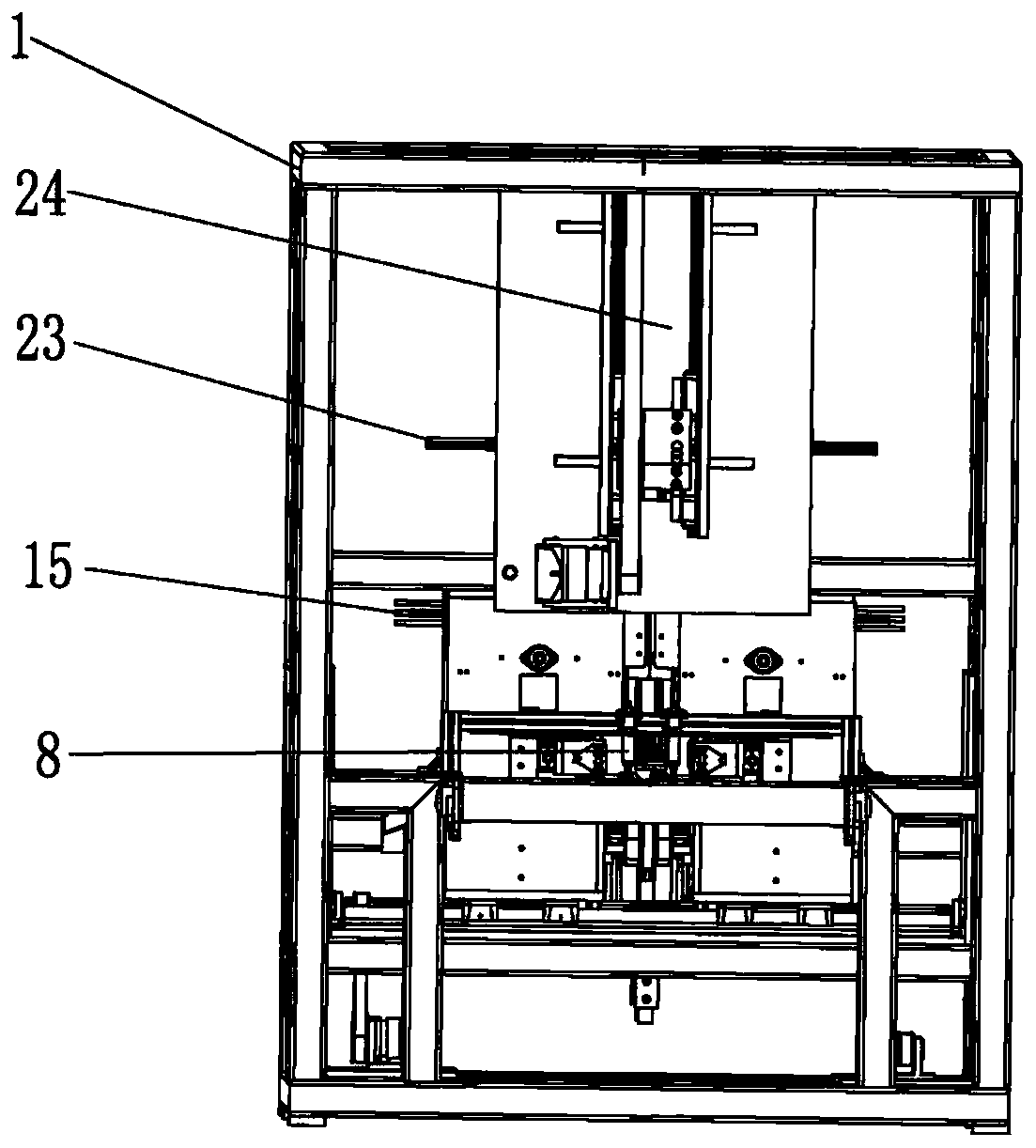

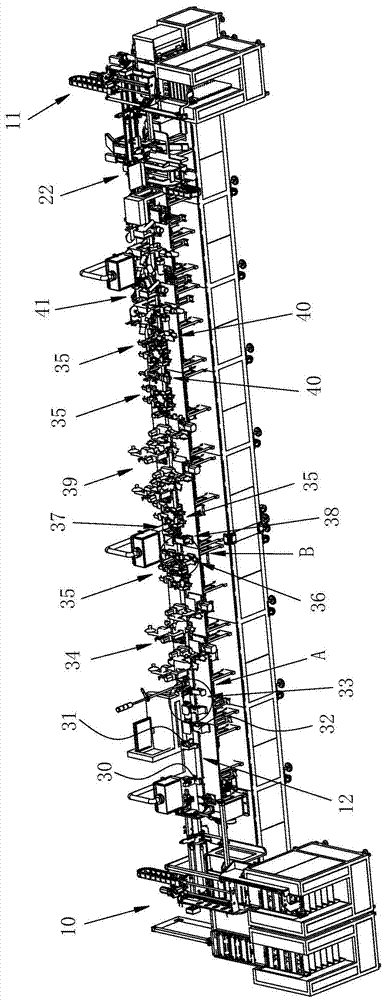

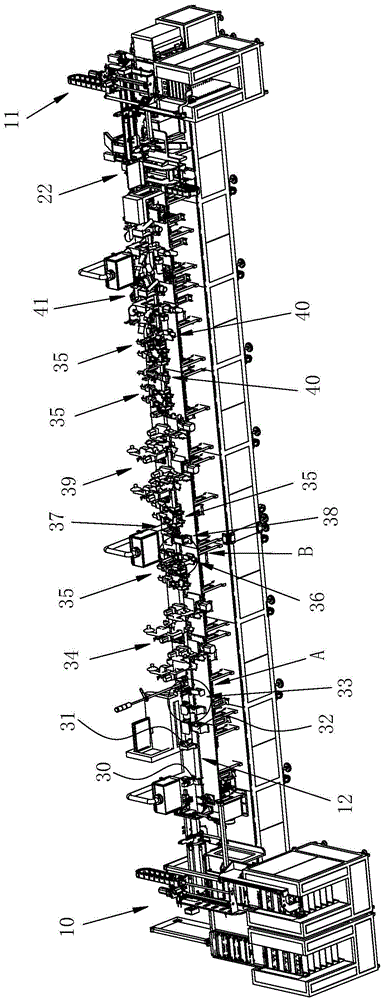

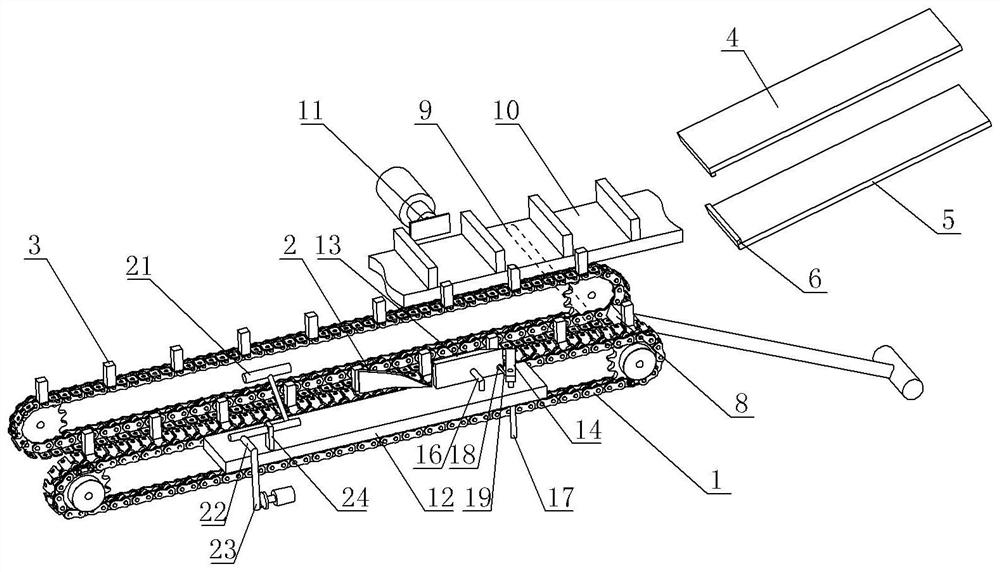

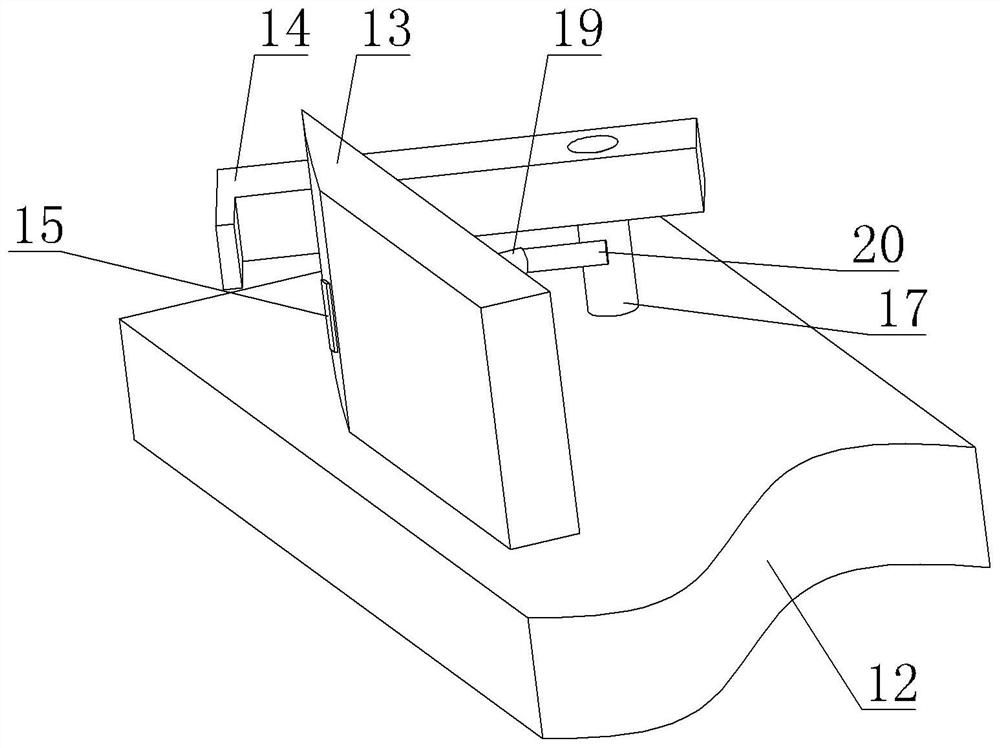

Material turnover system of automatic packing machine

The invention discloses a material turnover system of an automatic packing machine. The material turnover system of the automatic packing machine comprises a loading system and an unloading system, and further comprises an operation conveying line arranged between the loading system and the unloading system, wherein the loading system is provided with a loading mechanical arm which can transfer batteries in bulk, the unloading system is provided with an unloading mechanical arm which can transfer the batteries in bulk, the operation conveying line comprises a drive wheel located on a position close to one end of the loading system and a driven wheel located on a position close to one end of the unloading system, a mold chain is arranged between the drive wheel and the driven wheel in sleeve mode, and the mold chain is composed of a plurality of placement molds which are buckled together two by two and can selectively clamp the batteries. The material turnover system of the automatic packing machine achieves automatic transportation of the batteries during the pole ear folding and rubberizing process, and improves running reliability of a device.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Pole ear folding and rubberizing system of automatic packing machine

The invention discloses a pole ear folding and rubberizing system of an automatic packing machine. The pole ear folding and rubberizing system of the automatic packing machine comprises an operation conveying line used to convey batteries, and a pole ear deviator, a right angle rubberizing device, a pole ear folding device, a door-shaped rubberizing device, two pole ear extra edge shaving devices and a cylindrical glue rolling device, which are sequentially arranged along the forward direction of the operation conveying line, wherein a rotation mechanism which rotates the batteries is arranged between the right angle rubberizing device and the pole ear folding device, another rotation mechanism which rotates the batteries is arranged between the pole ear folding device and the door-shaped rubberizing device, and another rotation mechanism which rotates the batteries is arranged between the two pole ear extra edge shaving devices. The pole ear folding and rubberizing system of the automatic packing machine achieves automatic folding and rubberizing of pole ears of the batteries, and improves production efficiency and reliability.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

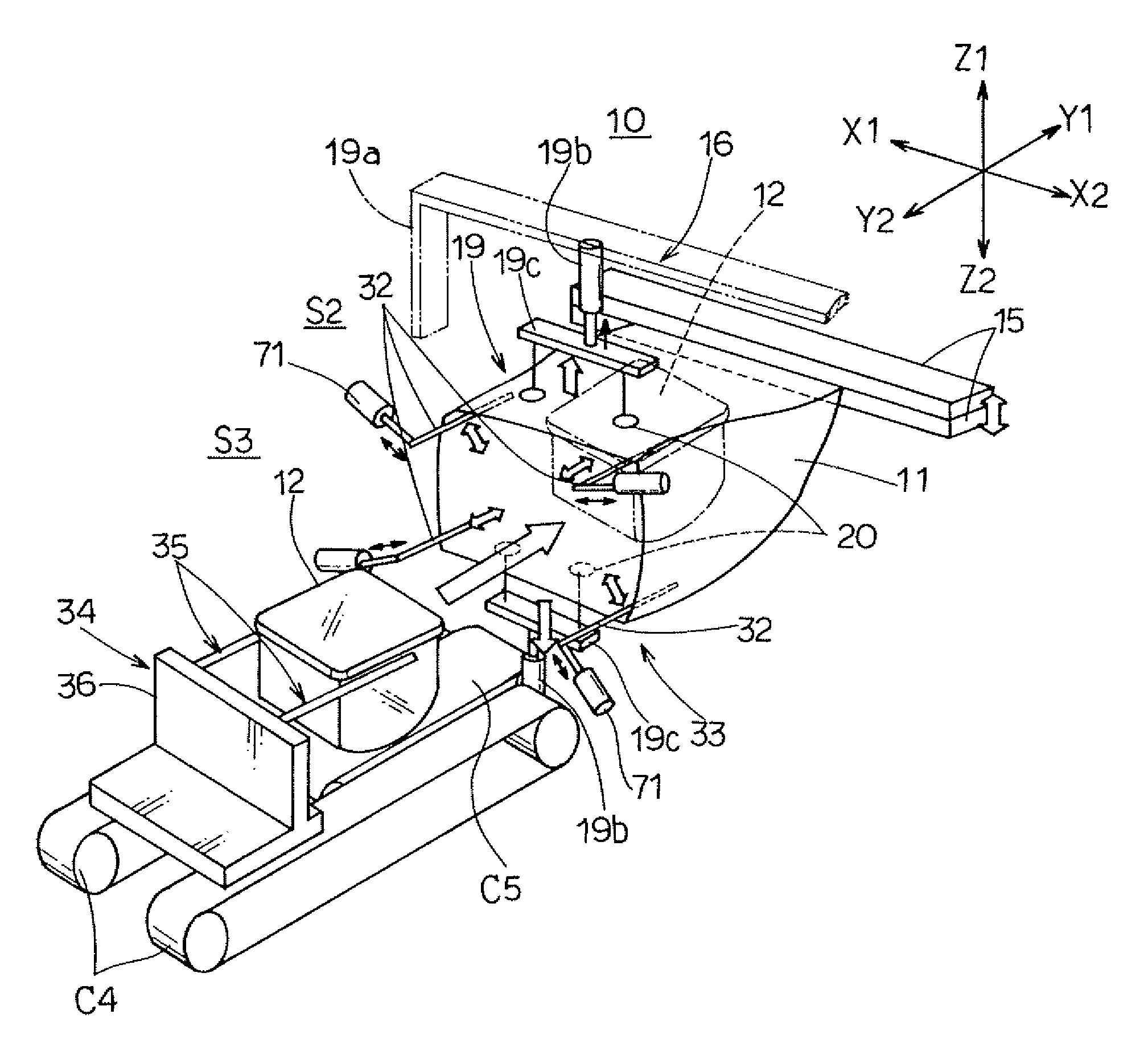

Container packaging apparatus

ActiveUS20060288668A1Process stabilityQuality improvementWrapping material feeding apparatusWrapper folding/bending apparatusEngineeringEAR FOLDING

After a wafer case having been inserted into a packaging bag, firstly an ear folding and shaping bar is pressed against a root of each corresponding triangular ear portion in its side to be folded back for making a folding-back line therein. After that, each of the triangular ear portions can be accordingly folded back over a container side surface by a bag rear end ear folding means. Consequently, this allows for the folding back operation for each of the triangular ear portions to be carried out precisely and smoothly.

Owner:SUMCO CORP

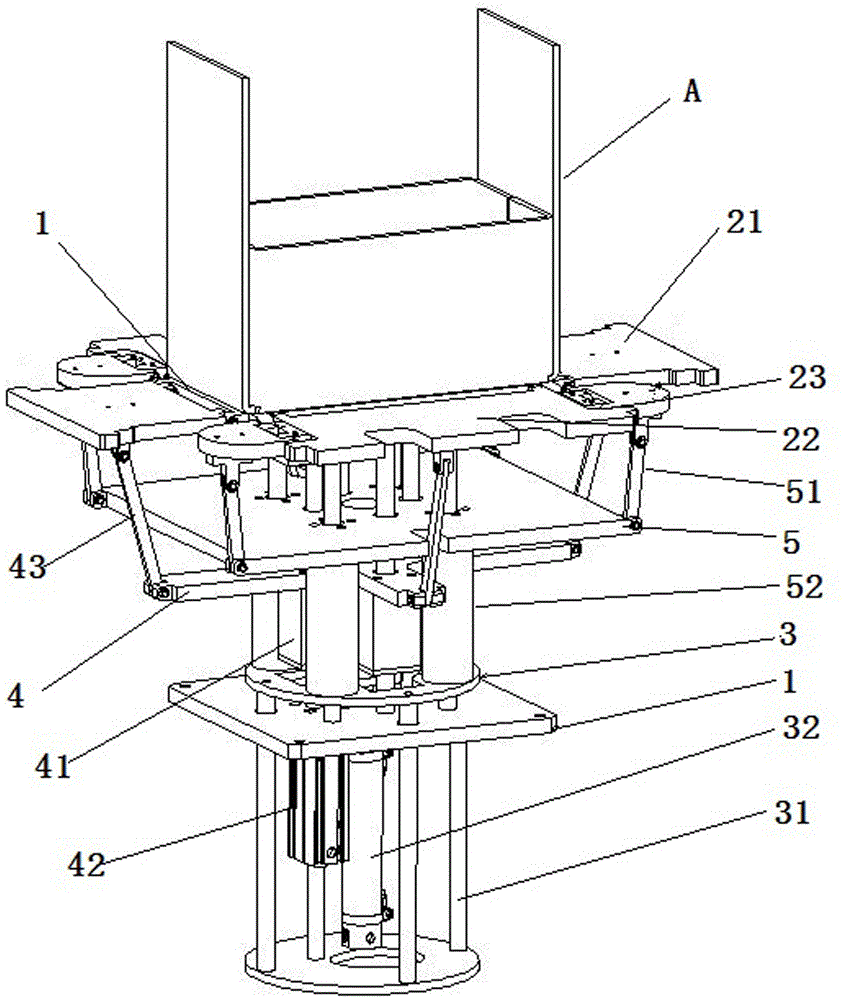

Ceramic tiles packaging machine

PendingCN110481849AFit tightlyWon't moveWrapping material feeding apparatusWrapper folding/bending apparatusPaperboardEngineering

The invention belongs to the field of intelligent packaging device, and particularly relates to a ceramic tiles packaging machine. The ceramic tiles packaging machine comprises a conveying device forconveying the ceramic tiles, a paperboard conveying device for conveying a paperboard to a packaging station, a grabbing device for grabbing ceramic tiles from the conveying device to the packaging station and a packaging device for packing ceramic tiles with the paperboard. The packaging device comprises a bearing seat, two rotating folding devices, two straight-line folding devices and a plurality of ear folding devices. The bearing seat is used for bearing the paperboard and the ceramic tiles, the two rotating folding devices are arranged on two sides of the bearing seat, the two straight-line folding devices are arranged on the other two sides of the bearing seat, and the plurality of ear folding devices are arranged under the two straight-line folding devices and are used for bendingthe paperboard rim angle inward. The ceramic tiles packaging machine can make the packaging paperboard closely fit the ceramic tiles, so that a gap between the ceramic tiles and the packaging paperboard does not exit, the ceramic tiles cannot move during the transportation process, and the risk of collision is reduced.

Owner:GUANGDONG EDING IND

Intelligent molding machine for pneumatic box and molding technology thereof

InactiveCN109203565AAvoid replacementReduce manual operationsBox making operationsPaper-makingMolding machineEngineering

The invention relates to the field of packaging equipment, in particular to an intelligent molding machine for a pneumatic box and a molding technology thereof. The intelligent molding machine for thepneumatic box comprises a pressing mechanism, a surface-folding device and a control device. The pressing mechanism comprises a box body mold and a lifting mechanism. The surface-folding device comprises a first fold-up mechanism, a second fold-up mechanism and an ear folding mechanism. The first fold-up mechanism comprises a first surface-folding assembly, a second surface-folding assembly and afirst driving assembly. The second fold-up mechanism comprises a third surface-folding assembly, a fourth surface-folding assembly and a second driving assembly. The control device comprises a controller and a sensor assembly. According to the intelligent molding machine for the pneumatic box and the molding technology thereof, automated production is achieved in the whole course; parametric equipment is achieved; after a parameter is input, a working position is reached automatically and rapidly; the situation that a scraper knife is replaced for a different one every time a different product is machined is avoided; straightness is better compared with that of a previous linear bearing; no gap is reserved; parallelism degree is high; guidance performance is good; and stability is good.

Owner:东莞市钧正机械有限公司

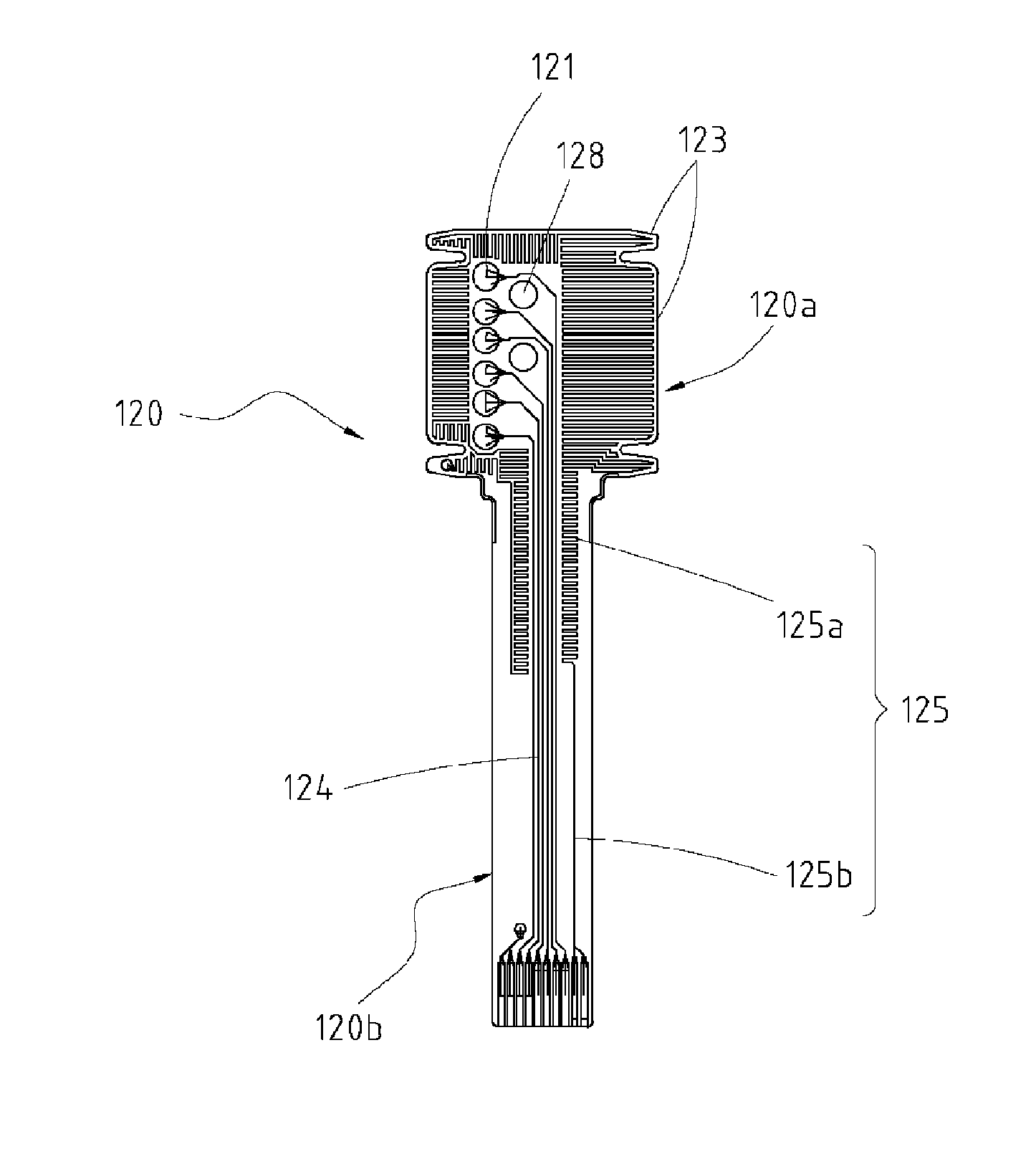

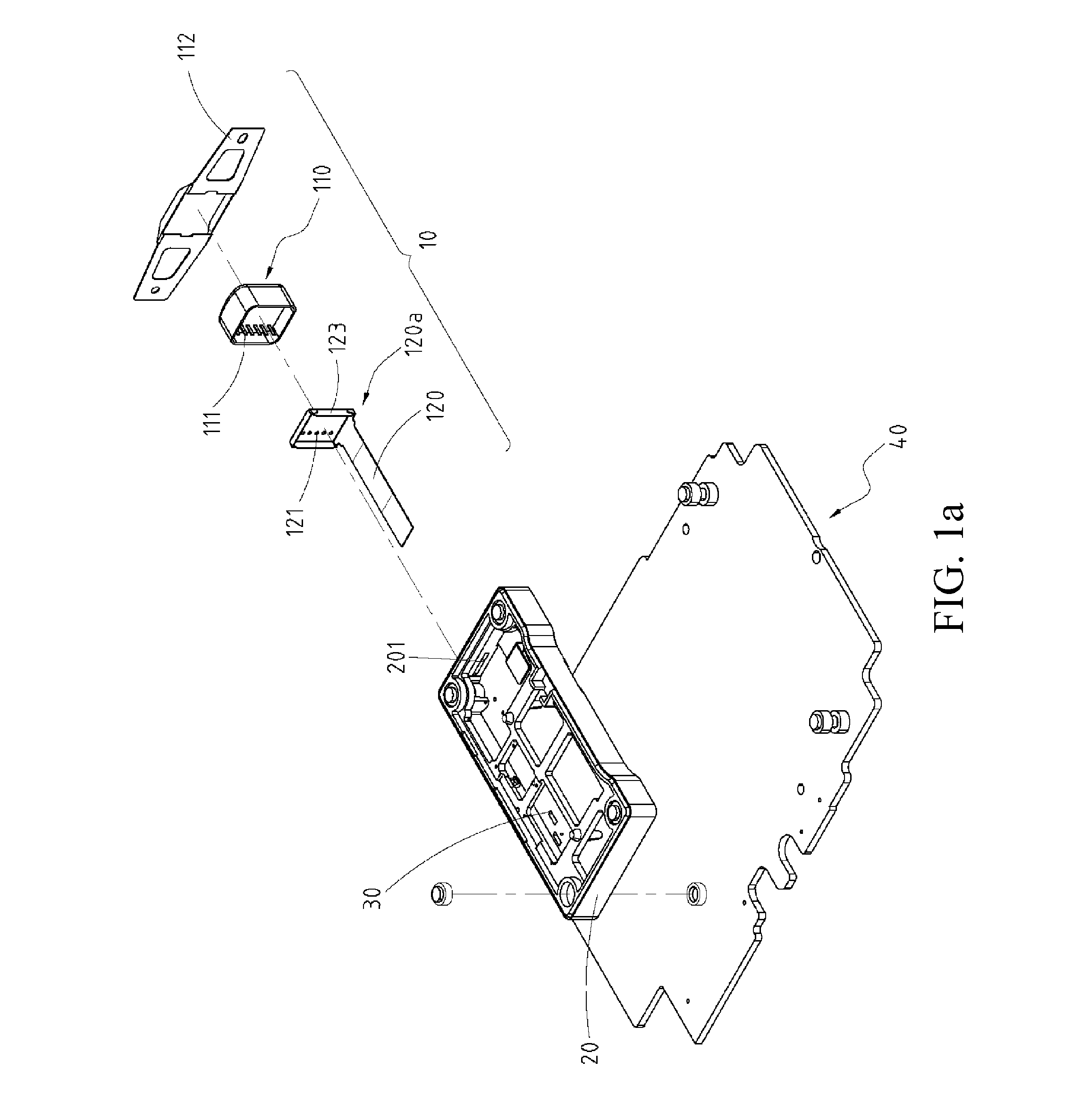

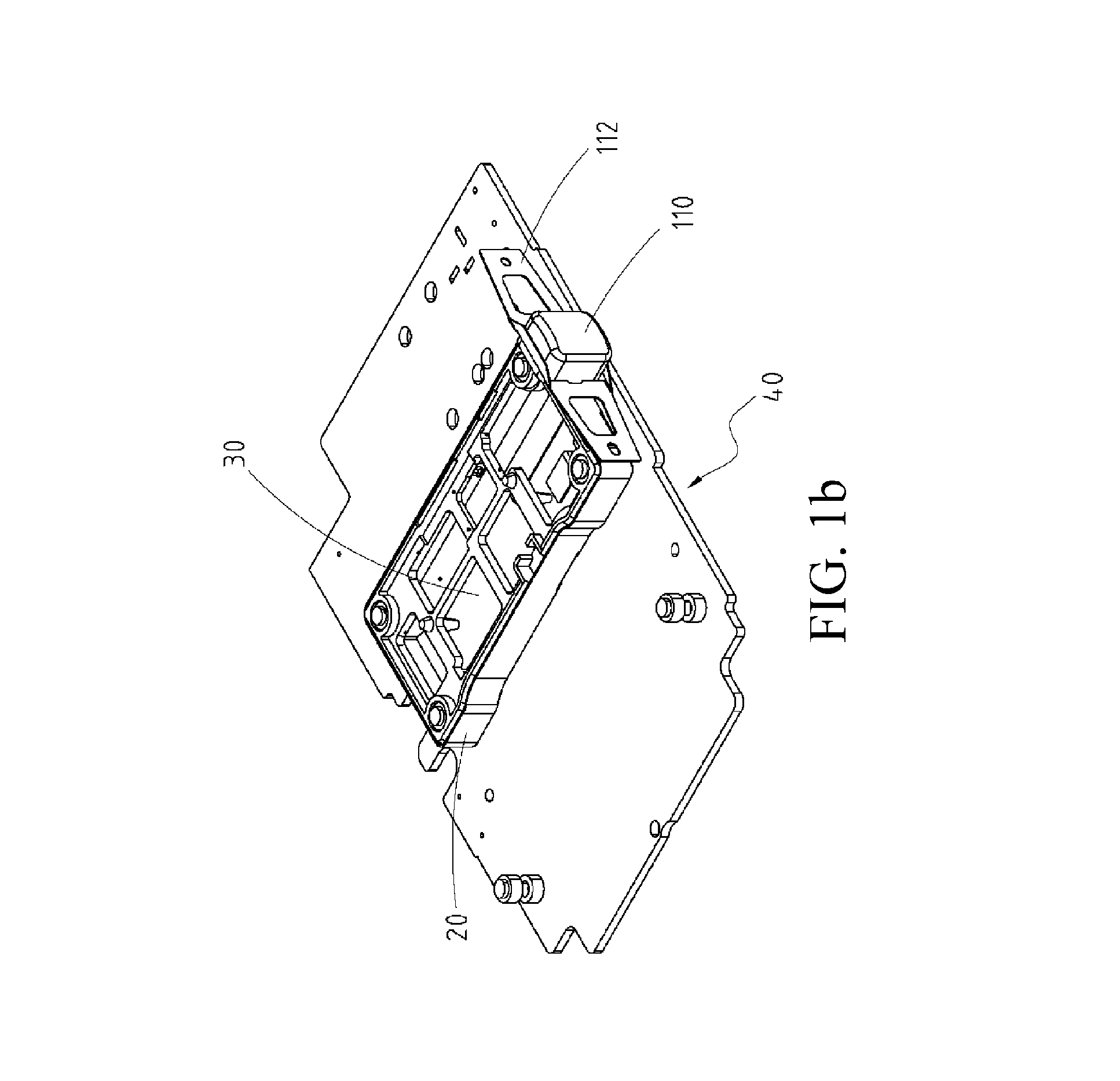

Anti-recording card reading device

InactiveUS9449204B1Avoid damageReduce exposureComplete banking machinesAcutation objectsFlexible circuitsEngineering

This anti-recording card reading device includes: a magnetic card reading head having a data reading terminal and a flexible circuit board, where the flexible circuit board has a plurality of ear-fold portions, a first line layer of the flexible circuit board is provided with a signal transmission line, a first protection line is disposed on two sides of the signal transmission line, a second line layer is provided with a second protection line, and the ear-fold portions can be fold and fitted in the magnetic card reading head; a mainboard, disposed neighboring to a card reading component; an anti-tamper framework, disposed on the mainboard; and a protection area bounded by the anti-tamper framework, where a terminal section of the flexible circuit board is connected to the data reading terminal, and the other side extends into the protection area and is connected to the mainboard.

Owner:UNIFORM INDAL CORP

Novel boxing machine

The invention provides a novel boxing machine. The novel boxing machine comprises a frame; a fence type conveying line module, a box opening module, an ear folding module, a double-faced adhesive tape tear type paper module, a molding positioning module, a mounting module and an inferior product discharging module are arranged on the frame, wherein the box opening module is positioned at the front end of the fence type conveying line module; the ear folding module, the double-faced adhesive tape tear type paper module and the molding positioning module are sequentially arranged at one side of the fence type conveying line module; the mounting module is positioned at the other side of the fence type conveying line module and behind the molding positioning module; the inferior product discharging module is arranged behind the mounting module and is positioned at the same side of the fence type conveying line module as the molding positioning module. The novel boxing machine disclosed by the invention is capable of realizing automatic molding and adhesion and is also capable of realizing boxing and removal of inferior products.

Owner:CHENGDU P&M AUTOMATION TECH

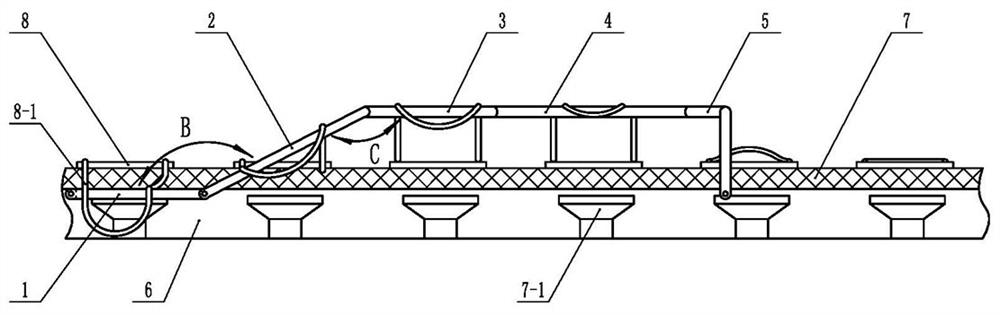

Production device of sweatpants

The invention relates to the field of sweatpants and discloses a production device of sweatpants. The device comprises a cotton core wood pulp material frame, a cotton core crushing and forming mechanism, a cotton-core-coated non-woven fabric material frame, a flow guiding layer material frame, a cotton core cutter, a crotch lifting rubber band material frame, a PE bottom film material frame, a surface-layer non-woven fabric material frame, an encircling rubber band material frame, an encircling non-woven fabric material frame, a core body cutter, a core body vertical transfer wheel, a speed-variable transverse change mechanism, a core body transverse transfer wheel, a waistline rubber band material frame, a waistline non-woven fabric material frame, a rear O-shaped cutter, folding conveying part, a corset conveying part and an ear folding mechanism which are arranged in sequence. An inner-layer non-woven fabric material frame, an arc-shaped rubber band material frame, an abdomen rubber band material frame, an outer-layer non-woven fabric material frame and an arc-shaped rubber band applying mechanism are sequentially arranged between the speed-variable transverse change mechanismand the core body transverse transfer wheel; a front cutter and a bifurcator are sequentially arranged between the arc-shaped rubber band applying mechanism and the core body transverse transfer wheel. The device can realize production switching between two-piece sweatpants and three-piece sweatpants and is reasonable in design.

Owner:JINHU THREE WOOD MACHINERY IND

Feed for Scottish fold

The invention discloses a feed for Scottish fold, which consists of corn protein powder, shrimp powder, chicken meal, duck blood powder, loach powder, beef powder, vitamin A, vitamin B, powdered milk, bone powder, sheep liver meal, sheep intestine powder, table salt, liquorice powder, hawthorn powder, tendrilled fritillaria bulb, wild chrysanthemum powder, honeysuckle powder and Chinese angelica powder. A preparation method comprises the following steps of: combining all the powder according to a ratio; stirring for 150 minutes in a ring mode stirrer; taking out, and drying for 1 to 2 hours in a drying machine; taking out, cooling, crushing into powder in a ring mode crusher; taking out, stirring for 70 minutes in the stirrer again; taking out, bulking for 1 to 2 hours in a bulking machine; taking out, cooling, and granulating into a precipitated 40-mesh hard granular feed in a ring mode hard granule machine set; and sieving by using a 40-mesh sieve, ensuring that each granule is 0.1 gram, and packaging according to required weight.

Owner:李晓云

Automatic winding and dog-ear folding machine for packaging boxes

PendingCN108202887ARealize automatic chamferAchieve smoothWrapper twisting/gatheringControl systemEngineering

The invention relates to an automatic adhesive tape winding and dog-ear folding device which adopts a PLC module control system and perfectly combines pneumatics, electrics and mechanics. Automatic feeding and discharging of packaging boxes are realized through a feeding conveying roller and a discharging conveying roller. A jacking positioning mechanism is matched with a pressing mechanism to realize positioning and clamping of the packaging boxes. An adhesive tape rolling mechanism attaches adhesive tape to appointed positions of the packaging boxes. A winding rotary mechanism drives a workpiece to rotate to achieve winding of the adhesive tape, and then a telescopic air cylinder drives a cutter to cut off the adhesive tape. A vacuum sucker mechanism is matched with a pinhole air pipe to achieve dog-ear folding of the tail end of the adhesive tape. An air brush evenly flattens the adhesive tape obtained after dog-ear folding on the surfaces of the packaging boxes. Automatic conveying, positioning and winding of the packaging boxes are realized, the winding angle and length of the adhesive tape can be adjusted according to the specifications of the packaging boxes, flat sealing and tidy cuts of the adhesive tape are guaranteed, automatic dog-ear folding and flattening at the cuts of the adhesive tape are realized, manual dog-ear folding is replaced, the dog-ear folding accuracy is high, and the efficiency is high.

Owner:SUZHOU YUEHENG AUTOMATION TECH CO LTD

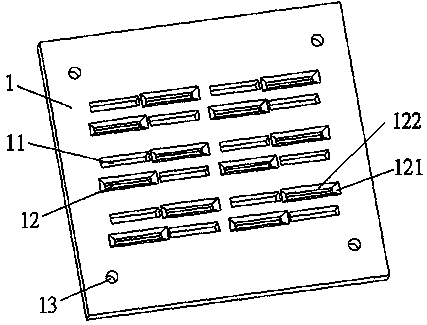

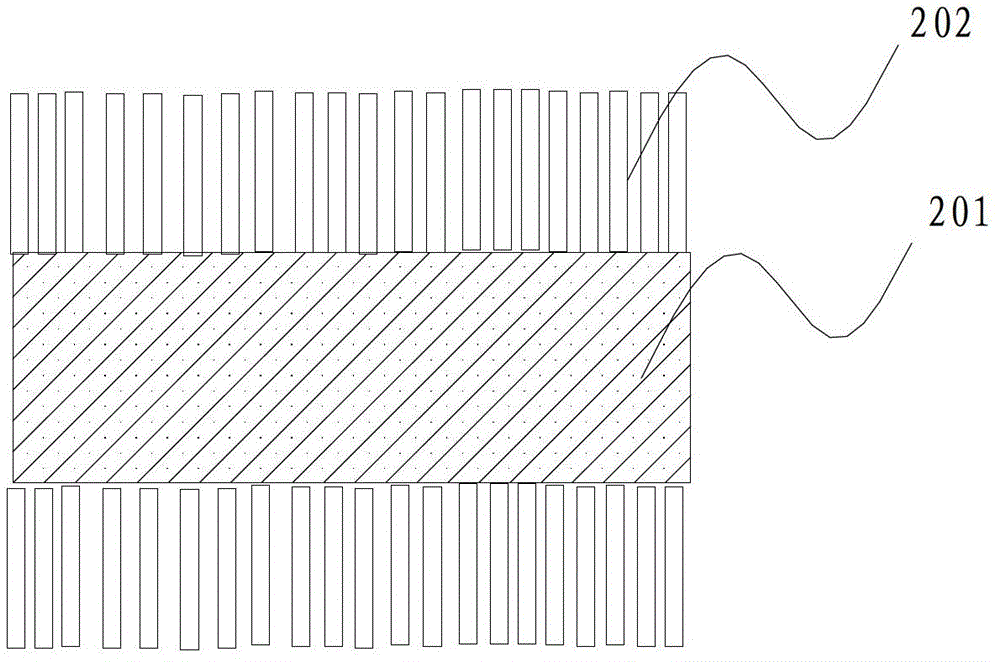

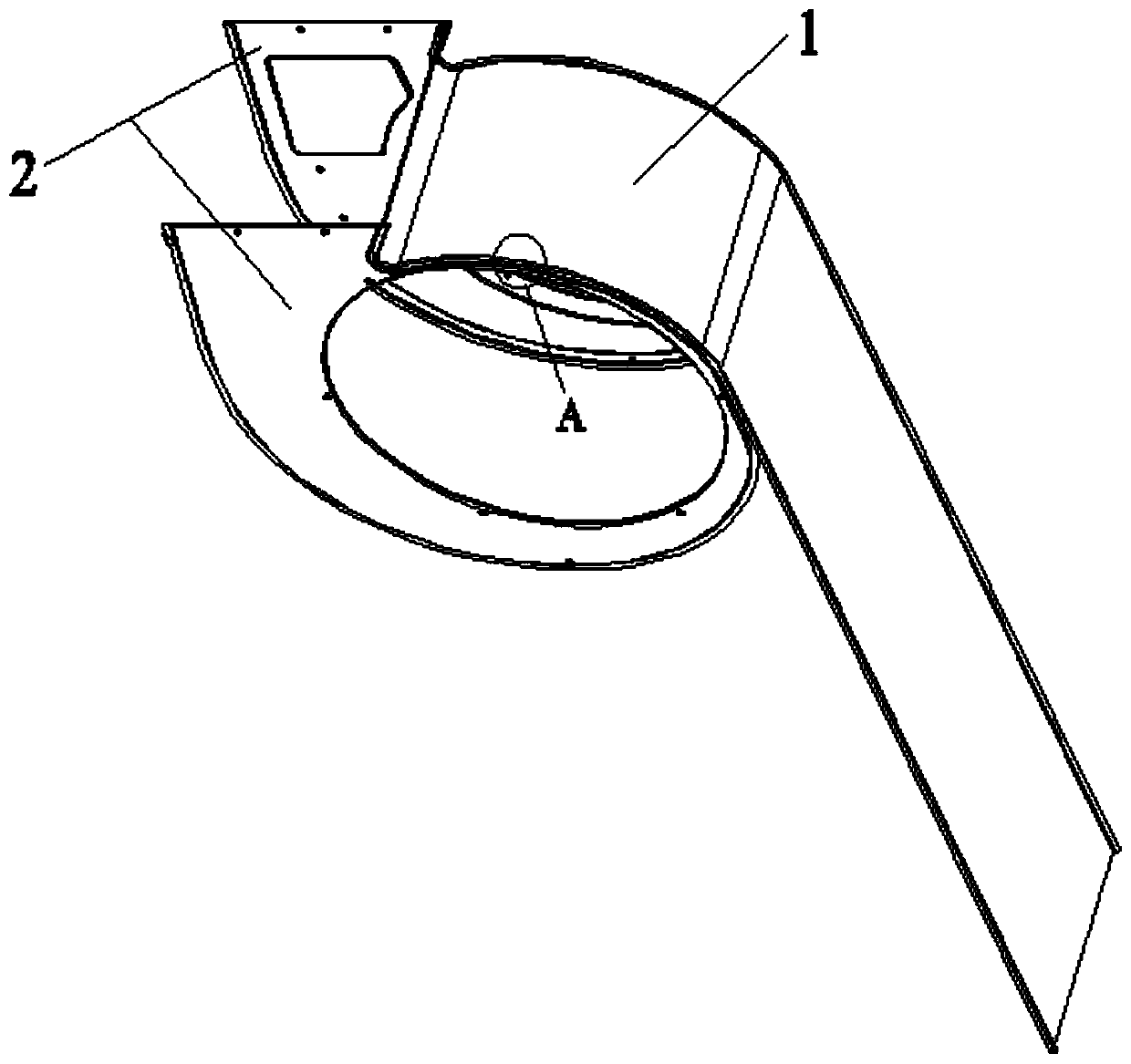

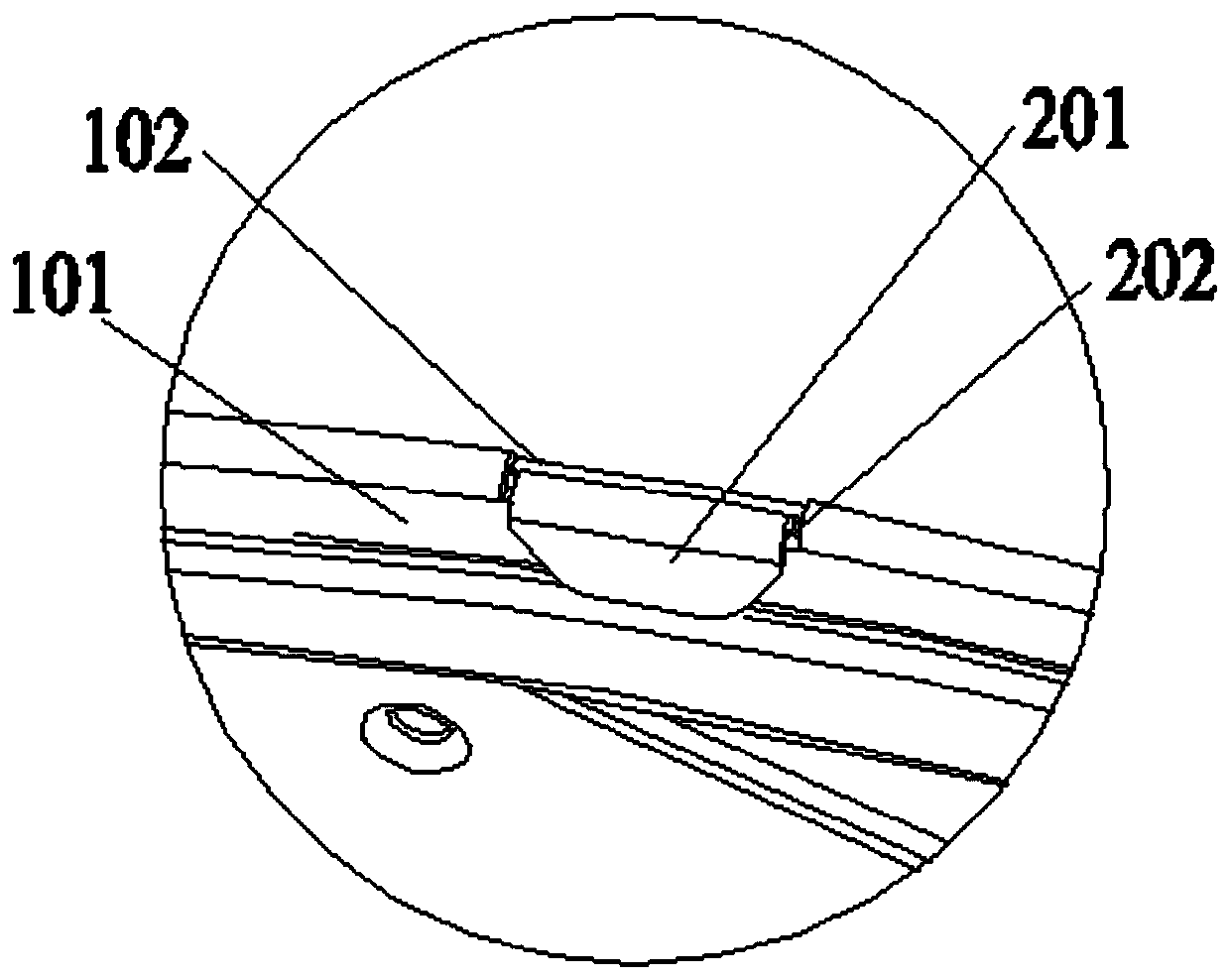

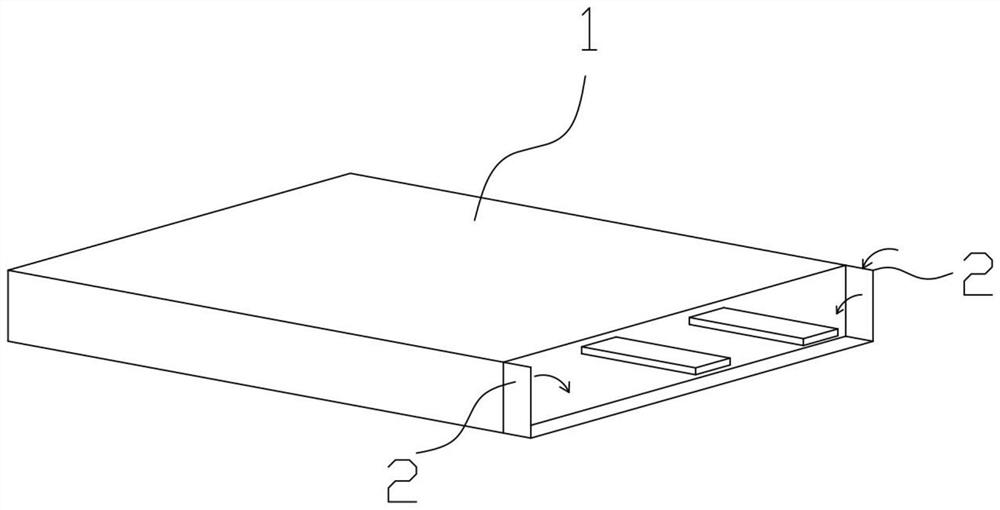

Pole-ear folding device for cast-welding storage battery

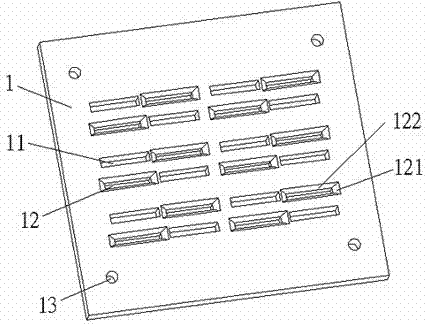

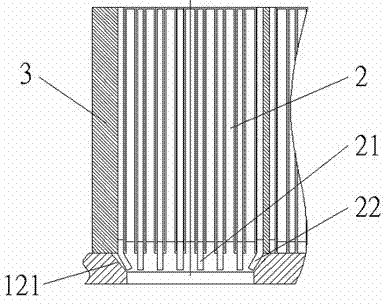

ActiveCN103367788AAccurate angleSimple structureFinal product manufactureSecondary cells manufactureEngineeringEAR FOLDING

The invention discloses a pole-ear folding device for a cast-welding storage battery. The device is a pole-ear folding plate, and a plurality of anode ear positioning grooves and cathode ear positioning grooves are formed in the pole-ear folding plate. Two short side walls of each cathode ear positioning groove incline for 30-45 degrees to the center direction of the groove, and two long side walls of each cathode ear positioning groove incline for 15-25 degrees to the center direction of the groove. The pole-ear folding device has the advantages of simple structure and accurate pole-ear folding angle, is beneficial to cast-welding forming, and ensures the product quality. Moreover, the pole-ear folding device is easily operated, the labor intensity is alleviated, and the production efficiency is improved.

Owner:TIANNENG GRP JIANGSU SPECIAL POWER SUPPLY

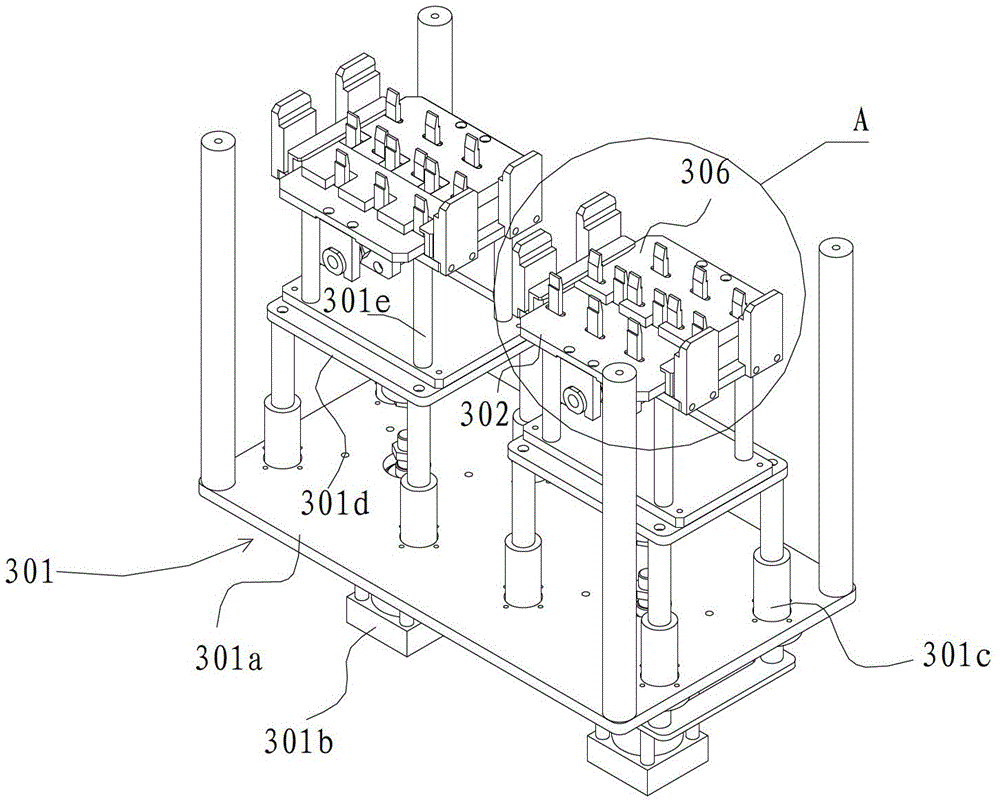

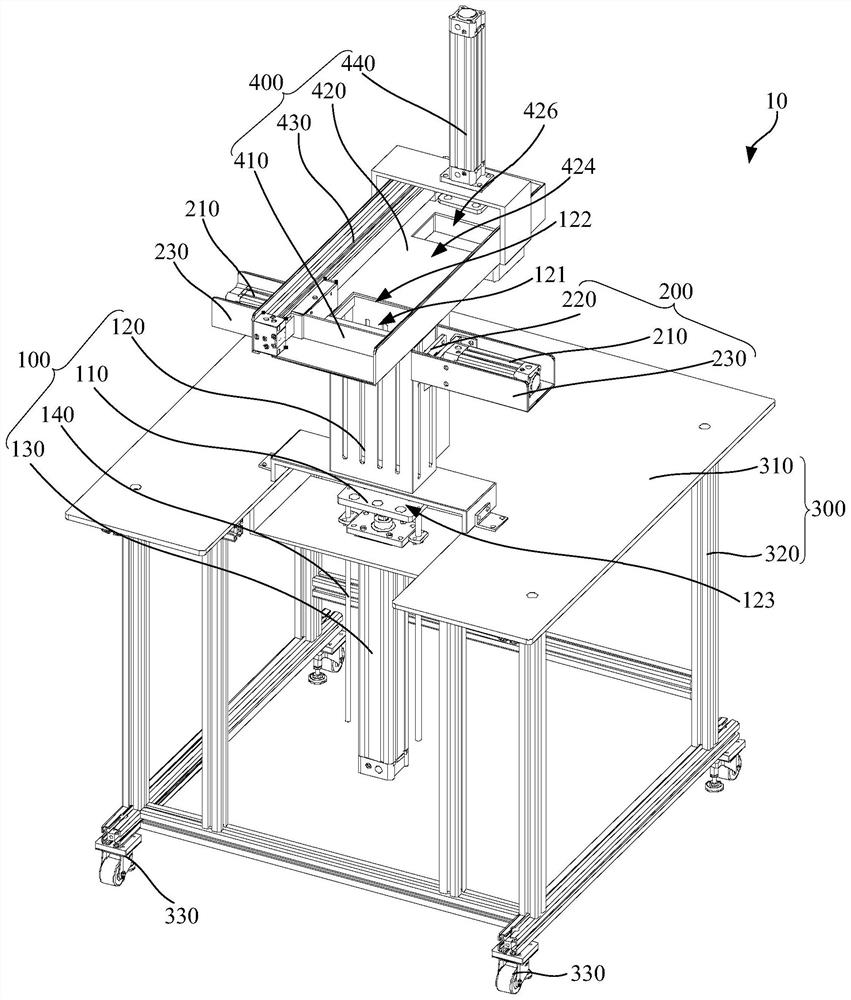

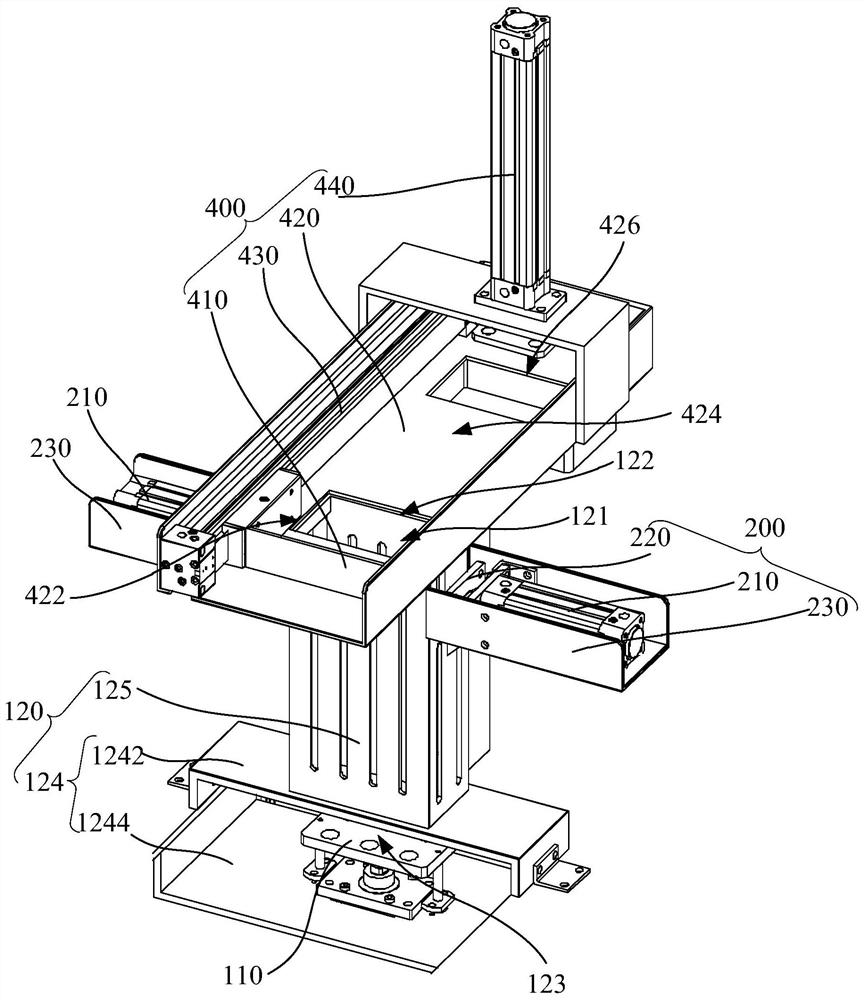

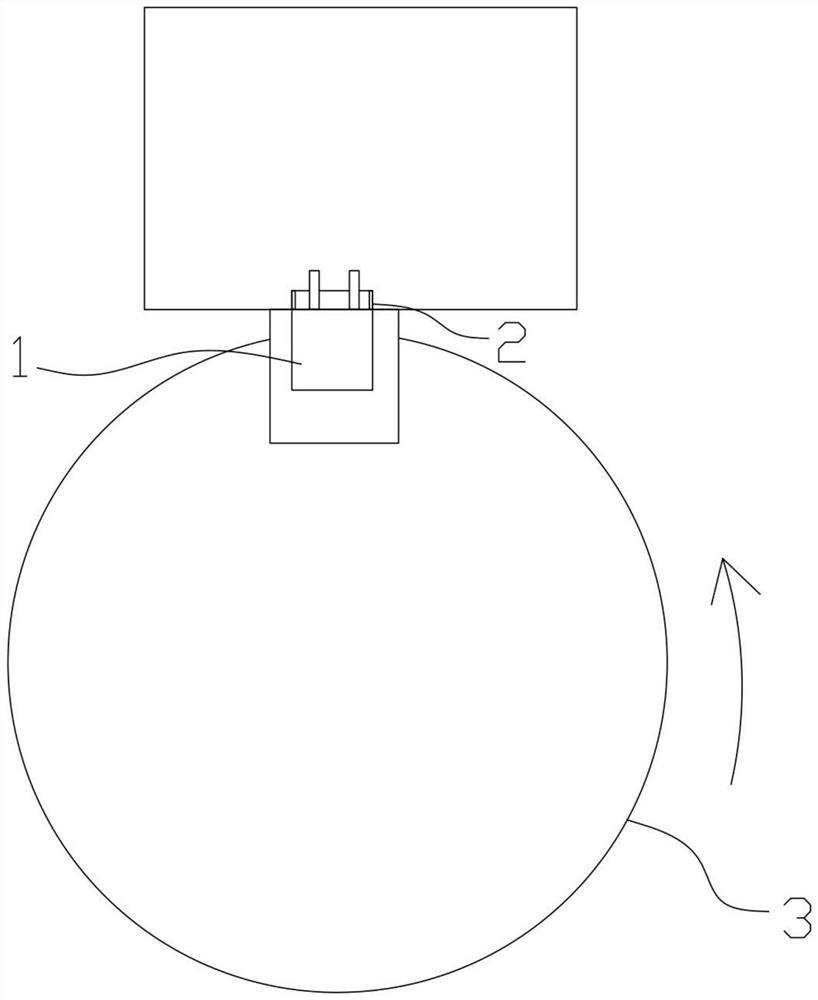

Pole ear sort-out device of storage battery pole group

ActiveCN102723457ASimple structureImprove work efficiencyCell component detailsAssembly lineEAR FOLDING

The invention discloses a pole ear sort-out device of a storage battery pole group, which comprises a storage battery conveying mechanism; an ear brushing mechanism, an ear folding mechanism and an ear cutting mechanism are sequentially arranged in the conveying direction of a storage battery pole group; the ear brushing mechanism comprises rollers which correspond to the positions of the pole ears of the storage battery pole group and brush hair which is distributed on the outer walls of the rollers; the ear folding mechanism comprises a support bench, a fixed plate which is fixedly arranged on the support bench, a plurality of first pole ear extrusion plates which are arranged on the fixed plate, a moving plate which is arranged on the support bench and is slidably matched with the fixed plate and a plurality of second pole ear extrusion plates which are arranged on the moving plate; the positions of the second pole ear extrusion plates correspond to those of the first pole ear extrusion plates; the ear cutting mechanism comprises a support frame, a die cutting template which is arranged in the support frame, a guide groove which is fixedly arranged on the bottom surface of the die cutting template and a cutter which slides along the guide groove; and through holes which correspond to the positions of the pole ears are arranged on the die cutting template. According to the pole ear sort-out device of the storage battery pole group, an assembly line of the brushing, folding and cutting processes of the pole ears is treated fully automatically, and the treatment efficiency is high.

Owner:ZHEJIANG TIANNENG POWER ENERGY

Automatic packaging machine

InactiveCN101525056BReduce laborQuality improvementWrapper twisting/gatheringSolid materialProduction lineEngineering

Owner:KUNMING DINGCHENG TECH

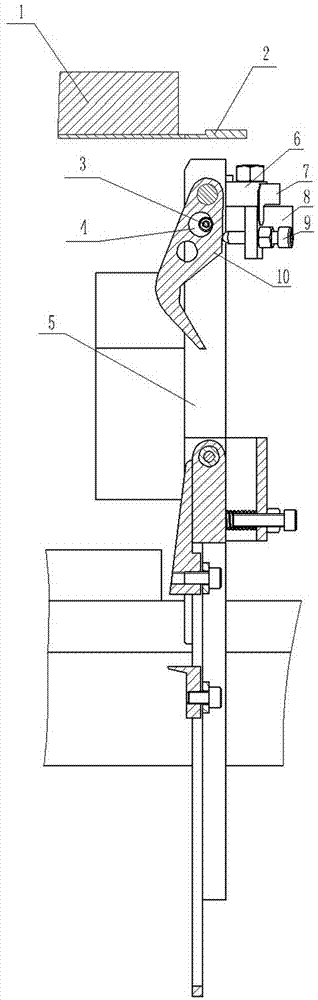

Ear folding mechanism of pasting box machine

The invention relates to a paper box forming machine, in particular to a mechanism for folding wide edges of a sample box board. The ear folding mechanism comprises a forming inner die and a lifting device of the forming inner die, and is characterized in that gear boards are respectviely arranged on two sides of the forming inner die; swing blocks are arranged at the outer sides of the gear boards, and the upper ends of the swing blocks are hinged onto the outer sides of the ger boards; infolding fixed blocks are arranged at the right sides of the gear boards, and 7-shaped infolding claws are hinged on the infolding fixed blocks; elastic parts are arranged between the infolding claws and the infolding fixed blocks or between the infolding claws and the gear boards; and support parts which can be acted on the lower ends of the swing blocks and can enable the swing blocks to cross the left sides of the gear boards are arranged at the tail ends of the infolding claws. The ear folding mechanism of a pasting box machine has the advantages of simple structure, flexible action and convenience in replacement.

Owner:温州中欣智能机械有限公司

Volute ear folding device

ActiveCN110508655AIncrease productivityImprove product qualityMetal-working feeding devicesPositioning devicesProcess equipmentEngineering

The invention relates to the technical field of air duct volute manufacturing, in particular to a volute ear folding device. The volute ear folding device comprises a coaming fixing mechanism for fixing coaming and a side plate fixing mechanism for fixing side plates. The volute ear folding device further comprises a bending mechanism. The bending mechanism comprises a transverse bending mechanismbody and a vertical bending mechanism body. Folded ears are transversely bent through the transverse bending mechanism body, and the transversely-bent folded ears are vertically bent through the vertical bending mechanism body. The automatic bending device is used for volute ear folding work, the problems that in the extruding and edge covering processes of a volute, in order to prevent the coaming and the upper and lower side plates from being scattered, the volute needs to be subjected to ear folding work firstly, and normal volute feeding and clamping of following process equipment are facilitated are solved, and the production efficiency and the product quality are effectively improved.

Owner:湖南创研智能装备有限公司

Dedicated cat food for Scottish fold

InactiveCN106615878AMeet daily nutritional needs for growthPrevent diseaseAnimal feeding stuffAccessory food factorsBiotechnologyDisease

The invention relates to cat food, in particular to dedicated cat food for a Scottish fold. The cat food is prepared from the following raw materials in parts by weight: fermented puffing fish flesh, fermented puffing chicken, fermented puffing rape straw, modified potato powder, compound vegetable and fruit powder and processed corn oil which are mixed. The dedicated cat food for the Scottish fold is specially designed for the Scottish fold, is lower in material selection cost, can meet the daily growth nutrient requirement of the Scottish fold and can effectively prevent diseases in a Scottish fold cultivation period; after taking the dedicated cat food, the Scottish fold can defecate excrement which is moderate in hardness and in a strip shape.

Owner:安徽赛澳生物工程有限公司

Corner-sticking-free mold-free lid and base box forming mechanism

PendingCN110421896AOvercome the defect of increased production costHigh degree of automationPaper-makingBox making operationsCardboardEngineering

The invention discloses a corner-sticking-free mold-free lid and base box forming mechanism. the mechanism comprises a conveying device, a gluing device, a lower side plate device, a positioning and ear folding device and a surface paper erecting device, wherein the lower side plate device is positioned above the conveying device, and the surface paper erecting device is positioned below the conveying device; the lower side plate device comprises a side plate mechanism, a side plate pressing down mechanism and a side plate guide mechanism, the side plate mechanism comprises a bearing plate anda push plate, the bearing plate is used for bearing side plates, the push plate is used for pushing the side plates to the side plate pressing down mechanism, and the side plate pressing down mechanism presses the side plates along the side plate guide mechanism to the front end and the rear end of a paper plate; the positioning and ear folding device comprises a positioning rod and an ear folding part, and is used for folding dog-ears on the surface paper; and the surface paper erecting device is used for erecting the surface paper on the periphery of a paper board. The mechanism is simple in overall structure, free of corner sticking, free of mold, capable of automatically positioning the side plates, capable of greatly reducing the production cost, high in automation degree, high in processing efficiency, high in bonding fastness and wide in application range.

Owner:东莞市坚基包装机械有限公司

Pole-ear folding device for cast-welding storage battery

ActiveCN103367788BAccurate angleSimple structureFinal product manufactureSecondary cells manufactureEngineeringUltimate tensile strength

The invention discloses a pole-ear folding device for a cast-welding storage battery. The device is a pole-ear folding plate, and a plurality of anode ear positioning grooves and cathode ear positioning grooves are formed in the pole-ear folding plate. Two short side walls of each cathode ear positioning groove incline for 30-45 degrees to the center direction of the groove, and two long side walls of each cathode ear positioning groove incline for 15-25 degrees to the center direction of the groove. The pole-ear folding device has the advantages of simple structure and accurate pole-ear folding angle, is beneficial to cast-welding forming, and ensures the product quality. Moreover, the pole-ear folding device is easily operated, the labor intensity is alleviated, and the production efficiency is improved.

Owner:TIANNENG GRP JIANGSU SPECIAL POWER SUPPLY

Mask packaging device and mask production equipment

PendingCN113479428AEasy to packAchieve stackingPackaging automatic controlIndividual articlesEAR FOLDINGElectrical and Electronics engineering

The invention relates to a mask packaging device and mask production equipment. The mask packaging device comprises a feeding assembly and an ear folding assembly, the feeding assembly comprises a moving part and a mask flow guide part, and the ear folding assembly comprises a driving source and an ear folding part. Masks are conveyed into a flow guide channel from the feeding channel of the mask flow guide part through a conveying mechanism. The moving part is located below the pushing opening of the mask flow guide part and pushes the masks to move to a stacking opening through the pushing opening. The size of the flow guide channel is smaller than that of a mask, and when the mask is pushed out of the stacking opening by the moving part, the mask can be supported at one end of the stacking opening. Ear belts of the mask fall into the flow guide channel. The driving source of the ear folding assembly is used for driving an ear folding part to extend into the flow guide channel through an ear folding hole, and the ear folding part can push an ear belt to be folded below the mask until the next mask is pushed to be stacked with the mask. According to the mask packaging device, mask ear belts can be effectively folded, so that the mask packaging process is convenient, and packaging efficiency is guaranteed.

Owner:GUANGDONG BAIYUN UNIV

Mask ear belt ear folding device

The invention discloses a mask ear belt ear folding device, which belongs to the technical field of mask production devices, and comprises a conveying belt arranged above a support seat, ear folding rods are arranged on the two sides of the support seat, the ear folding rods are positioned at the ascending end of the conveying belt, and each ear folding rod comprises an expansion rod, an upper inclined rod, a parallel rod and a retraction rod, the expansion rod and the supporting base extend outwards obliquely at an angle A, the upper inclined rod is connected to the expansion rod and extendsupwards obliquely at an angle B, the parallel rod is connected to the upper inclined rod and extends horizontally at an angle C, and the retraction rod is connected to the parallel rod and extends inwards at an angle D; the problem that time and labor are consumed due to the fact that existing mask ear bands are folded inwards manually is solved.

Owner:广西德福莱医疗器械有限公司

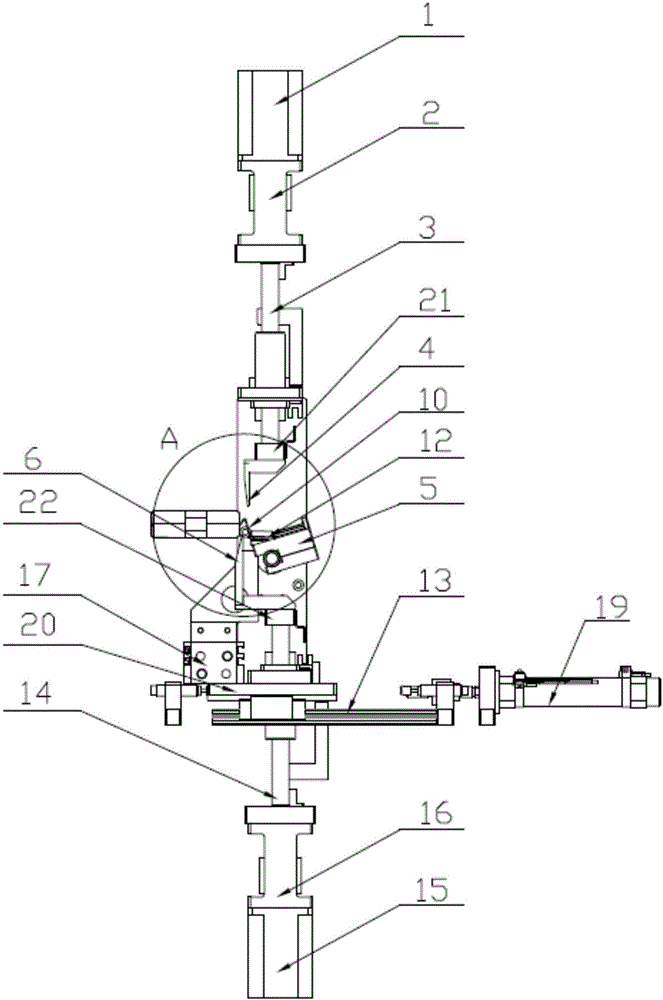

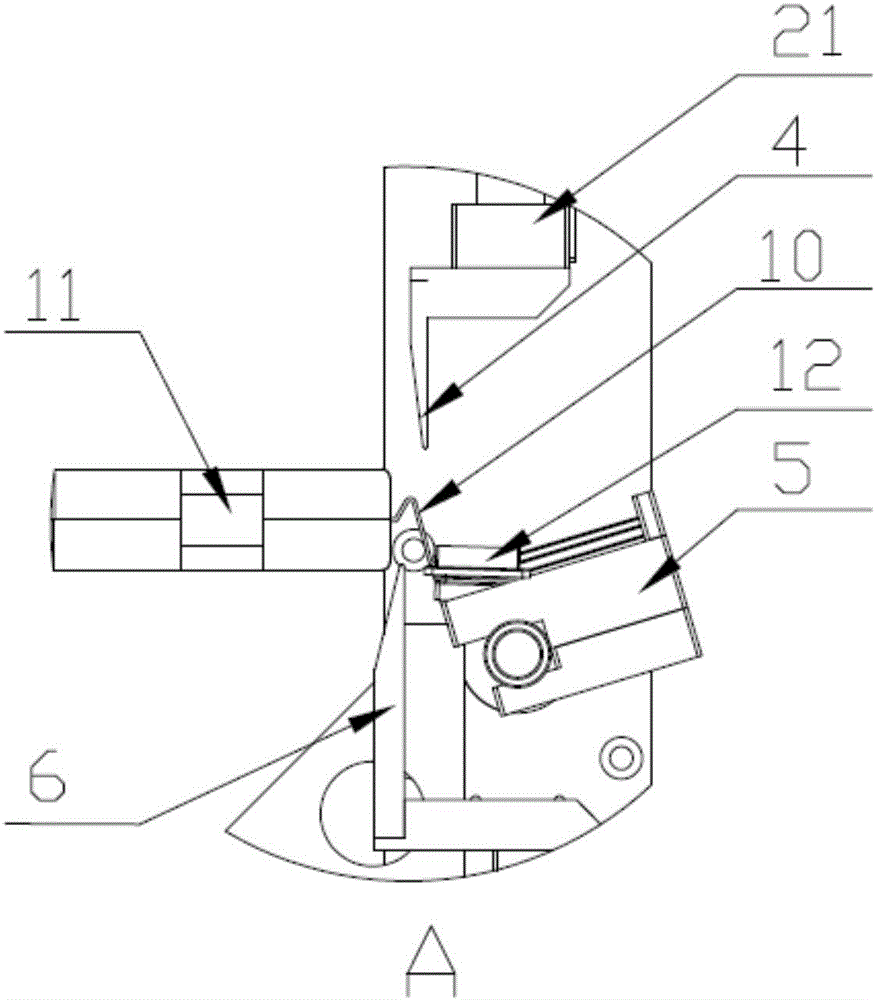

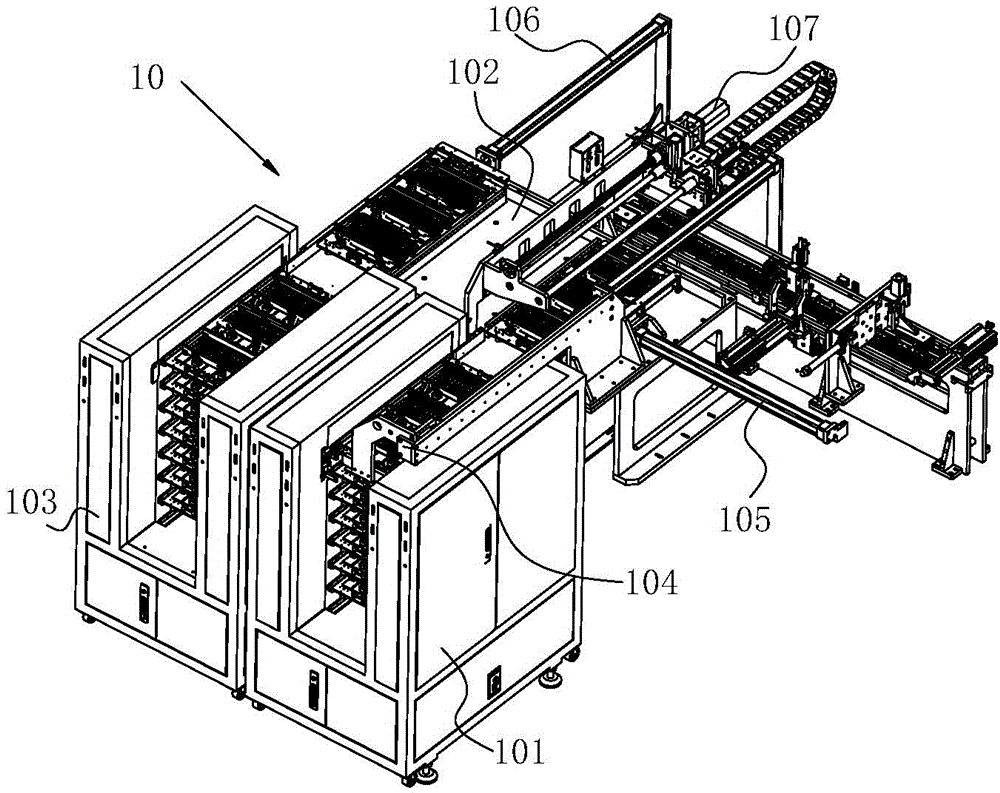

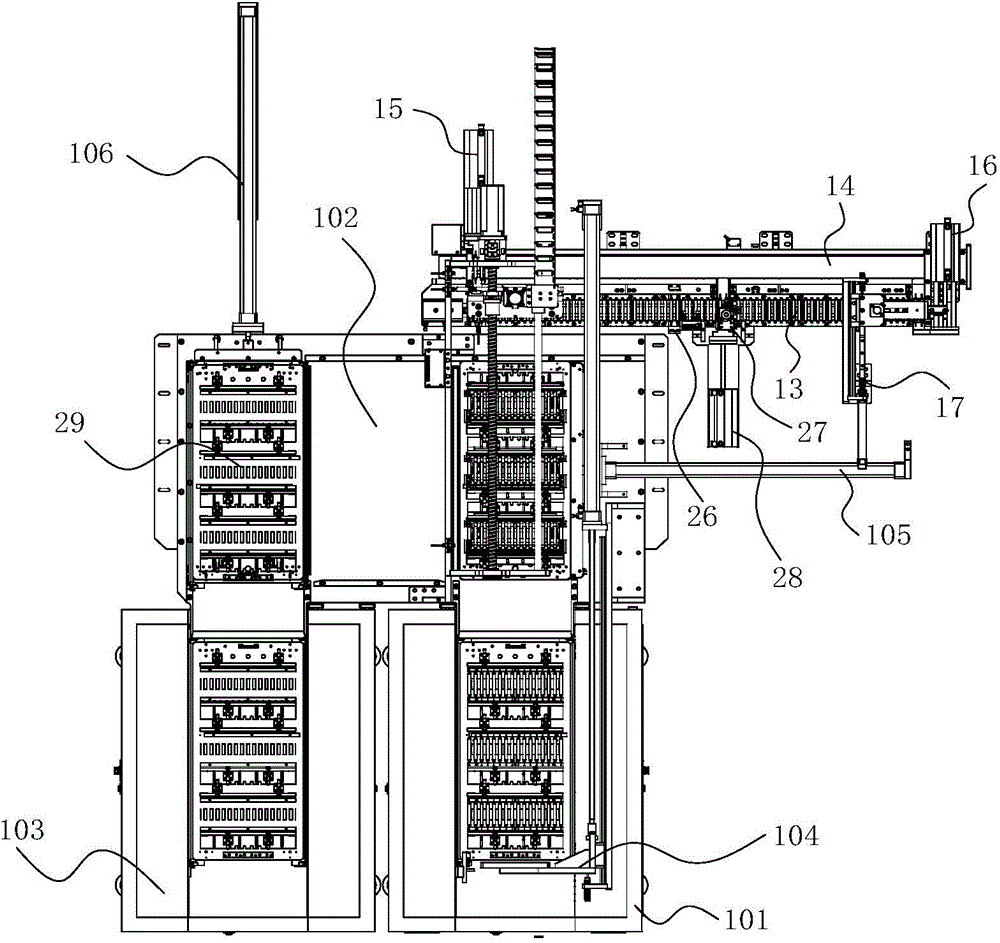

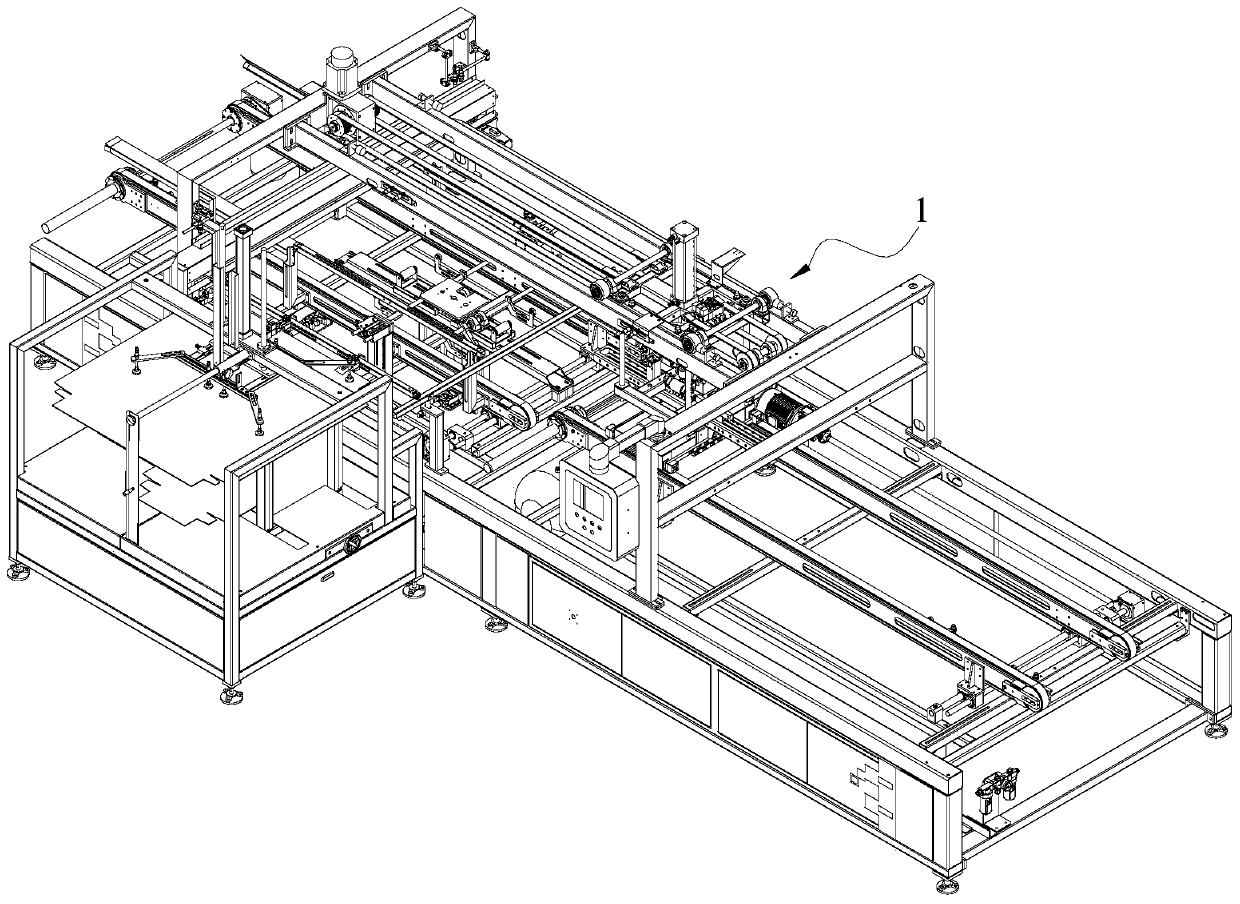

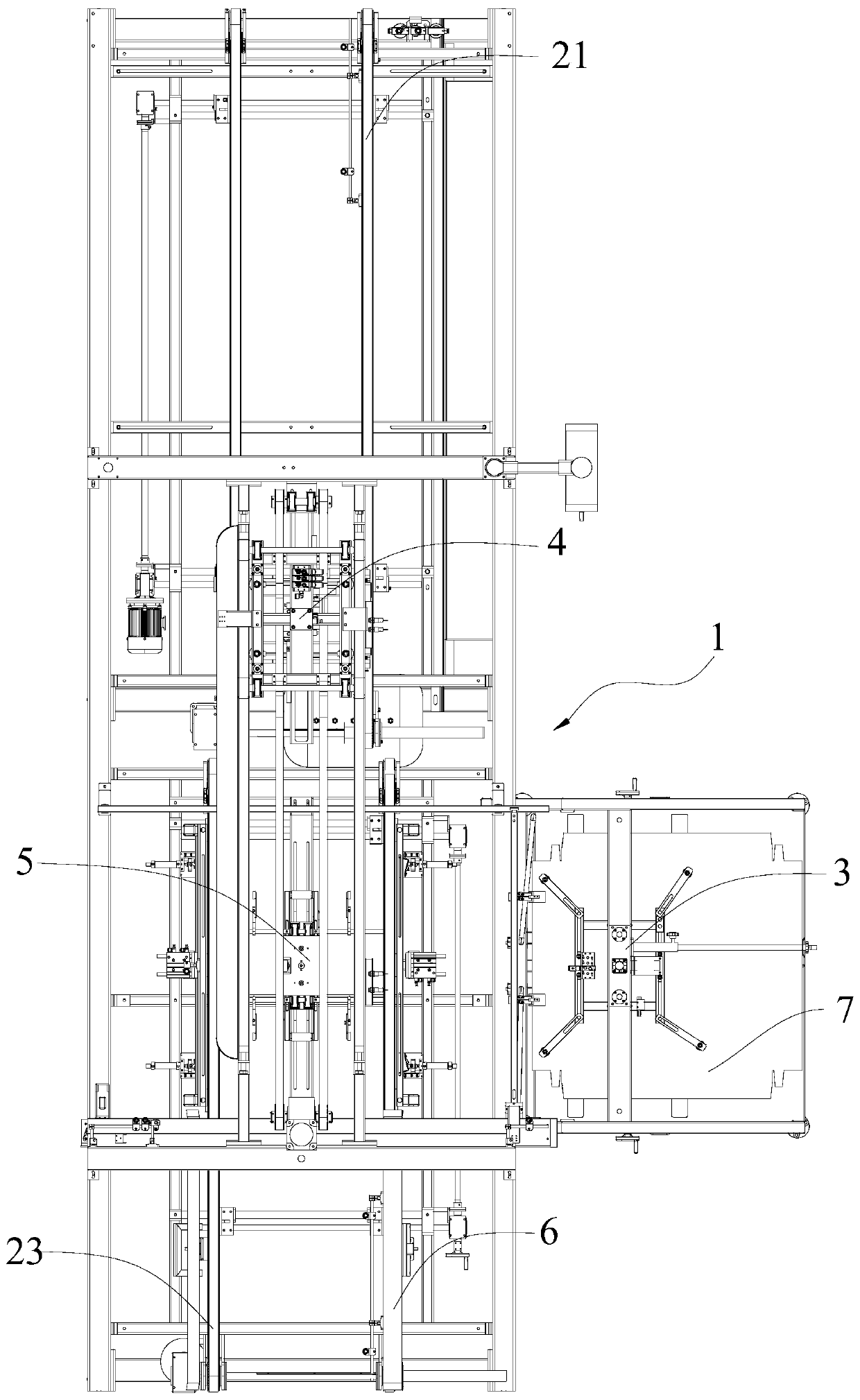

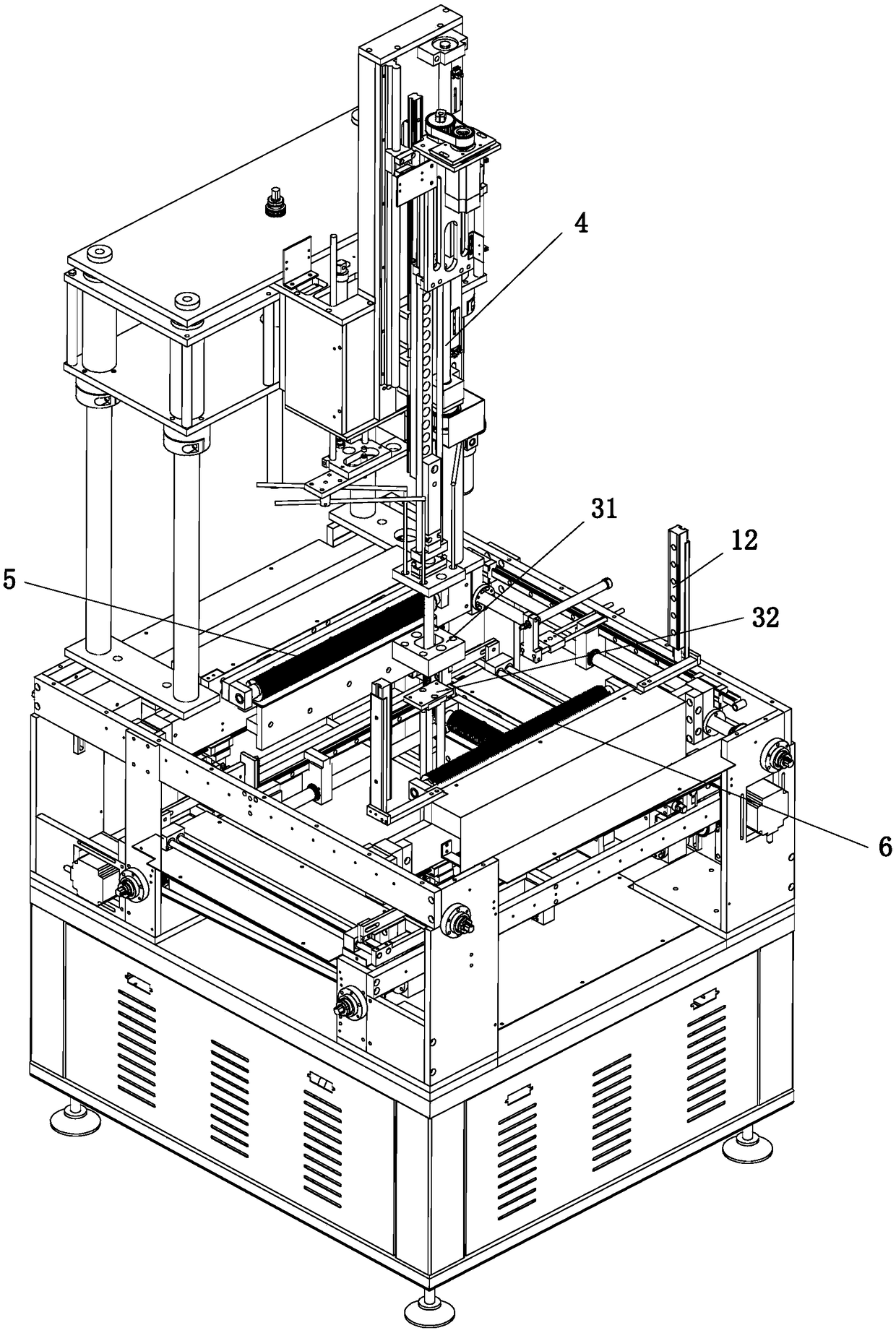

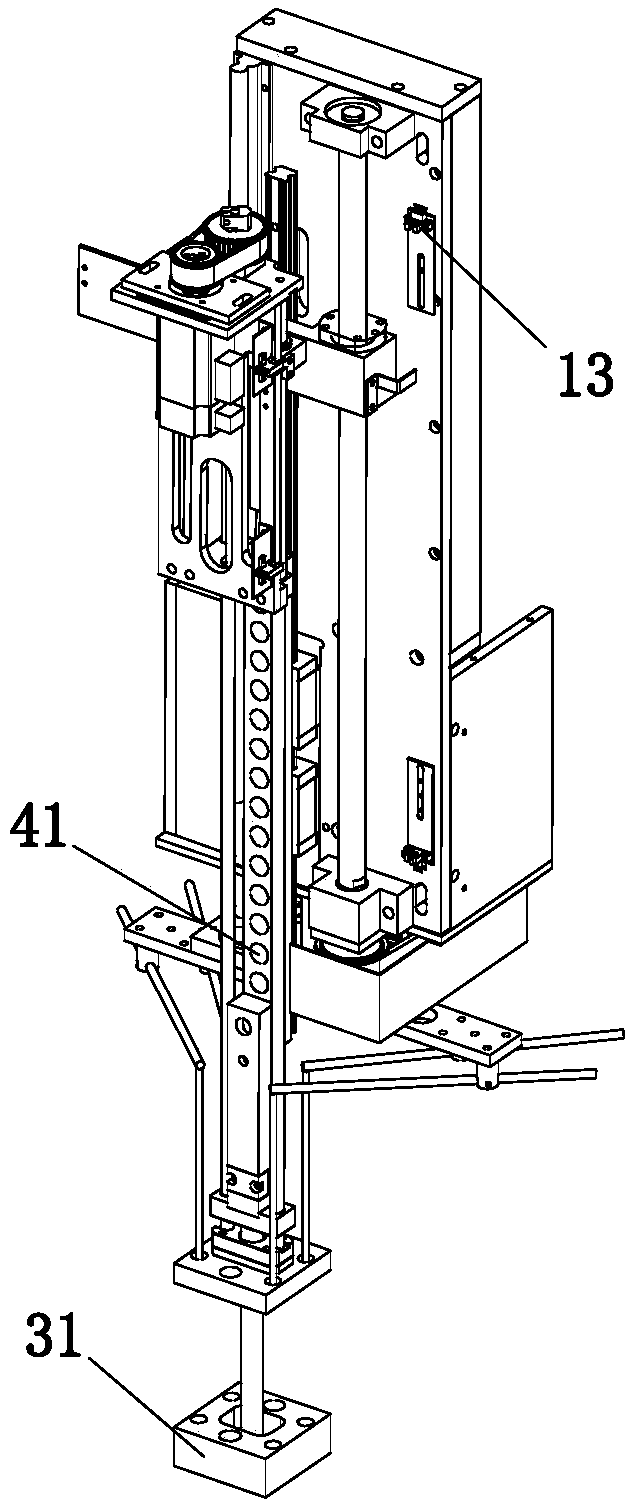

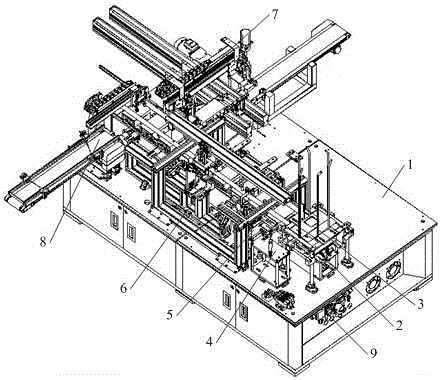

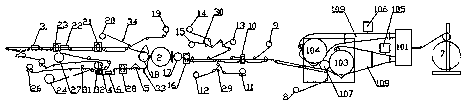

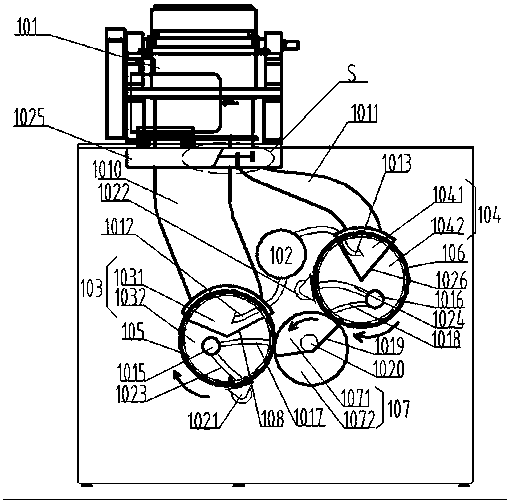

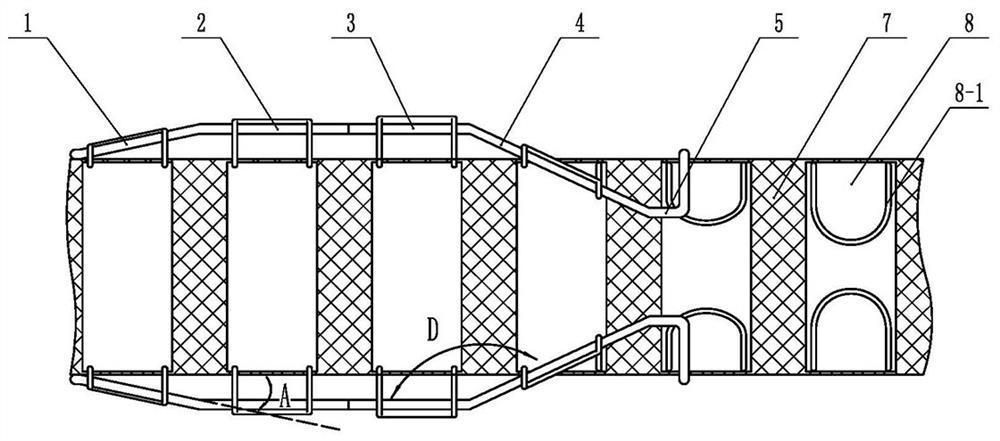

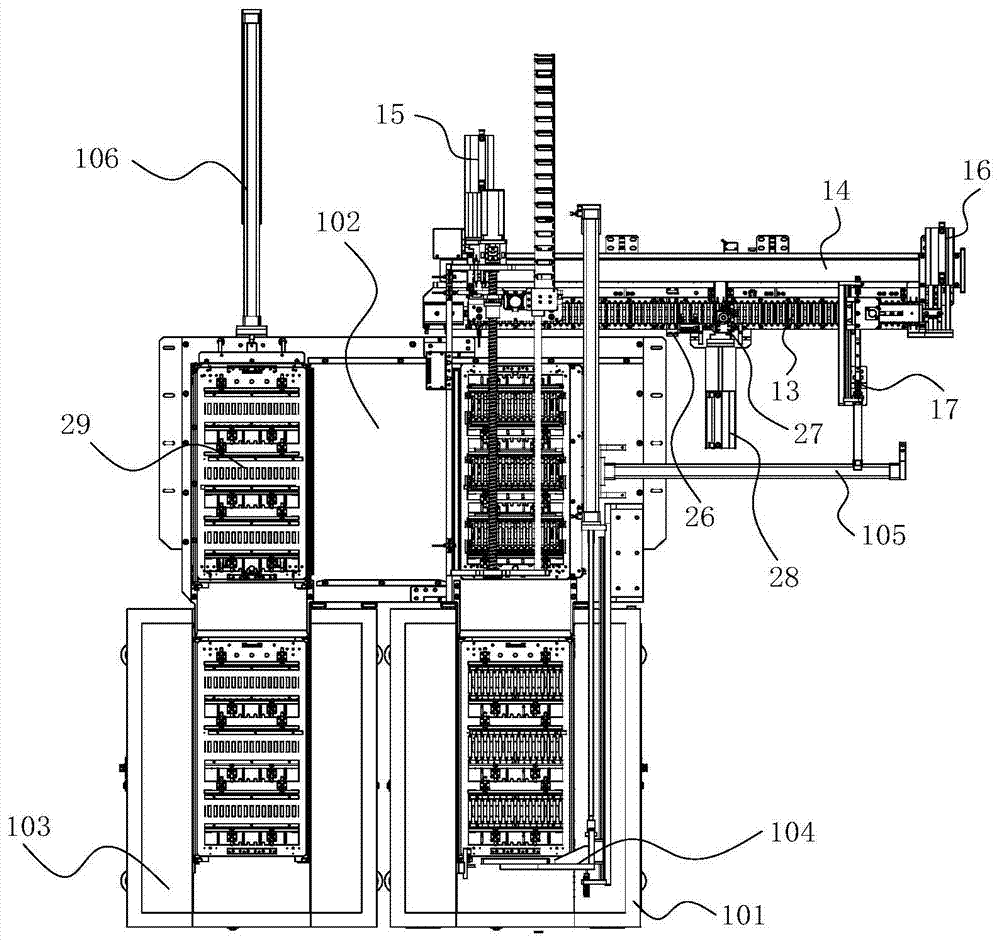

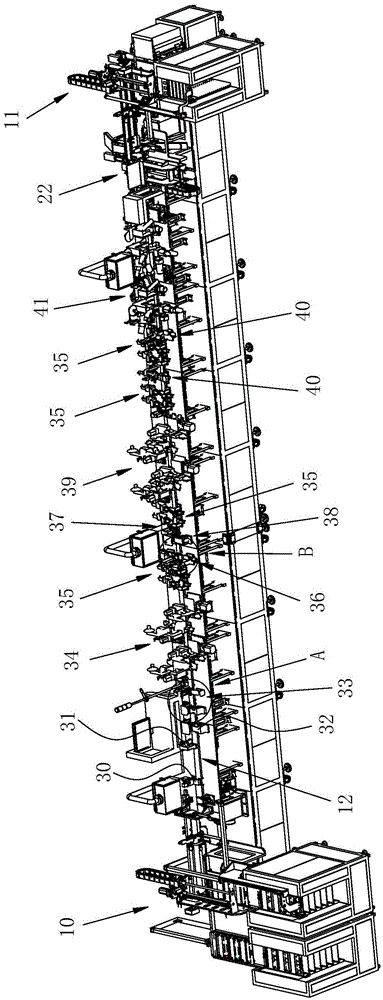

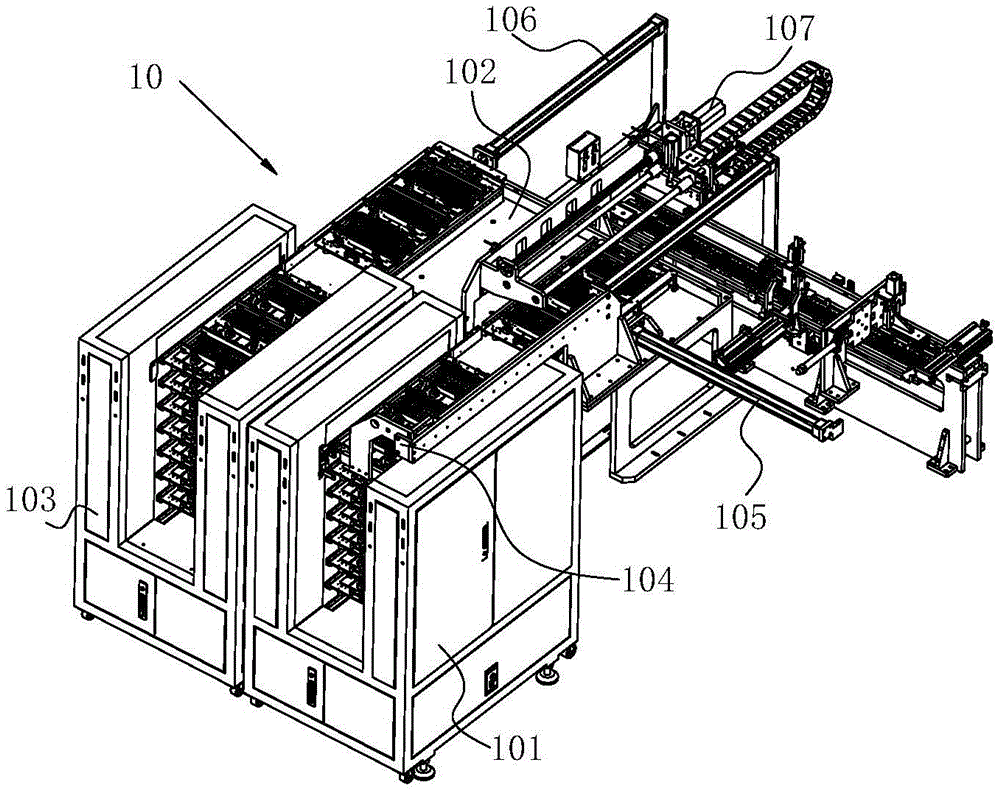

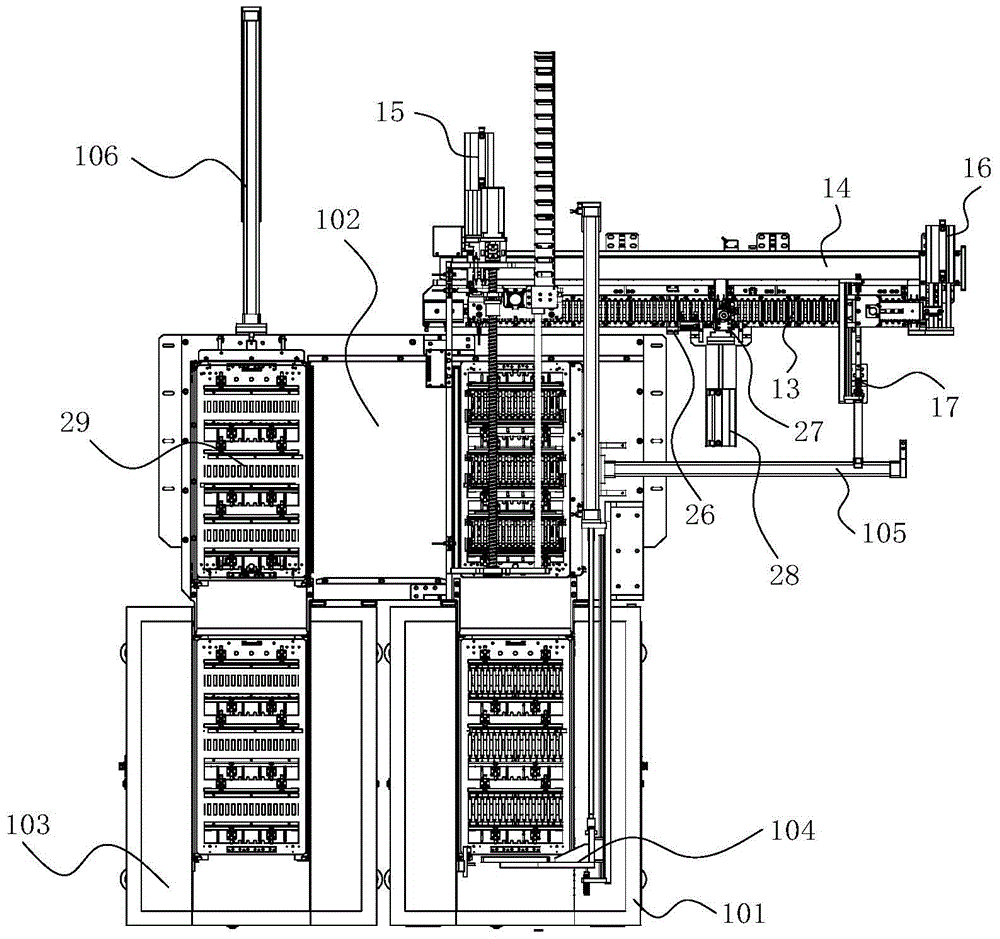

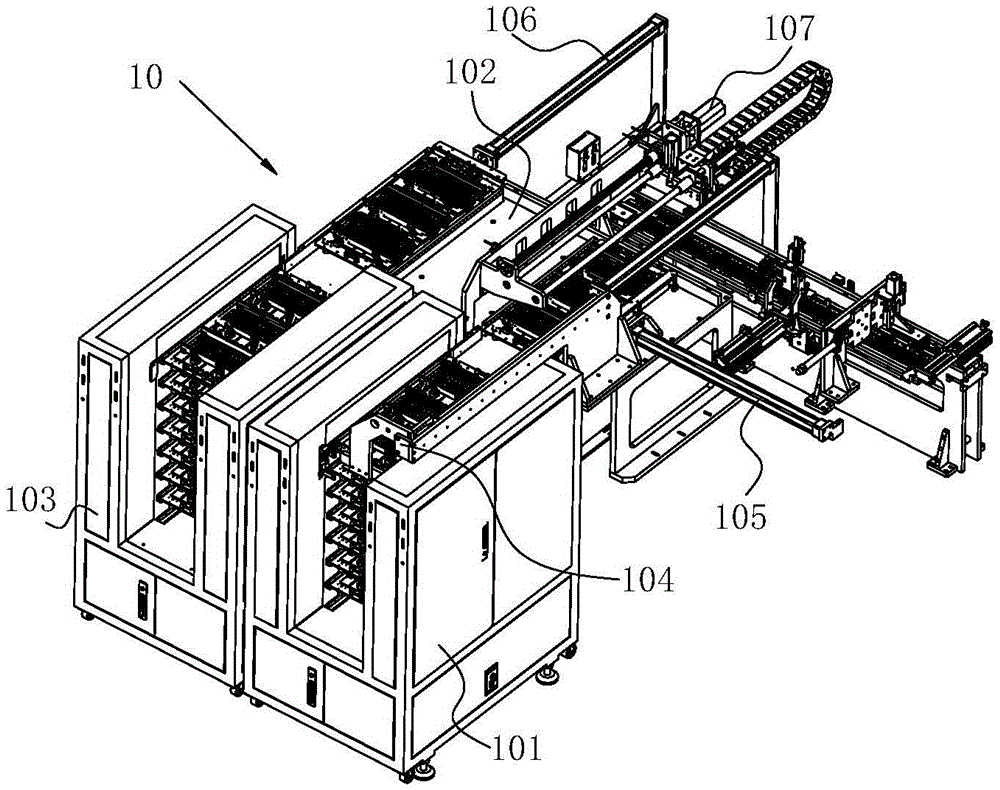

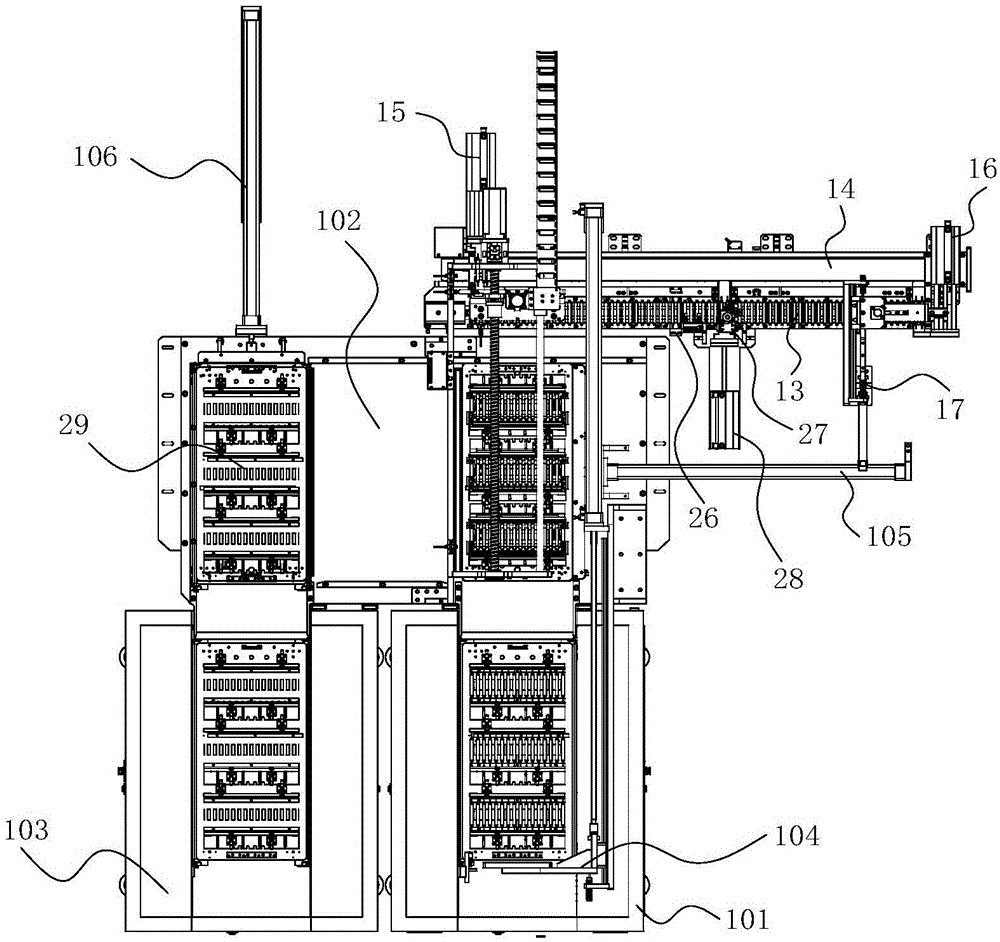

Automatic packaging machine

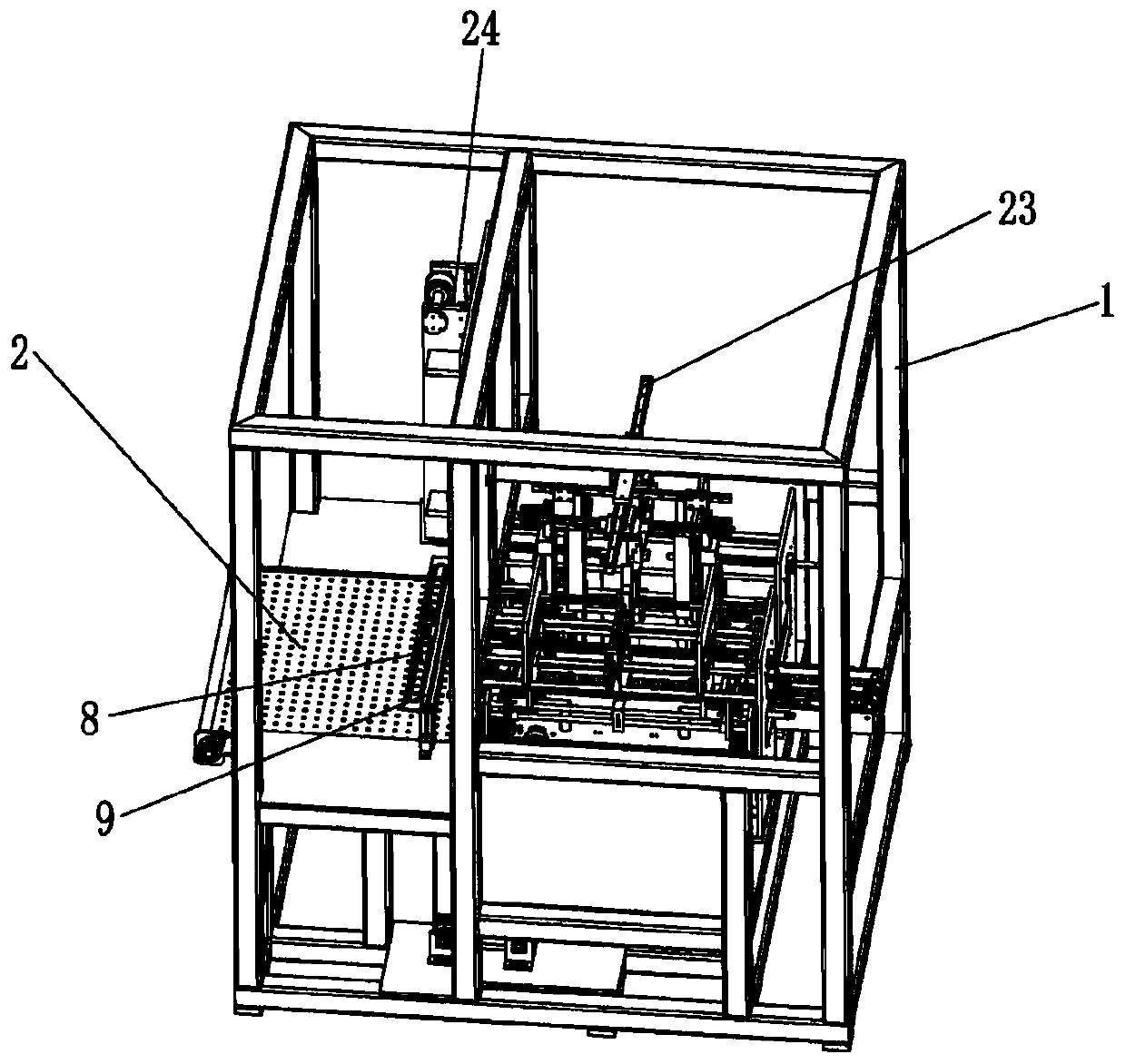

ActiveCN104477463BIncrease productivityImprove reliabilityFinal product manufacturePackaging automatic controlAdhesiveEngineering

The invention discloses an automatic packaging machine, which includes a feeding system and an unloading system, and an operation conveying line for conveying batteries located between the feeding system and the unloading system. In the forward direction of the conveying line, there are battery counters for counting the number of batteries, a centering mechanism for placing the batteries in the center, a tab flattening mechanism for pressing the battery tabs to a horizontal position, a tab change device, Right-angle gluing device, tab folding device, door-shaped gluing device, tab super-edge scraping device and cylindrical gluing device. This solution provides an automatic packaging machine to realize automatic folding and gluing of battery tabs, improving production efficiency and reliability.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Tab folding and gluing system of automatic packaging machine

The invention discloses a pole ear folding and rubberizing system of an automatic packing machine. The pole ear folding and rubberizing system of the automatic packing machine comprises an operation conveying line used to convey batteries, and a pole ear deviator, a right angle rubberizing device, a pole ear folding device, a door-shaped rubberizing device, two pole ear extra edge shaving devices and a cylindrical glue rolling device, which are sequentially arranged along the forward direction of the operation conveying line, wherein a rotation mechanism which rotates the batteries is arranged between the right angle rubberizing device and the pole ear folding device, another rotation mechanism which rotates the batteries is arranged between the pole ear folding device and the door-shaped rubberizing device, and another rotation mechanism which rotates the batteries is arranged between the two pole ear extra edge shaving devices. The pole ear folding and rubberizing system of the automatic packing machine achieves automatic folding and rubberizing of pole ears of the batteries, and improves production efficiency and reliability.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Method for preparing feed of Scottish fold

The invention relates to a method for preparing a feed of a Scottish fold. The feed comprises the following components in percentage by weight: 15-20 percent of vital wheat gluten, 12-16 percent of white fish meal, 8-10 percent of egg powder, 8-15 percent of chicken blood powder, 8-10 percent of trash fish powder, 3-5 percent of pork powder, 1-3 percent of vitamin A, 1-3 percent of vitamin B, 1-3 percent of vitamin D, 2-4 percent of calcium powder, 4-8 percent of pork liver powder, 2-4 percent of fish liver oil, 1-3 percent of salt, 2-4 percent of salvia miltiorrhiza bunge, 1-3 percent of red flower, 2-4 percent of poria cocos, 1-3 percent of semen cassiae, 2-4 percent of purple perilla and 1-3 percent of cyperus rotundus. Putting all the powder components which are taken in the proportion in a stirrer and stirring for 120 minutes; after being taken out, putting the stirred components in a drier for drying; after being cooled, putting all the components in a pulverizer for pulverizing; putting the pulverized components in the stirrer again for stirring; then taking the components out of the stirrer and putting in a puffing machine for puffing; after being taken out and cooled, putting the obtained material in an annular mode rigid particle machine set to produce deposited rigid feed particles of 40 meshes; then using a sieve of 40 meshes to sieve the feed particles, wherein the weight of each particle is 0.1g; packing the feed particles according to the required weight.

Owner:李晓云

Dog ear folding and pressing two-in-one mechanism

The invention provides a dog ear folding and pressing two-in-one mechanism which comprises a base, a vertical plate, a guide rail, a dog ear folding and pressing device and a dog ear bearing device; the guide rail is installed on the vertical plate, the vertical plate is installed on the base, and the dog ear folding and pressing device comprises dog ear folding assemblies, a dog ear pressing assembly and a first driving device; the first driving device comprises a first air cylinder, a first lifting seat and a first guide plate, the first air cylinder is installed on the upper portion of thevertical plate, the first lifting seat is installed on the guide rail, and the first guide plate is installed on the front side of the first lifting seat; the dog ear pressing assembly is installed onthe front side of the first lifting seat, and the dog ear folding assemblies are arranged on the two side edges of the dog ear pressing assembly respectively; and the dog ear bearing device comprisesa dog ear bearing strip, a dog ear bearing plate and a fourth driving device, the dog ear bearing strip is installed on the dog ear bearing plate, and the dog ear bearing plate is installed on the guide rail. The dog ear folding and pressing two-in-one mechanism can realize automatic dog ear folding and pressing, so that the labor intensity of workers is greatly reduced, and the dog ear folding and pressing efficiency is also improved.

Owner:东莞市爱康智能技术有限公司

Material turnover system of automatic packaging machine

The invention discloses a material turnover system of an automatic packing machine. The material turnover system of the automatic packing machine comprises a loading system and an unloading system, and further comprises an operation conveying line arranged between the loading system and the unloading system, wherein the loading system is provided with a loading mechanical arm which can transfer batteries in bulk, the unloading system is provided with an unloading mechanical arm which can transfer the batteries in bulk, the operation conveying line comprises a drive wheel located on a position close to one end of the loading system and a driven wheel located on a position close to one end of the unloading system, a mold chain is arranged between the drive wheel and the driven wheel in sleeve mode, and the mold chain is composed of a plurality of placement molds which are buckled together two by two and can selectively clamp the batteries. The material turnover system of the automatic packing machine achieves automatic transportation of the batteries during the pole ear folding and rubberizing process, and improves running reliability of a device.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Walnut chip boxing equipment

The invention relates to the field of packaging, in particular to walnut chip boxing equipment, including a box feeding mechanism, a material feeding mechanism and two boxing mechanisms, each boxing mechanism includes a transmission chain and a side ear folding unit and a lower ear folding unit located outside the transmission chain. block and upper ear folding unit, the conveyor chain is evenly equipped with blocks, the box feeding mechanism can send the packaging box between two adjacent blocks, the feeding mechanism is located outside one of the conveyor chains, and can pack walnut slices Packed into the packaging box; the lower ear folding block is fixedly arranged between the side ear folding unit and the upper ear folding unit, the upper ear folding unit includes upper ear folding rollers that swing in the vertical direction, and the side ear folding unit includes fixed side ear folding blocks 1. The pre-folding block set by reciprocating rotation and the pressing block slidingly arranged with the side ear folding block, when the pre-folding block rotates away from the side ear folding block, the pressing block moves towards the chain direction. When the technical scheme is adopted, it is beneficial to improve the packing effect of the walnut slices.

Owner:重庆市合川区三江印象桃片有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com