Processing process of ear band edge covering mask

A processing technology and outsourcing edge technology, which is applied in the field of earband outsourcing edge mask processing technology, and can solve the problems of folding on the sheet body and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

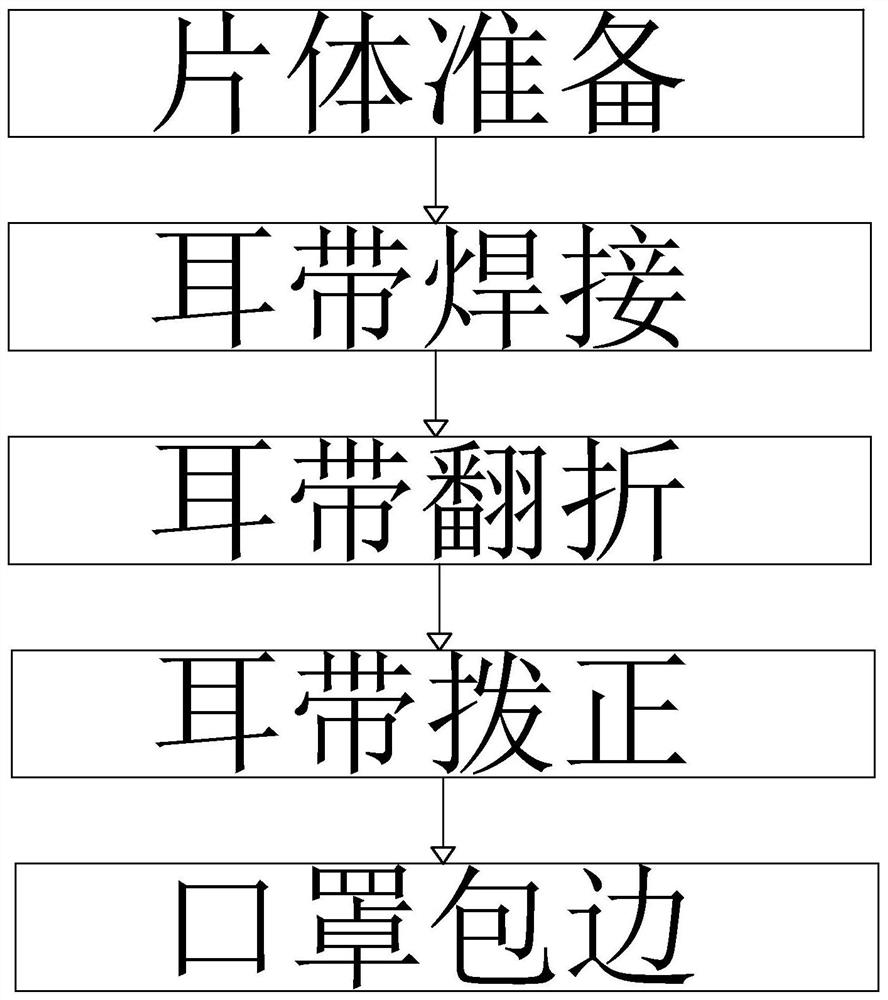

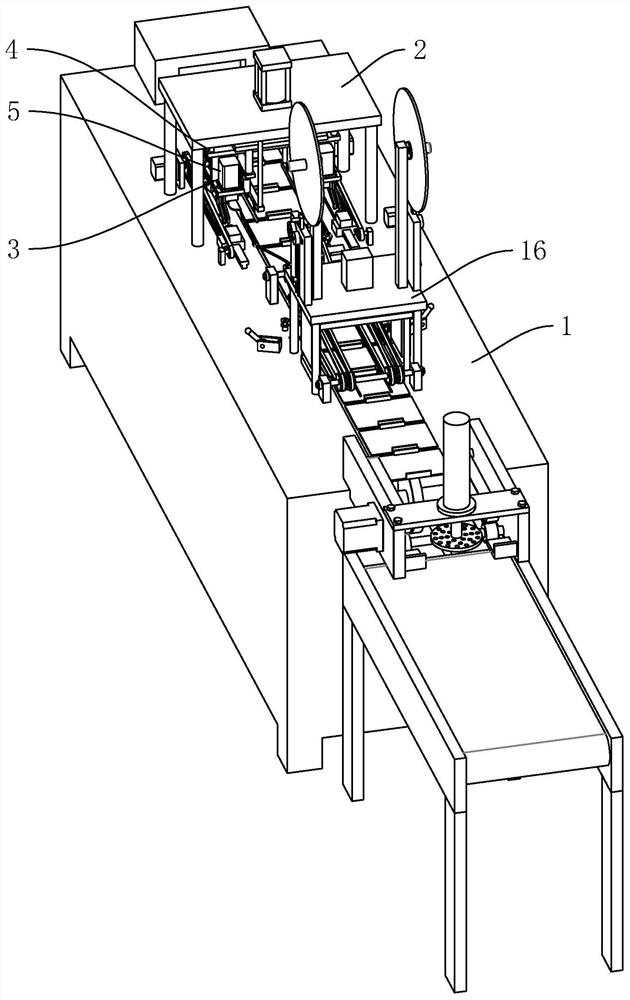

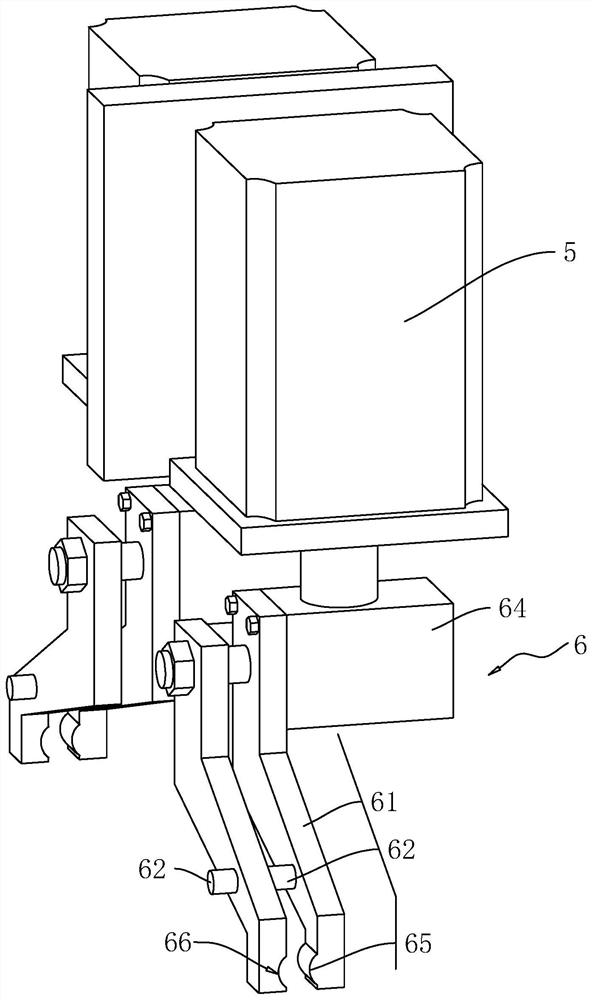

[0062] The following is attached Figure 1-8 The application is described in further detail.

[0063] The embodiment of the present application discloses a process for processing a mask with ear loops and edges. refer to figure 1 , the processing technology of the mask with ear straps outsourcing includes the following steps:

[0064] S1: sheet preparation, the melt blown cloth is sandwiched between two layers of non-woven fabrics, so that the three are stacked together to obtain a continuous long mask sheet, this step is usually used in the specific production process Mask punching machine to achieve, mask punching machine can produce the required mask sheet.

[0065] S2: Ear strap welding, use the ear strap welding part in the ear strap outsourcing welding system to weld the ear straps symmetrically at both ends of the piece in the length direction;

[0066] S3: Fold the ear straps, and use the ear strap folding part in the ear strap outsourcing welding system to fold th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com