Production device of sweatpants

A technology of production equipment and sanitary pants, which is applied in the field of diapers, can solve the problems of increasing equipment investment costs, and achieve the effect of precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

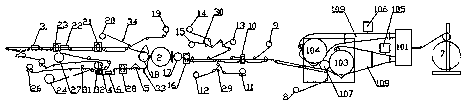

[0097] This embodiment provides a production device for sanitary pants, such as figure 1 As shown, it is mainly composed of cotton core wood pulp rack 7, cotton core crushing and forming mechanism 1, cotton core coated non-woven fabric rack 8, diversion layer material rack 9, cotton core cutter 10, and crotch lifter that are arranged in sequence. Pull elastic material rack 11, PE bottom film material rack 12, surface layer non-woven fabric rack 13, protective elastic material rack 14, protective non-woven fabric rack 15, core body cutter 16, core body vertical transfer Wheel 17, variable speed and horizontal mechanism 2, core body horizontal transfer wheel 18, waist elastic material rack 19, waist non-woven fabric rack 20, rear O cutter 21, half-fold conveying 22, girdle conveying 23 and ear folding mechanism 3 Composition; between the variable-speed and horizontal-transfer mechanism 2 and the core body horizontal transfer wheel 18, an inner layer non-woven fabric rack 24, an ...

Embodiment approach 2

[0121] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, after the abdominal elastic and curved elastic are applied, since there are more abdominal elastics, more glue is applied. It will be harder and uncomfortable to wear, but in this embodiment, part of the abdominal elastic can be broken through the hot pressing point of the elastic hot pressing point mechanism 6, so that it will be more comfortable to wear afterwards.

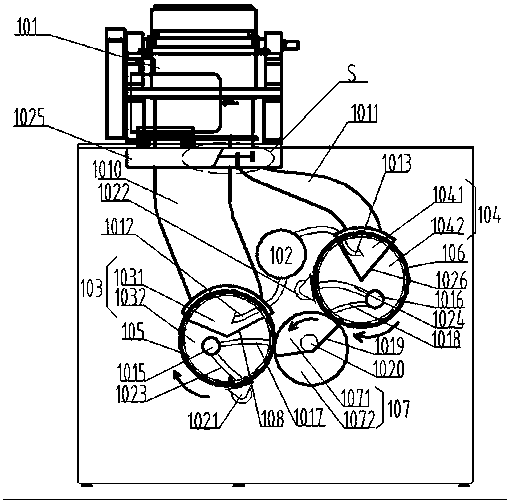

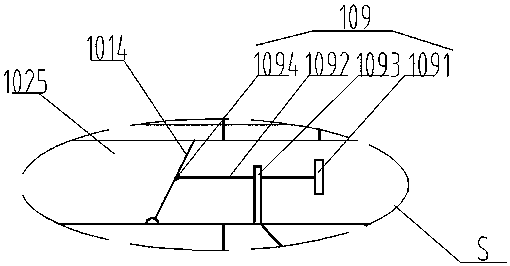

[0122] Specifically, in this embodiment, as figure 1 , the elastic hot-pressing point mechanism 6 is also set between the curved elastic applying mechanism 4 and the first cutting knife 28, as Figures 32 to 36, the elastic hot-pressing point mechanism 6 is mainly composed of a bracket 601, a bottom roller 602, a mold roller 603 and two hot-pressing blocks 604 with hot-pressing bumps on the surface, and the bottom roller 602 and the mold roller 603 are arranged parallel to each other and both rotate Co...

Embodiment approach 3

[0127] This embodiment is a further improvement of Embodiment 2. The main improvement is that, in Embodiment 2, due to the gap between the outer surface of the bottom roller 602 in the elastic hot-pressing point mechanism 6 and the outer surfaces of the two upper hot-pressing blocks 604 Always in contact, when the equipment needs to be shut down or overhauled, the non-woven fabric between the two will be scorched by the heat on the hot pressing block 604. In addition, if the two are in contact for a long time, the bottom roller 602 and the heat will The hot pressing bumps on the outer surface of the pressing block 604 are damaged by extrusion. However, in the present embodiment, the above-mentioned defects can be effectively overcome.

[0128] Specifically, in this embodiment, as Figures 32 to 34 , the rubber hot-pressing point mechanism 6 also includes a mold roll adjustment mechanism, which is mainly composed of an inner slider 608, an outer slider 609, and a first cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com