Portable lead wire end bender

A portable, bender technology, applied in the field of electrical equipment, can solve the problems of inconvenient adjustment of the radius of the bend, difficulty in accurately controlling the central angle, etc., to achieve the effect of simple structure and rapid bending and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

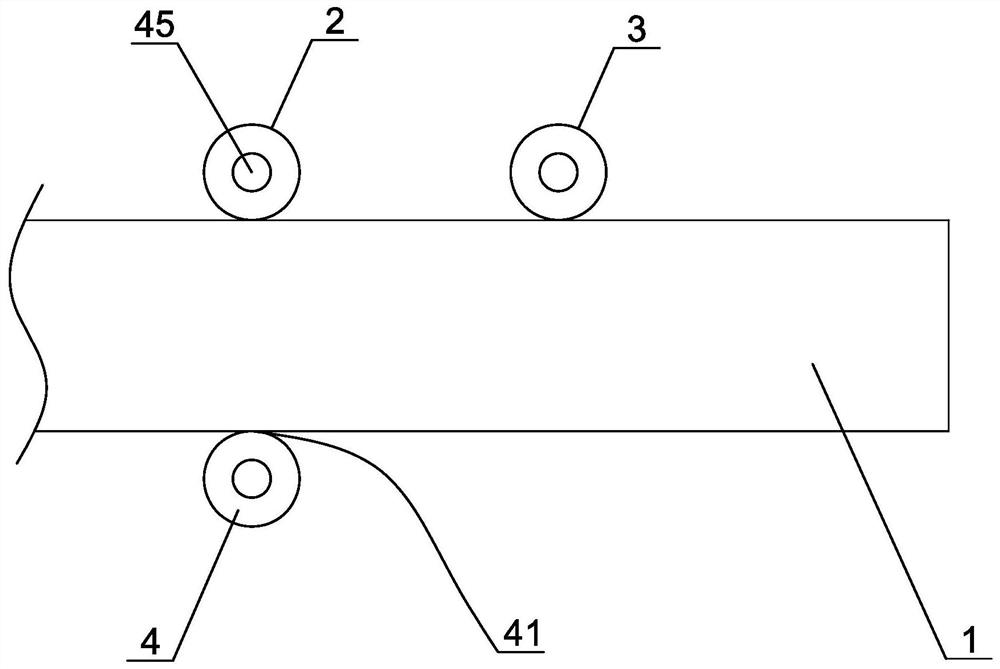

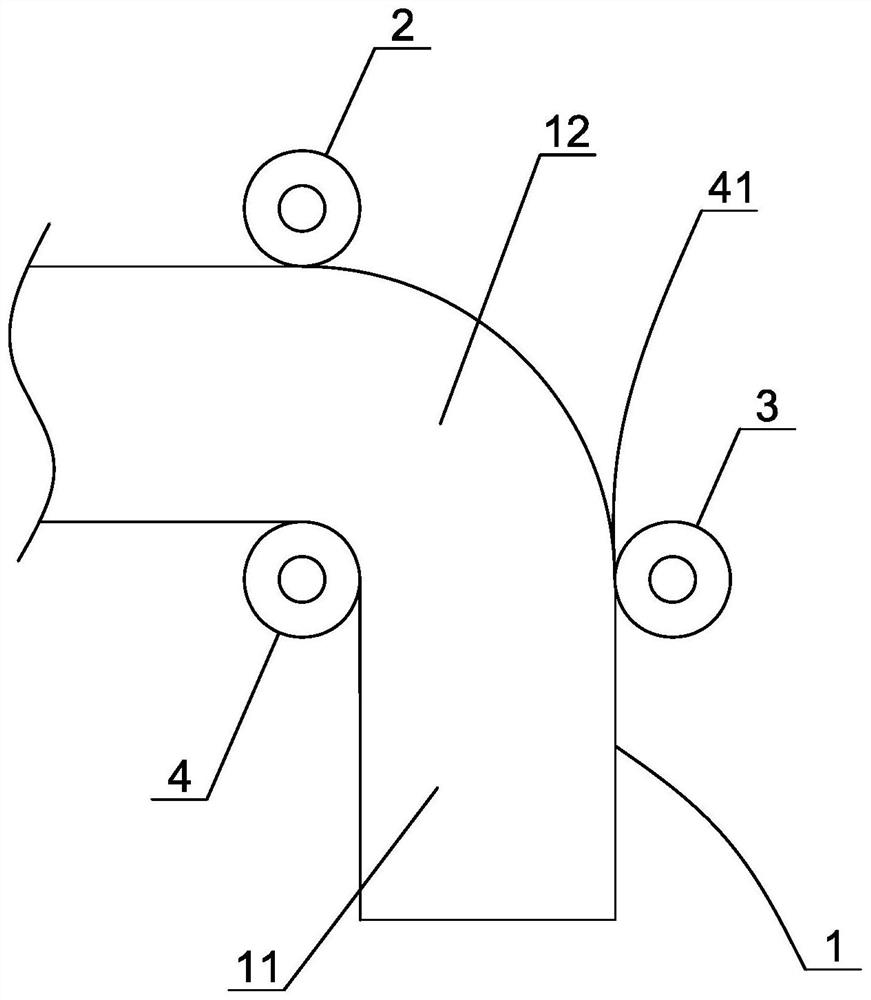

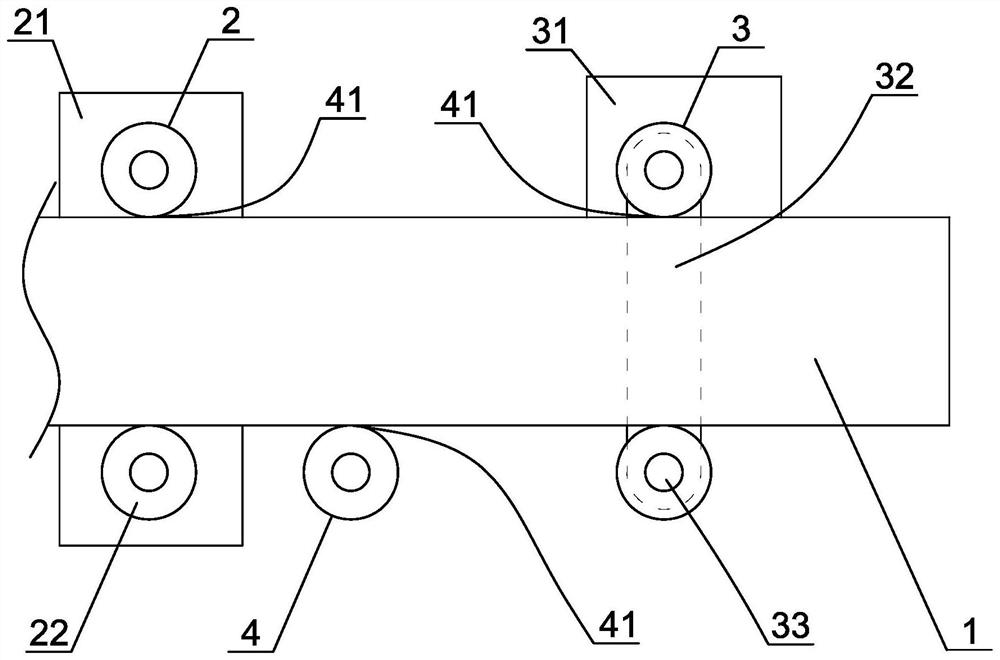

[0029] Such as figure 1 , figure 2 As shown in the figure, a portable lead wire end bender is suitable for arc bending treatment of exposed lead wire ends after stripping off the insulation layer of cables and the like. It specifically includes a first outer pressure wheel 2, a second outer pressure wheel 3, and an inner pressure wheel 4. In addition, it also includes a lead wire clamping device (not shown) that can fix and clamp the lead wire head. Of course, the first outer pressure wheel The axes of the pressure roller, the second outer pressure roller and the inner pressure roller should be parallel to each other. The first outer pressure wheel and the second outer pressure wheel are respectively associated with a linear drive mechanism, so that the first outer pressure wheel can move in the first direction, and the second outer pressure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com