Mask machine folding ear belt forming mechanism and forming method thereof

A molding mechanism and a technology for folding ears, which are applied to other household appliances, household components, tools for sewing clothes, etc., can solve problems such as affecting product quality, affecting production efficiency, and affecting the alignment accuracy of ear straps and mask bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

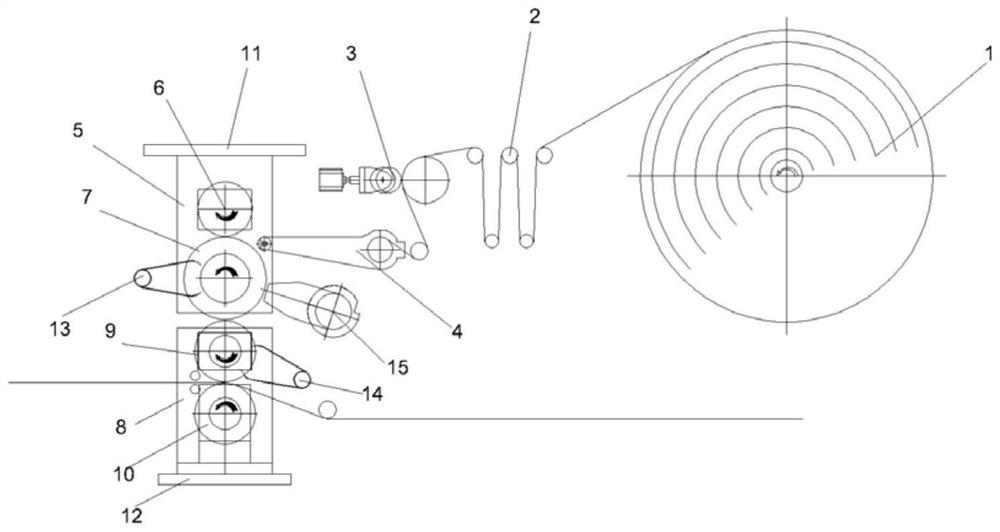

[0023] like figure 1 As shown, a folding earband forming mechanism of a mask machine includes an earband fabric uncoiling device 1, a tension swing rod assembly 2 that cooperates with the earband fabric uncoiling device 1, an active pinch device 3, and a conveying wind for conveying earband fabrics. Bucket 4, a slitting knife box for cutting the earband fabric and a hot-pressing knife box for hot-pressing the earband to the filter fabric, the slitting knife box is located above the hot-pressing knife box, and the hot-pressing knife box The knife box and the slitting knife box are connected with each other. The tension swing rod assembly 2 is located between the earband fabric unwinding device 1 and the active pinch device 3. It is used to detect and adjust the conveying tension of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com