Patents

Literature

41 results about "Folded ears" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

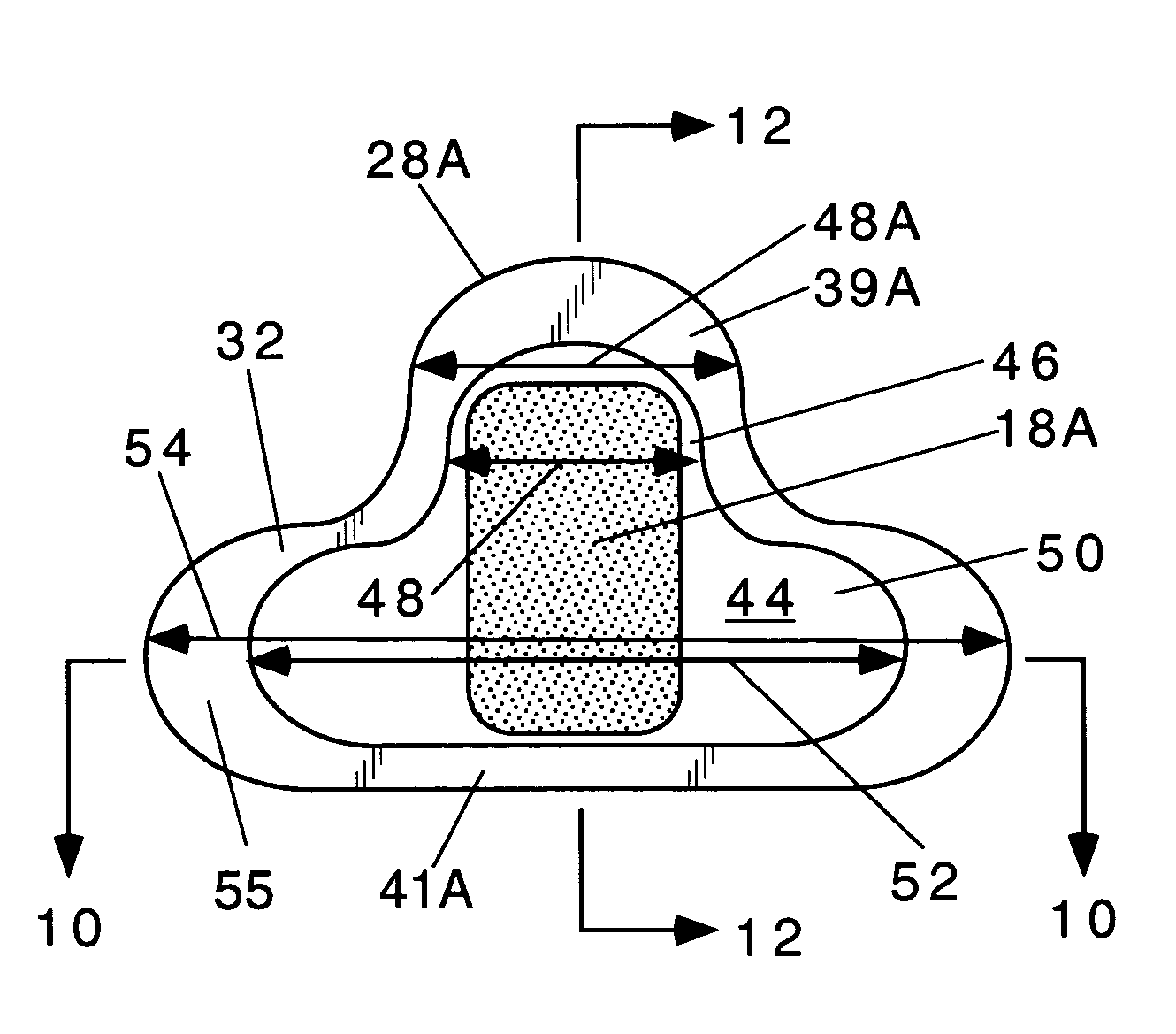

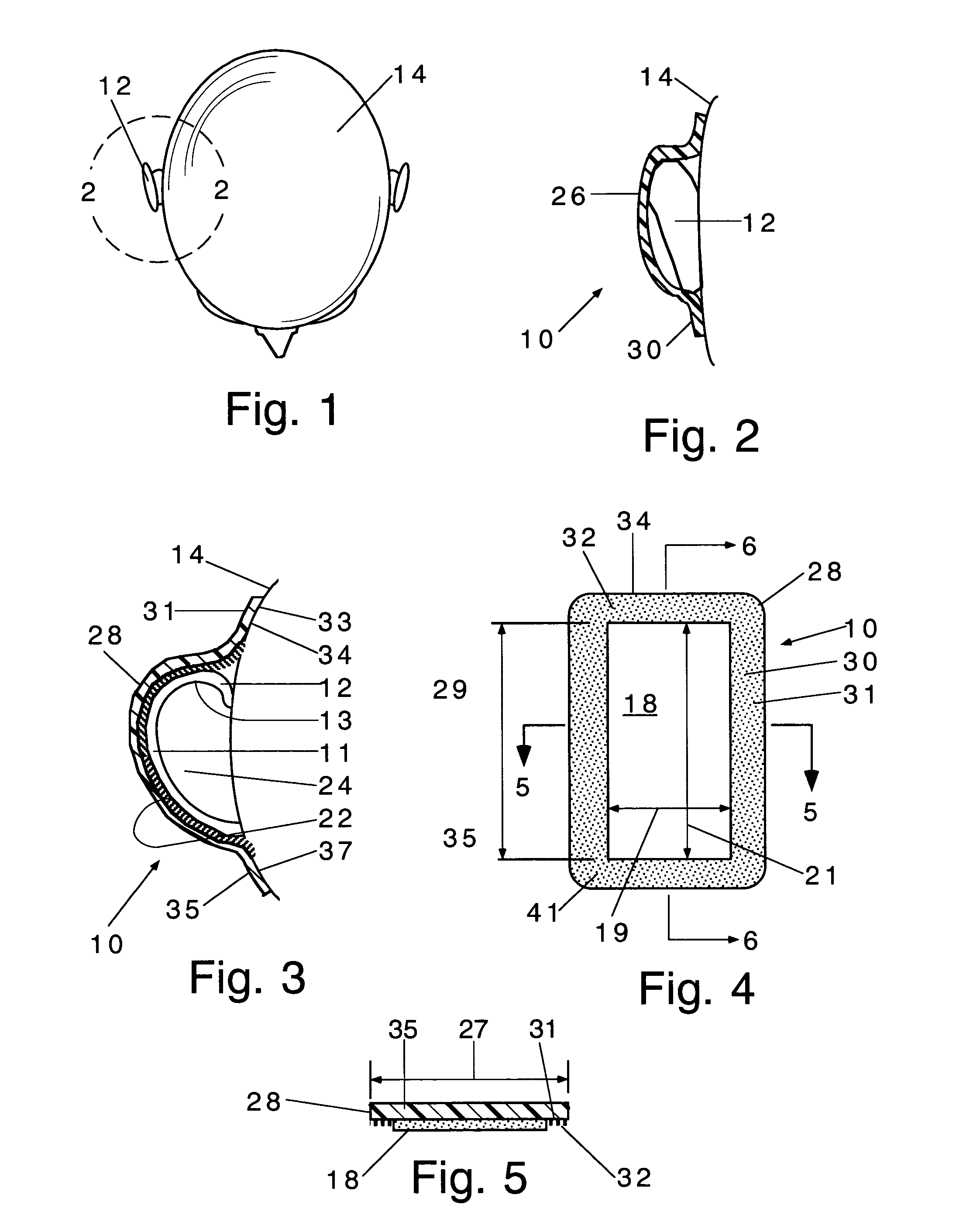

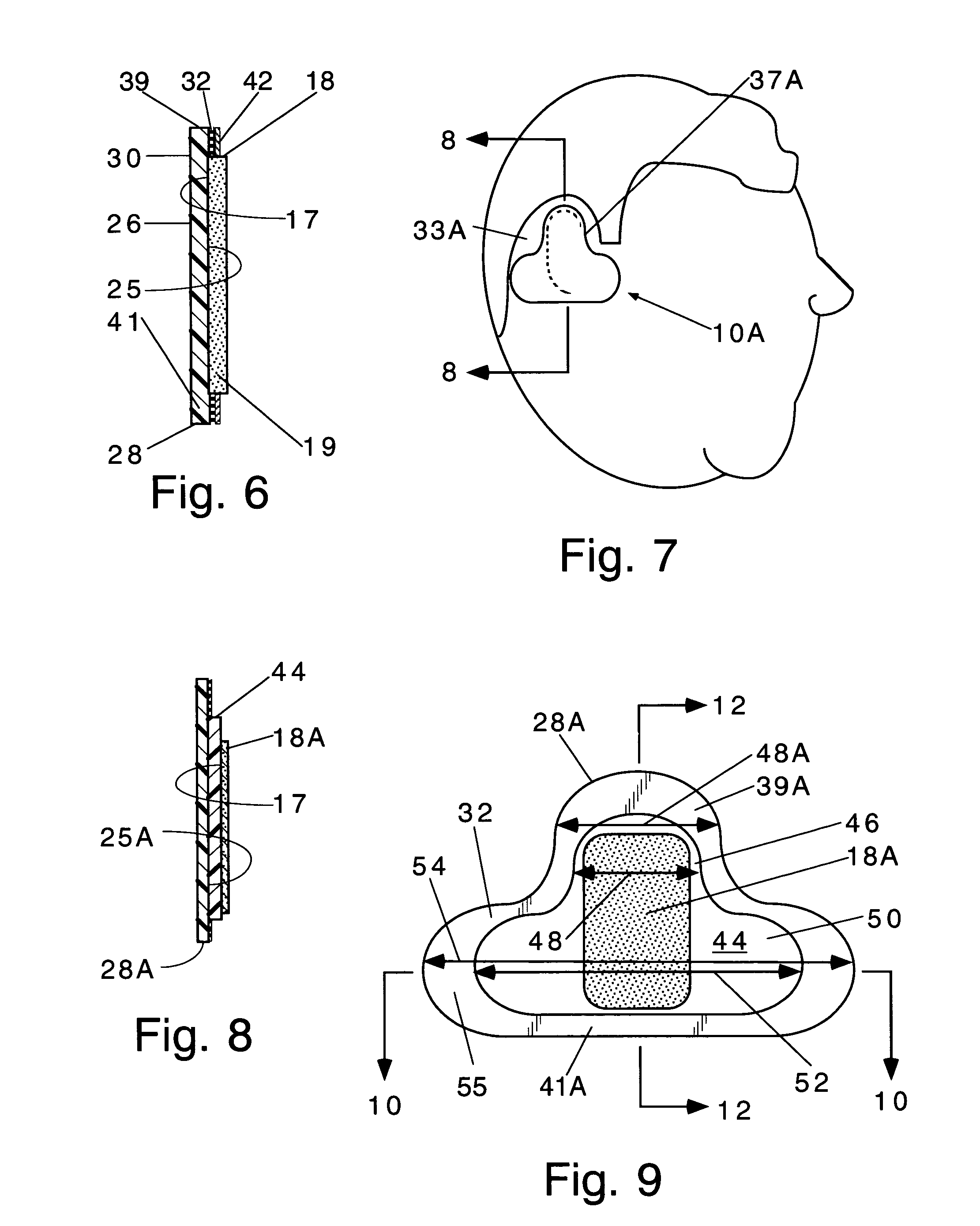

Ear cover and method

An ear protector and ear cover for and method covering, protecting and holding the folded ear on a person's head while the hair of the person is being treated. The cover includes a flexible, water impervious strip shield for covering and holding the ear in a forwardly folded condition. The flexible strip shield includes one side with a central non-adhesive ear engaging portion for bearing against the folded ear and an adhesive border strip surrounding the central portion for adhesively sealing to the portion of the person's head surrounding the ear.

Owner:WATSON DEBORAH

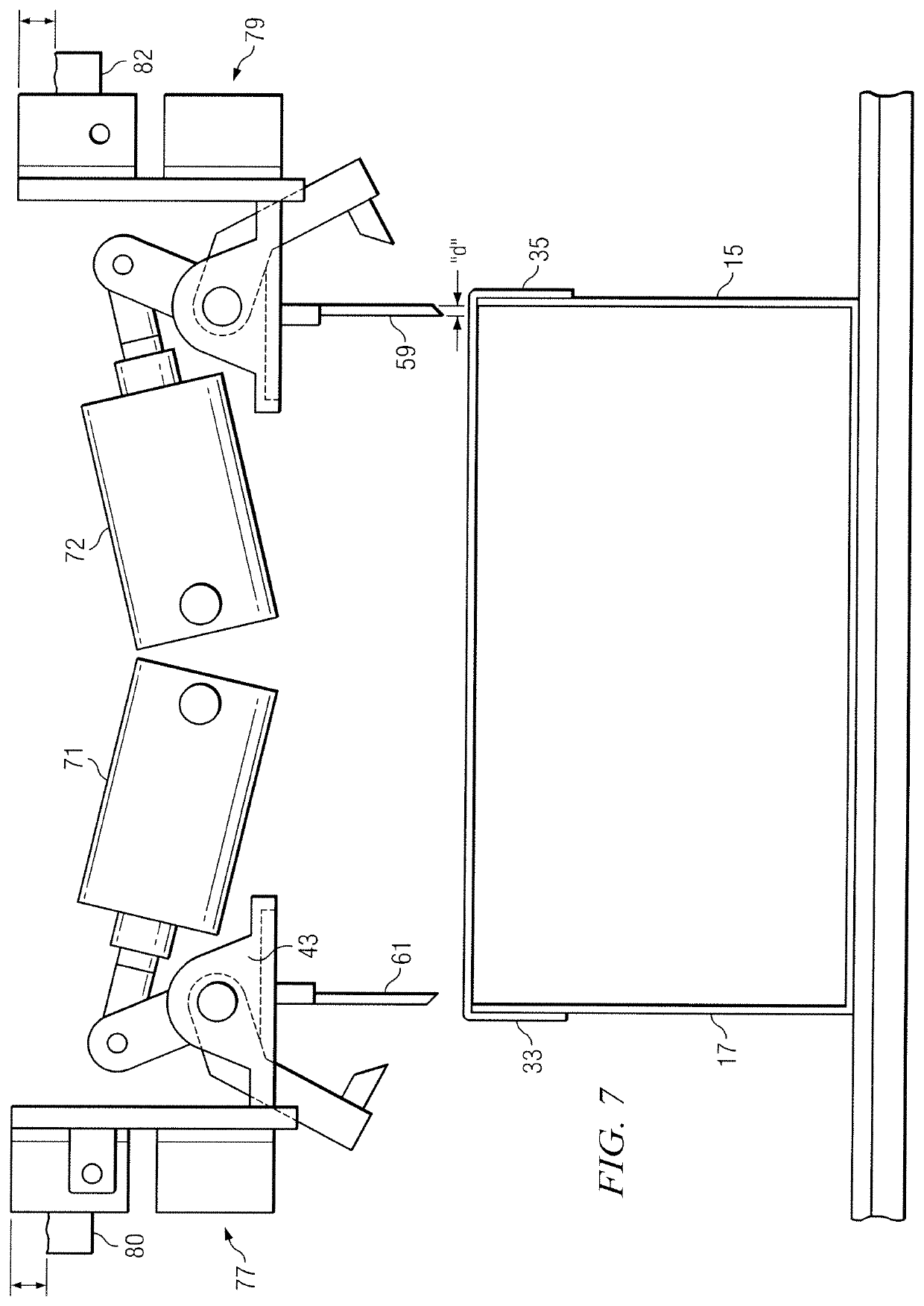

Packaging Apparatus and Method

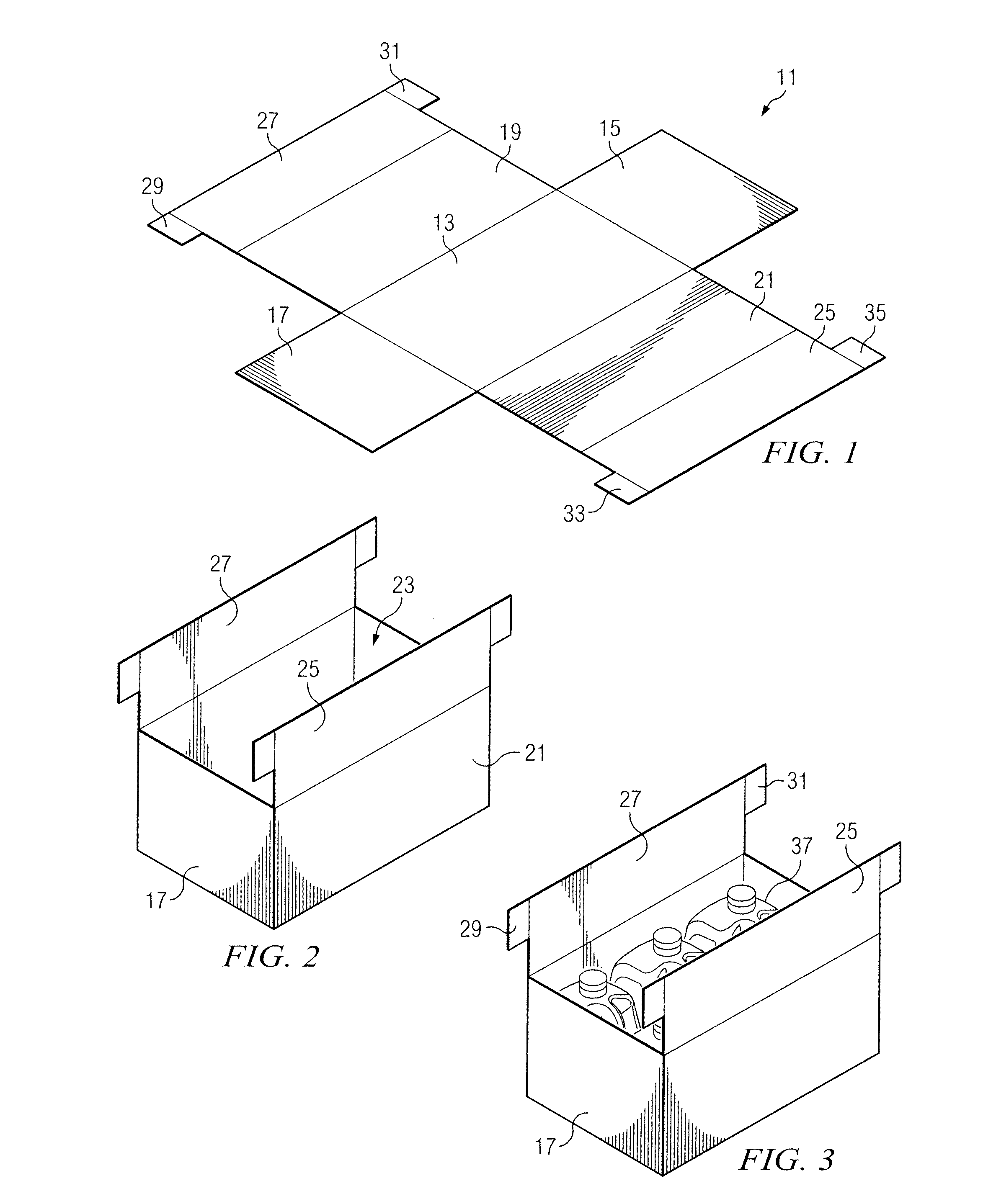

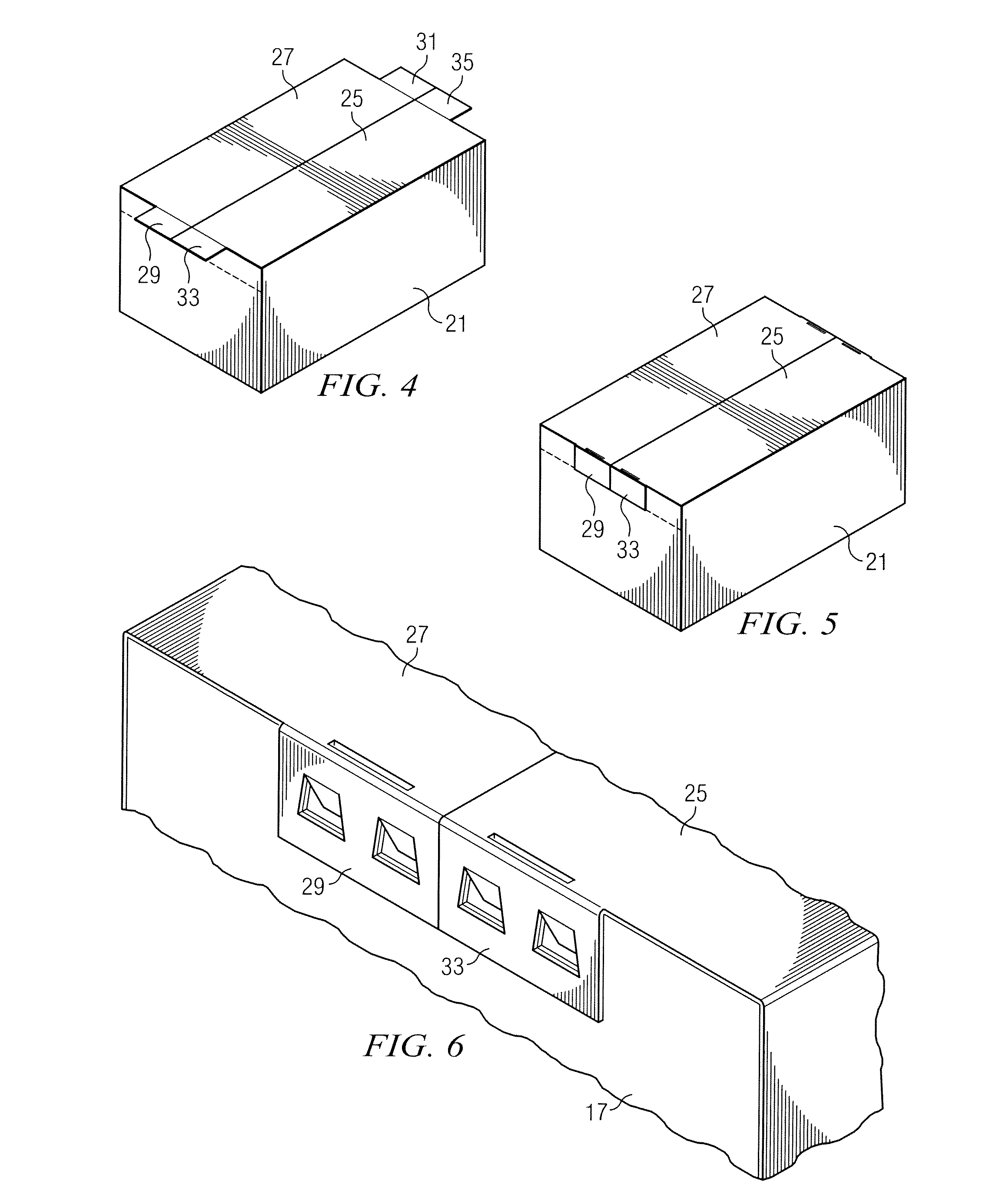

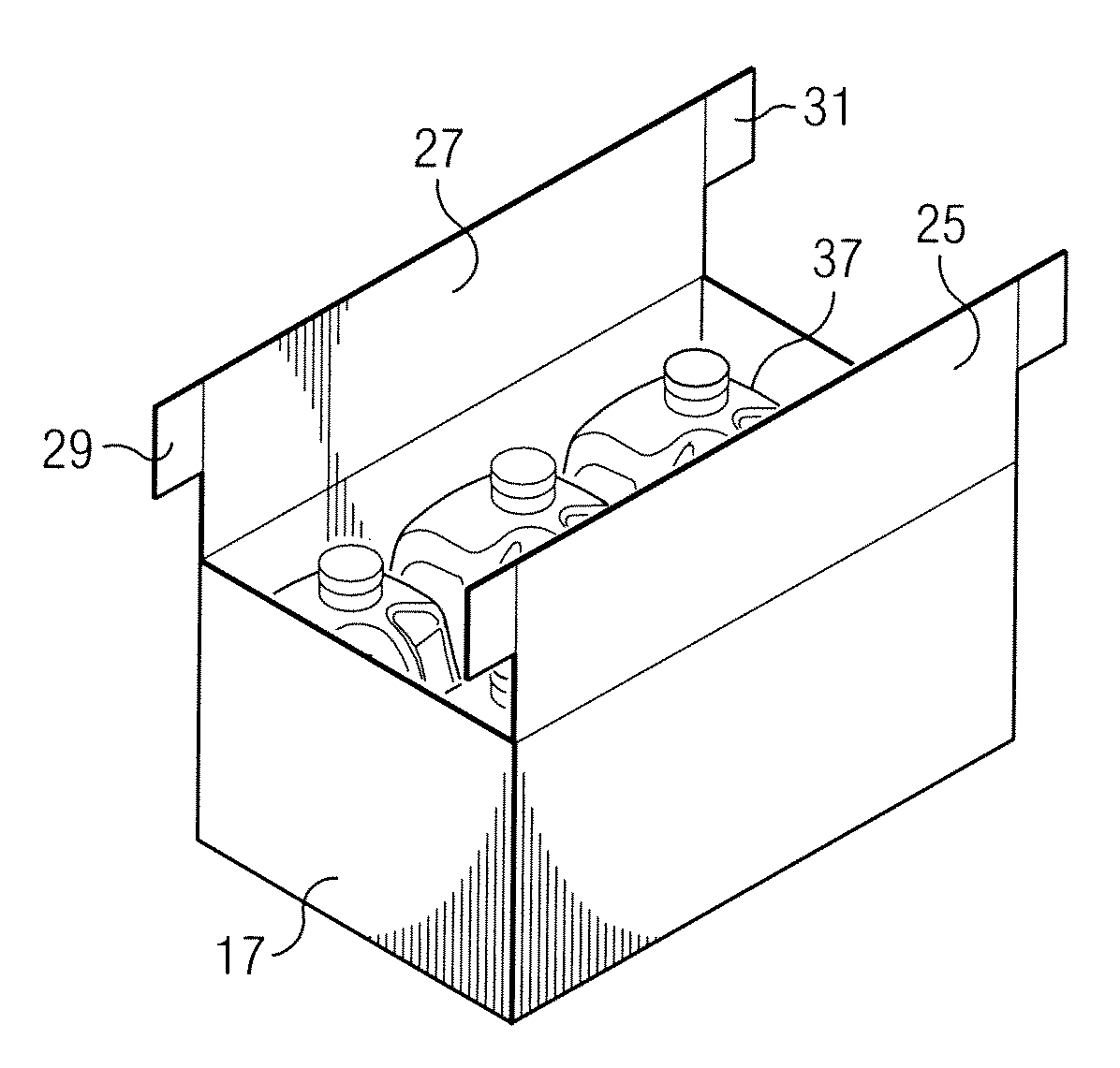

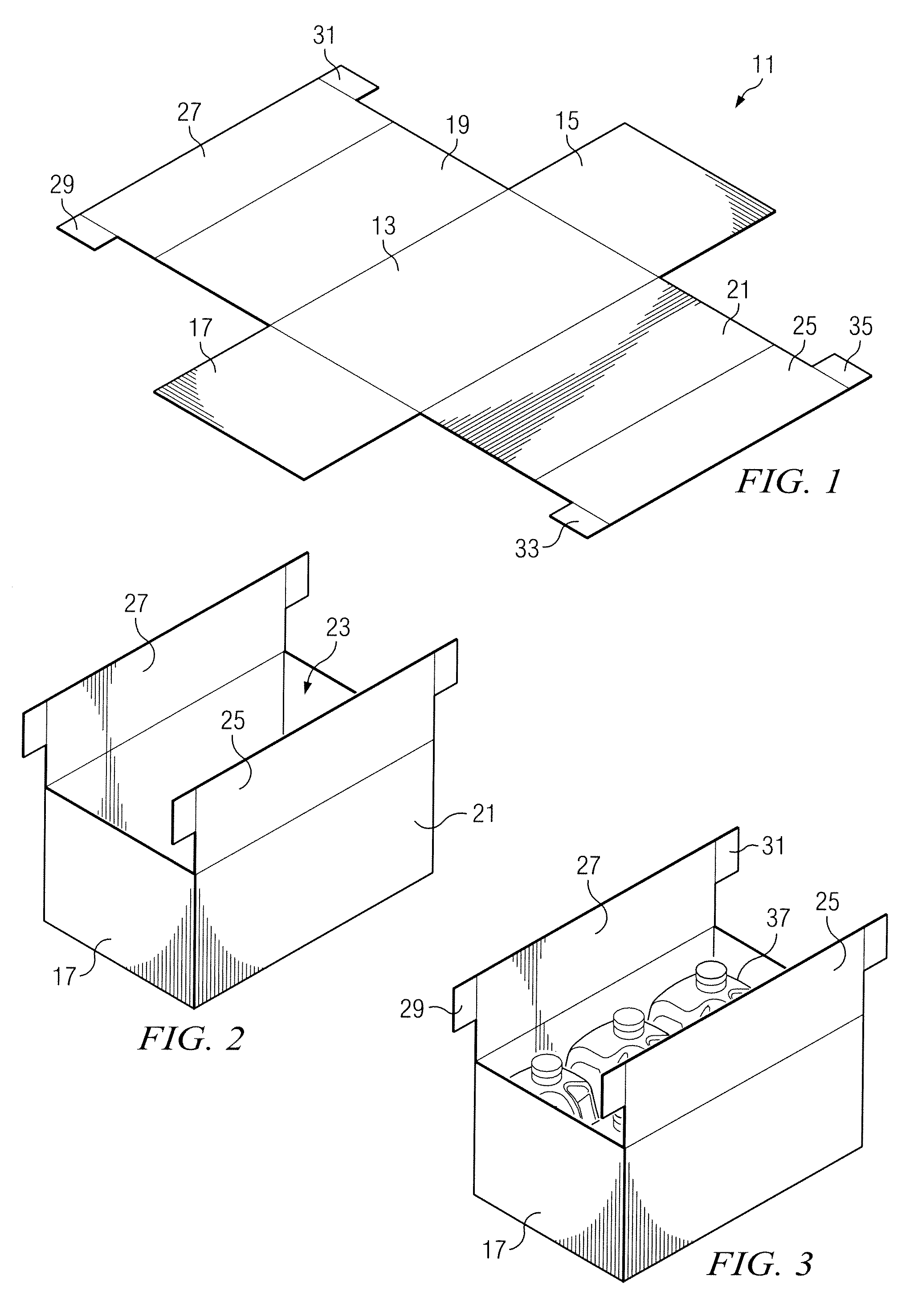

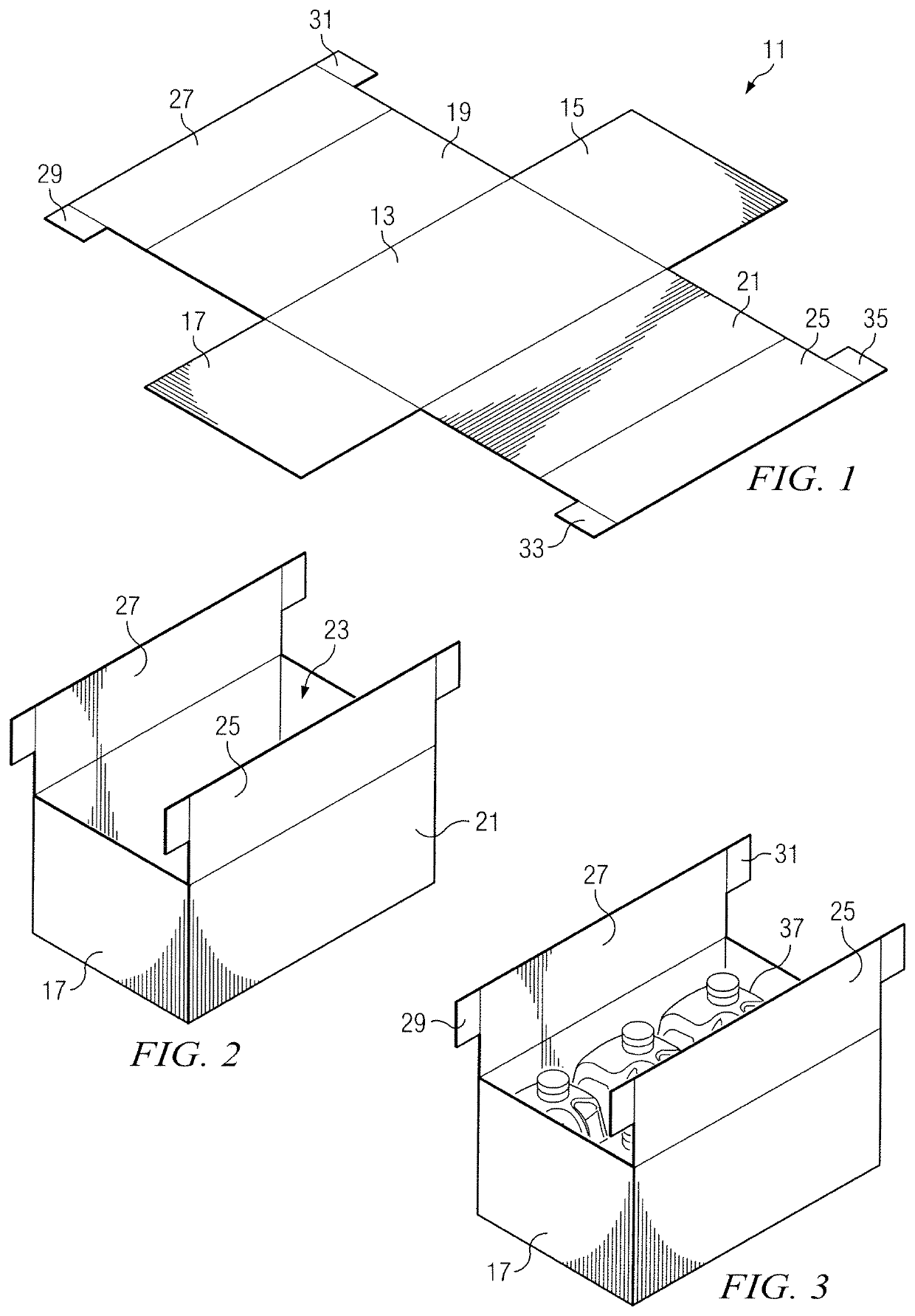

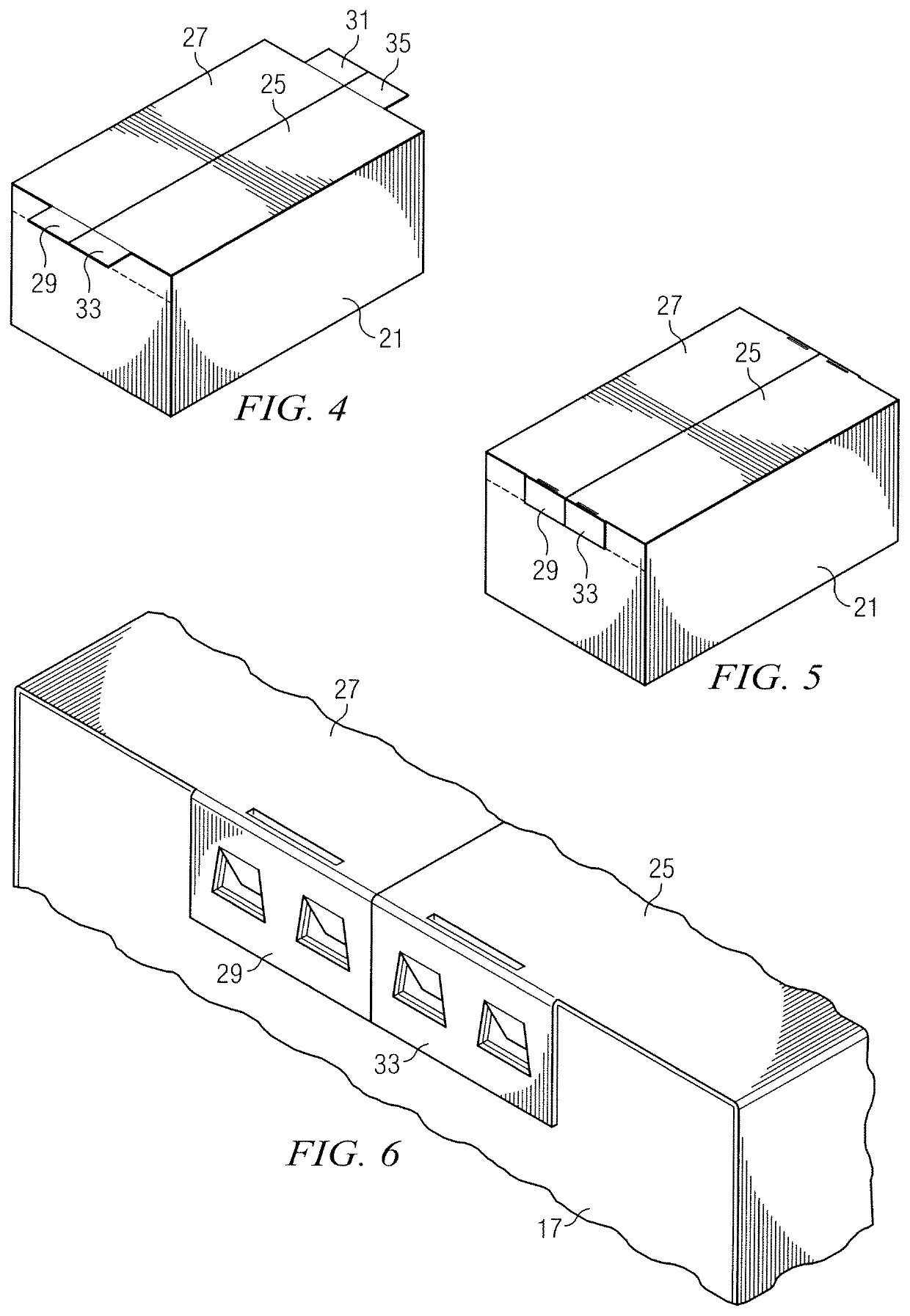

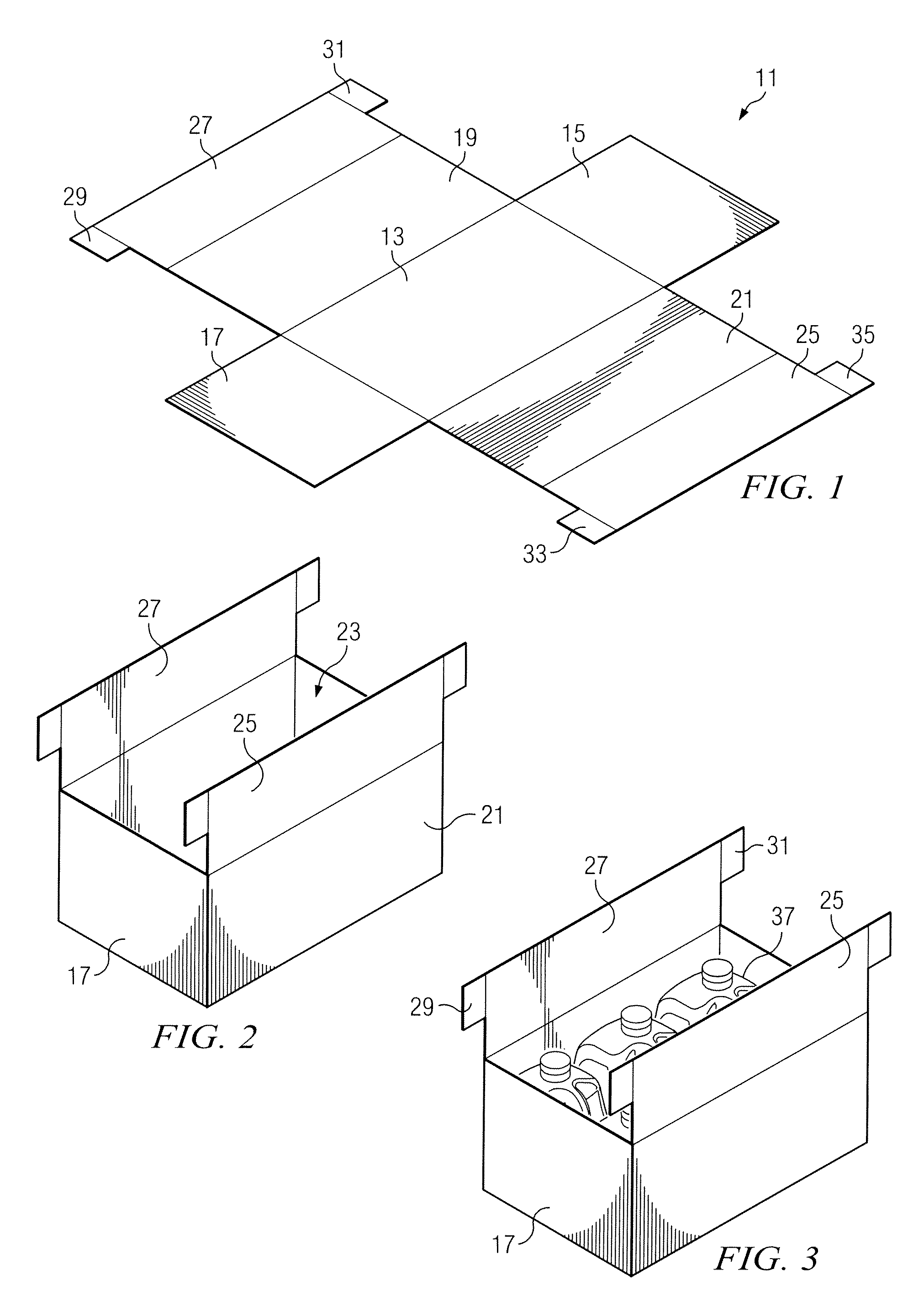

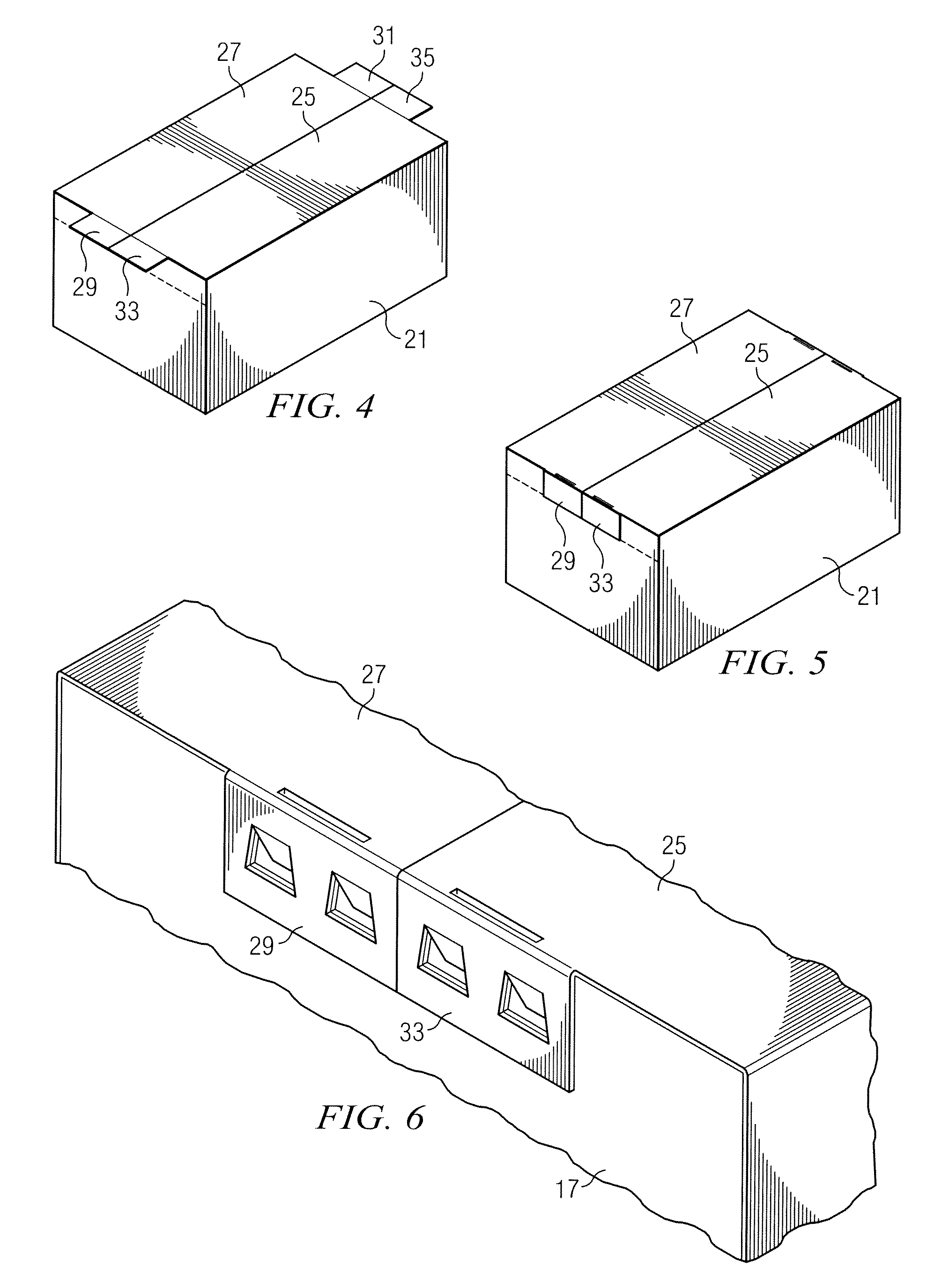

ActiveUS20120317932A1Easy to mergeVersatile in useBox making operationsWrapper twisting/gatheringCardboardPunching

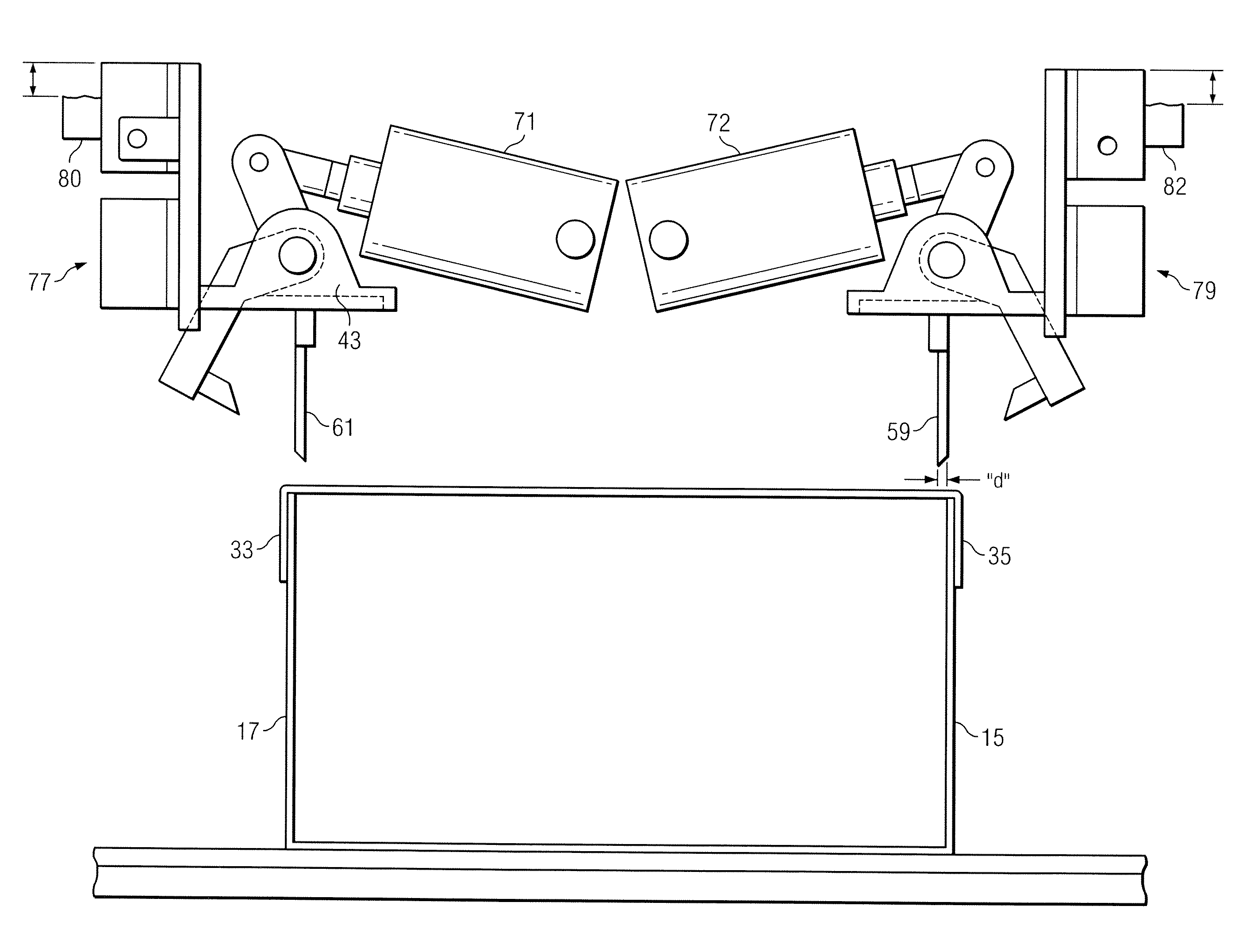

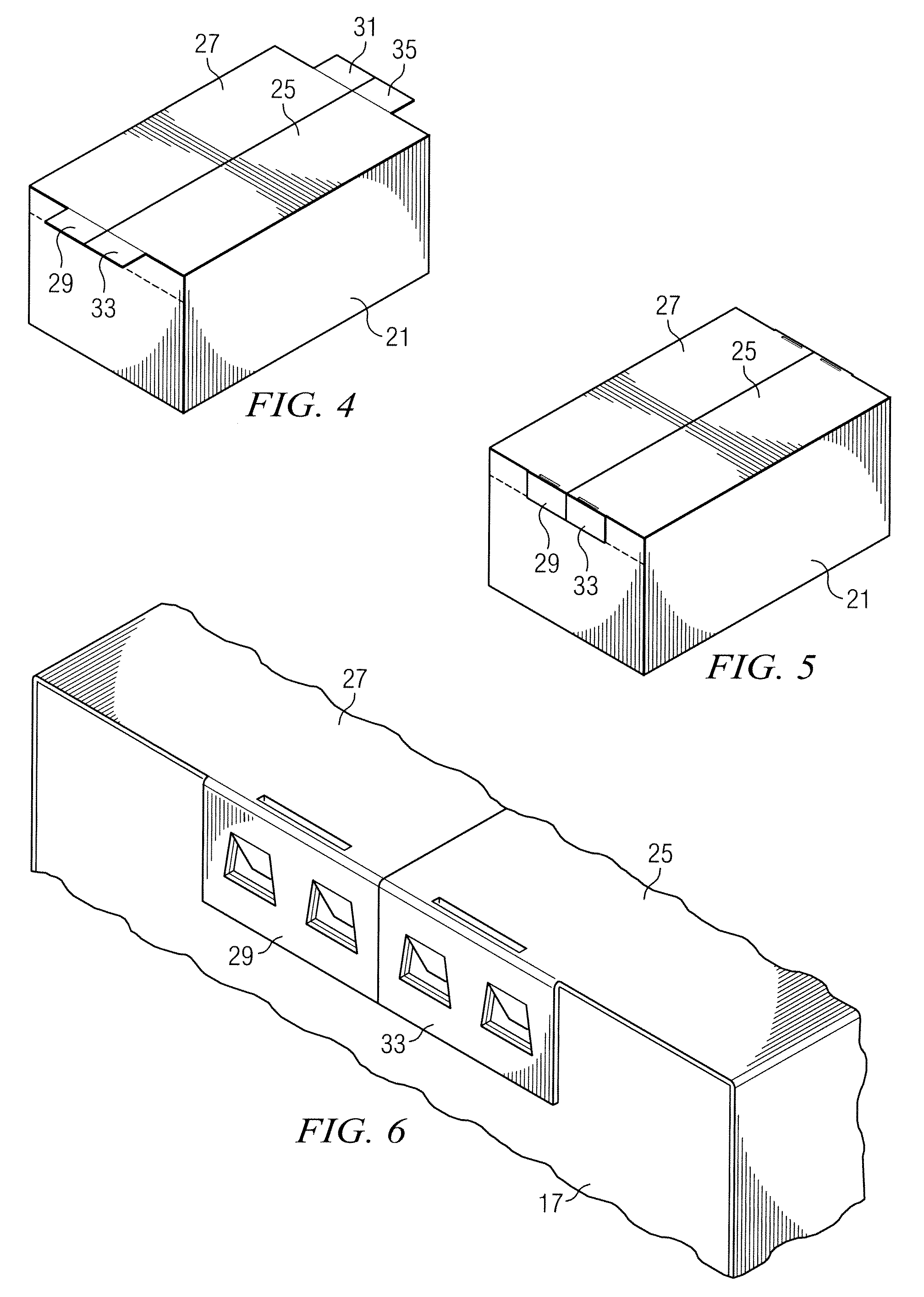

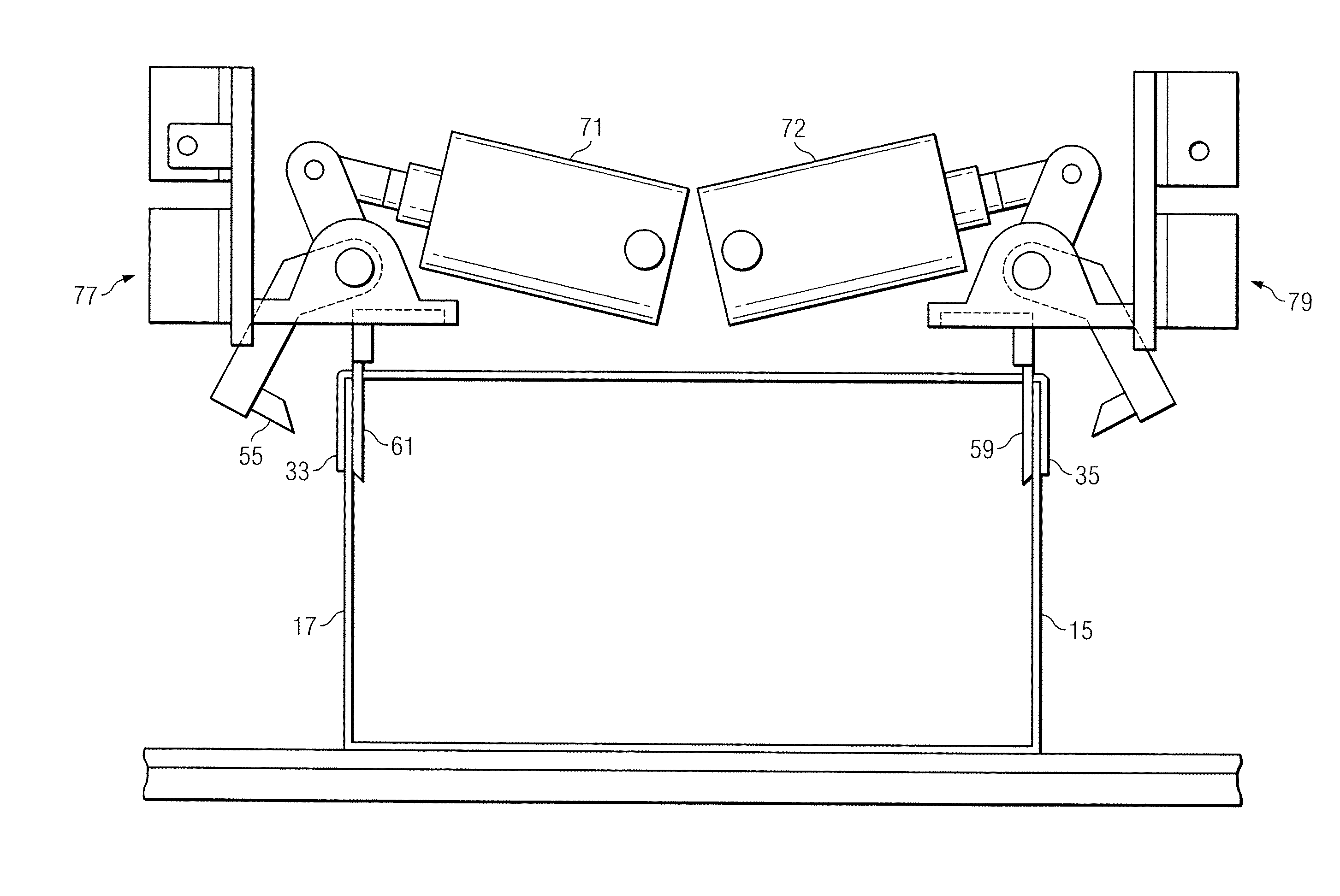

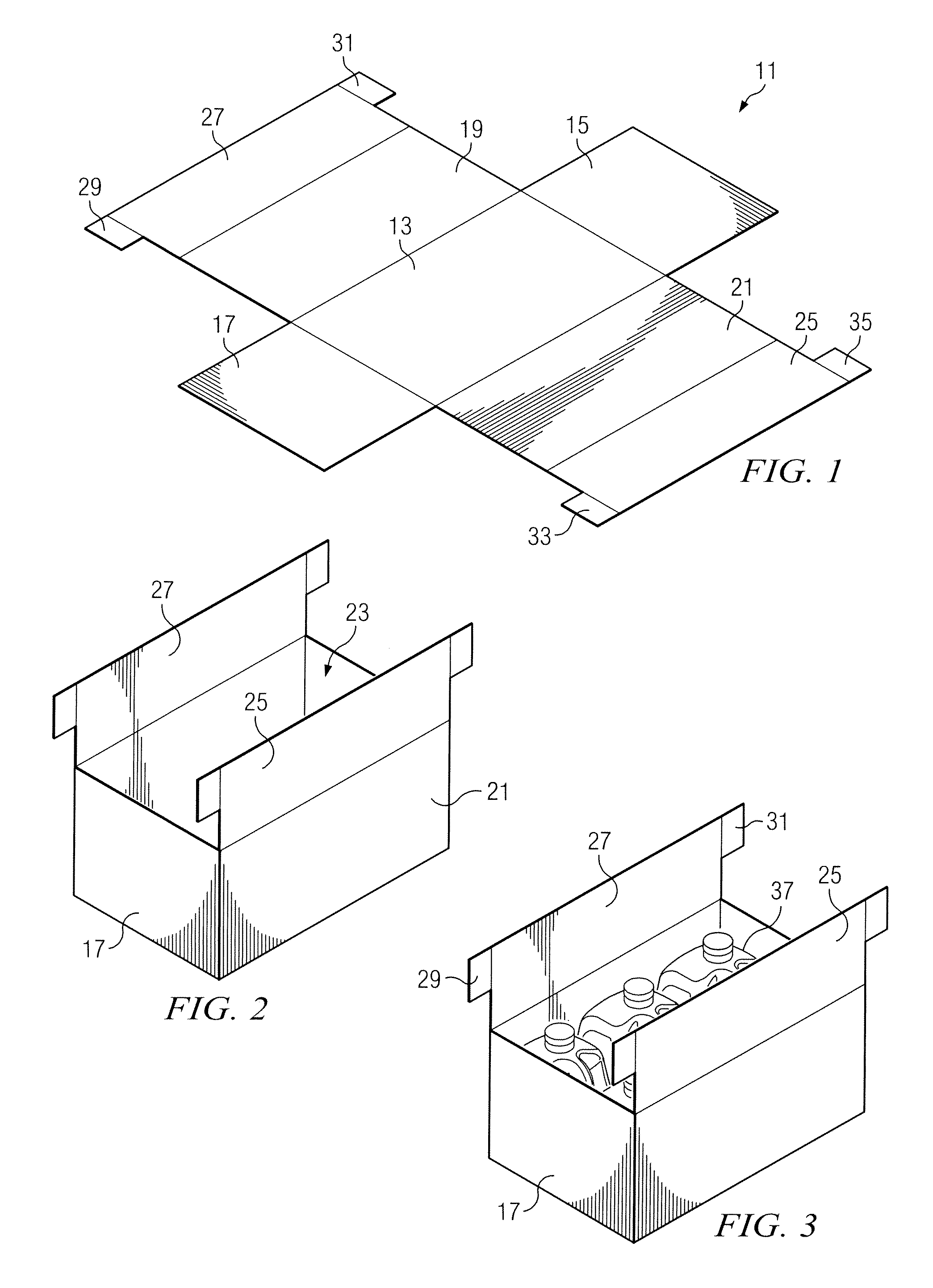

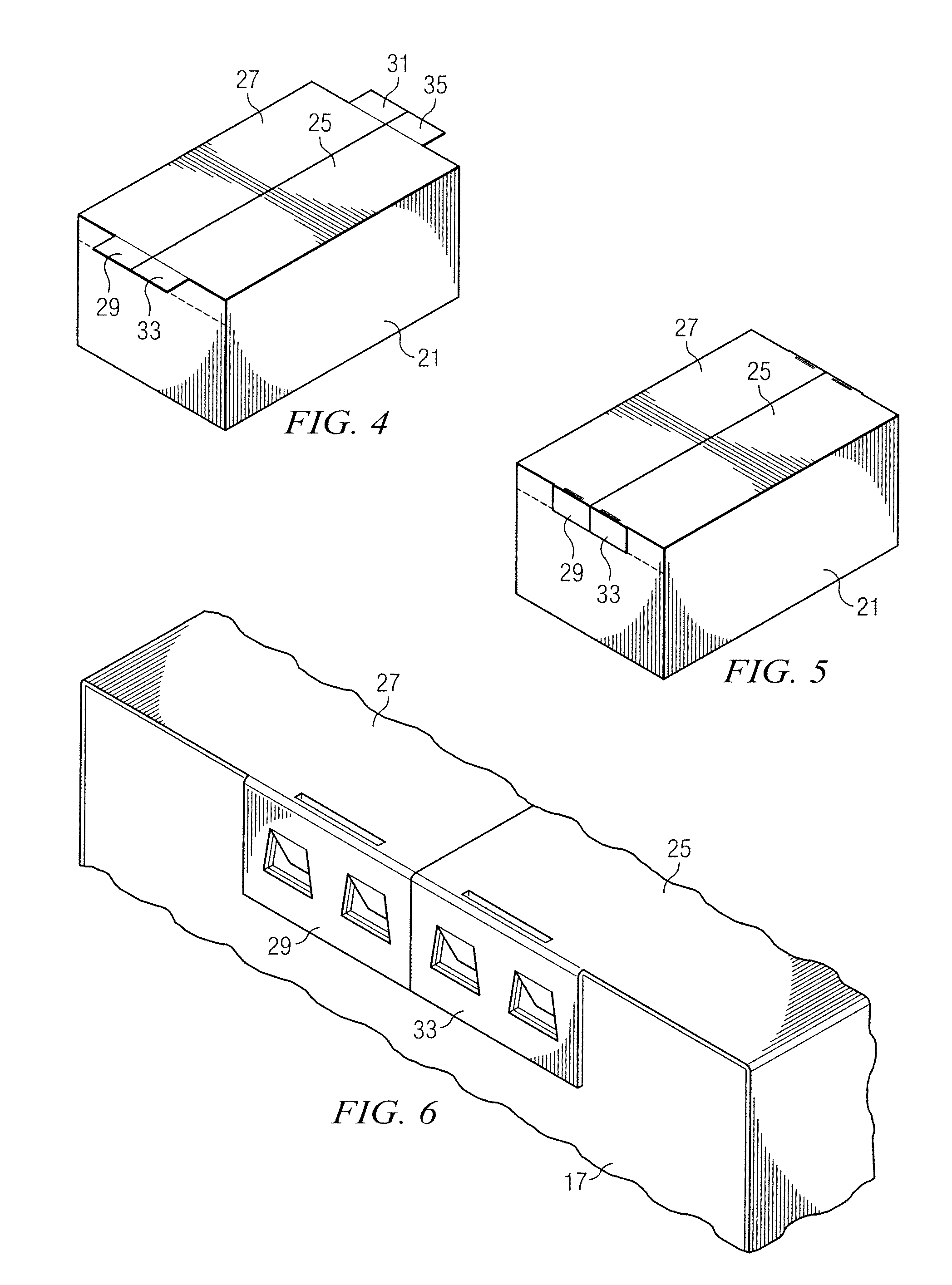

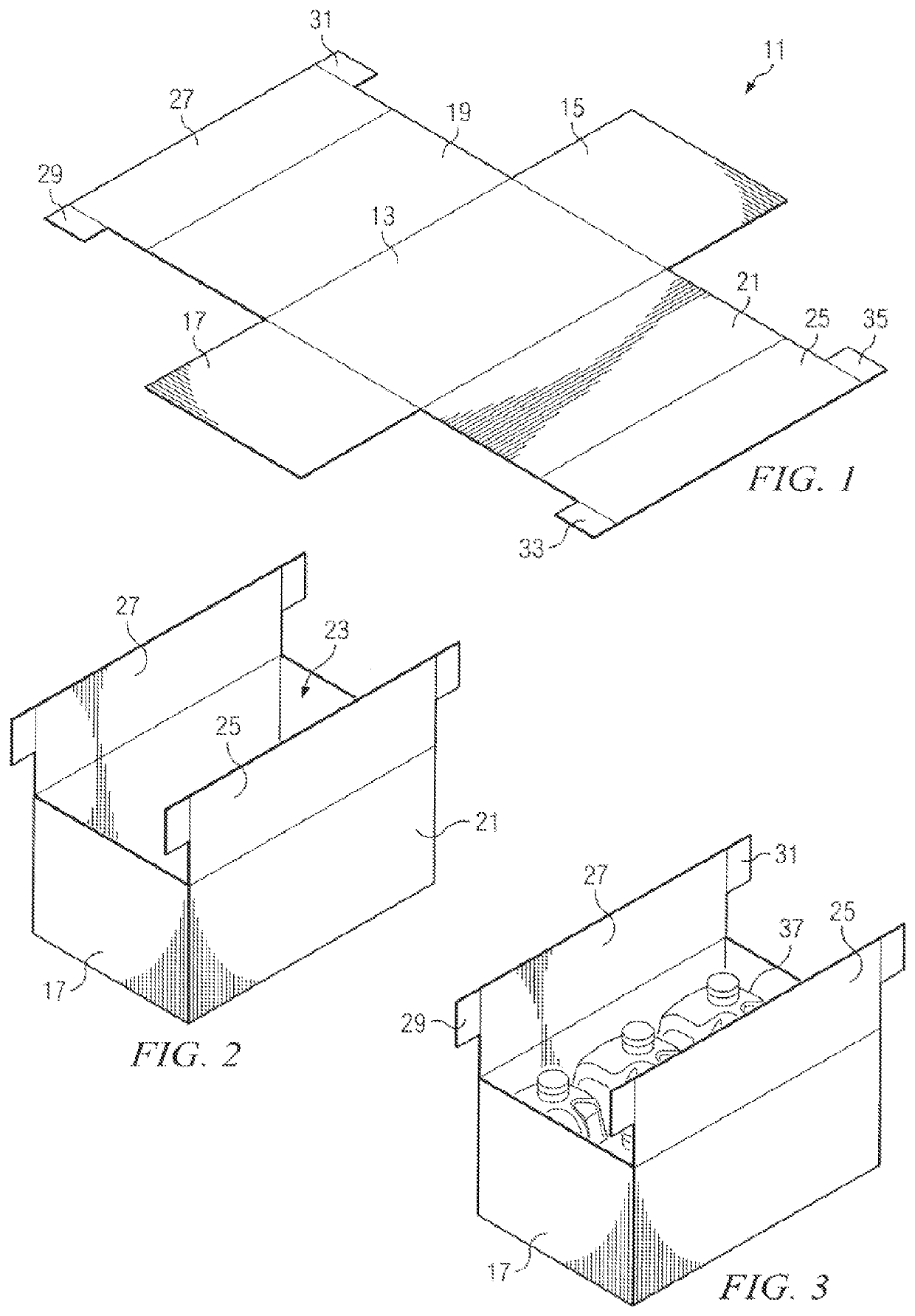

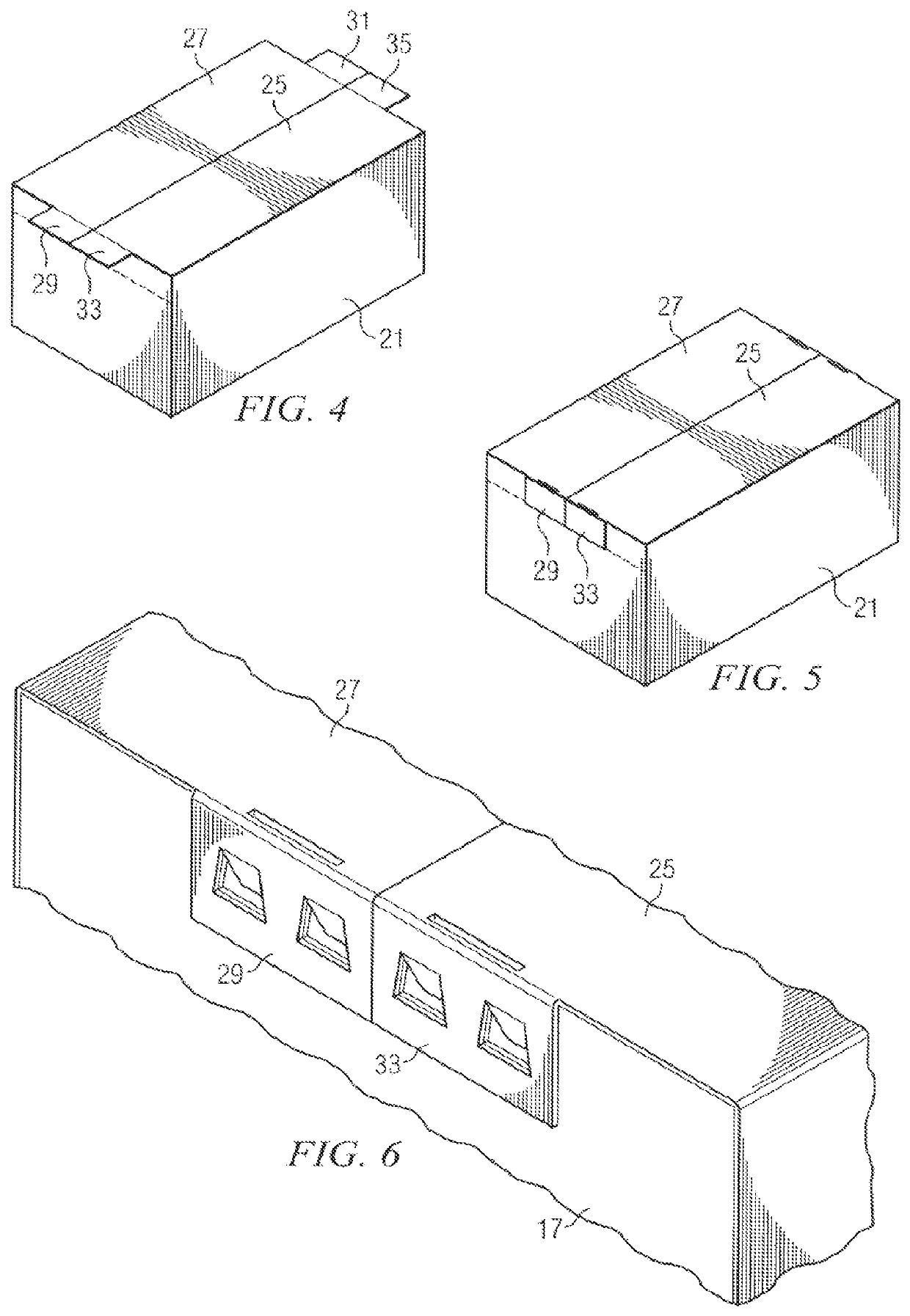

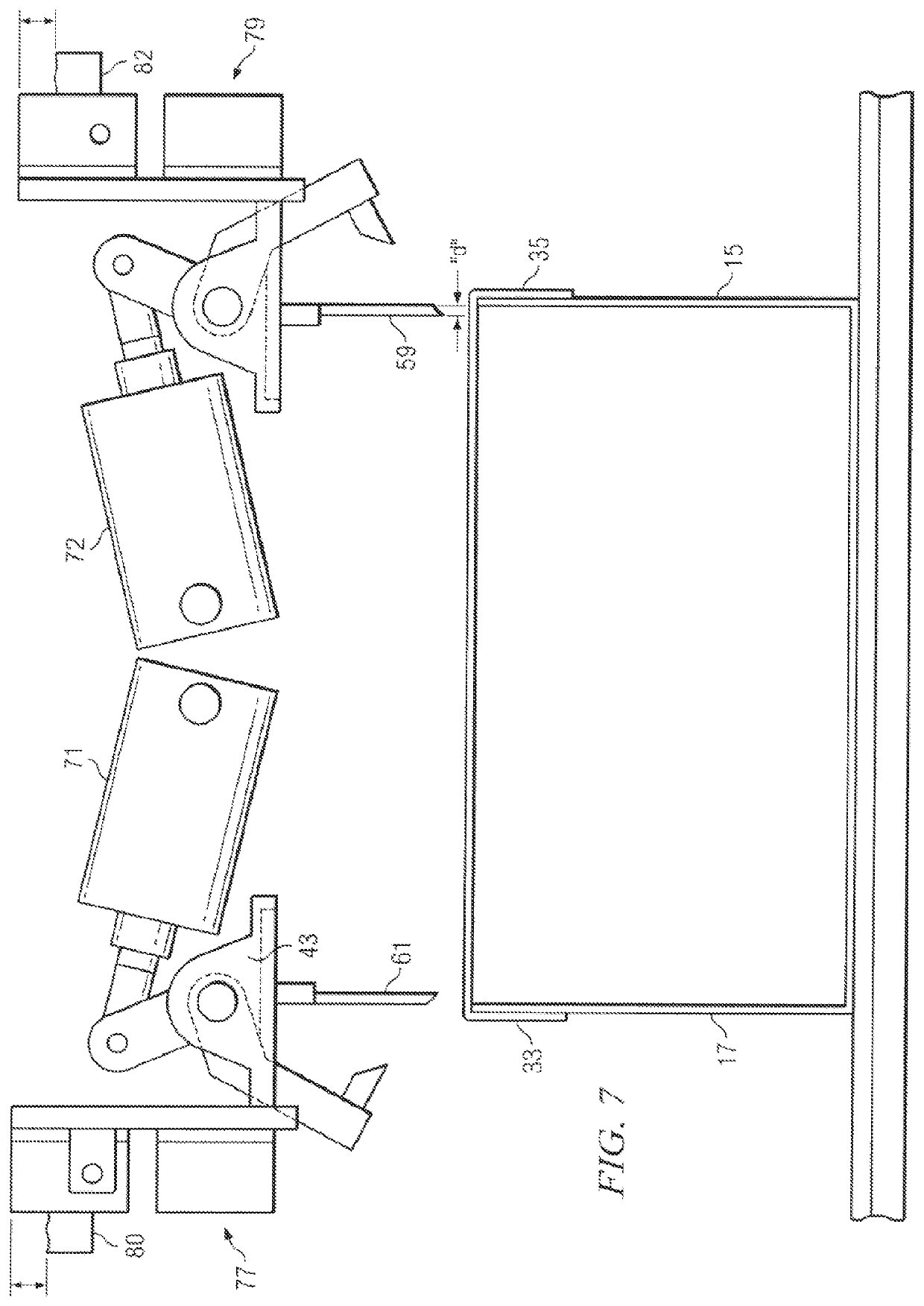

A method and apparatus are shown for securing a top for a cardboard carton where the carton has a bottom wall and integral sidewalls, an initially open interior and initially open top flaps with outwardly extending ears. The top flaps are folded to a carton closing position which closes off the initially open interior of the cardboard carton. The ears are also folded to a position in contact with the sidewalls of the carton. A set of punches are aligned with the folded ears of the carton and are actuated to force a first layer of cardboard from a respective top flap through an underlying region of the carton sidewall. A set of platens are located so as to underlie and reinforce the sidewalls of the carton as the punching operation takes place.

Owner:PLAINS DAIRY

Packaging Apparatus and Method

A method and apparatus are shown for securing a top for a cardboard carton where the carton has a bottom wall and integral sidewalls defining an initially open interior and initially open top flaps with outwardly extending ears, the initially open top flaps being integrally formed with a first pair of opposing sidewalls of the carton. The top flaps are folded to a carton closing position which closes off the initially open interior of the cardboard carton. The ears are also folded to a position in contact with a second set of opposing sidewalls of the carton intermediate the first set of opposing sidewalls. A set of rotatable punches are aligned with the folded ears of the carton and rotated to force a first layer of cardboard from a respective top flap through an associated second layer of an underlying sidewall of the carton. A set of platens are located so as to underlie and reinforce the sidewalls of the carton as the punching operation takes place.

Owner:PLAINS DAIRY

Packaging Apparatus and Method

A method and apparatus are shown for securing a top for a cardboard carton where the carton has a bottom wall and integral sidewalls, an initially open interior and initially open top flaps with outwardly extending ears. The top flaps are folded to a carton closing position which closes off the initially open interior of the cardboard carton. The ears are also folded to a position in contact with the sidewalls of the carton. A set of punches are aligned with the folded ears of the carton and are actuated to force a first layer of cardboard from a respective top flap through an underlying region of the carton sidewall. A set of platens are located so as to underlie and reinforce the sidewalls of the carton as the punching operation takes place.

Owner:DUNIVAN STEVE +2

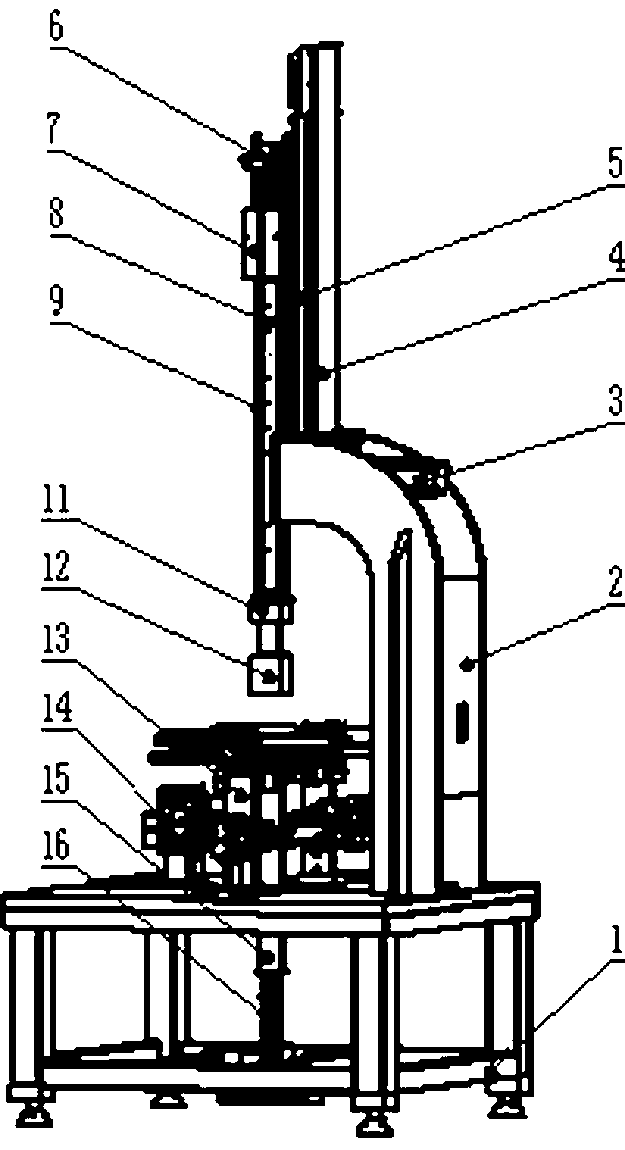

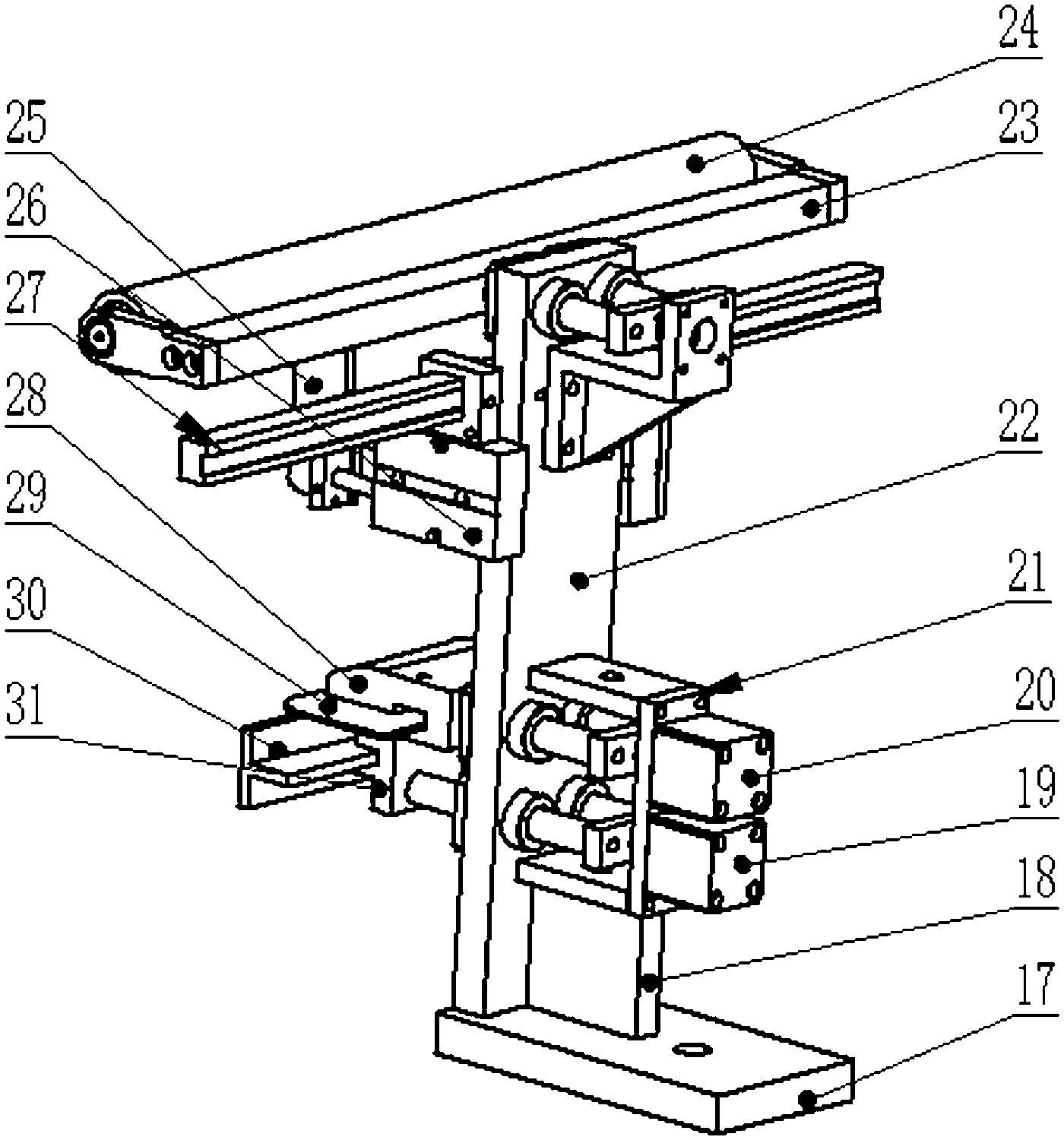

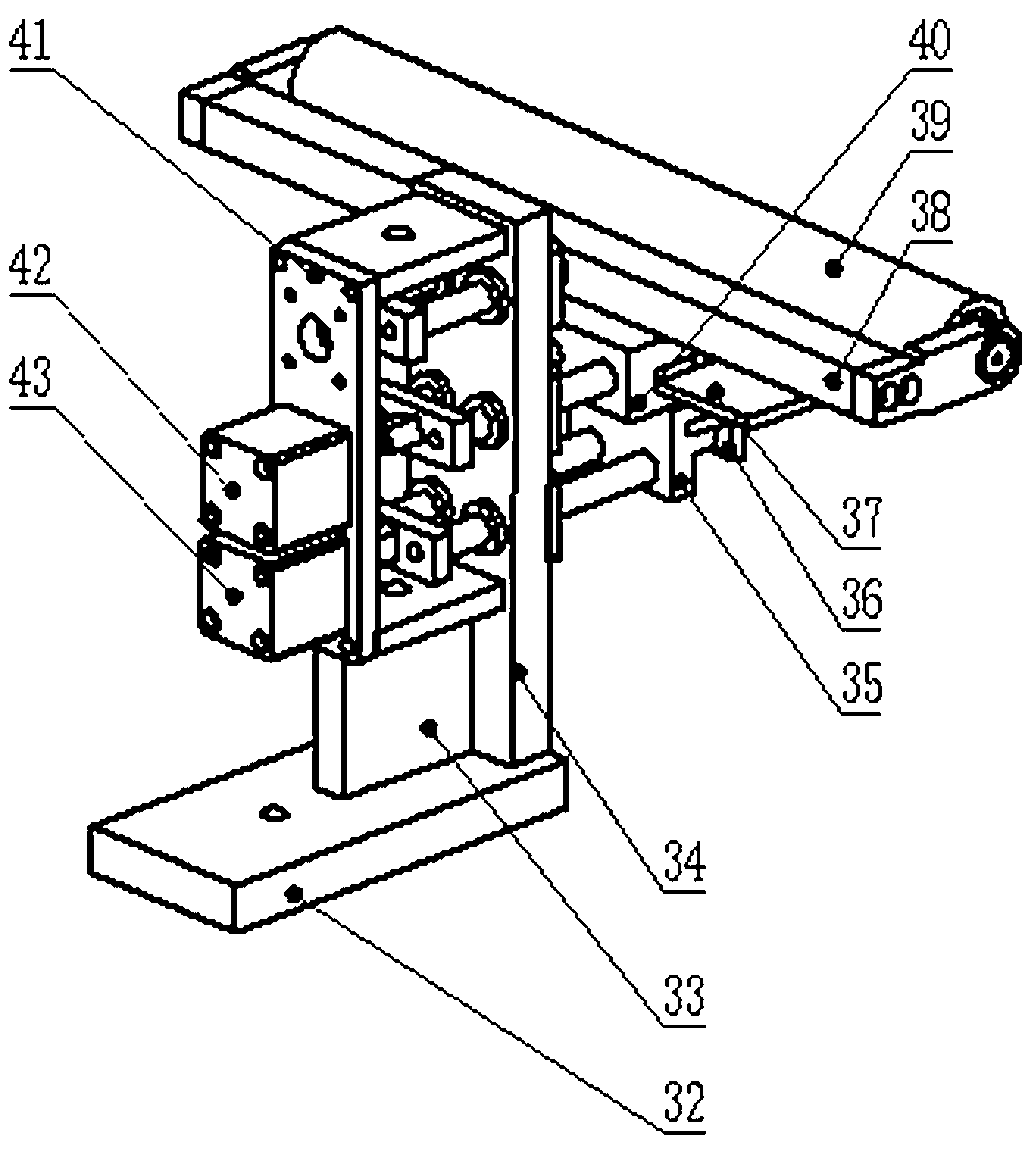

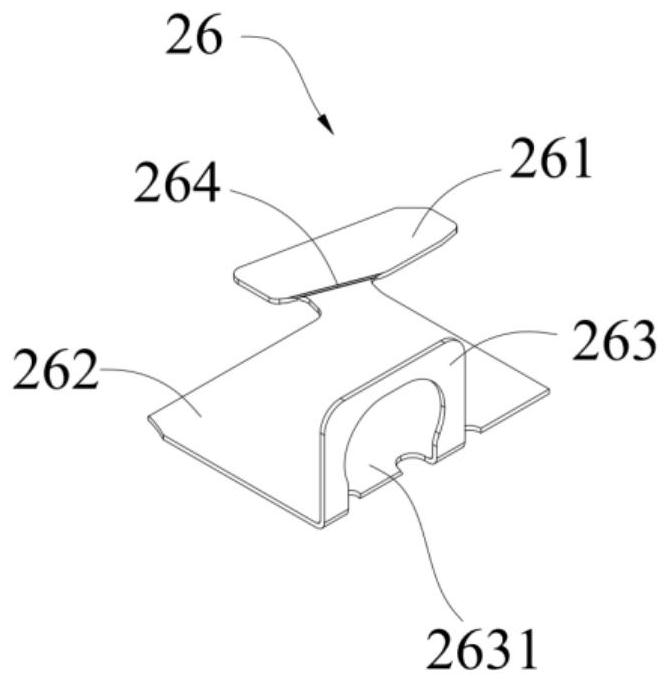

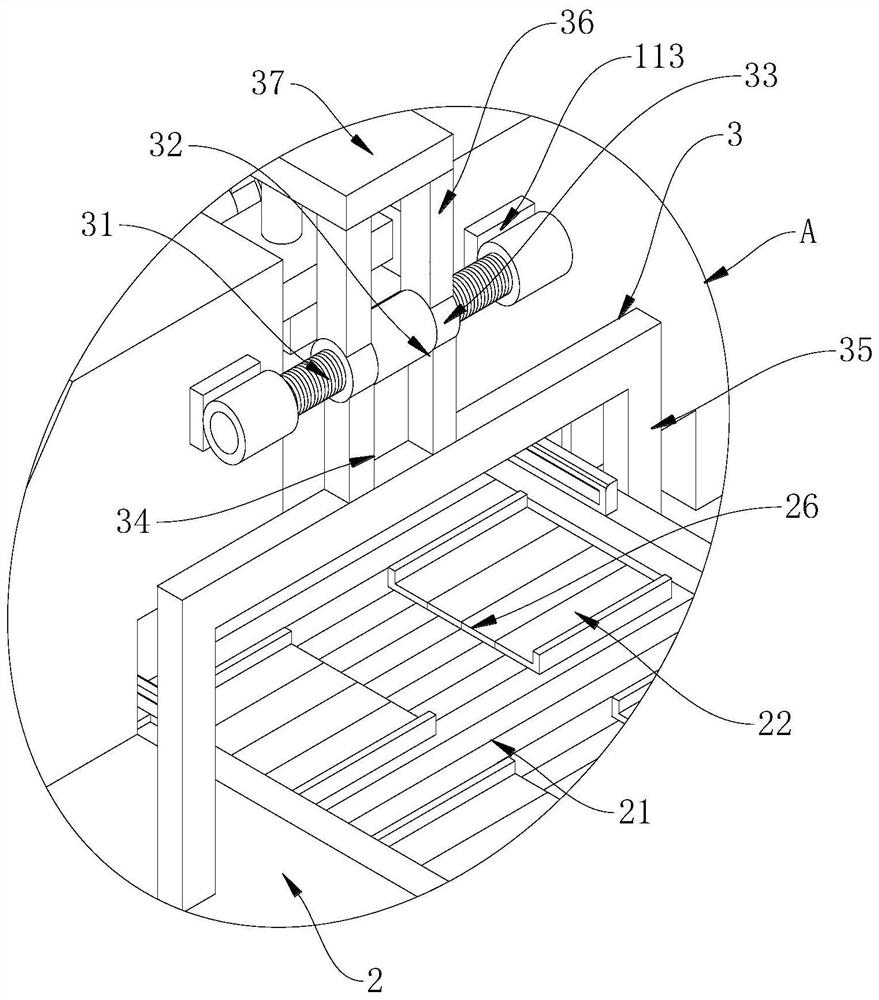

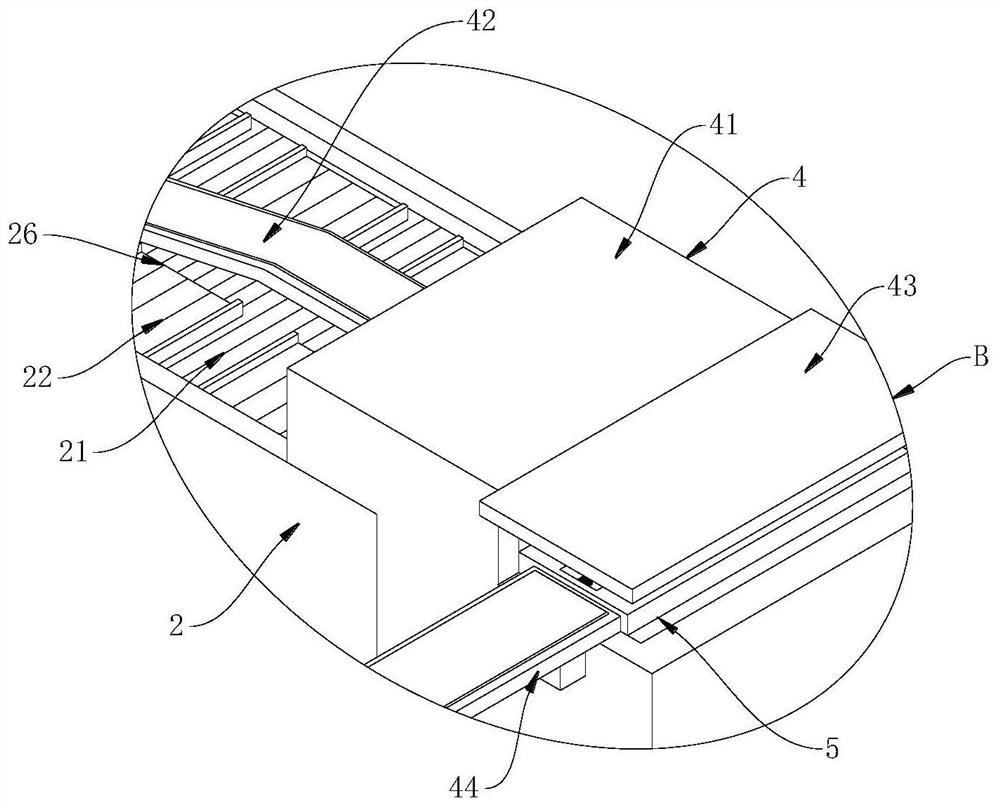

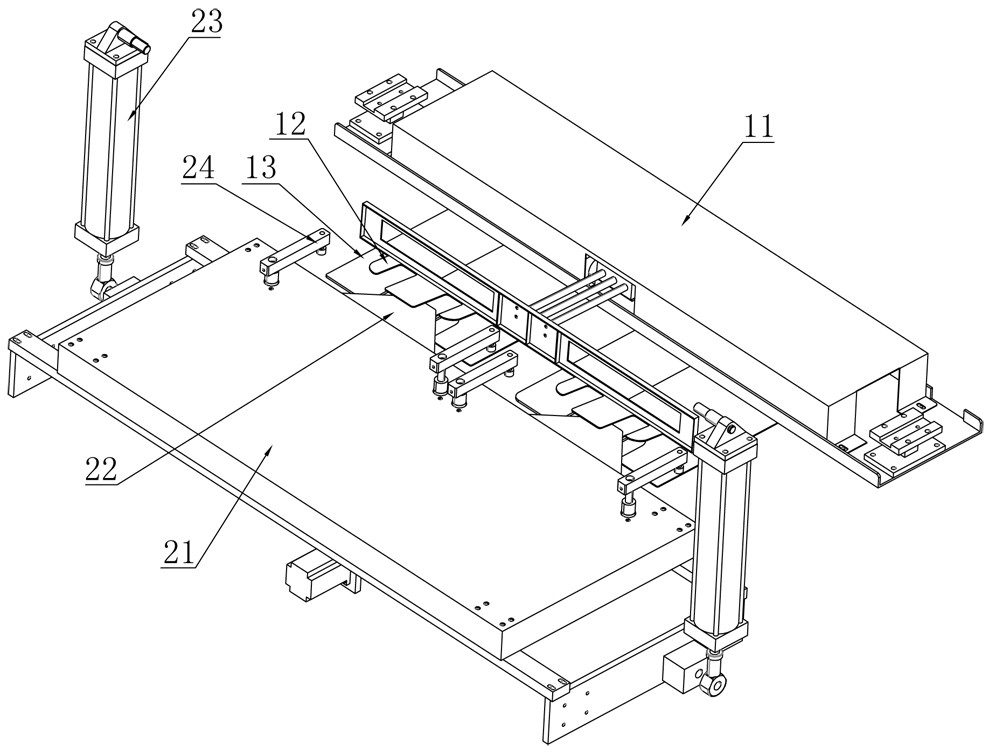

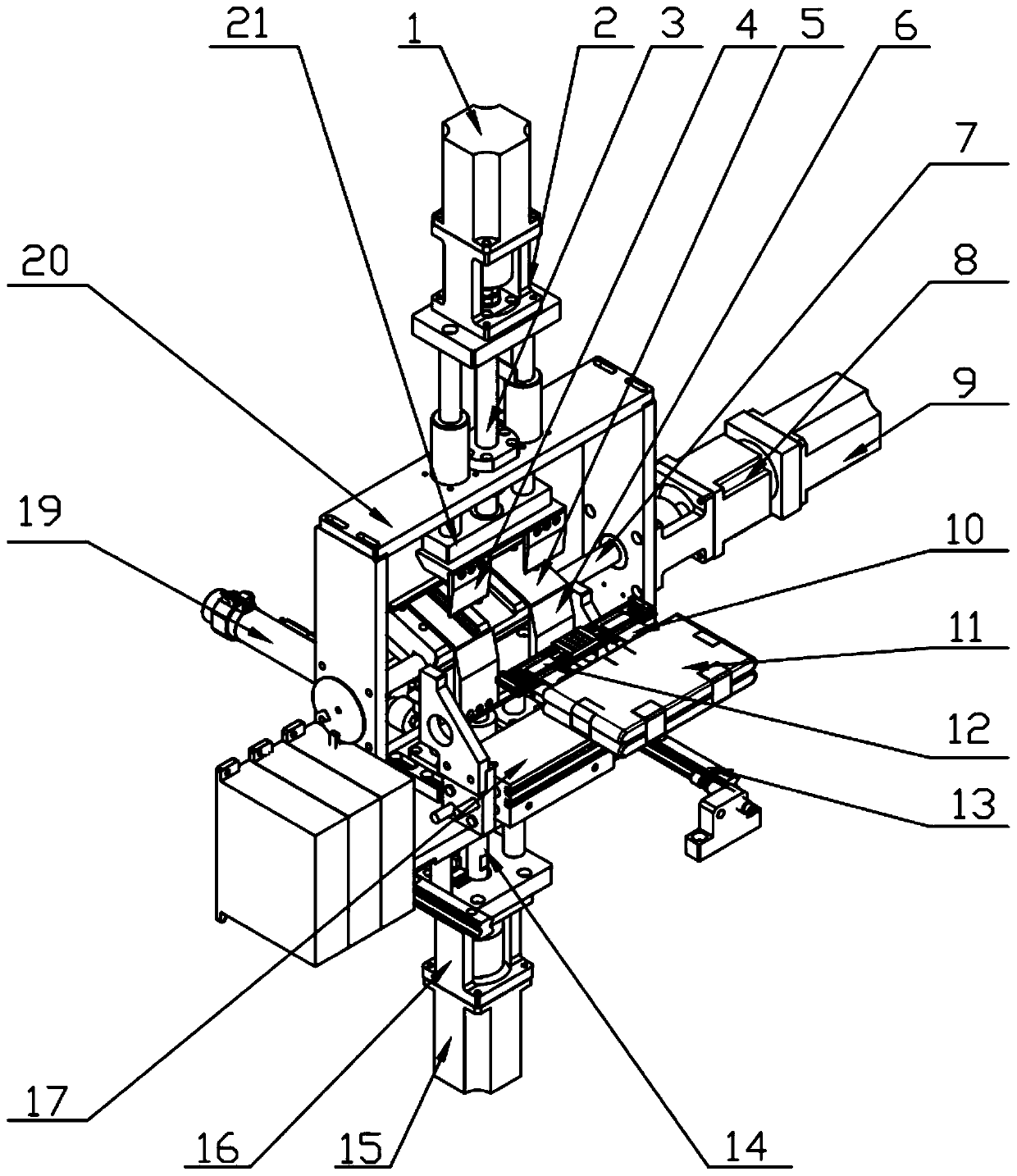

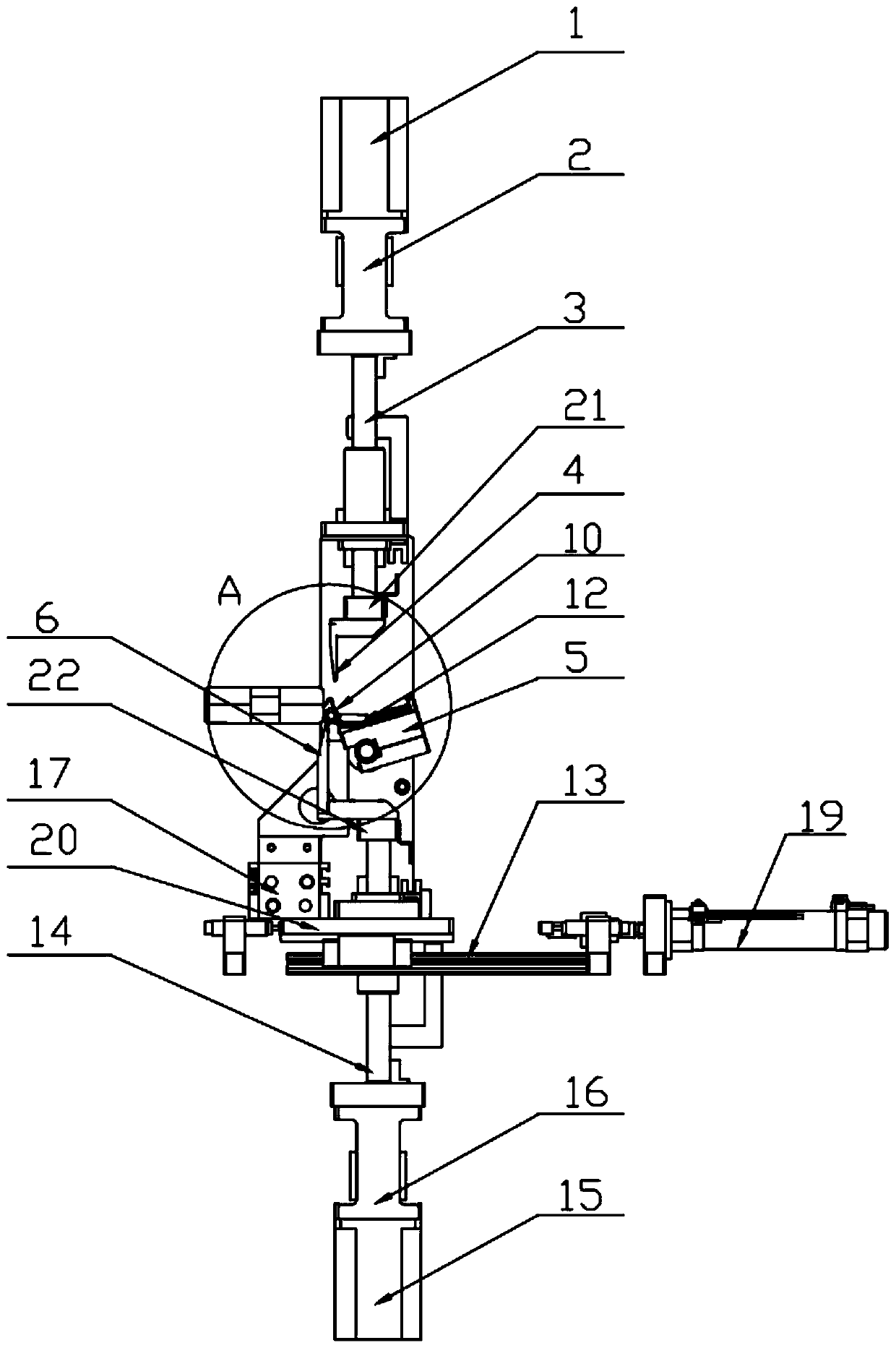

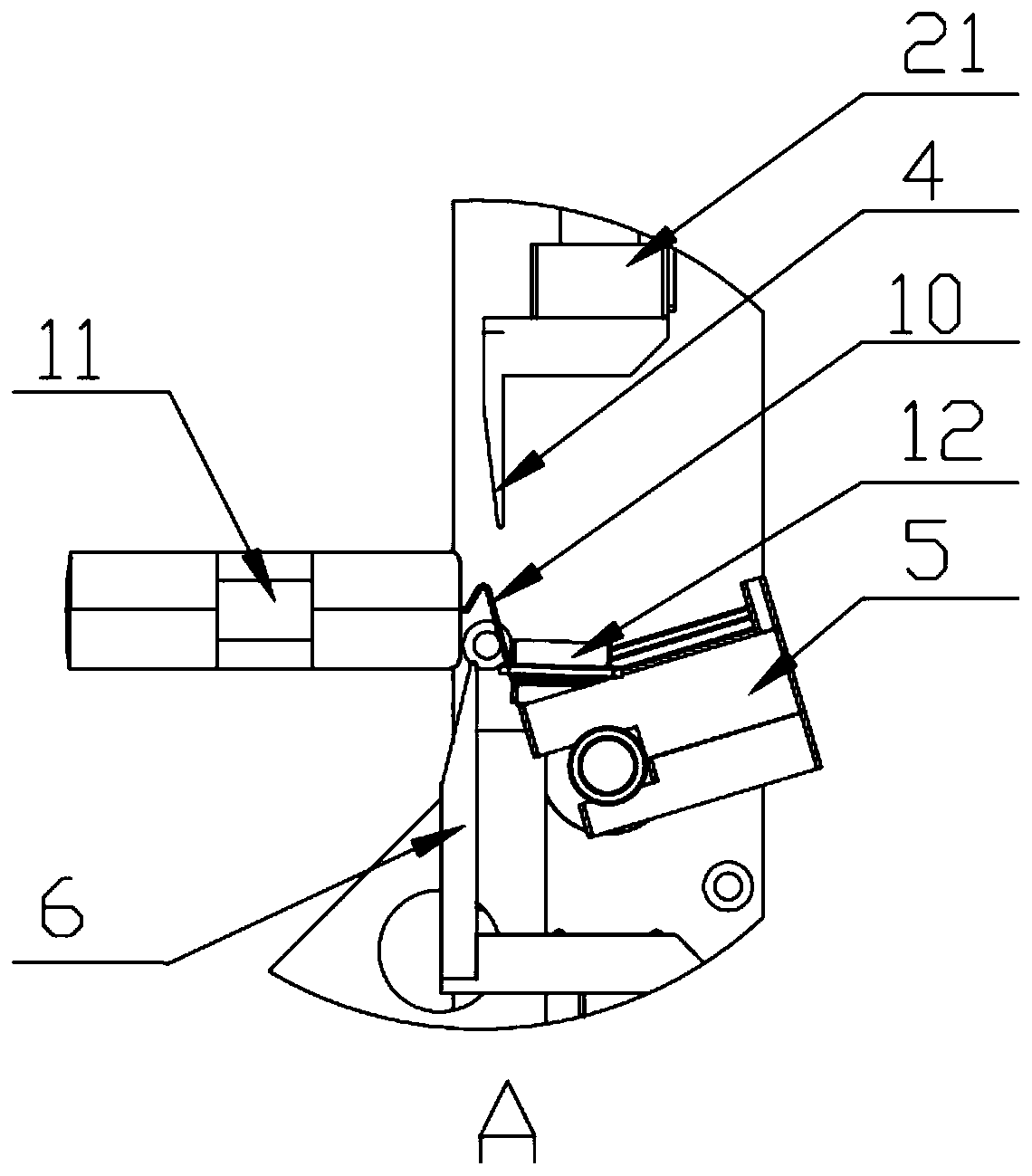

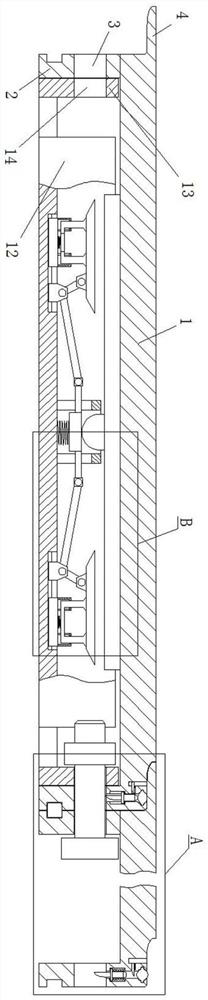

Programmable cylinder-driven carton machine with forming and inward-folding function

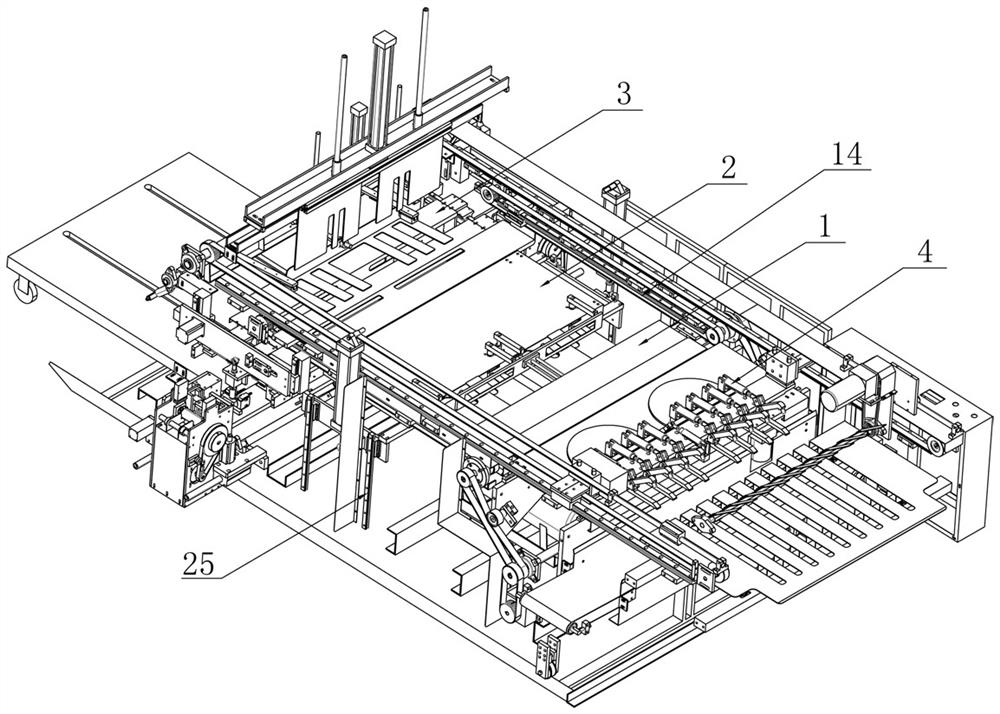

ActiveCN103252920AReduce manufacturing costBig ear sizeBox making operationsPaper-makingCartonEngineering

A programmable cylinder-driven carton machine with forming and folding inwardly function comprises a rack, a tower, a column assembly, two long side box pasting working position assemblies, two short side box pasting working position assemblies, a spring tray and a programming device. The programmable cylinder-driven carton machine is characterized in that the tower is fixed on the rack, the column assembly is vertically fixed on a vertical connecting surface at the top of the tower, the long side box pasting working position assemblies are arranged at an interval and fixed on the rack and in front of the tower, and the short side box pasting working position assemblies are arranged at an interval, fixed on the rack and in front of the tower and are misaligned with the long side box pasting working position assemblies in a plane by a 90-degree angle. Since the programmable cylinder-driven carton machine is driven by the cylinder, and software program regulates the box pasting process through a programming device, the programmable cylinder-driven carton machine is simple in equipment, low in production cost, greatly improved in efficiency, full in folded edge, large in folded ear size and suitable for various product specifications, and has obvious green production benefit and great market needs.

Owner:曹臣明

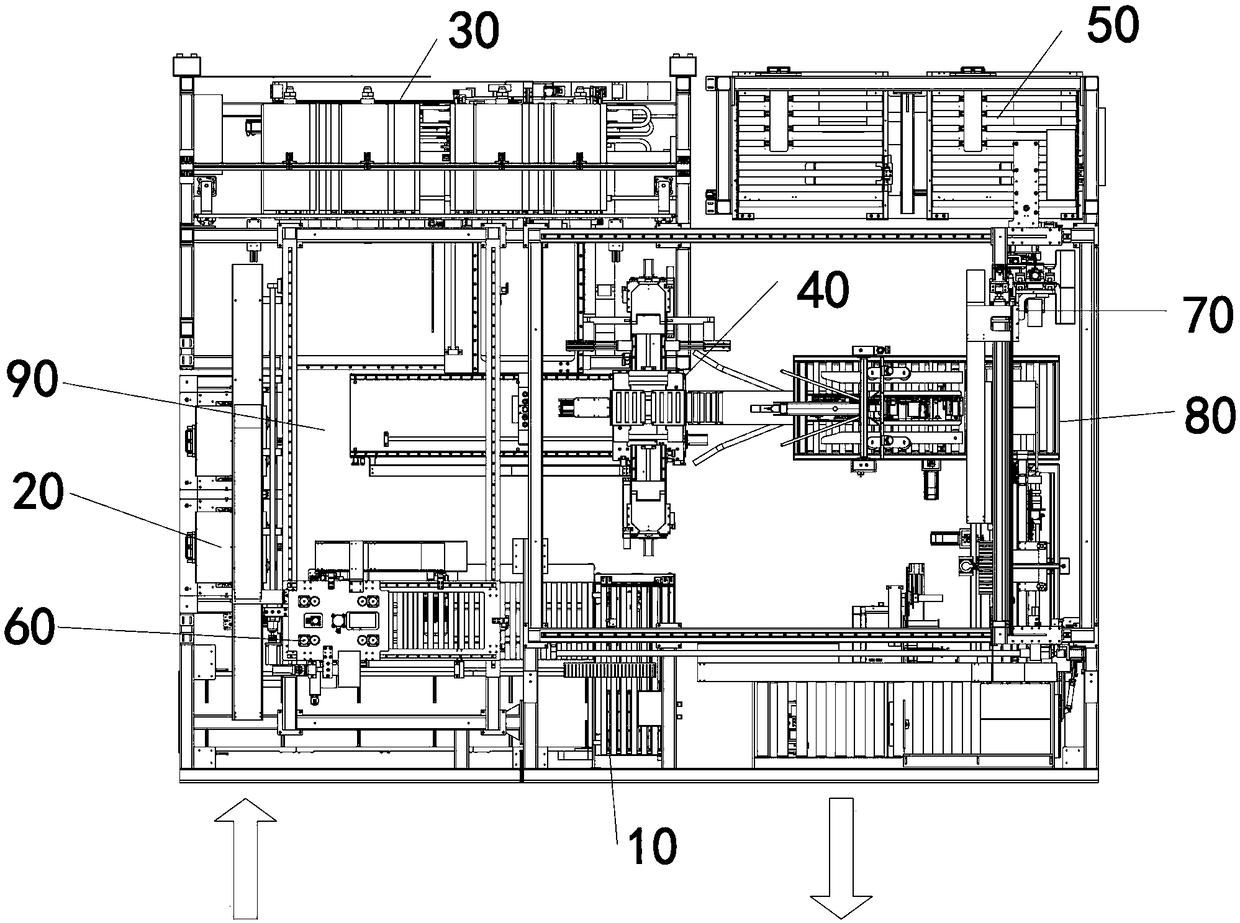

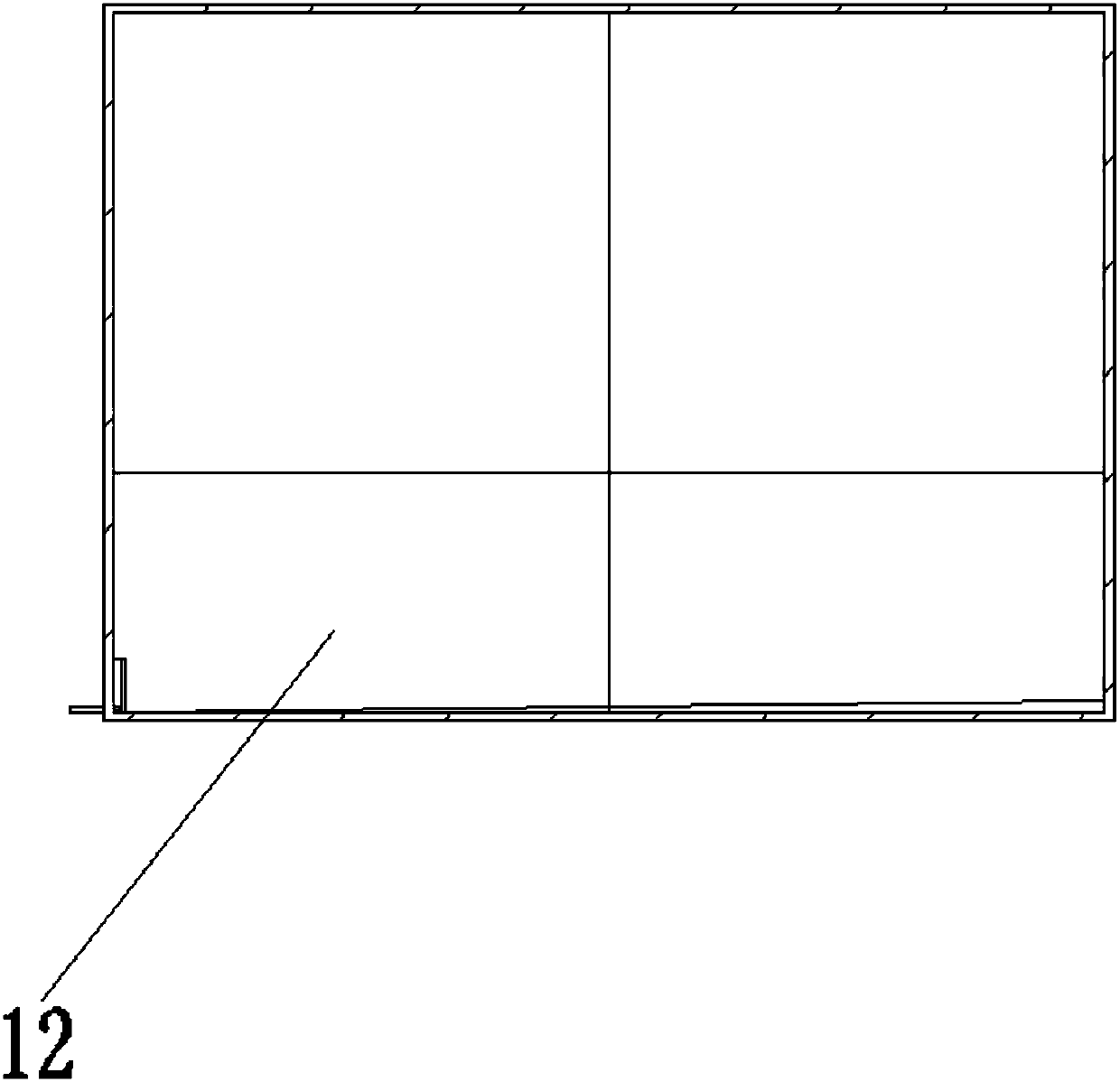

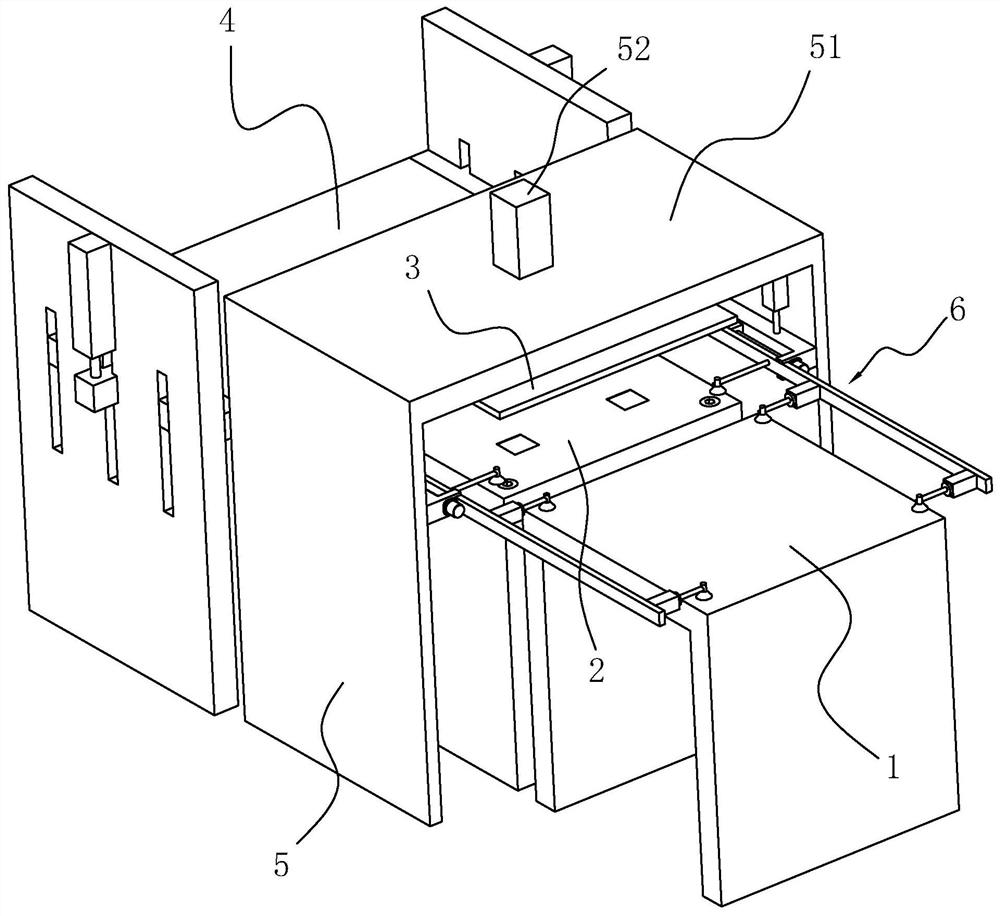

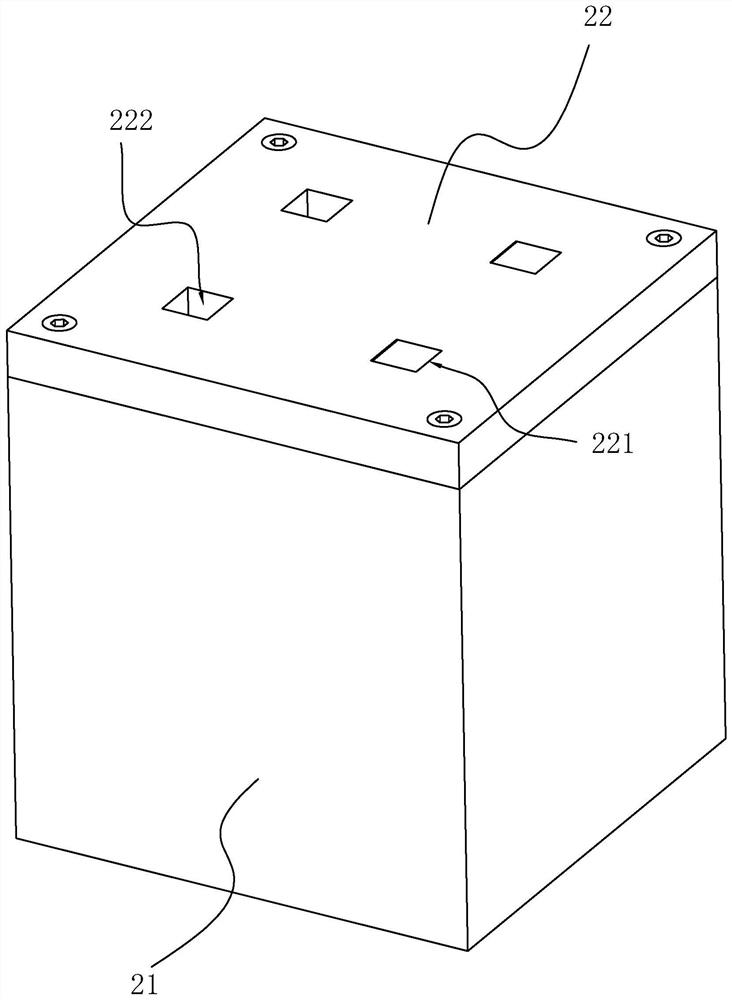

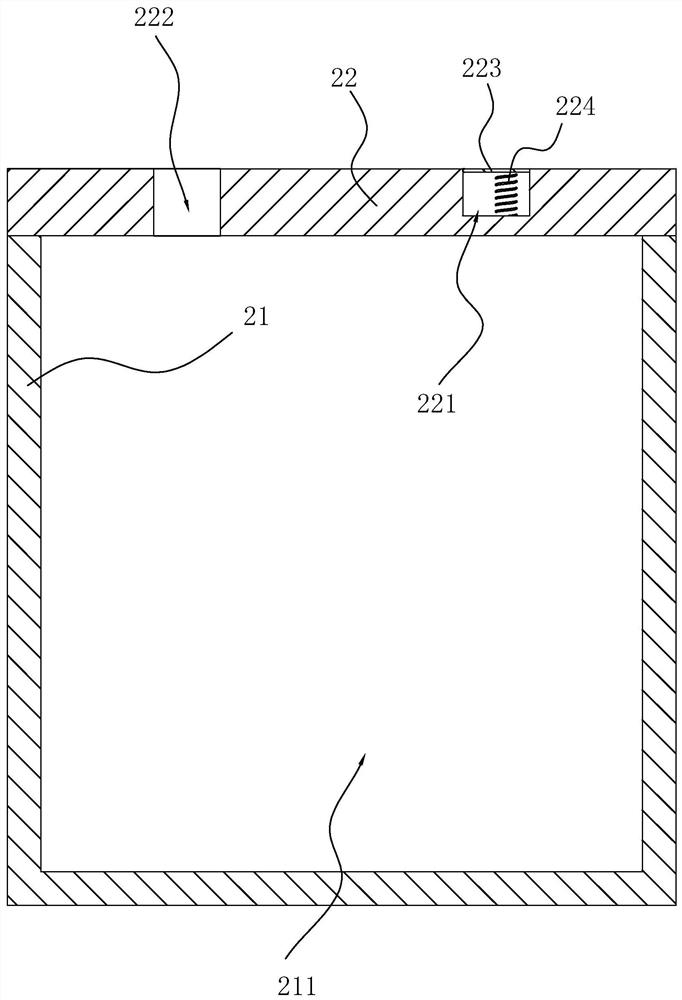

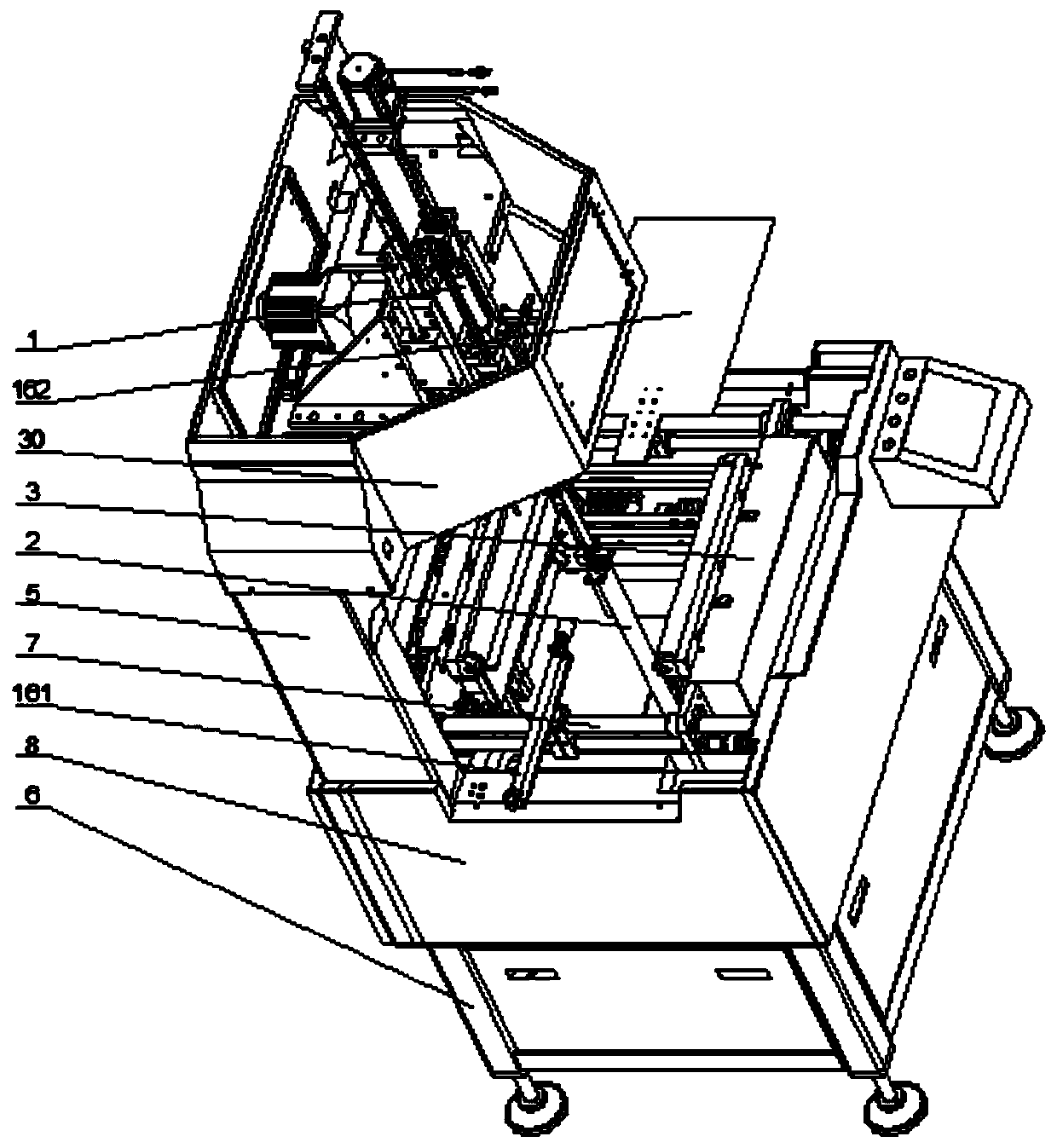

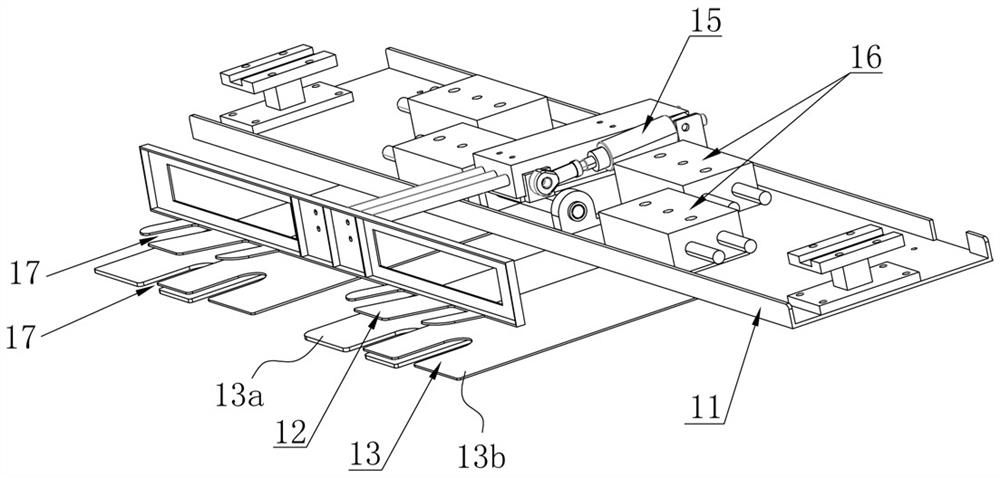

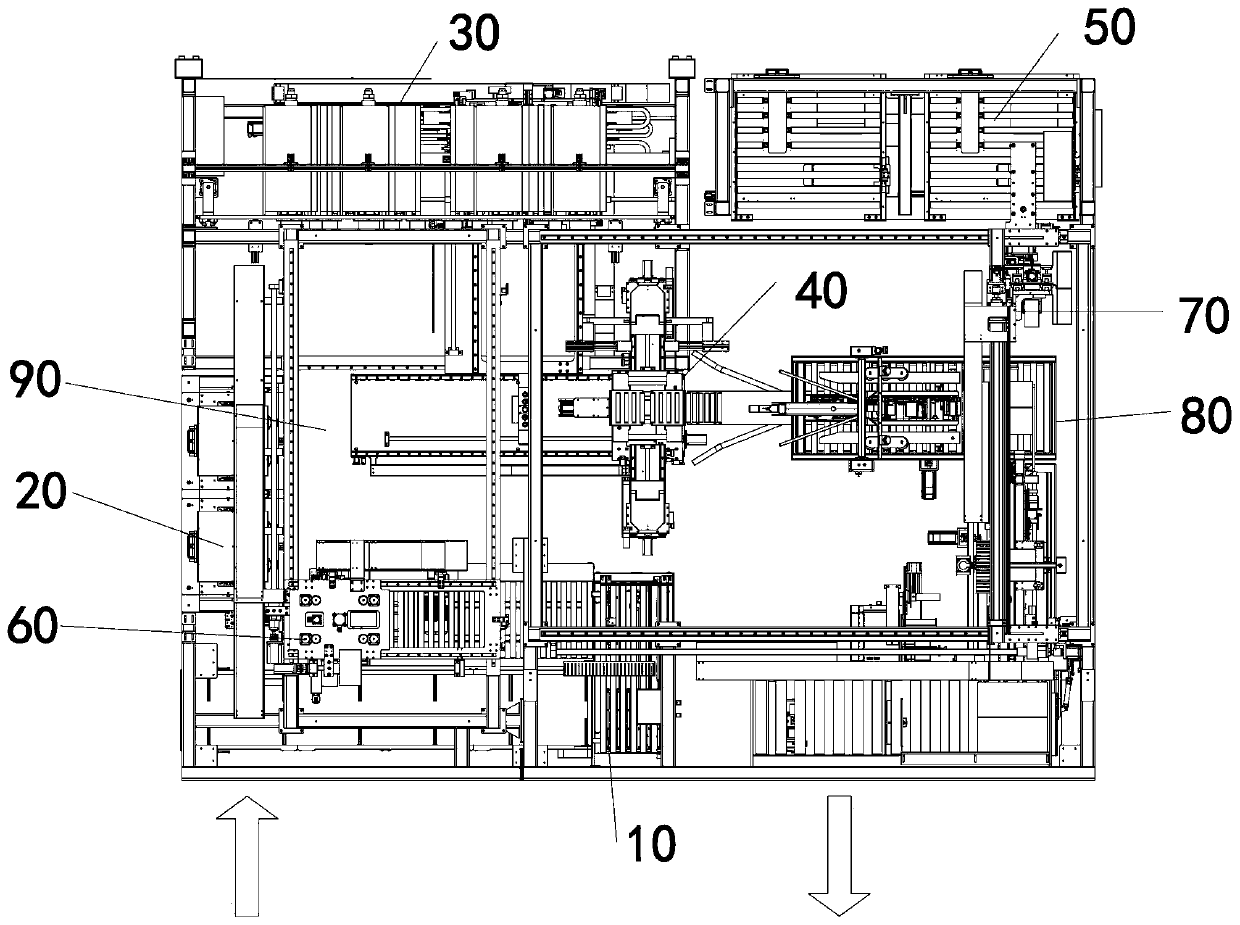

Automatic packaging equipment for lithium batteries

ActiveCN109132002AImprove work efficiencyReduce the use of laborPackaging by pressurising/gasifyingWrapper twisting/gatheringCartonMaterial transfer

The invention discloses automatic packaging equipment for lithium batteries. The automatic packaging equipment comprises an automatic feeding device, a foam storage bin, a material transfer gantry device, a PE bag automatic packaging device, a carton storage bin, a carton transfer gantry device, an automatic transfer folding ear device and an automatic box sealing and labeling device. The PE bag automatic packaging device, the automatic feeding device, the carton storage bin, the foam storage bin and the automatic box sealing and labeling device are enclosed to form a preliminary packaging area. A carrying platform of the PE bag automatic packaging device and the automatic transfer folding ear device are all installed in the preliminary packaging area for preliminary packaging. The outputposition of a preliminary packaging box on the automatic transfer folding ear device is butted with a box sealing inlet of the automatic box sealing and labeling device. The material transfer gantry device and the carton transfer gantry device are fixed above the preliminary packaging area in parallel, and the carton transfer gantry device is located above the box sealing inlet of the automatic box sealing and labeling device. By the adoption of the equipment, the labor cost is lowered, and the working efficiency is high and is increased by at least 5-8 times.

Owner:宁波格劳博智能工业有限公司

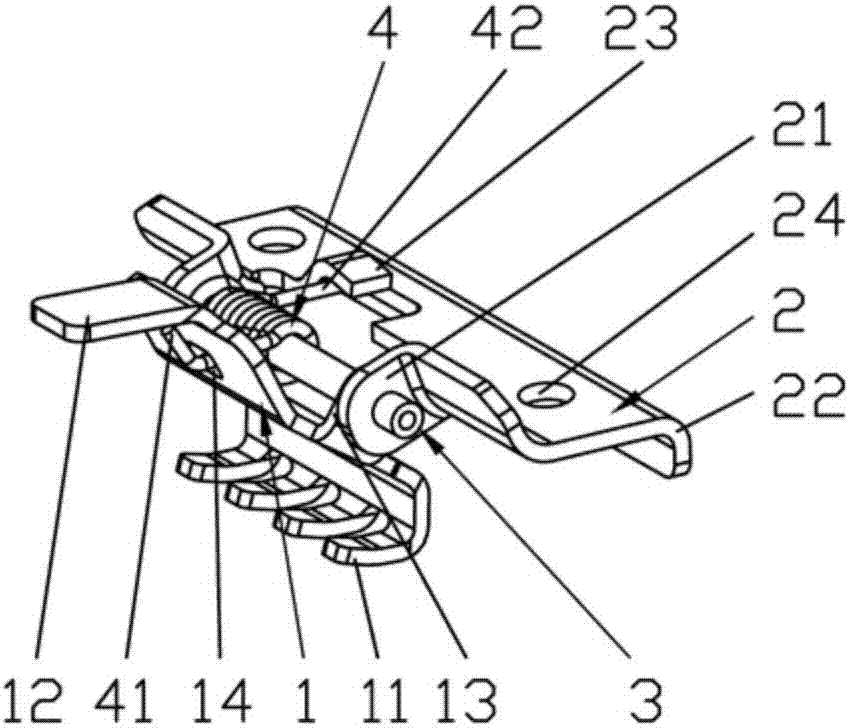

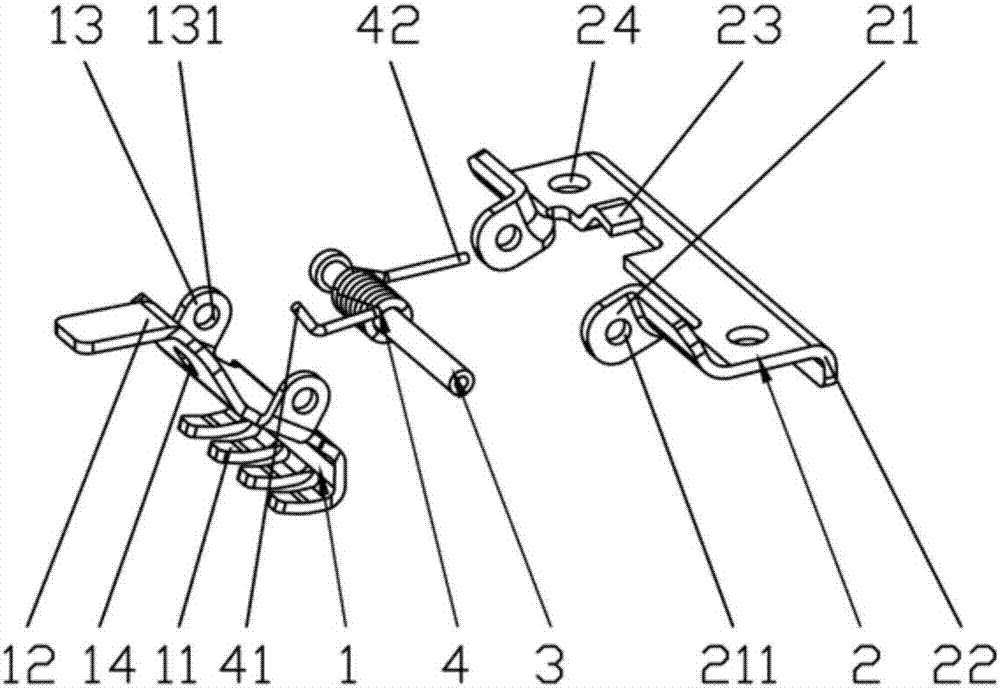

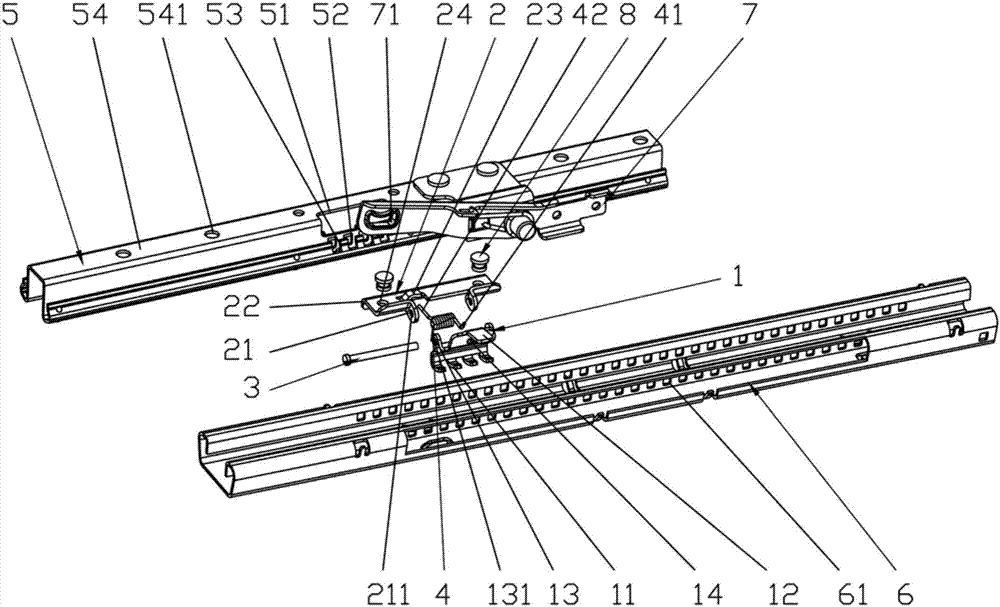

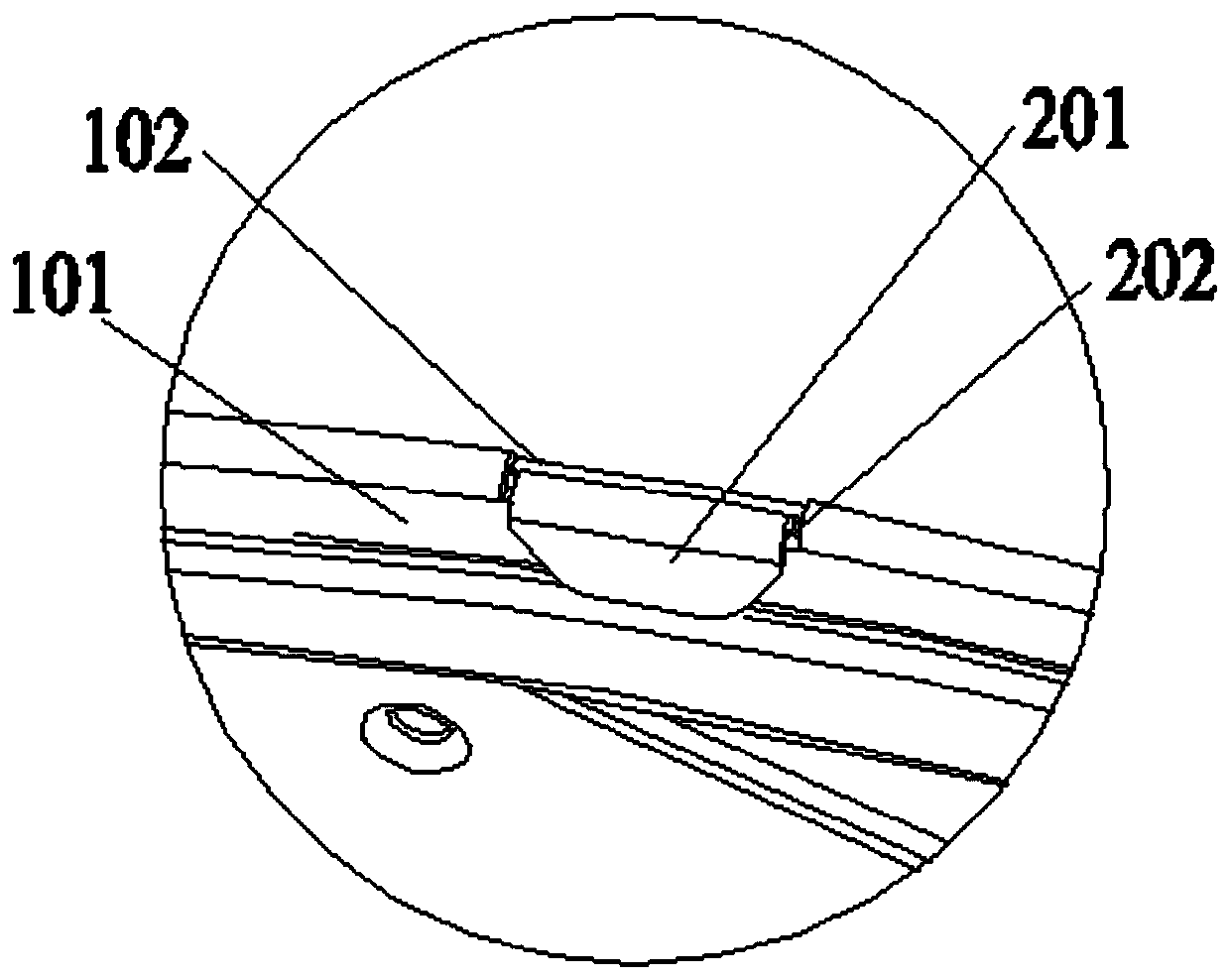

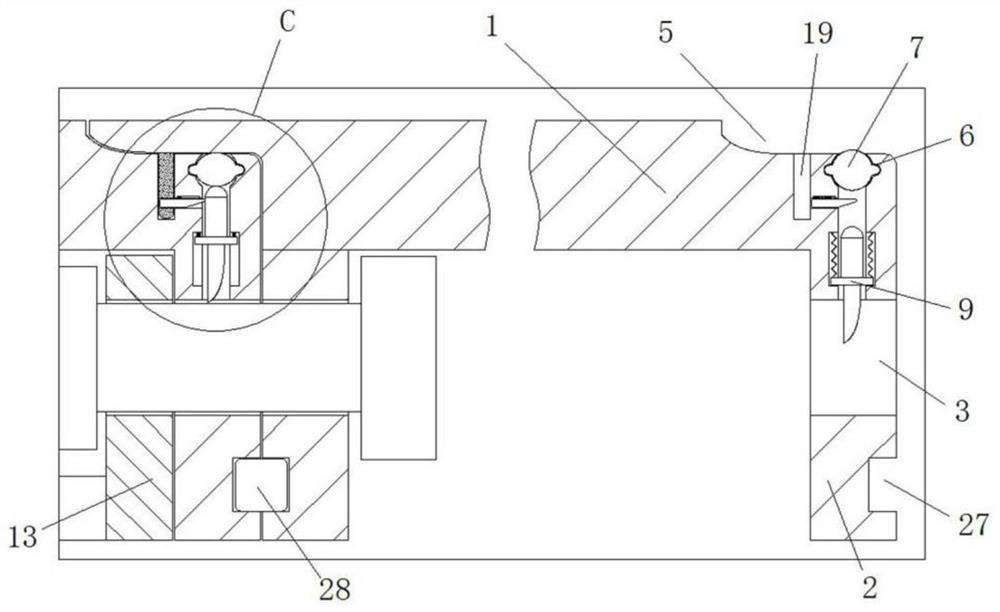

Car seat sliding rail locking mechanism

ActiveCN106864314AHigh locking strengthNot easy to skip teethInternal combustion piston enginesMovable seatsCar seatWrench

Provided is a car seat sliding rail locking mechanism. The locking mechanism comprises a movable guide rail, a fixed guide rail, a locking mechanism and an unlocking mechanism. The locking mechanism further comprises a locking claw, a fixed bracket, a rotating shaft and a locking spring. The lower end of the lock claw is provided with a plurality of lock gears; the upper end of the lock claw is provided with a control panel; the middle two sides of the lock claw is provided with a pair of first fold ears; a spring hole is installed at the connection part of the control panel and the lock gear; the one side of the fixed bracket is provided with a pair of second fold ears, and the other side of the fixed bracket is provided with a reinforced flanging and the middle of the fixed bracket is provided a hook spring slot; the locking spring is installed between a pair of the first fold ears, wherein a first spring hook at the one end is hooked up to the spring hole, and a second spring hook at the other end is hooked up to the hook spring groove; the middle of the rotating shaft is provided with the locking spring in a clamping mode, and both ends of the rotating shaft are passed through and formed in shaft holes of a pair of first fold ears and a pair of second fold ears; an abdication groove, a square hole and a lock groove are formed in the moving guide rail; a plurality of locking row holes are formed in the edgefold of the fixed guide rail; a wrench hole is formed in the locking mechanism. The sliding rail locking mechanism has the advantages that the locking strength is high; a gear of the locking mechanism is prevented from skipping under impact; the unlocking trip is short; the unlocking force is weak; the processing is convenient; the locking is reliable; the processing accuracy requirement is low and the assembling is convenient.

Owner:JIANGSU ZHONGMING XIANGHE SEIKO

Method for curing winy bacon

The invention provides a method for pickling wine-flavored bacon. It selects fresh pork leg meat and cuts it into strips with a width of 3-8cm; puts the cut meat strips into a container, and pours 53-degree white wine and Zheergen Fermentation liquid, so that the mixed liquid is completely submerged in the meat strips, wherein the weight ratio of white wine and meat strips is 1:5, and the balance is fermented liquid of Zheergen, then put in pickling auxiliary materials, seal and marinate for 8‑12 days, during Stir 5-8 times; bake the marinated meat strips at a temperature of 80-100°C for 3-5 hours; then bake them at a temperature of 20-25°C and a relative humidity of 75-90%. Hang it to dry for 5-7 days; sterilize the dried bacon, pack it in vacuum, and store it in an environment with a temperature of 25-29°C and a relative humidity of 70-80%. The invention belongs to the field of bacon processing.

Owner:贵州福润心坊食品开发有限公司

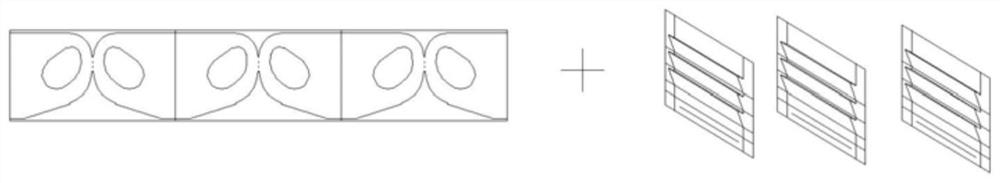

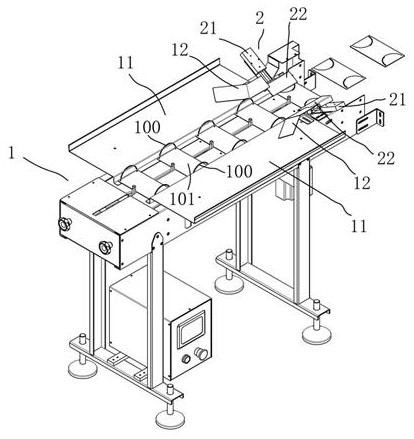

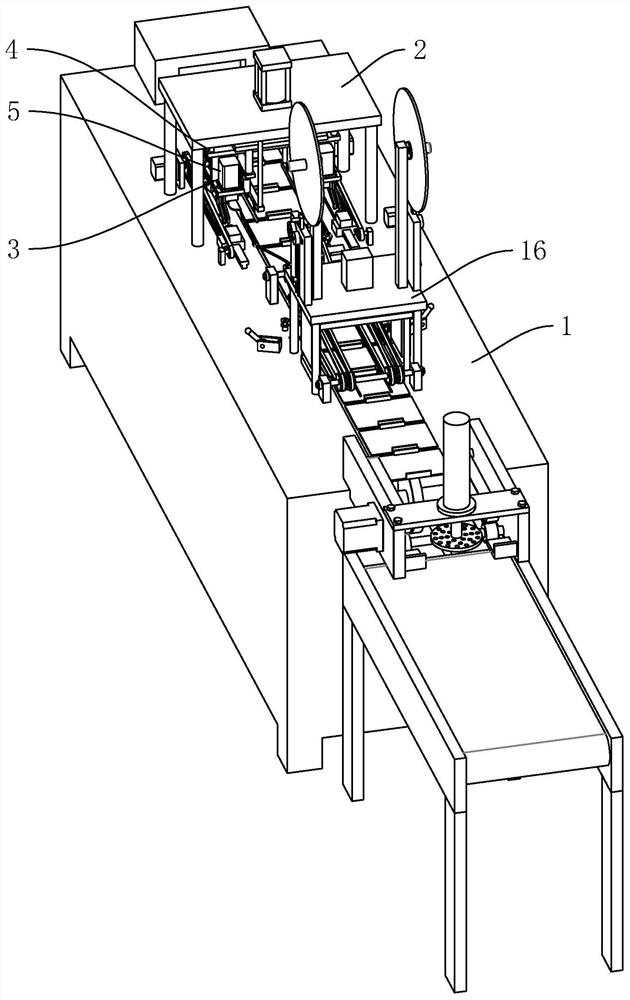

Mask machine folding ear belt forming mechanism and forming method thereof

PendingCN113334787AEnsure hot pressing speedGuaranteed hot pressing speedDomestic articlesClothes making applicancesEngineeringMechanical engineering

The invention discloses a mask machine folding ear belt forming mechanism and a forming method thereof. The mask machine folding ear belt forming mechanism comprises an ear belt fabric uncoiling device, a tension swing rod assembly, an active clamping and conveying device, a conveying wind scoop, a slitting knife box and a hot-pressing knife box, the slitting knife box is located above the hot-pressing knife box, the hot-pressing knife box and the slitting knife box are connected with each other, the tension swing rod assembly is located between the ear belt fabric uncoiling device and the active clamping and conveying device and used for detecting and adjusting the conveying tension of ear belt fabric, and the active clamping and conveying device is located between the tension swing rod assembly and the conveying wind scoop and used for adjusting the uncoiling speed of the ear belt fabric uncoiling device. According to the mechanism, the hot-pressing knife box and the slitting knife box are integrated together and are connected and matched with each other, so that ear belts can be quickly transferred to the hot-pressing knife box and hot-pressed to a mask main body after being formed on the slitting knife box, the alignment precision of the ear belts and a mask main body is ensured, the product quality is ensured, the hot-pressing speed of the ear belts can be ensured, and the production efficiency is ensured.

Owner:HANGZHOU XINYUHONG INTELLIGENT EQUIP CO LTD

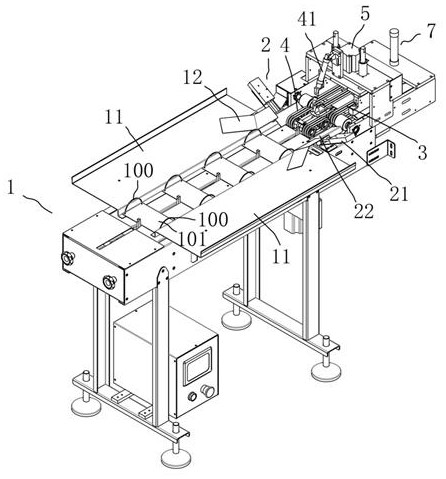

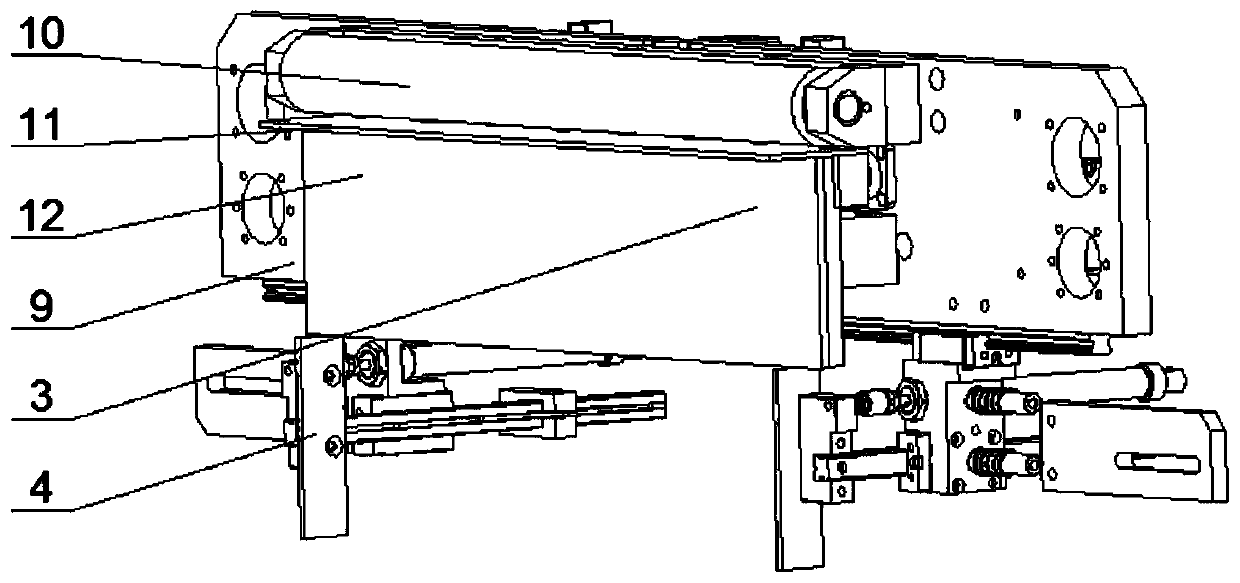

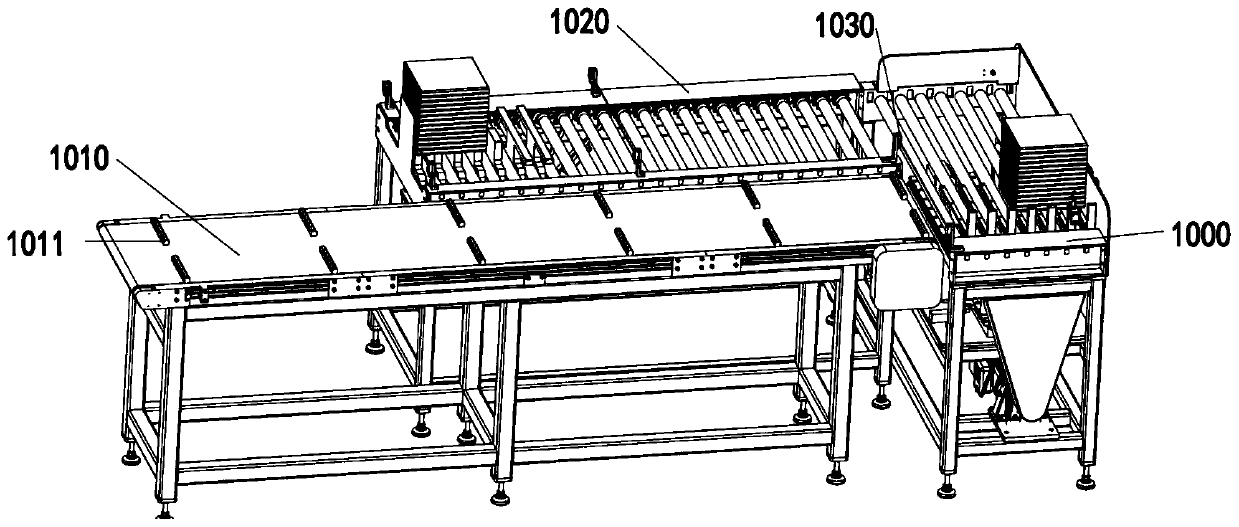

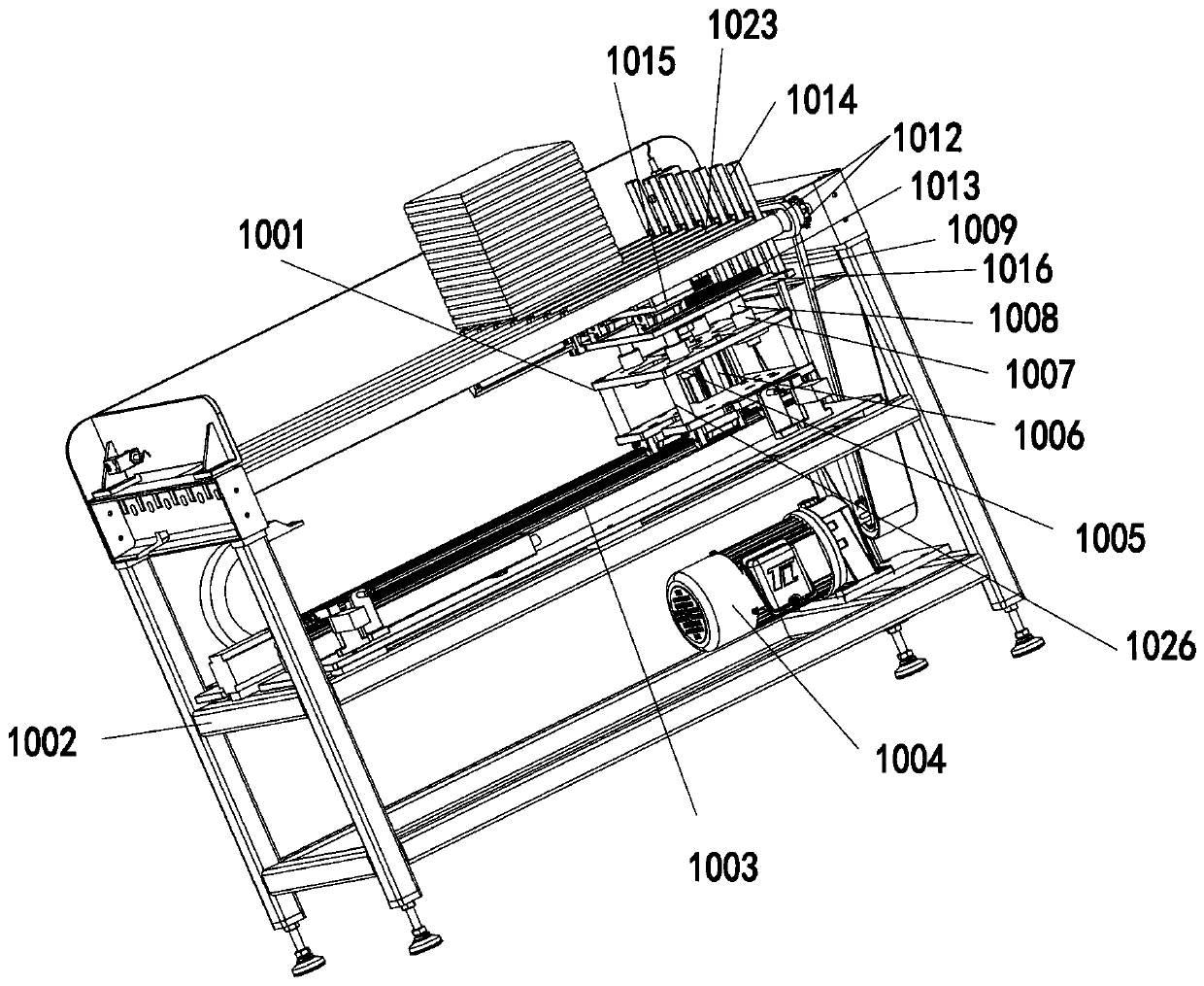

Ear band folding feeding system for outer ear mask and mask packaging line based on system

The invention discloses an ear band folding feeding system for an outer ear mask and a mask packaging line based on the system. Ear bands of the outer ear mask are conveyed to an ear band folding device in a standing form, the ear bands are folded and pressed against the surface of a mask piece by the ear band folding device, meanwhile, a material guide belt component acts to be pressed on the earbands and the mask piece to push the outer ear mask to a belt conveying component, the ear bands are hot-pressed and shaped on the mask piece by a hot pressing shaping device, and then the outer earmask with the shaped folded ear bands is continuously conveyed by the belt conveying component so that the ear bands can be automatically folded on the surface of the mask piece during the feeding andconveying process of the outer ear mask, and the automatic ear band folding function is achieved; the mask packaging line adopting the ear band folding feeding system for the outer ear mask has the advantages that the ear band folding packaging speed is high, the efficiency is high, the ear bands do not pop up and deflect after being folded, and the packaging yield is high; and the mask packagingline can be suitable for ear band folding packaging of the outer ear masks with different ear band lengths and different soft-hard degree of mask pieces after the corresponding adjustment.

Owner:佛山市唐氏智能科技有限公司

Volute ear folding device

ActiveCN110508655AIncrease productivityImprove product qualityMetal-working feeding devicesPositioning devicesProcess equipmentEngineering

The invention relates to the technical field of air duct volute manufacturing, in particular to a volute ear folding device. The volute ear folding device comprises a coaming fixing mechanism for fixing coaming and a side plate fixing mechanism for fixing side plates. The volute ear folding device further comprises a bending mechanism. The bending mechanism comprises a transverse bending mechanismbody and a vertical bending mechanism body. Folded ears are transversely bent through the transverse bending mechanism body, and the transversely-bent folded ears are vertically bent through the vertical bending mechanism body. The automatic bending device is used for volute ear folding work, the problems that in the extruding and edge covering processes of a volute, in order to prevent the coaming and the upper and lower side plates from being scattered, the volute needs to be subjected to ear folding work firstly, and normal volute feeding and clamping of following process equipment are facilitated are solved, and the production efficiency and the product quality are effectively improved.

Owner:湖南创研智能装备有限公司

Carton box with water drainage trough

The invention provides a carton box with a water drainage trough. The main structure of the carton box is a box body, an opening is formed in the position, close to the bottom, of any one side wall ofthe box body, the bottom surface of the box body is bevel, and the gradient of the bottom surface needs to be gradually decreased on the diagonal line, where the opening is located, in the directionfrom far to near; the water drainage trough is hinged to the bottom of the opening, and folding ear plates are arranged on the two sides of the water drainage trough; water-proof layers are arranged on the inner side and the outer side on the bottom of the box body respectively.

Owner:天津唯楚科技有限公司

Die cutting machine blanking equipment

ActiveCN110948934BEasy to transportLess prone to paper jamsBox making operationsPaper-makingCardboardStructural engineering

The invention discloses a die-cutting machine blanking device, which relates to the technical field of cardboard die-cutting, and solves the problem of paper jamming of the paper folding machine caused by incomplete cutting of the folding ears on the cardboard and the cutting part of the cardboard, and the main points of the technical scheme It includes a detection table, a raw material table, a blanking board, a detection board and a transmission mechanism. There is a detection hole on the top of the detection table, and an elastic plate is arranged on the top of the detection hole. The shape and size of the elastic plate are the same as the shape and size of the detection hole. The cardboard that has been cut in the die-cutting machine is transported to the raw material table, and the conveying mechanism transports the cardboard on the raw material table to the detection table, and the detection board moves downward, and the folding ears are folded through the cooperation of the thimble and the elastic plate. Ensure that the folded ear and the cutting part of the paper are completely separated from the cardboard. After the inspection is completed, the folded ear is pushed to the same side as the cardboard under the elastic action of the elastic plate, which is convenient for the later transportation of the cardboard and also makes the cardboard enter into the Paper jams are less likely to occur during processing in the origami machine.

Owner:青岛鑫凯顺包装有限公司

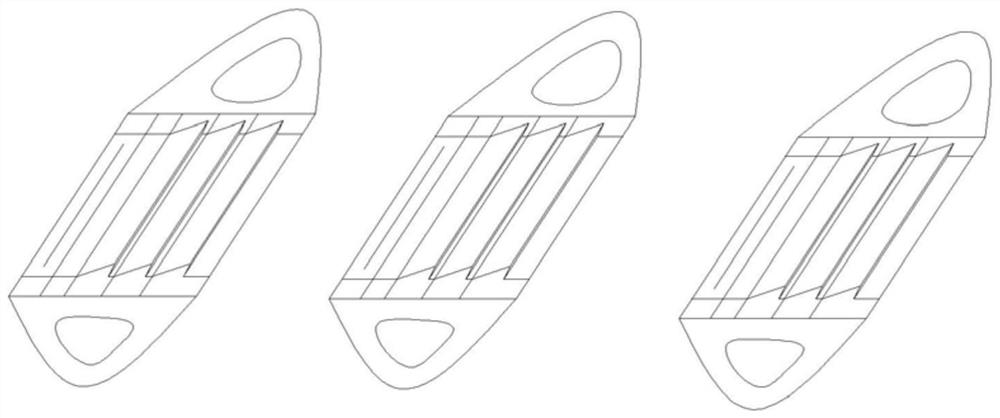

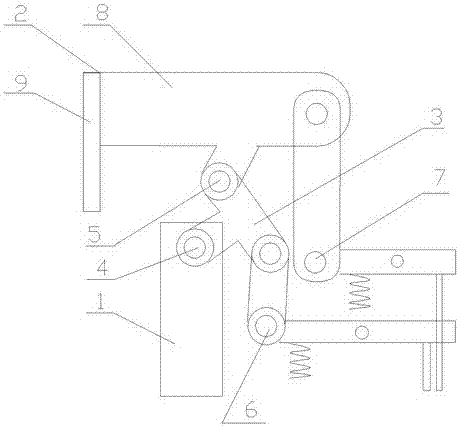

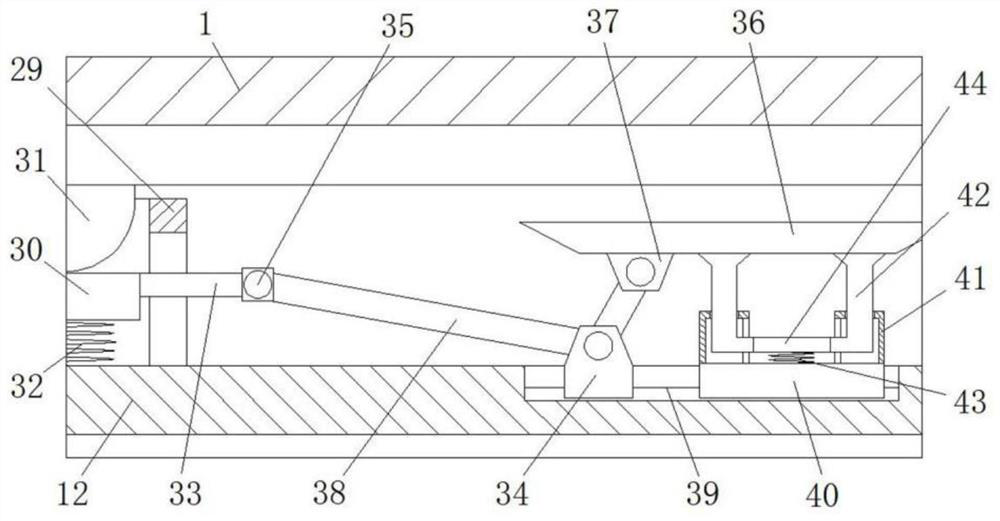

An ear-folding mechanism for metal plate punching and folding earphones

The invention relates to the field of machining, in particular to a lug folding mechanism for a metal plate punching and lug folding machine. The lug folding mechanism comprises a base plate and a machining table, the base plate is fixed to the machining table, the base plate is provided with a second sliding plate, and the front end of the second sliding plate is provided with a pressing block moving up and down; the position, behind the pressing block, of the second sliding plate is provided with pre-bending blocks moving up and down, the front ends of the pre-bending blocks are provided with openings, the pre-bending blocks are provided with a row of inserting needles moving up and down, and the pre-bending blocks are internally provided with jacking blocks moving horizontally; the front end of the base plate is provided with a hanging rack, the top of the hanging rack is provided with an installation frame, the top of the installation frame is provided with a pressing air cylinder, the two sides of the installation frames are provided with guide rails, the pressing block is in sliding fit with the guide rails, and the output end of the pressing air cylinder is fixedly connected with the top of the pressing block. By means of the lug folding mechanism, rapid forming of a workpiece folded lug is achieved, operation is simple, excessive participation of manpower is not needed, and production efficiency can be effectively improved.

Owner:佛山市顺森洋科技有限公司

A snap-off assembly that separates accessories from workpieces

Owner:苏州捷胜科技有限公司

Automatic packaging device

The invention relates to the technical field of packaging equipment, in particular to an automatic packaging device. A packaging portal frame is provided with a folding ear positioning mechanism. A bearing seat is arranged on the middle part of an axle body of a two-way threaded rod, and the bearing seat is rotatably connected with the two-way threaded rod. The bearing seat and a motor are fixed to the top of the packaging portal frame. Roller sliding devices are separately fixed to a first nut and a second nut. Sliding blocks are embedded in guide rails, and connecting rods are fixed to the sliding blocks. The top ends of movable rods are inserted into guide holes to be fixedly connected with springs, and U-shaped frames with downward openings are fixed to the bottom ends of the movable rods. Every two vertical rods on the same connecting rod are separately disposed on the front side and the rear side of the packaging portal frame. During the use of the automatic packaging device, inthe structure, folding ears on both sides of the top surface of a box body are pre-positioned and then bundled by the two roller sliding devices, so that the bundling quality of the box body is improved, and the folding ears are prevented from being torn when the box body is packaged.

Owner:ZHONGSHAN DEFENG TECH SERVICES CO LTD

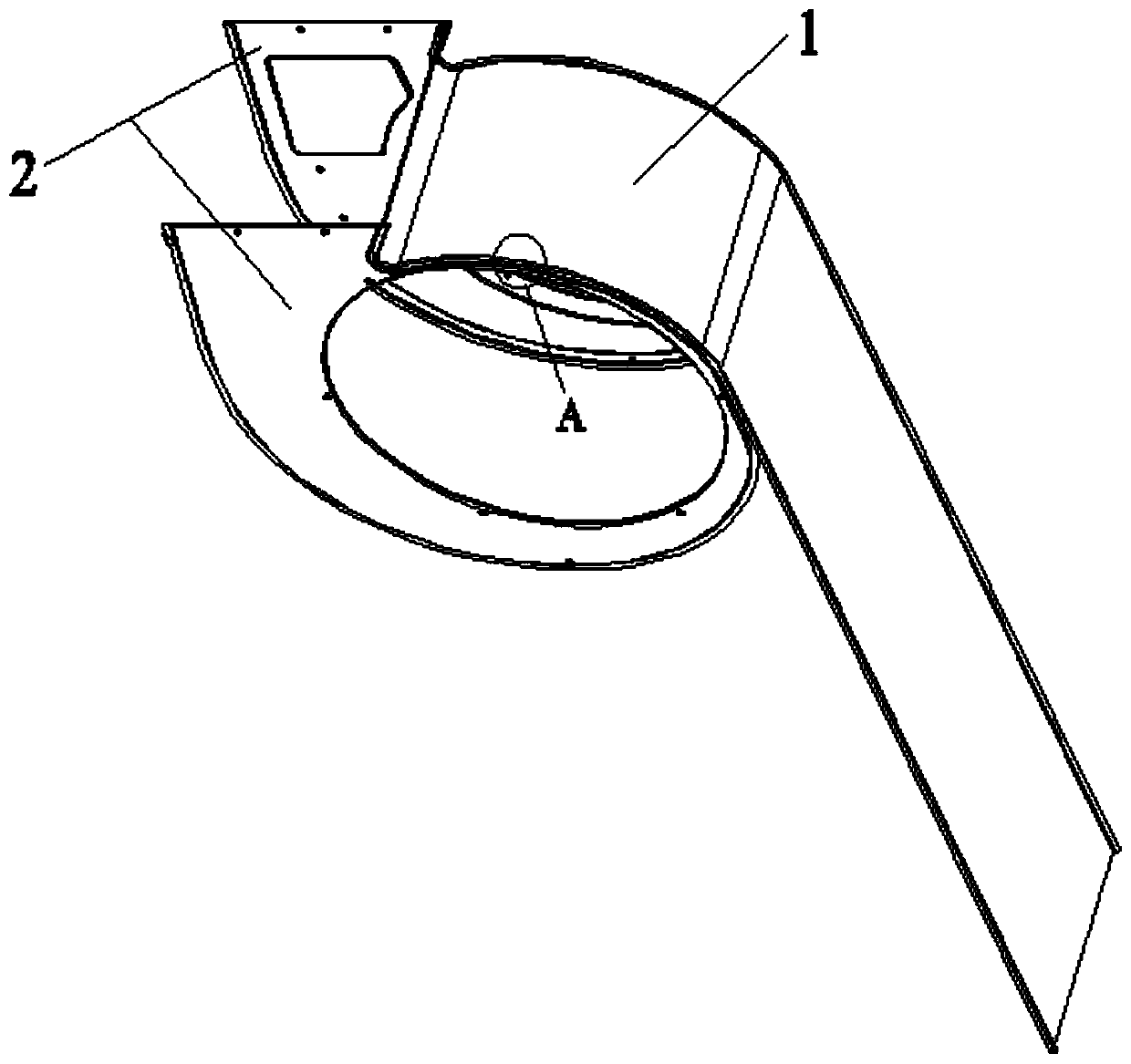

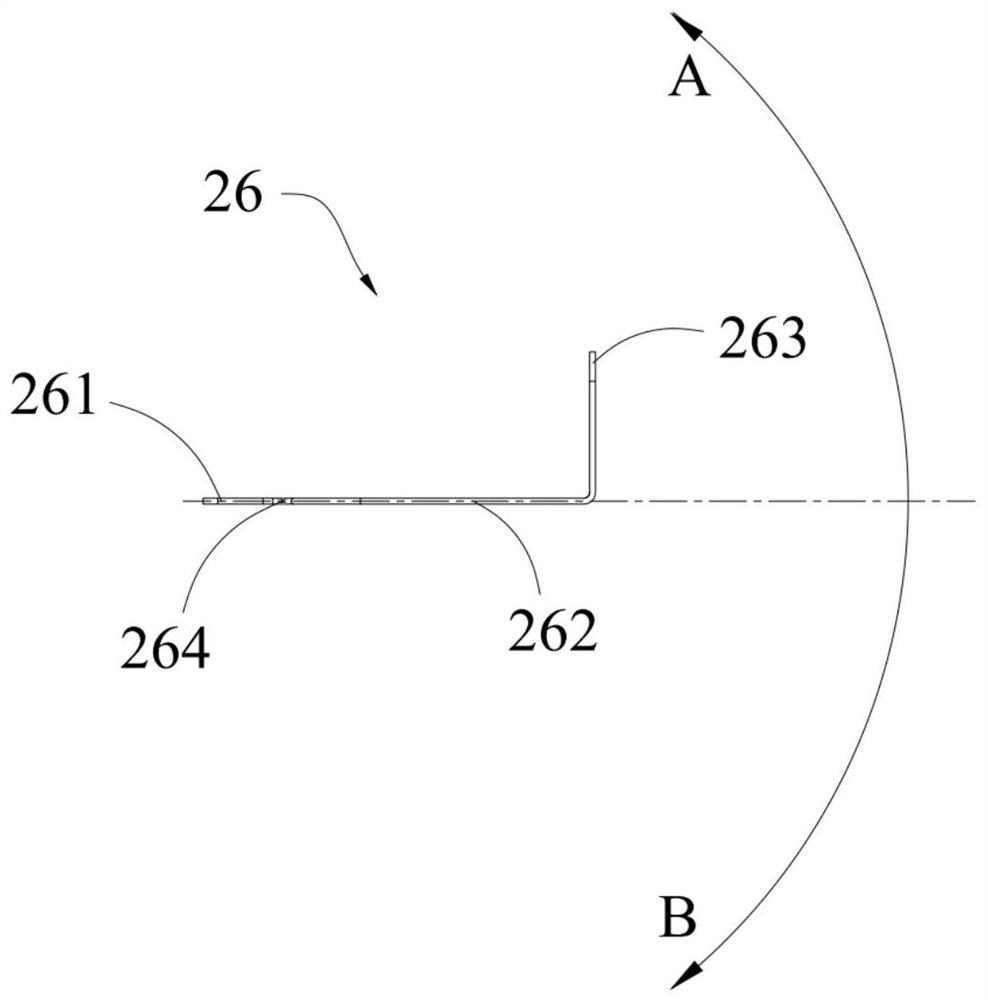

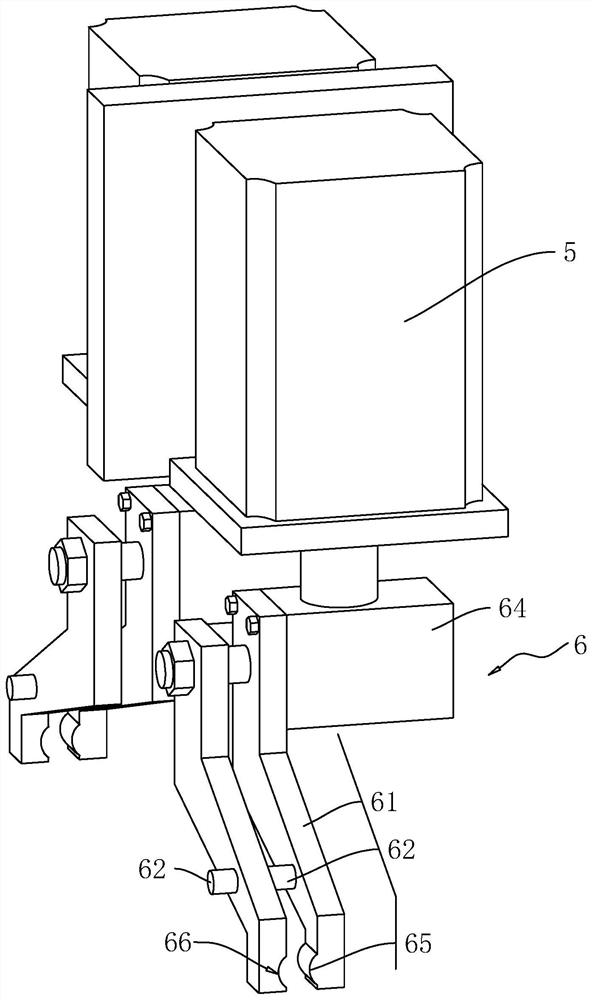

An ear-folding and straightening mechanism

The invention relates to an ear-folding and straightening mechanism, which is used to form the ear on the inner ring of a ring-shaped workpiece, comprising: a suction component, used to grab the ring-shaped workpiece; a carrier, used to hold the ring-shaped workpiece; It has a pushing module and a forming head; a push hole is opened on the carrier; the suction assembly includes a suction nozzle body, which is hollow inside and opens at the bottom, and a number of axially arranged ring-shaped workpieces are arranged on the periphery of the opening. The suction hole; the suction component absorbs the annular workpiece and moves it to the carrier, and pushes the forming head through the push hole by pushing the module, so that the forming head drives the ears into the opening.

Owner:SUZHOU RS TECH

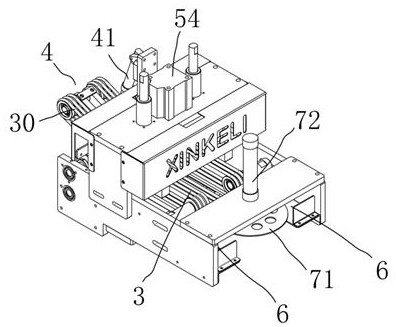

Device for converting outwards-folded ear cords into inwards-folded ear cords of mask machine

InactiveCN113619175AReduce energy consumptionReduce processing costsDomestic articlesRadiationEngineeringMechanical engineering

The invention discloses a device for converting outwards-folded ear cords into inwards-folded ear cords of a mask machine, and relates to the technical field of mask processing equipment. The device comprises an ear cord folding mechanism used for converting the outwards-folded ear cords into the inwards-folded ear cords of a mask, the ear cord folding mechanism comprises a fixing cover and a linkage block, a connecting plate is movably arranged in the fixing cover, a first rack is arranged at the top of the connecting plate, an ear cord folding plate is arranged at one end of the connecting plate, a flow guide plate is arranged at one side of the fixing cover, and a fixing rod is fixedly arranged in the fixing cover. By arranging the ear cord folding mechanism and a conveying mechanism, an air cylinder is started to drive a hot melting pressing block to descend, meanwhile, a second rack abuts against a first gear along with descending of a driving block, the ear cord folding plate moves synchronously, and therefore ear cord folding and shaping operation is conducted on the mask, the ear cord folding procedure and the positioning procedure of the device are driven by the same power source, the use energy consumption is reduced, the processing cost is reduced, economic benefits are met, and wide application prospects are achieved.

Owner:淮北市蓝天医用科技有限公司

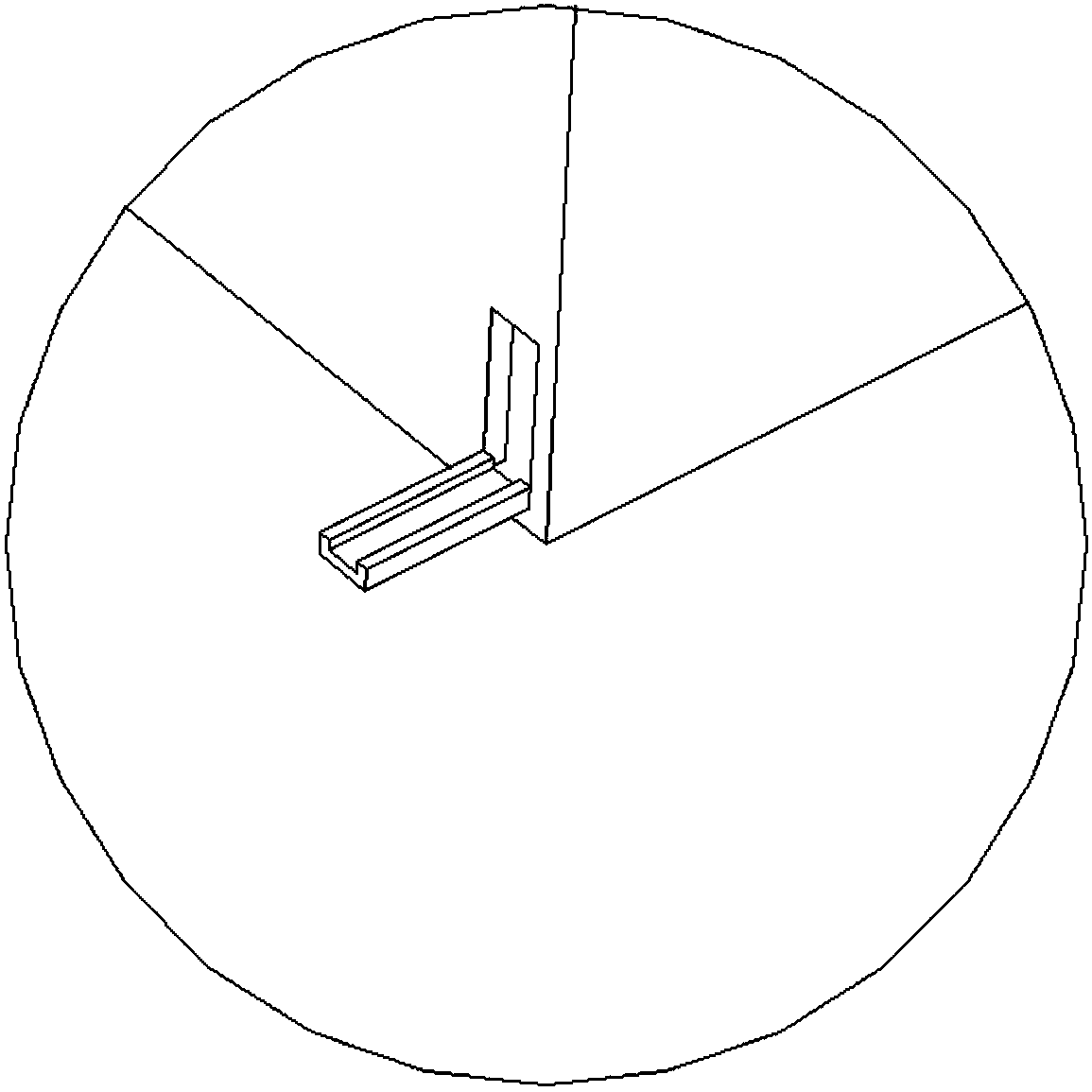

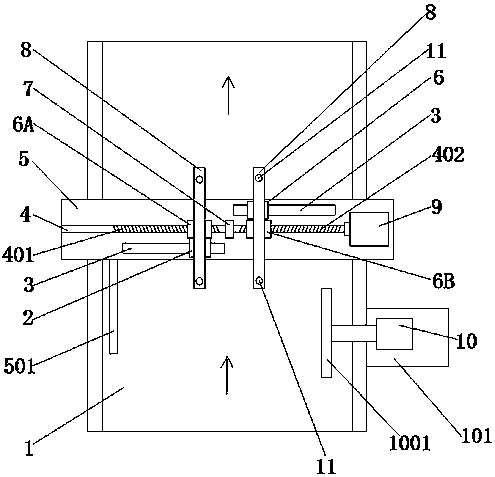

Ear folding mechanism of a carton forming machine

The invention discloses an ear folding mechanism of a carton forming machine, which includes a bracket and ear folding parts, and is characterized in that: the bracket is provided with a first rotating shaft, the first rotating shaft is provided with a swing member, and the swing member There is a second rotating shaft on the top; the folding ear part can be swingably arranged on the second rotating shaft; the swinging part is connected with a first power source, and is driven by the first power source to rotate and drive the folding ear part to complete the preliminary half-folding , the ear folding part is connected with a second power source, and is driven to rotate by the second power source to complete the final full ear folding. The present invention makes ear folding more reasonable through two-step ear folding actions, effectively avoids the influence on the flatness of the carton surface, and improves the quality of the carton.

Owner:平阳县瑞科机械有限公司

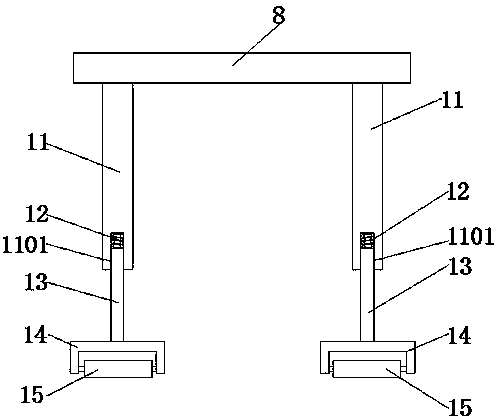

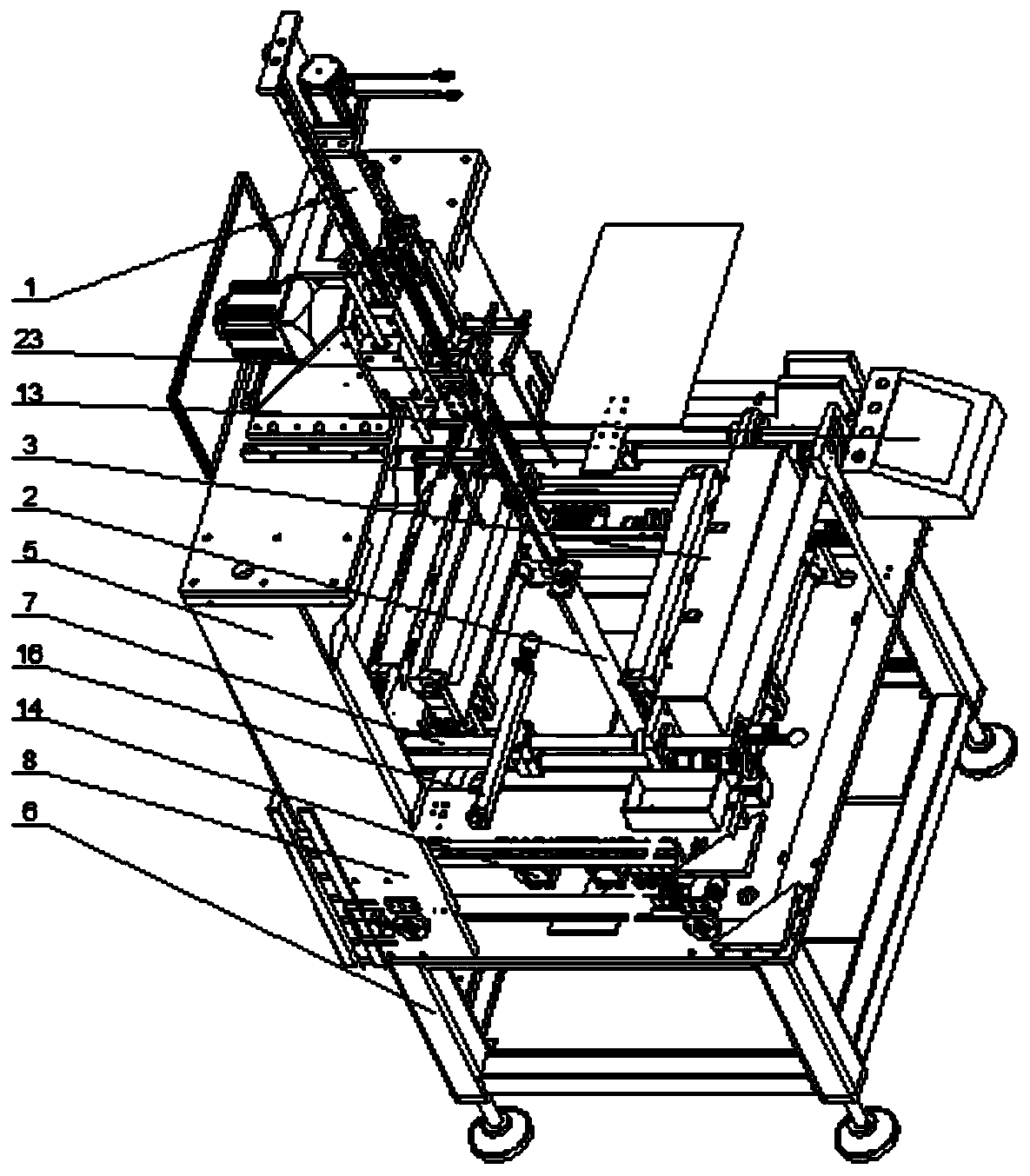

A box-making intelligent mold-adjusting and forming machine

ActiveCN108819342BSimple structurePrecise positioningBox making operationsPaper-makingMotor driveVertical edge

The invention discloses a box-making intelligent mold adjusting and forming all-in-one machine. The machine comprises an upper mold device, an ejection mold device, first vertical edge folding and bubble pressing devices and folding ear device, wherein two first vertical edge folding and bubble pressing devices are arranged, and can be arranged in a front-back mode or a left-right symmetric mode according to needs; the first vertical edge folding and bubble pressing devices are arranged in an upper machine frame below the upper mold device through two first stepping ball transmission guide roddevices, and the upper machine frame is arranged above a lower machine frame; each first stepping ball transmission guide rod device comprises a stepping motor, a stepping transmission guide rod, a stepping screw rod and a synchronous wheel belt, wherein the stepping motors drive the stepping screw rods through the synchronous wheel belts, and then the first vertical edge folding and bubble pressing devices are driven to move on the stepping transmission guide rods; and the positions of the vertical edge folding and bubble pressing devices and the position of the folding ear device are adjusted by adopting the design mode, so that the positioning can be more accurate, and the efficiency and the harmony are greatly improved.

Owner:深圳市腾飞达自动化设备有限公司

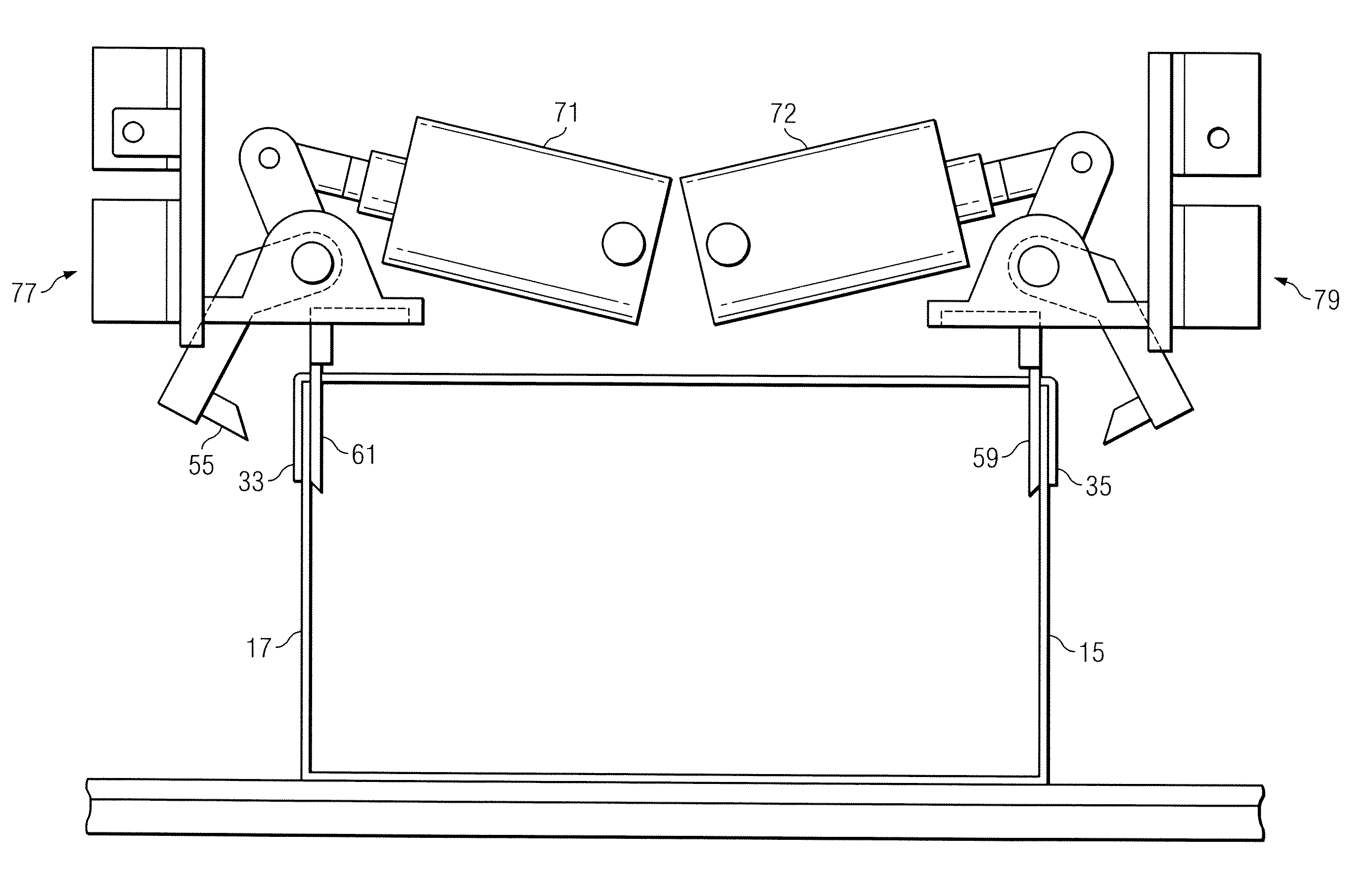

Packaging Apparatus and Method

A method and apparatus are shown for securing a top for a cardboard carton where the carton has a bottom wall and integral sidewalls, an initially open interior and initially open top flaps with outwardly extending ears. The top flaps are folded to a carton closing position which closes off the initially open interior of the cardboard carton. The ears are also folded to a position in contact with the sidewalls of the carton. A set of punches are aligned with the folded ears of the carton and are actuated to force a first layer of cardboard from a respective top flap through an underlying region of the carton sidewall. A set of platens are located so as to underlie and reinforce the sidewalls of the carton as the punching operation takes place.

Owner:DUNIVAN STEVE +2

Vest bag folding equipment

ActiveCN113060374BSave flipping stepsSimple structurePaper article packagingBundling machine detailsStructural engineeringMechanical engineering

The invention discloses a vest bag folding device, which includes a pinch and fold ear mechanism, a bag body receiving mechanism and a bag body folding mechanism. The pinch and fold ear mechanism travels between the bag body receiving mechanism and the bag body folding mechanism. The pinch and fold ear mechanism includes Translational workbench, telescopic pressure plate and a pair of folding ear plates for folding two hand straps, the telescopic pressure plate and ear plate are set up and down and located on the front side of the translation workbench, the telescopic pressure plate is driven by the power mechanism Stretching back and forth and moving up and down, the bag body receiving mechanism includes a lifting table and a telescopic receiving plate located on the rear side of the lifting table, and the bag body folding mechanism includes a folding table, a folding plate, a bag folding head and a pressing head. Bag board, the head of the bag body is folded backwards, which is opposite to the forward direction of the bag body, so that the folded bag body can be folded for the first time during the transmission process, saving the cost of completing the first time. The step of folding and turning over the bag body has high efficiency.

Owner:苏立西 +1

Packaging apparatus and method

A method and apparatus are shown for securing a top for a cardboard carton where the carton has a bottom wall and integral sidewalls, an initially open interior and initially open top flaps with outwardly extending ears. The top flaps are folded to a carton closing position which closes off the initially open interior of the cardboard carton. The ears are also folded to a position in contact with the sidewalls of the carton. A set of punches are aligned with the folded ears of the carton and are actuated to force a first layer of cardboard from a respective top flap through an underlying region of the carton sidewall. A set of platens are located so as to underlie and reinforce the sidewalls of the carton as the punching operation takes place.

Owner:DUNIVAN STEVE +2

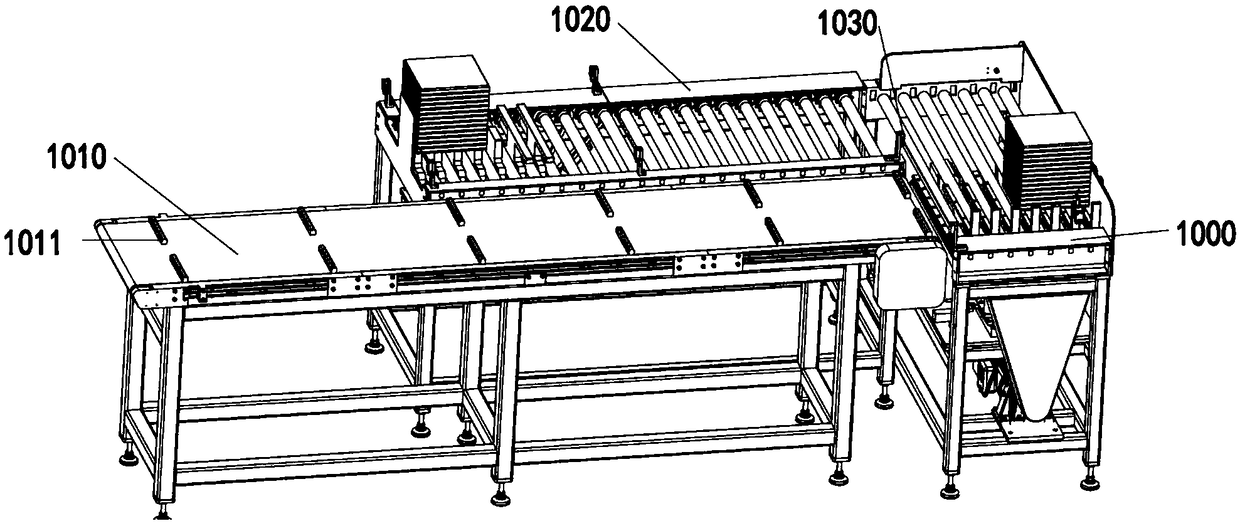

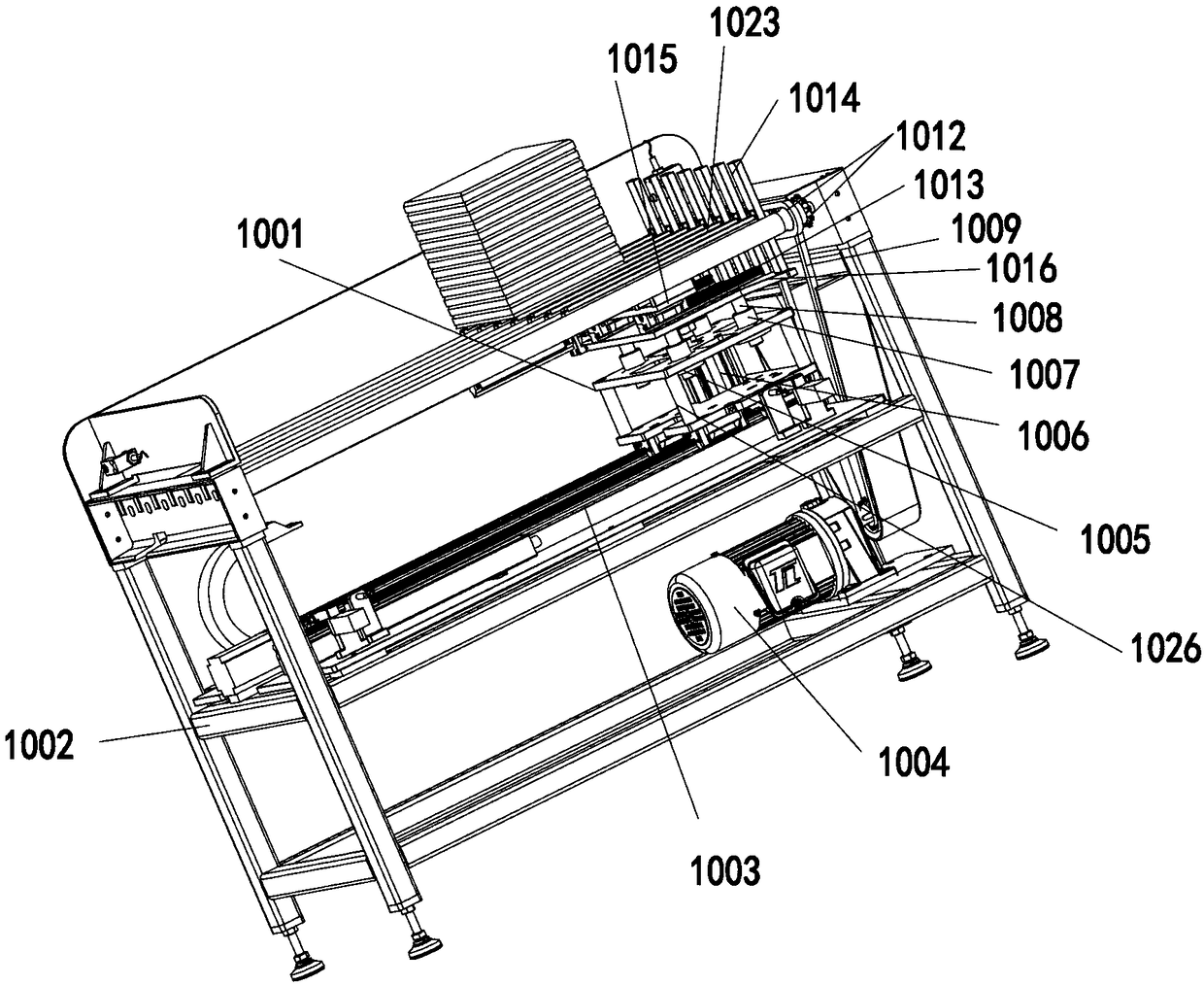

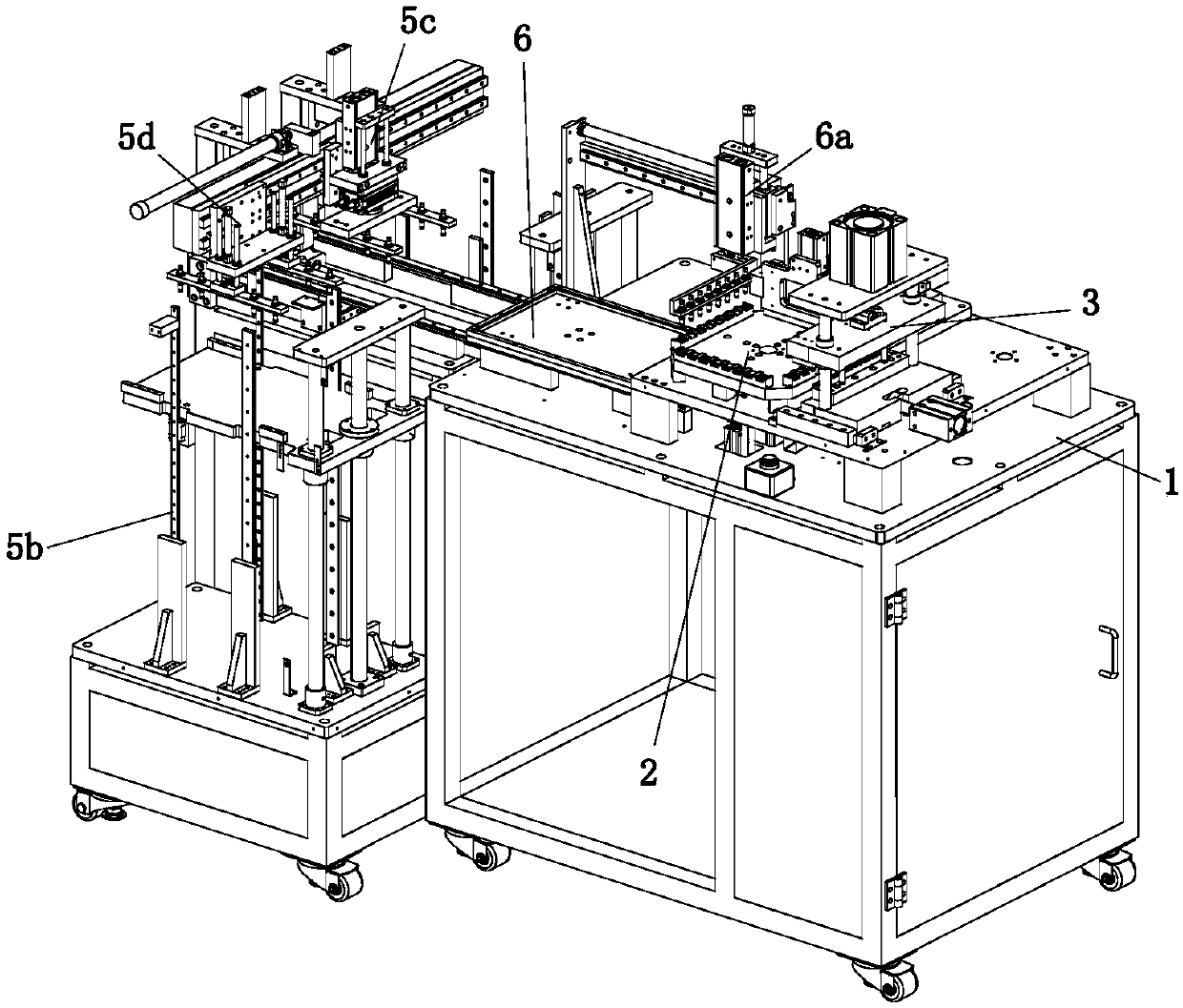

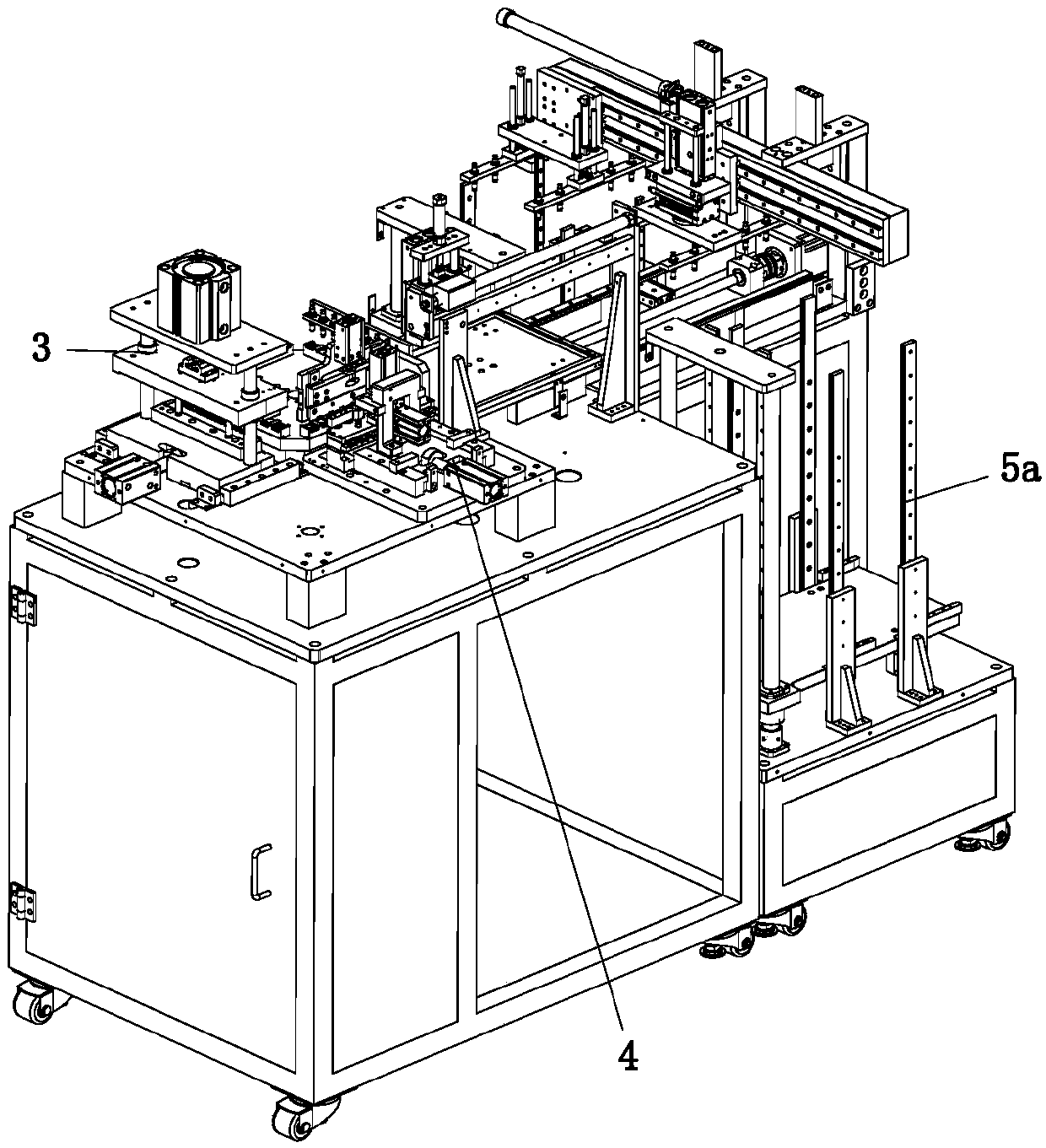

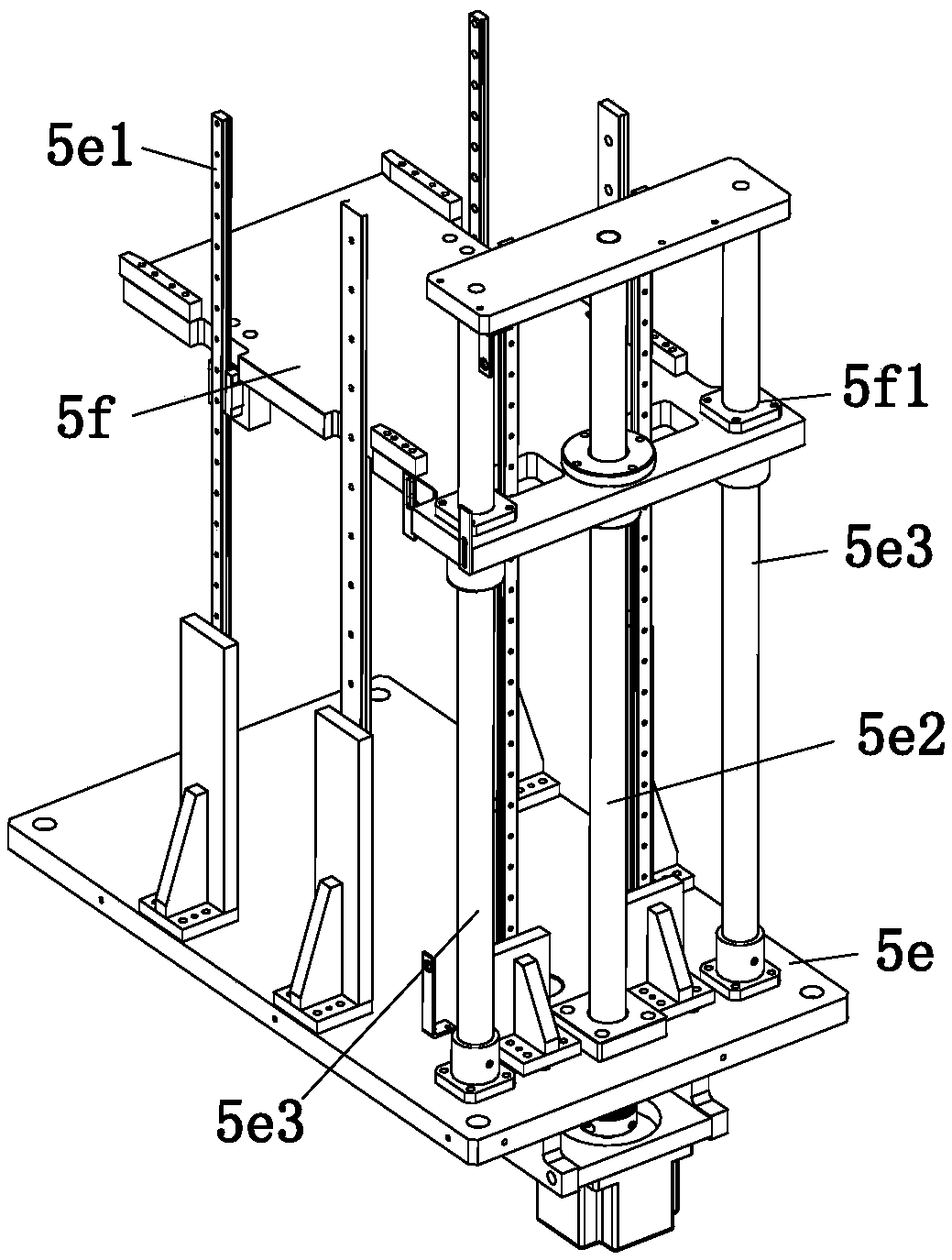

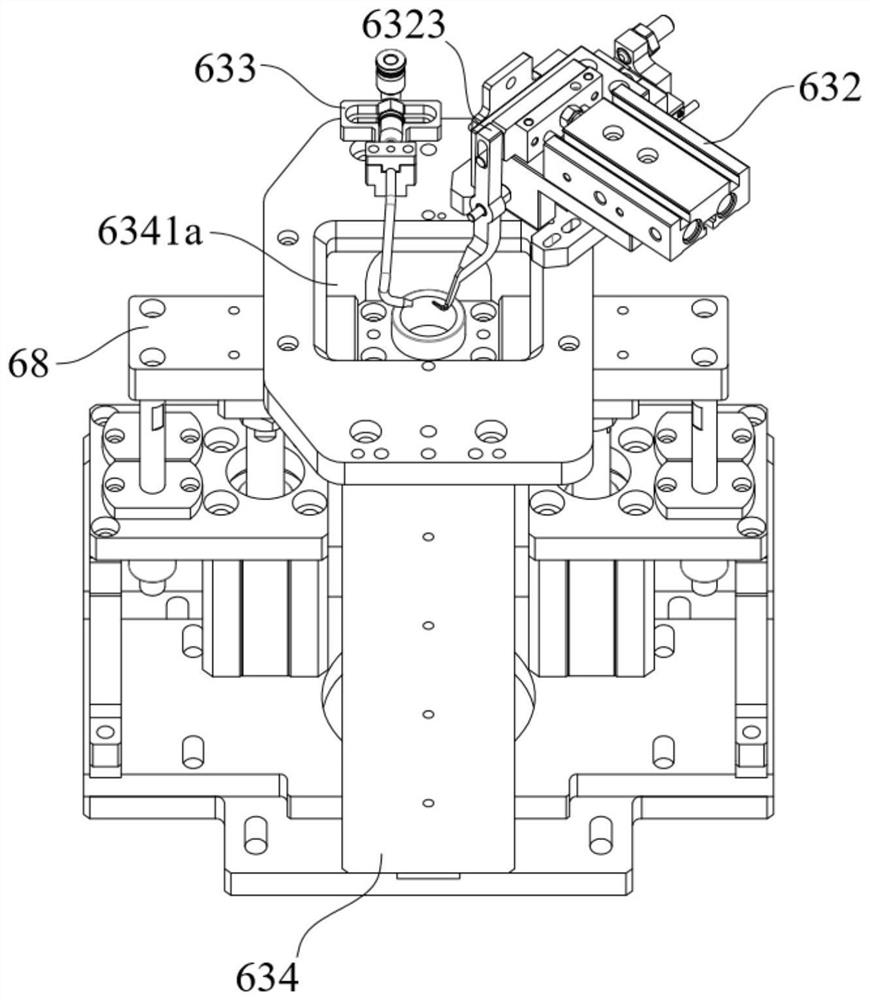

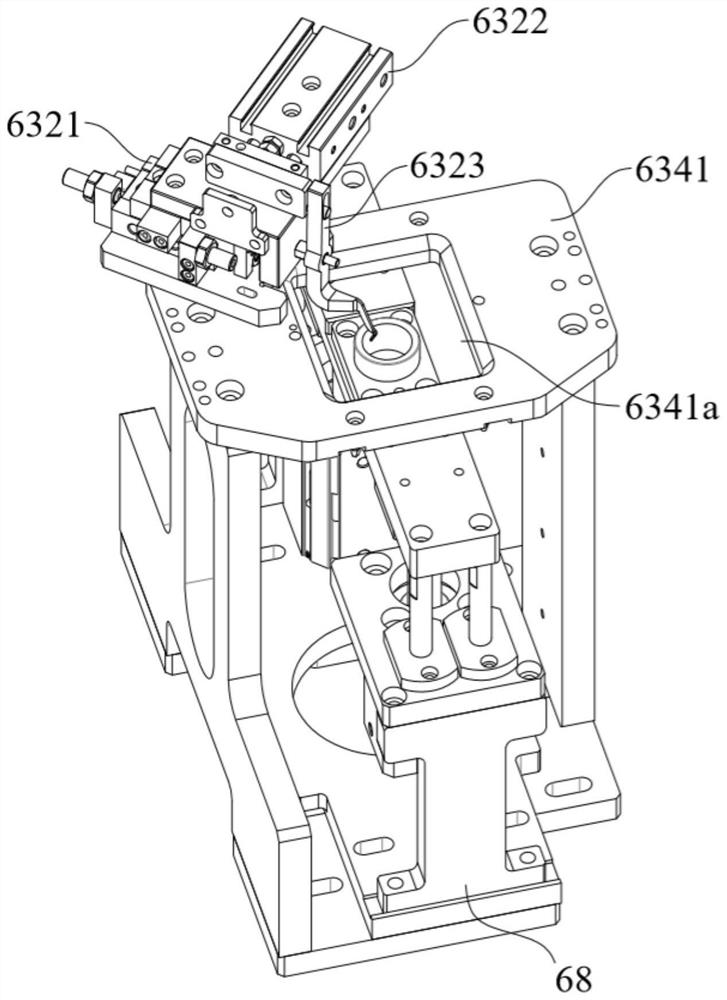

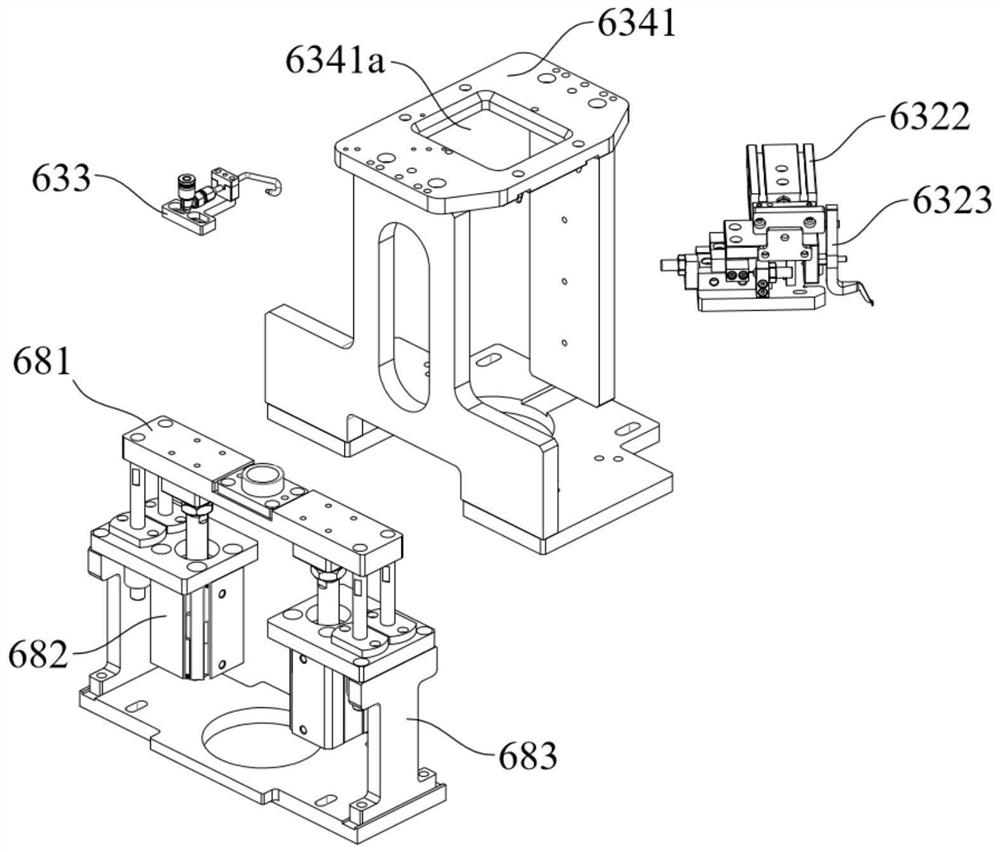

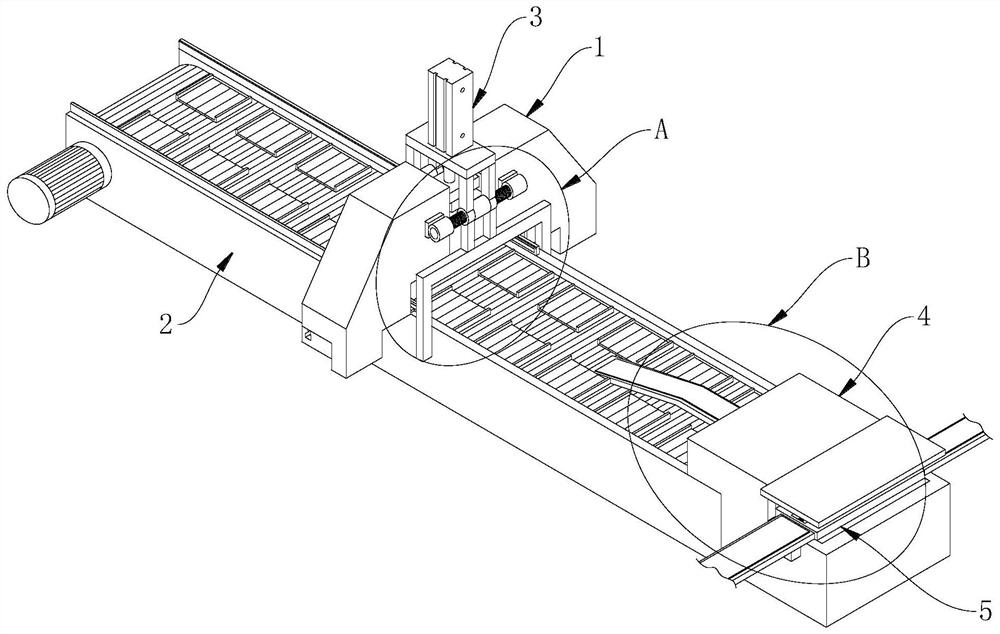

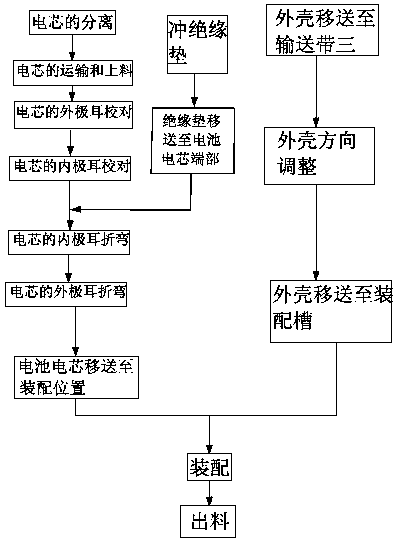

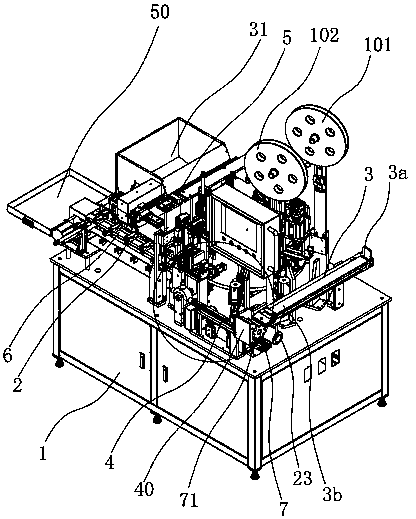

A lithium battery automatic packaging equipment

ActiveCN109132002BImprove work efficiencyReduce the use of laborPackaging by pressurising/gasifyingWrapper twisting/gatheringCartonMaterial transfer

The invention discloses automatic packaging equipment for lithium batteries. The automatic packaging equipment comprises an automatic feeding device, a foam storage bin, a material transfer gantry device, a PE bag automatic packaging device, a carton storage bin, a carton transfer gantry device, an automatic transfer folding ear device and an automatic box sealing and labeling device. The PE bag automatic packaging device, the automatic feeding device, the carton storage bin, the foam storage bin and the automatic box sealing and labeling device are enclosed to form a preliminary packaging area. A carrying platform of the PE bag automatic packaging device and the automatic transfer folding ear device are all installed in the preliminary packaging area for preliminary packaging. The outputposition of a preliminary packaging box on the automatic transfer folding ear device is butted with a box sealing inlet of the automatic box sealing and labeling device. The material transfer gantry device and the carton transfer gantry device are fixed above the preliminary packaging area in parallel, and the carton transfer gantry device is located above the box sealing inlet of the automatic box sealing and labeling device. By the adoption of the equipment, the labor cost is lowered, and the working efficiency is high and is increased by at least 5-8 times.

Owner:宁波格劳博智能工业有限公司

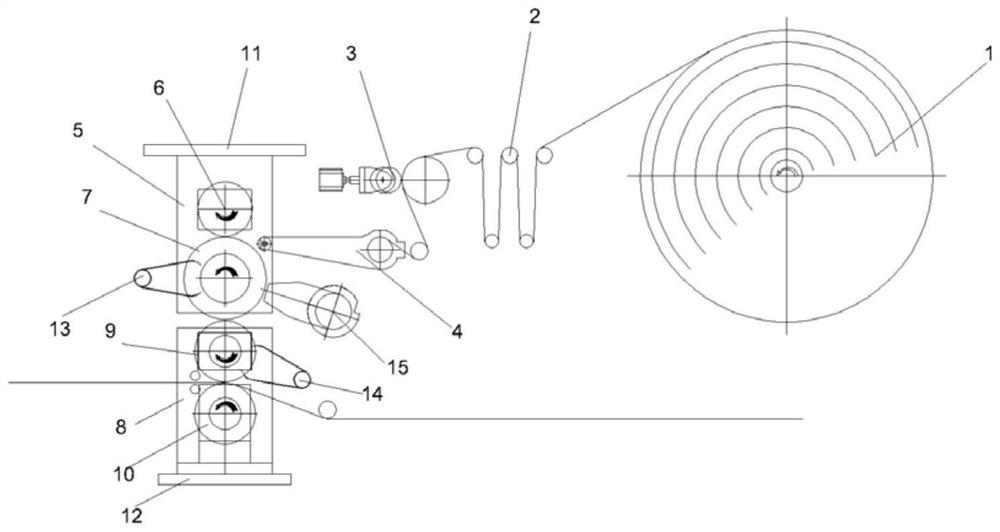

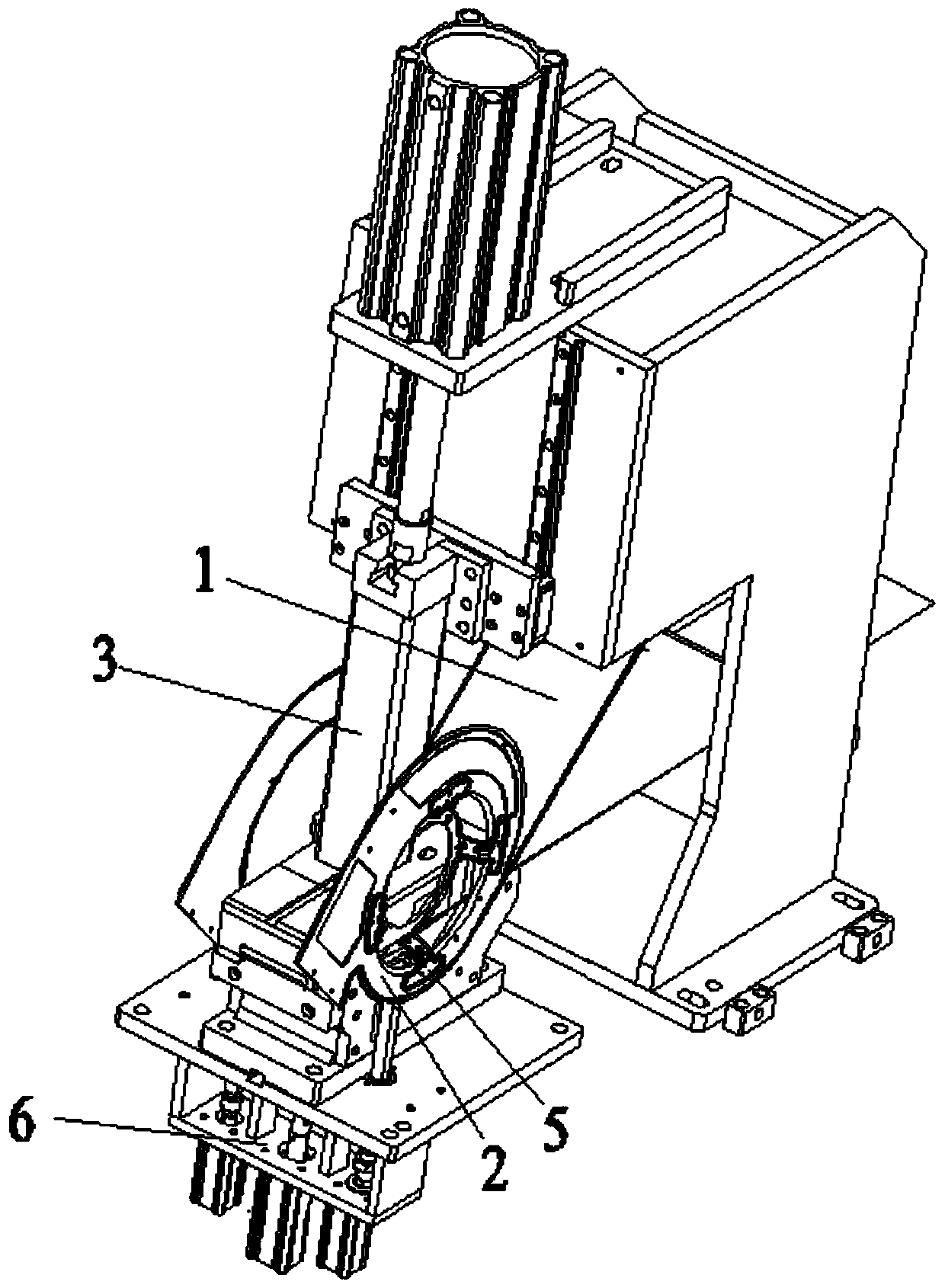

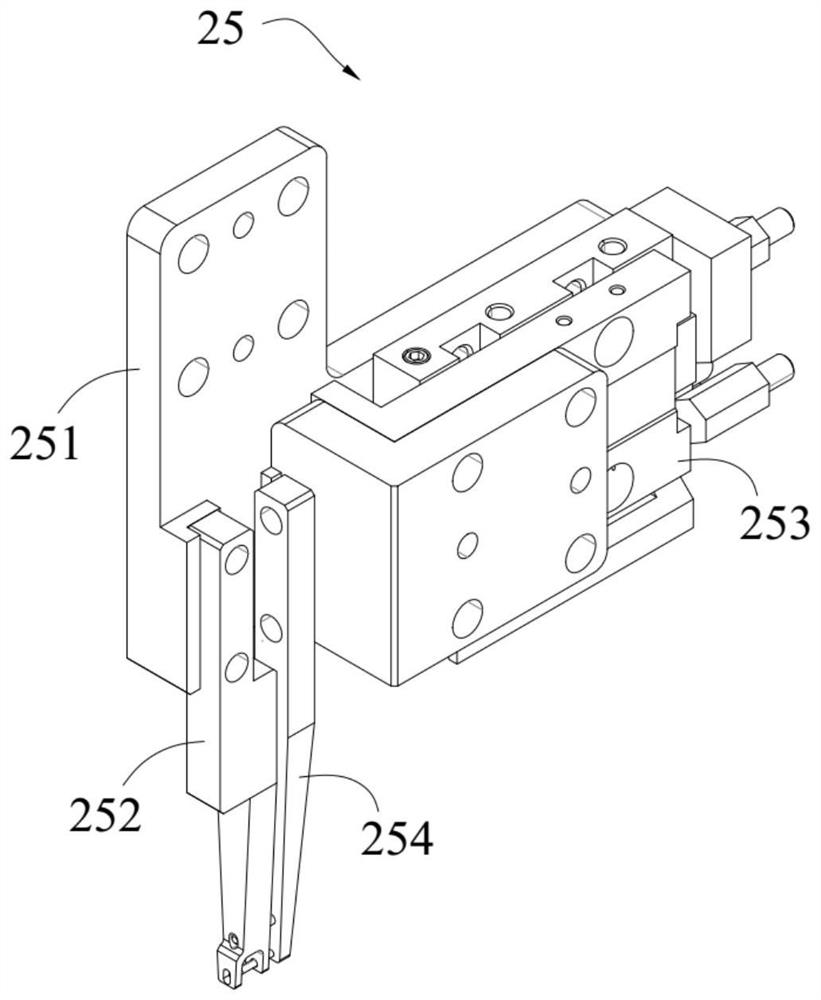

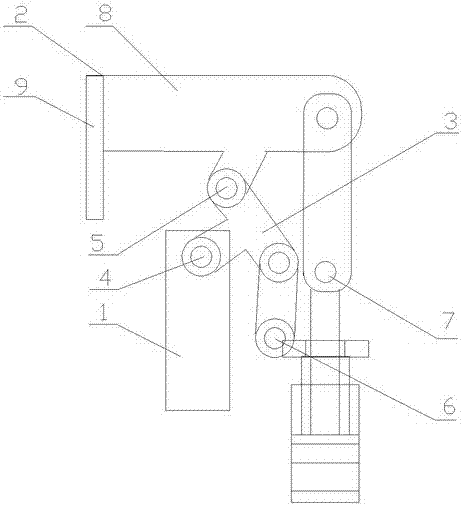

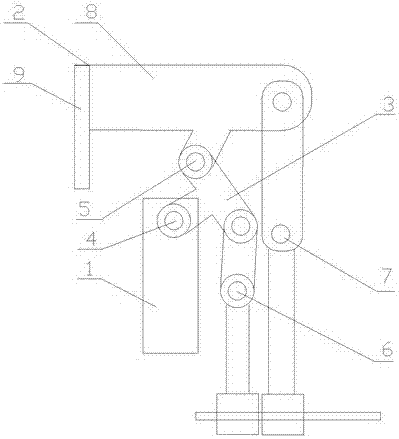

Power battery tab automatic bending mechanism and its working method

InactiveCN106583508BRapid BendingImprove automationPrimary cell manufactureFinal product manufacturePower batteryElectricity

The invention relates to an automatic bending mechanism for power battery tabs, comprising a frame workbench, an upfolding motor fixedly arranged on the upper side of the frame workbench, a downfolding motor fixedly arranged on the lower side of the frame workbench, and an upfolding motor The upper folded lug block driven and connected and the lower folded lug block driven and connected with the down folded motor; also includes a rotating motor fixedly arranged on the left or right side of the frame workbench, and a cover plate rotating device driven and connected with the rotating motor; The lower folded lug block is provided with a vertically upward lower insert, the upper folded lug block is provided with a vertically downward upper insert, and the lower insert is set opposite to the upper insert and staggered in the horizontal direction The distance is set; a control device is also included, and the control device is electrically connected with the folding up motor, the folding down motor and the rotating motor. This solution realizes rapid bending and forming of power battery tabs, which greatly improves the automation of folding tabs and bending of various tabs, which is conducive to improving the quality of folded tabs, improving equipment production efficiency, and reducing equipment costs.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Packaging apparatus and method

A method and apparatus are shown for securing a top for a cardboard carton where the carton has a bottom wall and integral sidewalls, an initially open interior and initially open top flaps with outwardly extending ears. The top flaps are folded to a carton closing position which closes off the initially open interior of the cardboard carton. The ears are also folded to a position in contact with the sidewalls of the carton. A set of punches are aligned with the folded ears of the carton and are actuated to force a first layer of cardboard from a respective top flap through an underlying region of the carton sidewall. A set of platens are located so as to underlie and reinforce the sidewalls of the carton as the punching operation takes place.

Owner:PLAINS DAIRY

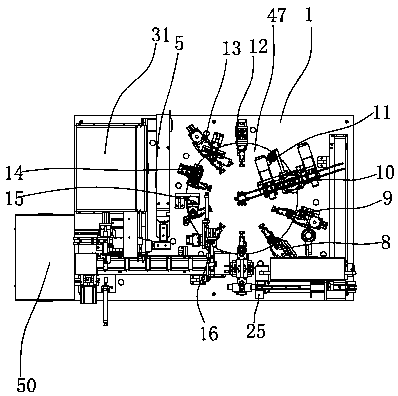

A power type cylindrical battery automatic casing machine

ActiveCN105304928BSimple structureSmall footprintPrimary cell manufactureAssembling battery machinesCircular discConveyor belt

The invention provides a power-type cylindrical battery automatic casing machine, which belongs to the technical field of battery manufacturing. It solves the technical problems such as the low degree of automation in the assembly of the existing cylindrical battery cells into the shell. The shelling machine includes a cabinet on which there are conveyor belts 1 and 2 capable of transporting batteries, conveyor belt 3 capable of transporting shells, and conveyor belt 4 capable of transporting battery carriers. The upper side of the rotating disc is provided with a number of clamping mechanisms capable of clamping the battery cells along the circumference of the rotating disc, and the cabinet is sequentially fixed with an external tab device, an internal tab device, Upper insulating pad device, folded inner lug device, folded outer lug device, defective product detection device and unloading device, the above-mentioned outer lug device, inner lug device, upper insulating pad device, inner lug device, outer pole Ear measurement device and folded outer pole ear device. The invention has the advantage of high degree of automation.

Owner:深圳市圣瀚宇自动化设备有限公司

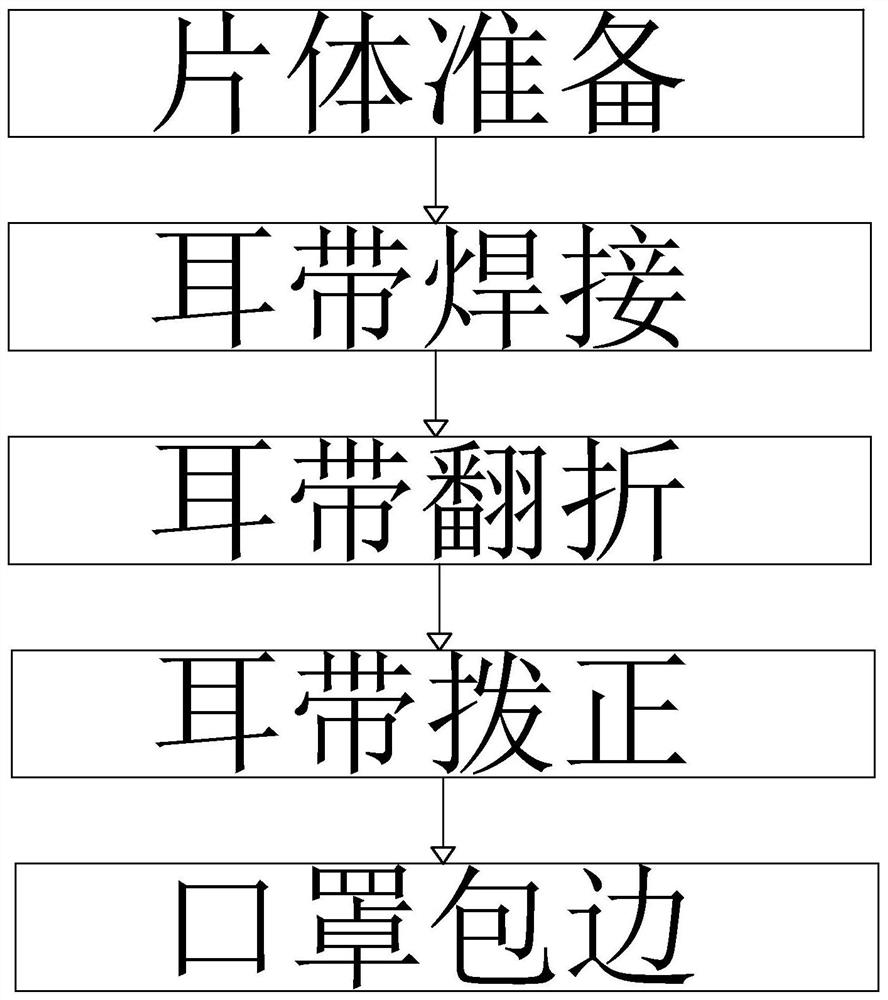

Processing process of ear band edge covering mask

PendingCN112932004AAvoid misalignmentProtective garmentClothes making applicancesEngineeringNonwoven fabric

The invention relates to the field of mask production and particularly relates to a process for processing a mask with edges wrapped by ear bands. The process comprises the following steps of preparing a sheet body, clamping melt-blown cloth between two layers of non-woven fabrics, and performing sheet making to form a single mask sheet body; lug belt welding, symmetrically welding lug belts at two ends of the sheet body in the length direction by using a lug belt welding part in a lug belt outer covering edge welding system; folding an ear belt, folding the ear belt to a surface body of the sheet body by using an ear folding part in the ear belt outer covering edge welding system; correcting the ear belt, correcting the part, positioned on one side of the sheet body advancing direction, of the ear belt by using an ear belt correcting part in the ear belt outer wrapping edge welding system; edge covering on the side edges, ear bands being welded, of the sheet bodies through edge covering parts in the ear band edge covering welding system. The process has effects of improving mask production efficiency and improving the mask quality.

Owner:湖北羽林自动化设备有限公司

A High Stability Architectural Aluminum Formwork

ActiveCN112227703BEasy to installGuaranteed anti-seepage effectAuxillary members of forms/shuttering/falseworksForming/stuttering elementsStructural engineeringMechanical engineering

Owner:湖南三湘和高新科技有限公司

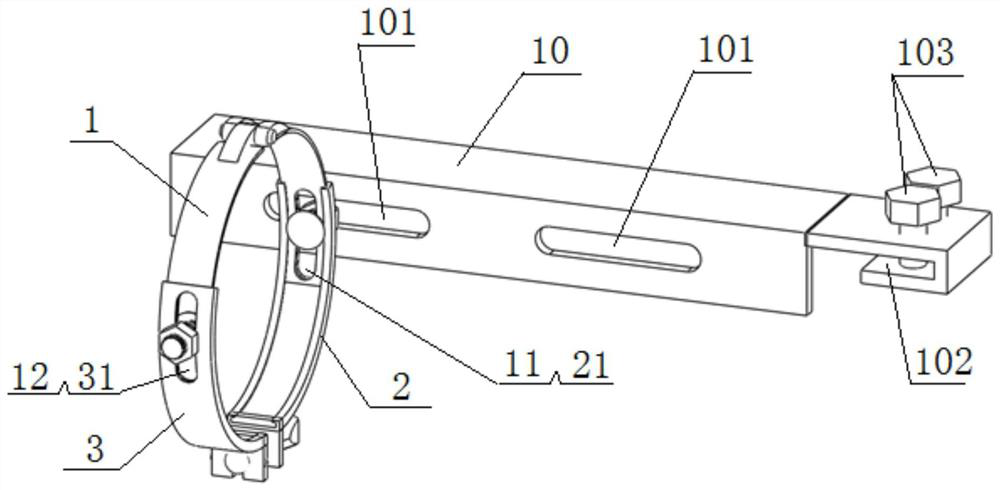

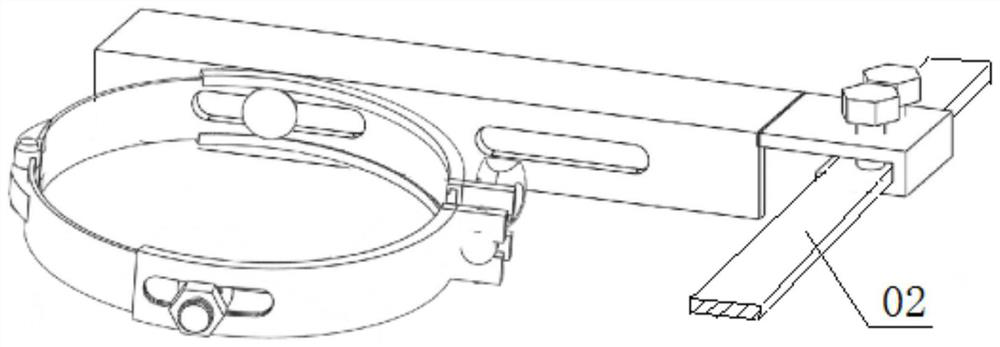

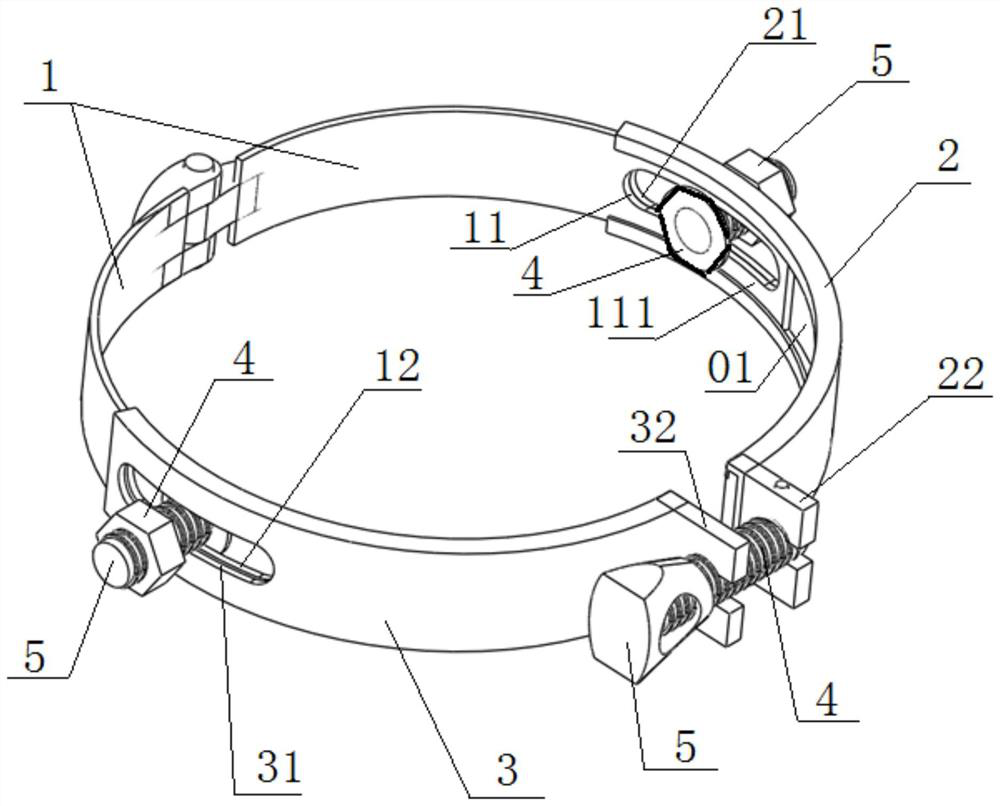

An adjustable cable fixing bracket

ActiveCN110739648BEasy to installEasy to fixElectrical apparatusStructural engineeringElectric cables

The invention discloses an adjustable cable fixing bracket, which includes a connecting frame and an adjustable hoop. The adjustable hoop includes a rear hoop, a front left hoop, and a front right hoop. Both ends of the rear hoop A first long adjustment slot and a second long adjustment slot are provided respectively, a third long adjustment slot is provided at the rear end of the front left hoop, a fourth long adjustment slot is provided at the rear end of the front right hoop, and a long adjustment slot is provided at the rear end of the front right hoop. The left hoop is connected to the rear hoop through the first locking member, the front right hoop is connected to the rear hoop through the second locking member, the front end of the front left hoop is provided with a left folding ear, and the front right hoop The right folded ear at the front end of the ring, the left folded ear and the right folded ear are connected by the third locking piece; the adjustable hoop is also installed on the connecting frame through the first locking piece or the second locking piece, and the connecting frame is provided with Connector designed to match external firmware. In this solution, the caliber can be adjusted by adjusting the cooperation between the long groove and the first locking member. At the same time, it cooperates with the design of the locking part to realize the orientation adjustment of the hoop.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com