Automatic packaging machine

An automatic packaging machine, packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as low work efficiency, surface damage of items, and impact on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

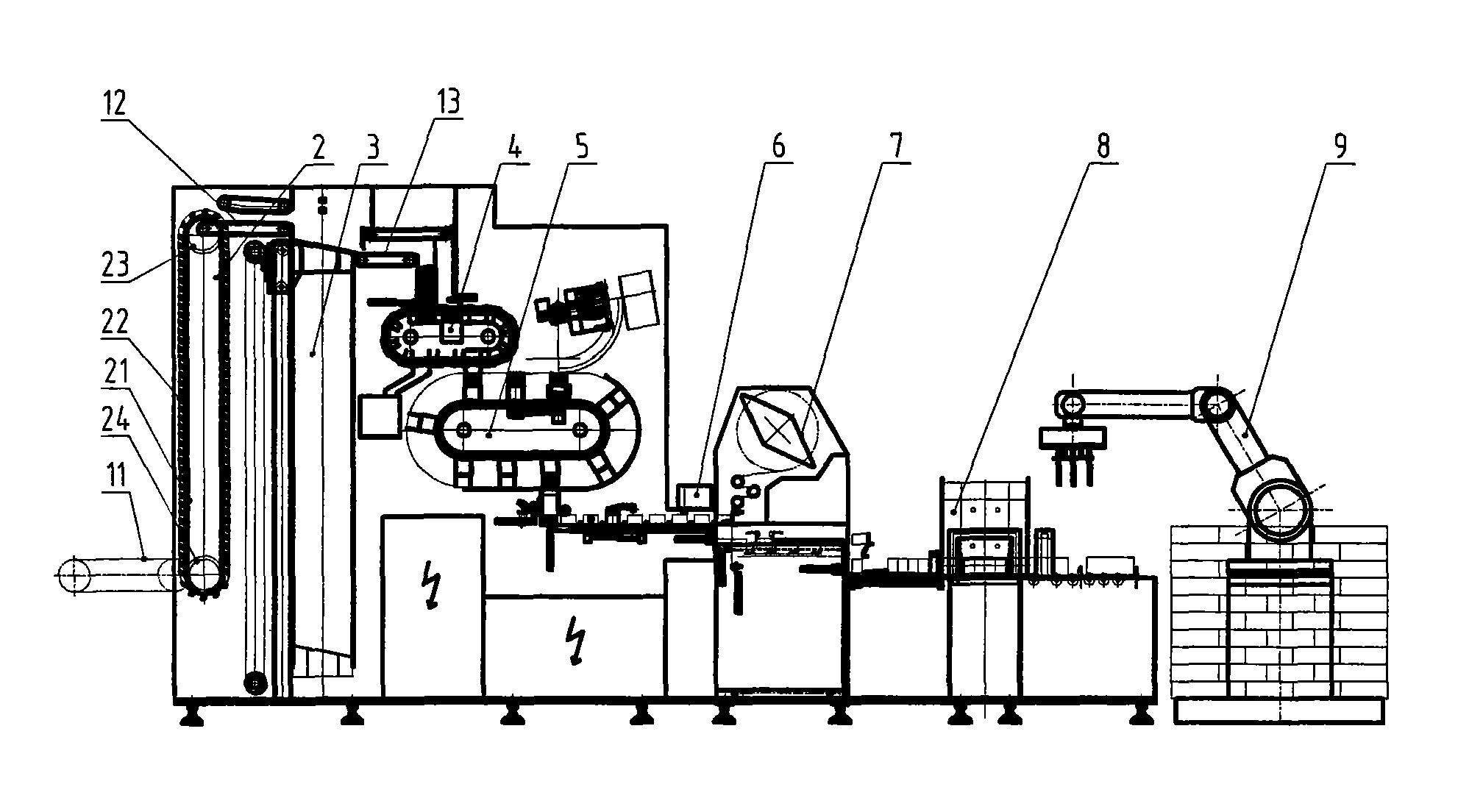

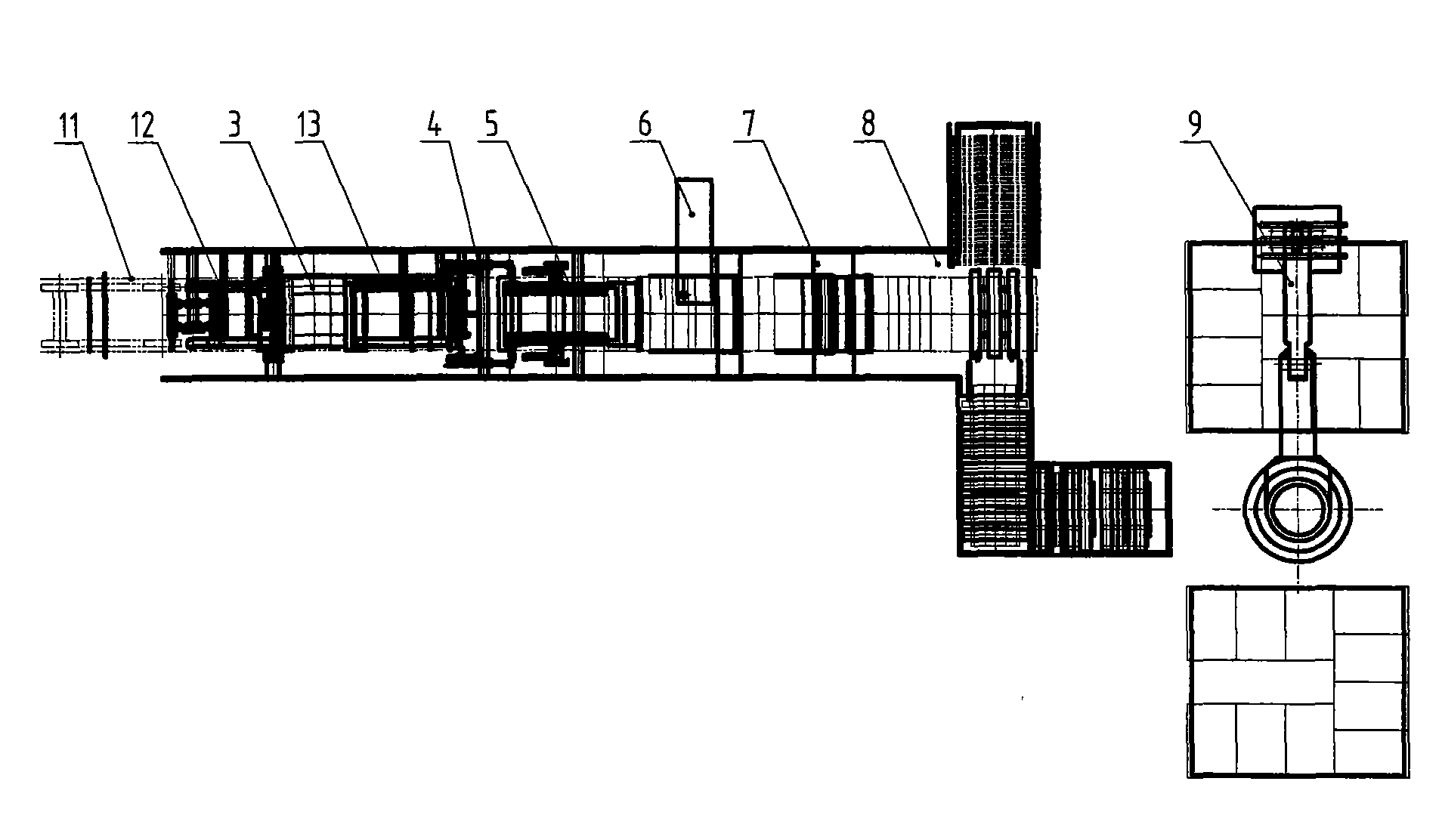

[0042] The automatic packaging machine provided by the present invention includes four conventional belt conveyors and drive motors of the prior art, also includes a hoist 2, a storage device 3, a case weighing machine 4, and a box packing machine 5, and also includes prior art Carton laminator 6, carton packaging machine 7, manipulator 8, such as figure 1 , figure 2 ,in:

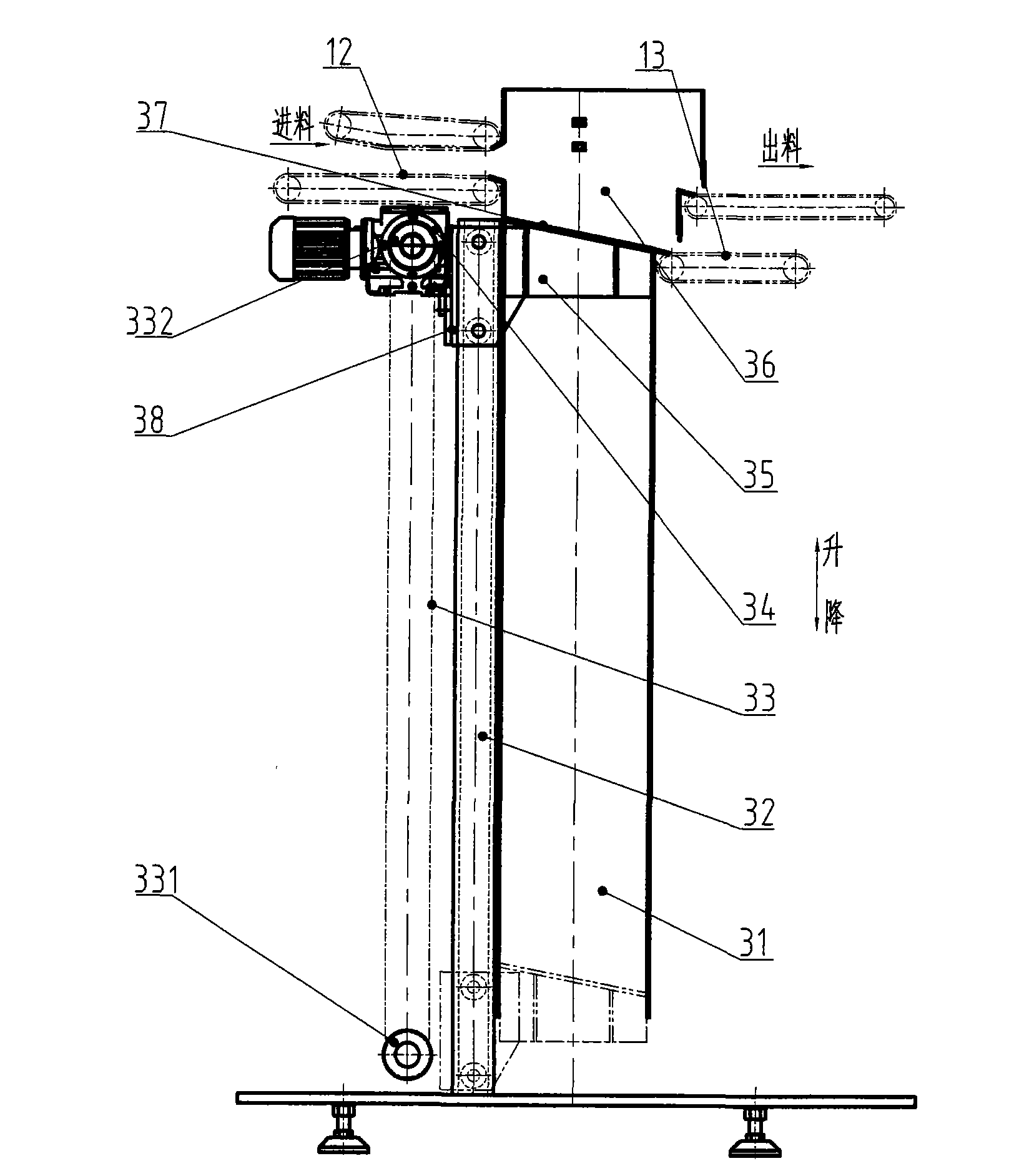

[0043] Elevator 2 comprises longitudinal lifting chain 21, is located at the horizontal hopper 22 of vertical lifting chain 21 outer surfaces, and lifting chain 21 is respectively fixed on the upper and lower rollers 23,24, and wherein roller 23 links to each other with driving motor, and the hoisting machine 2 The input end (low position) is connected with the belt conveyor 11, and the output end (high position) is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com