Volute ear folding device

A volute and bending block technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity, low production efficiency, unsightly welding seam, etc., and improve production efficiency and product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

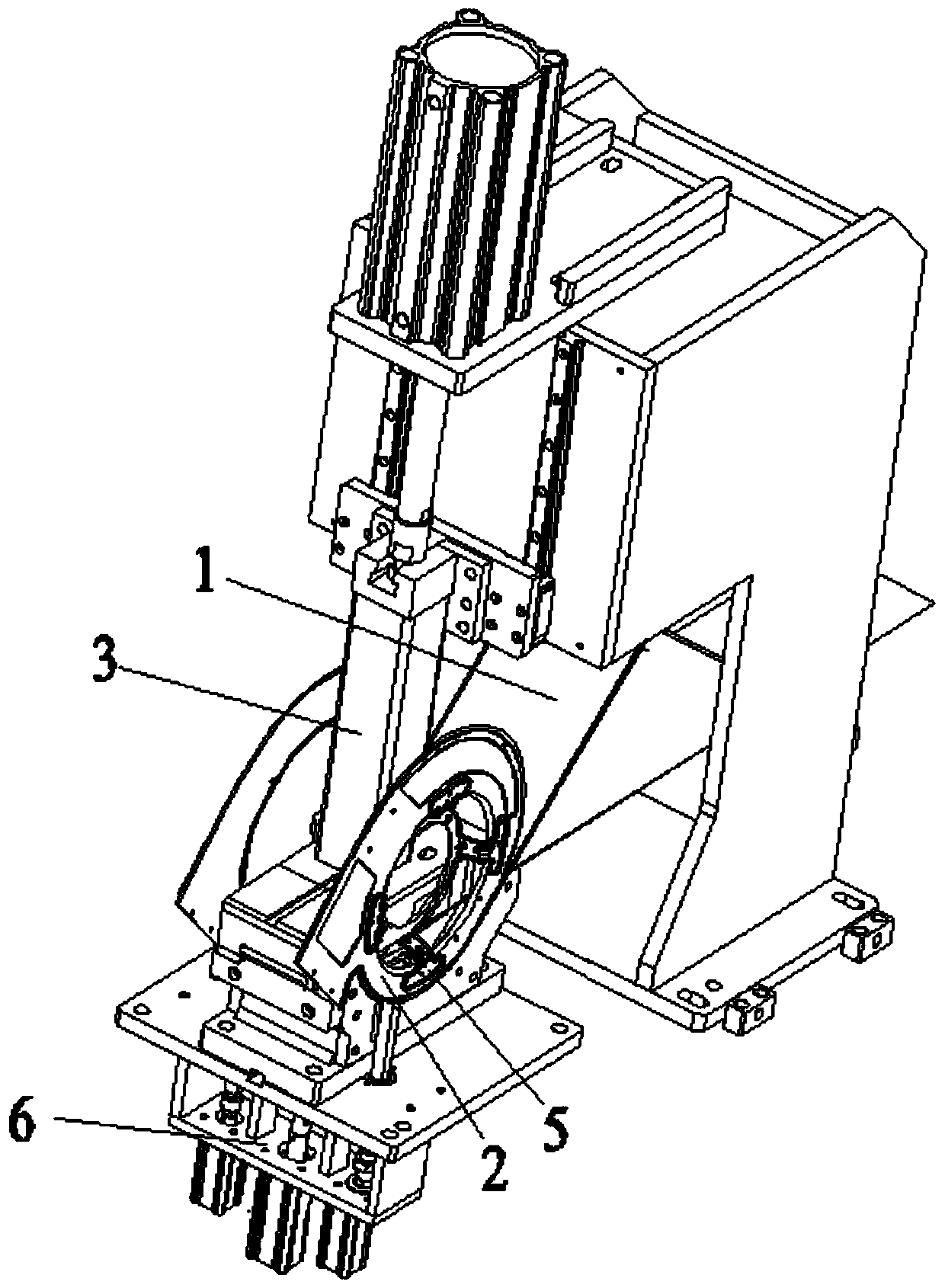

[0029] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

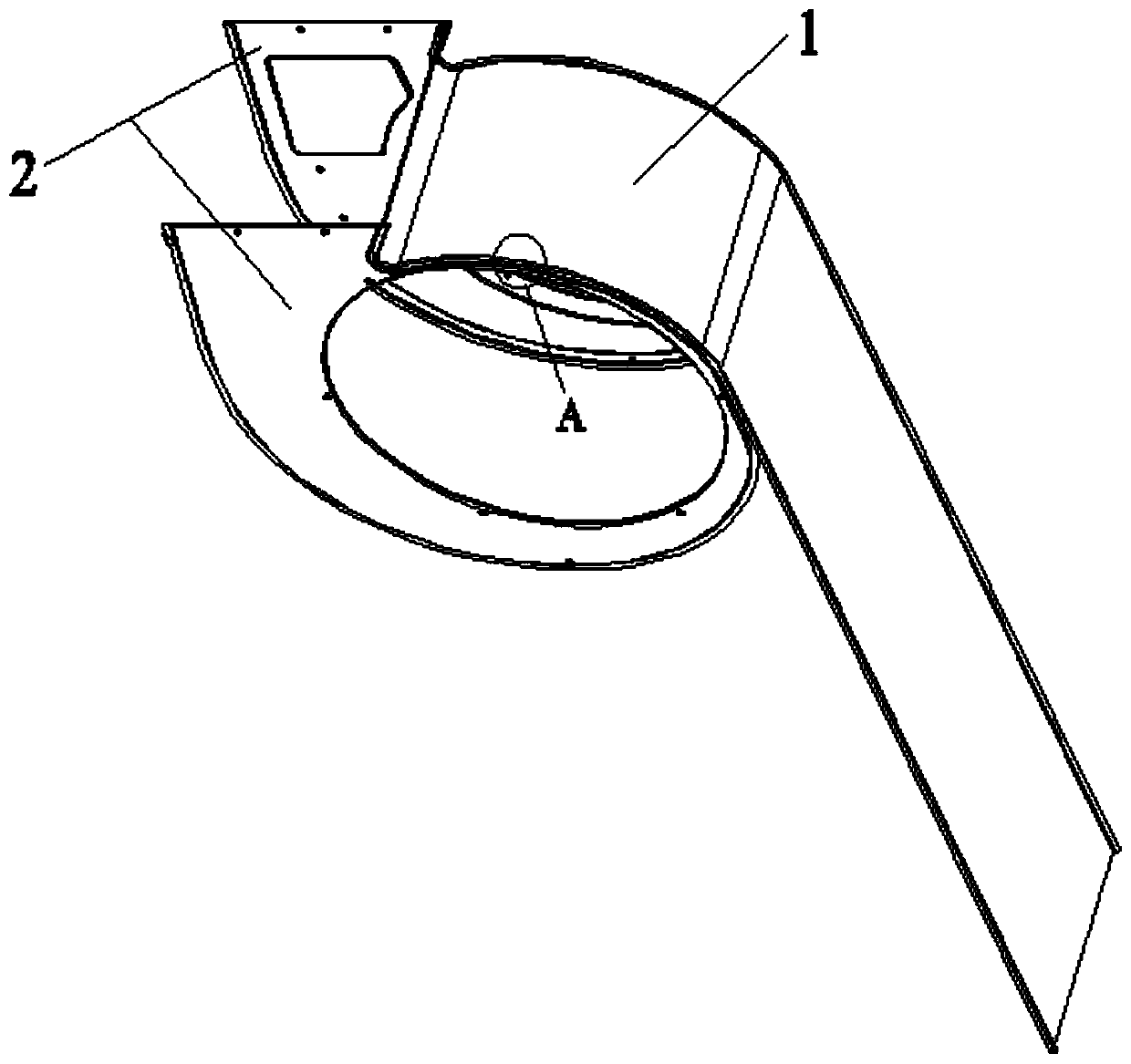

[0030] Specific examples are as follows, such as figure 1 As shown, the three-dimensional structural diagram of the air duct volute, the air duct volute is composed of two side plates 2 and an arc-shaped surrounding plate 1, and the side plates 2 and the surrounding plate 1 are processed in the form of extrusion wrapping.

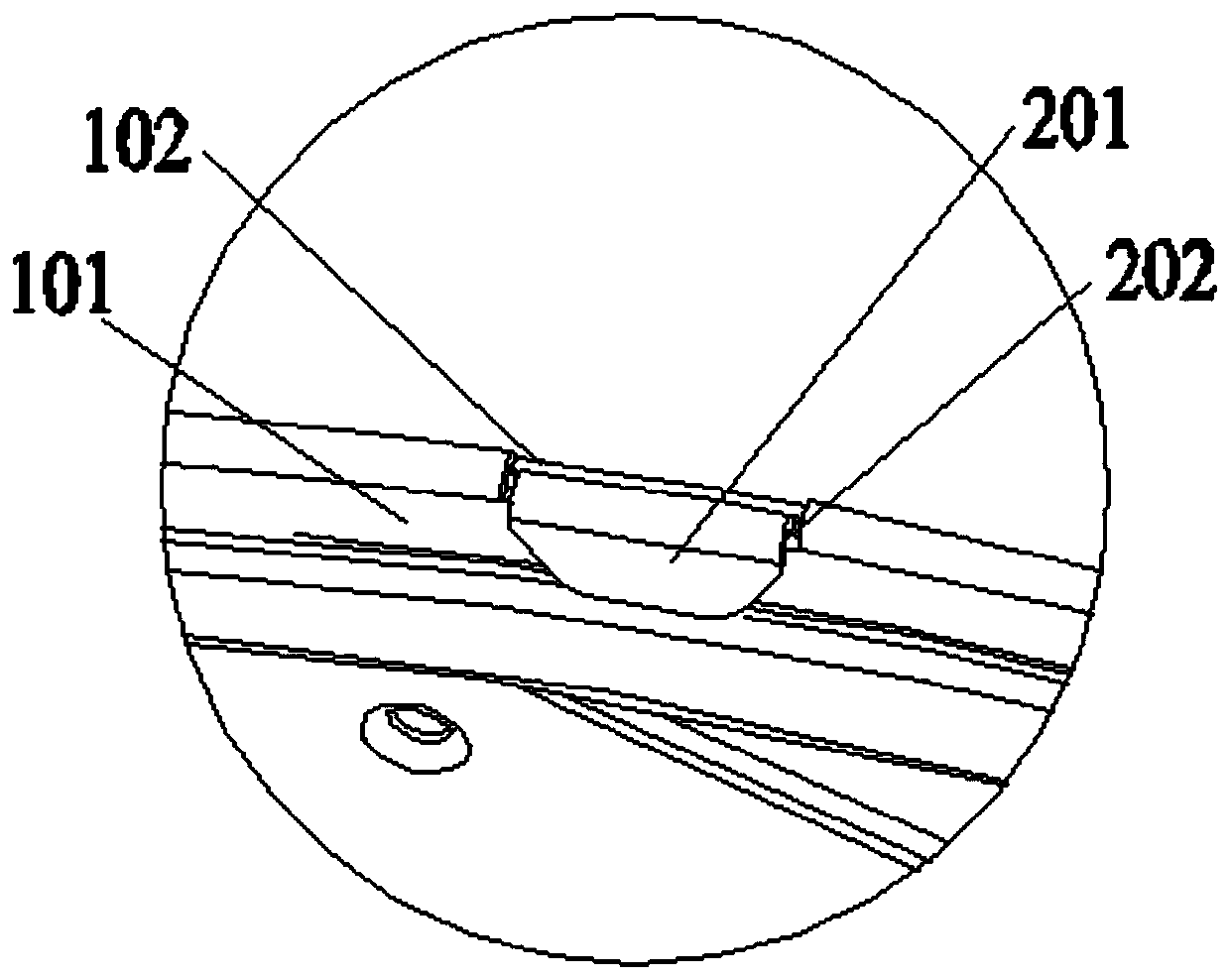

[0031] like figure 1 and figure 2 As shown, the panel 1 includes a panel body 102 and a folded edge 101, and the side panel 2 includes a side panel body 202 and a folding ear 201. The folding ear 201 is at the same level as the side panel body 202 before being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com