A box-making intelligent mold-adjusting and forming machine

An all-in-one, intelligent technology, applied in the direction of container manufacturing machinery, box making operations, rigid/semi-rigid container manufacturing, etc., can solve problems such as low coordination, inaccurate positioning, and low efficiency, and achieve efficiency and coordination The effect of improvement, accurate positioning and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

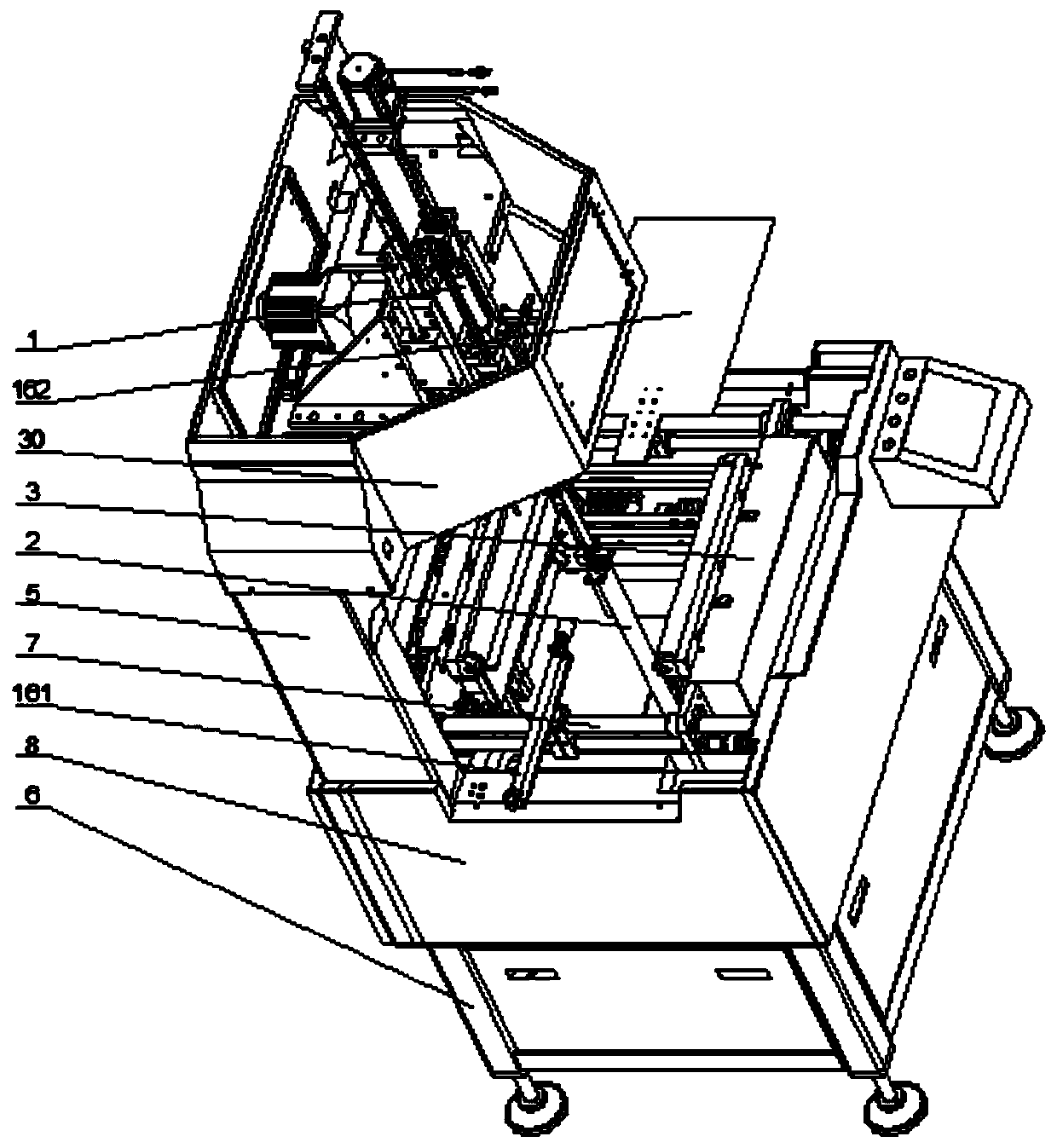

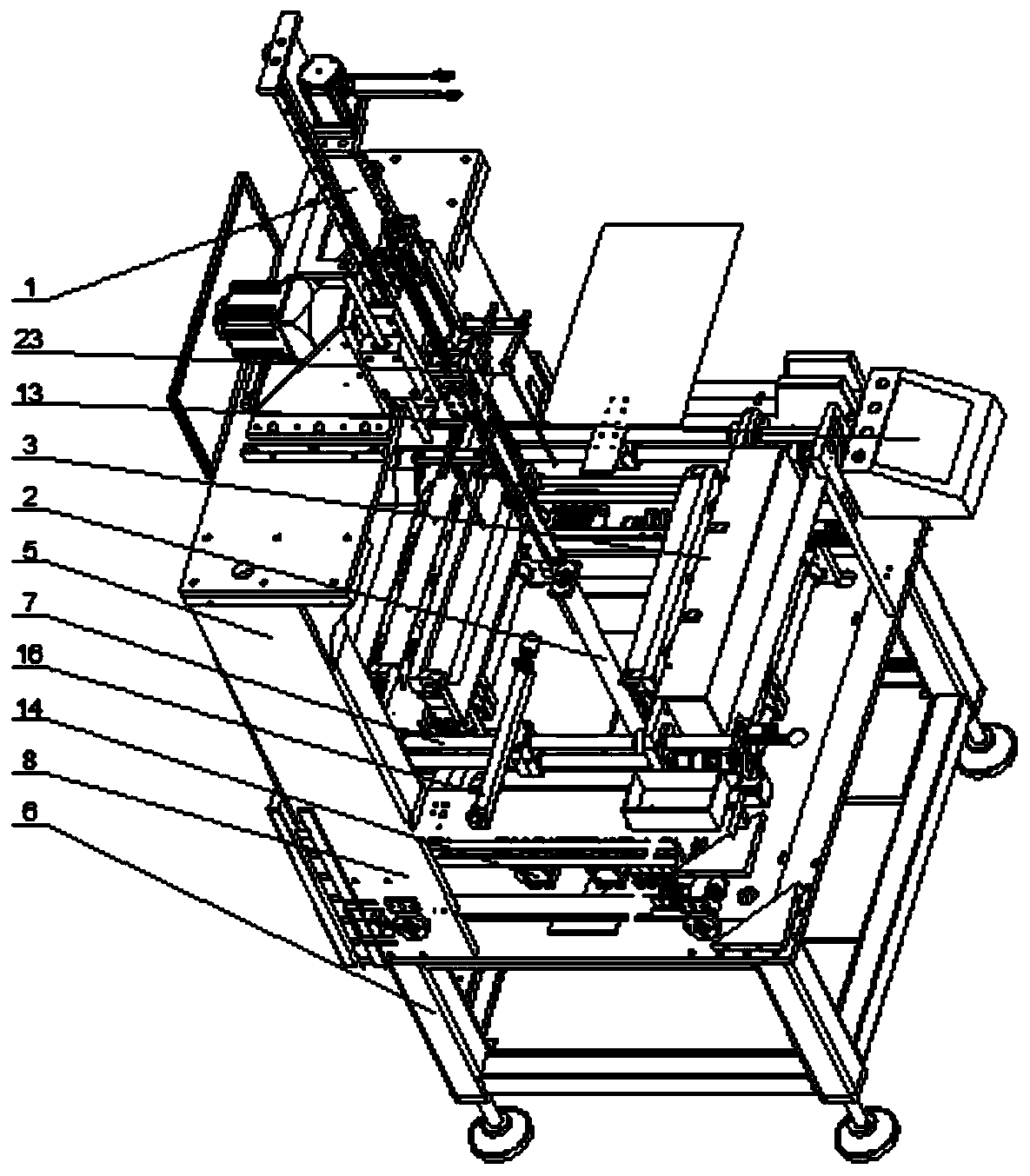

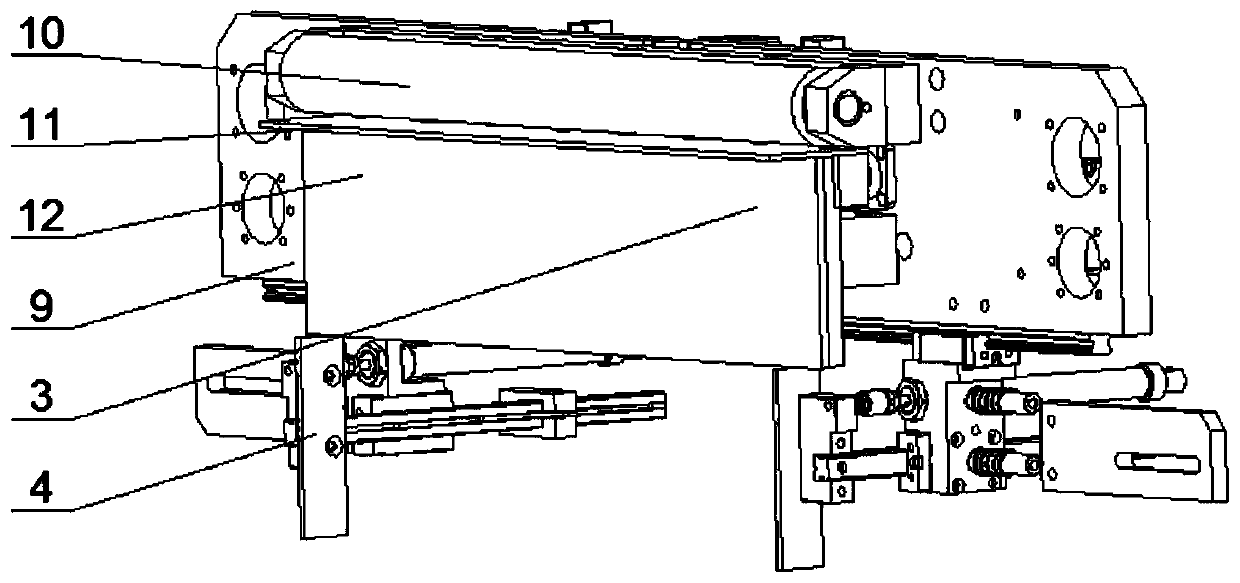

[0044] Such as Figure 1~6As shown, the box-making intelligent mold-adjusting and forming integrated machine according to the present invention includes an upper mold device 1, a top mold device 2, a first group of vertical edge folding and pressing bubble devices 3, and an ear folding device 4; the upper mold device 1 is arranged in the upper middle part of the whole machine through the support column 5, and the top mold device 2 is arranged in the lower middle part of the whole machine through the lower frame 6 in accordance with the upper mold device 1; the first group of vertical edge folding There are two side pressure bubble devices 3, which can be symmetrically arranged front-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com