Power battery tab automatic bending mechanism and its working method

A power battery and bending mechanism technology, which is applied in the manufacture of primary batteries, battery pack components, secondary batteries, etc., can solve problems such as inconsistent size, low efficiency, and unstable tabs of manual folding, and achieve product quality improvement , Improving automation and improving equipment production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

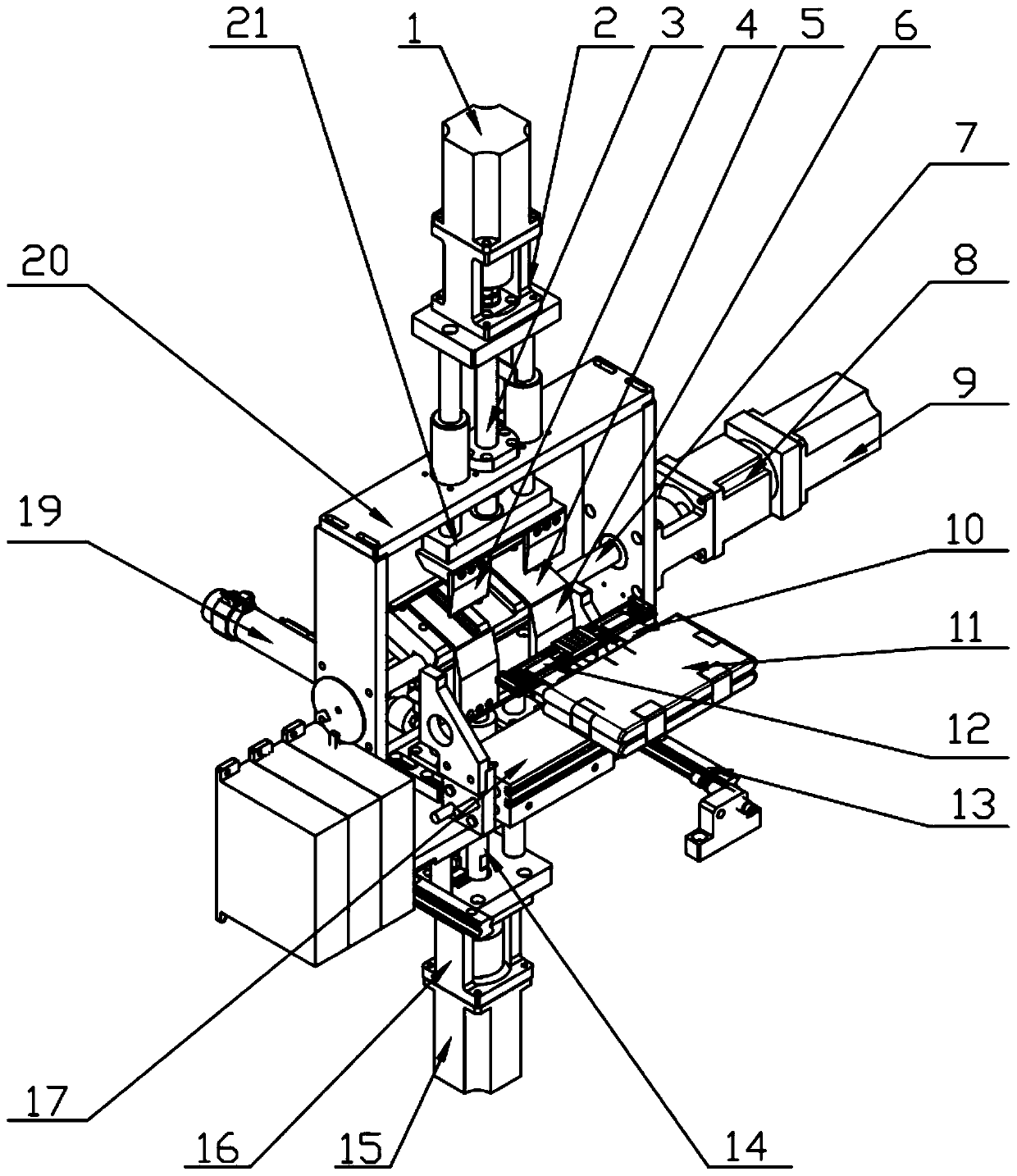

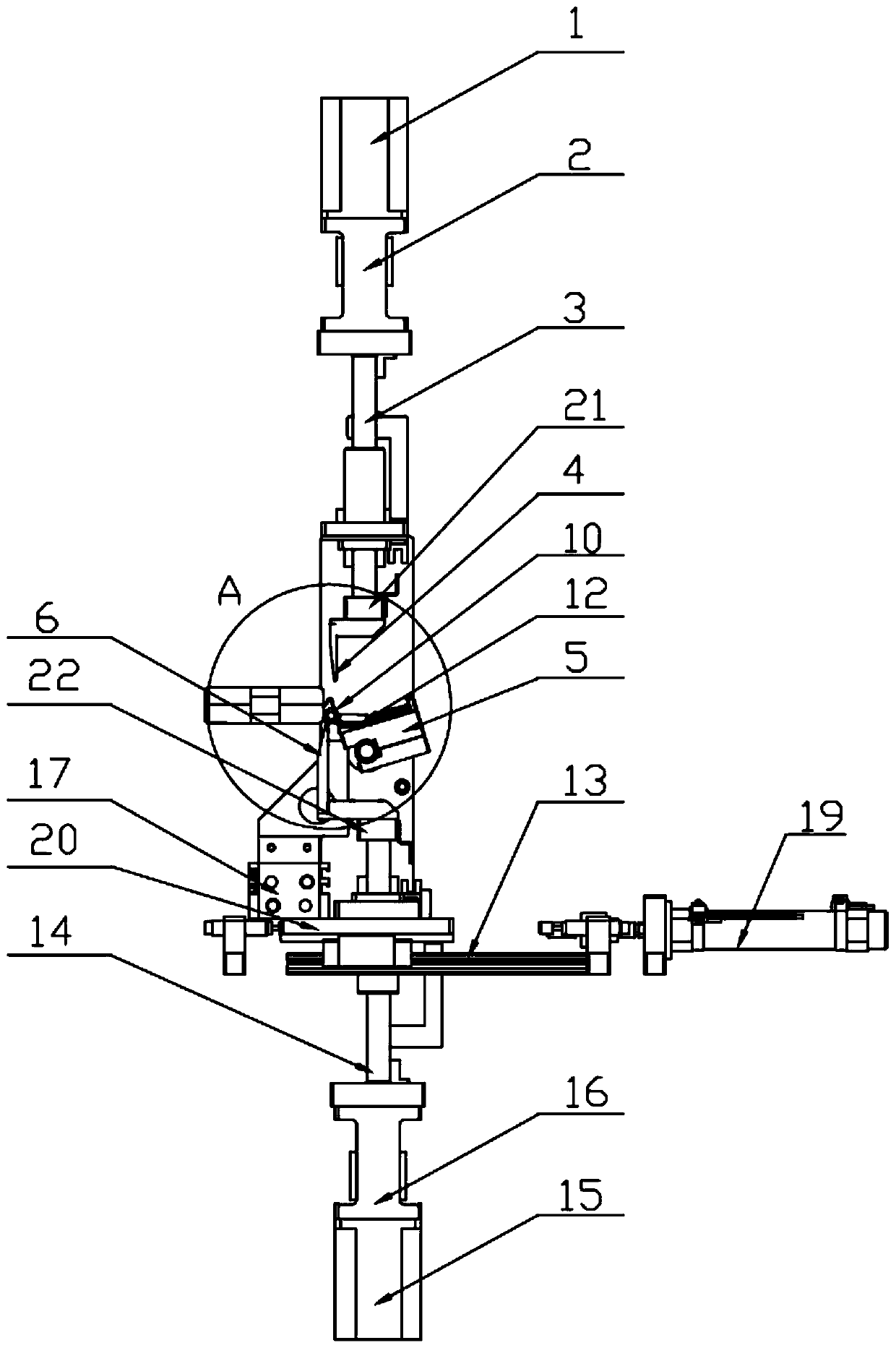

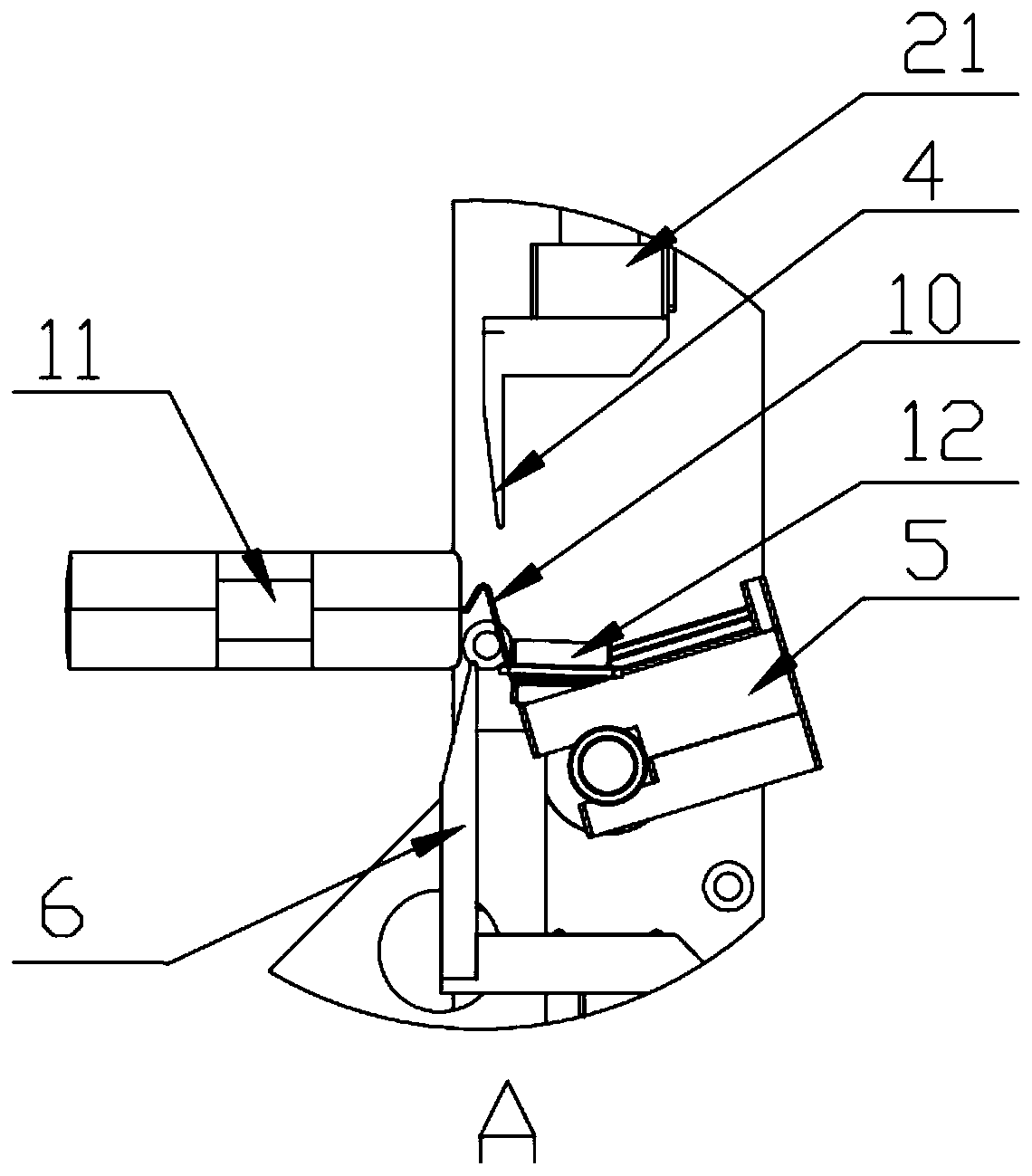

[0030] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides an automatic bending mechanism for power battery tabs, including an upfolding motor 1, a downfolding motor 15, a frame workbench 20, a rotating motor 9, an upfolding tab block 21, and a downfolding pole Ear piece 22, cover plate rotating device 5.

[0031] It is assumed here that the frame workbench 20 is placed in a vertical direction, and the frame workbench 20 is generally arranged in a vertical direction in actual work. The upfolding motor 1 is fixedly arranged on the upper side of the frame workbench 20, and the upfolding motor 1 is drivingly connected to the upfolding lug block 21; the downfolding motor 15 is fixedly arranged on the frame working On the lower side of the platform 20 , the down-folding motor 15 is drivingly connected to the dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com