A bra support shaping device

A shaping device and steel support technology, which is applied in the field of bra steel support, can solve problems such as low efficiency and inaccurate bending radian, and achieve the effects of improving efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

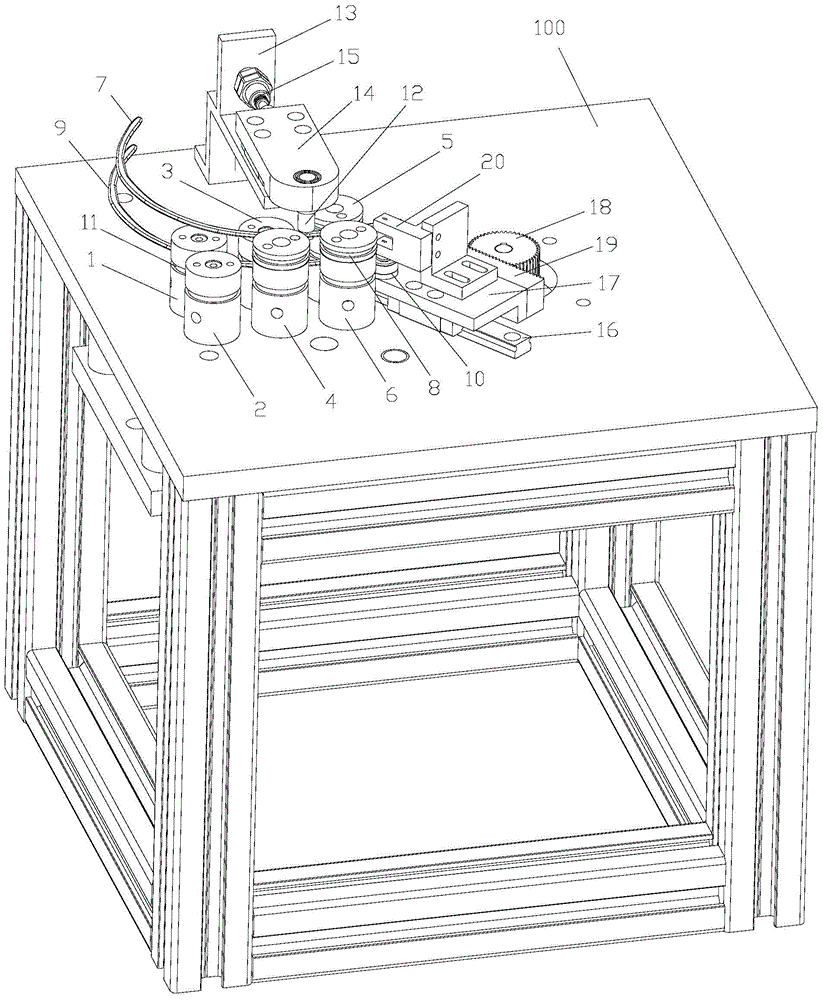

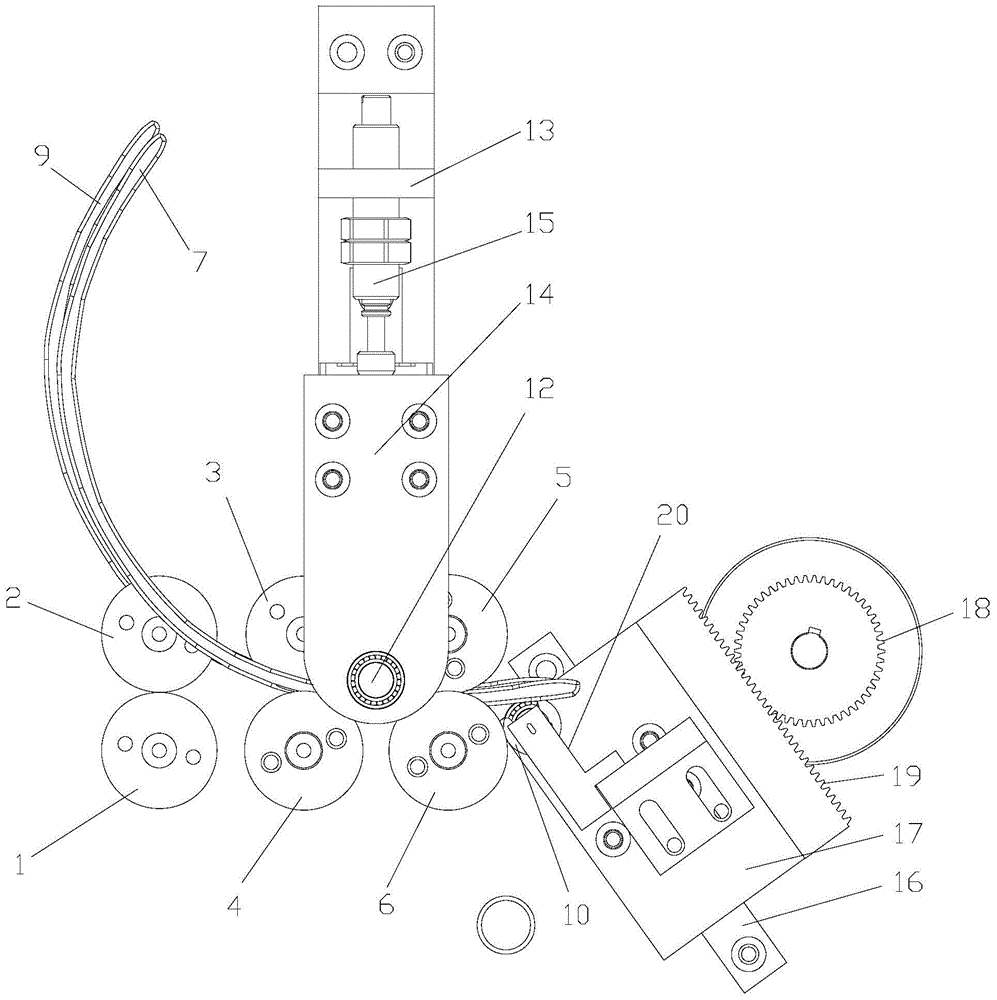

[0025] see figure 1 and 2 , the bra underwire shaping device of the first embodiment includes an underwire bending part, and the underwire bending part is installed on the operating table 100 . The bending part of the steel support includes a first wheel set, a second wheel set and a third wheel set arranged at intervals in sequence, and the first wheel set includes a first transmission wheel 1 and a second transmission wheel 2 matched left and right, so The second set of wheels includes the third transmission wheel 3 and the first positioning wheel 4 that cooperate left and right, and the third set of wheels includes the first bending wheel 5 and the second positioning wheel 6 that cooperate with the left and right; the first positioning wheel 4, The outer peripheral surfaces of the second positioning wheel 6 and the first bending wheel 5 are respectively provided with upper positioning grooves 8 at the same height for transferring standard steel brackets 7 . The bending pa...

Embodiment 2

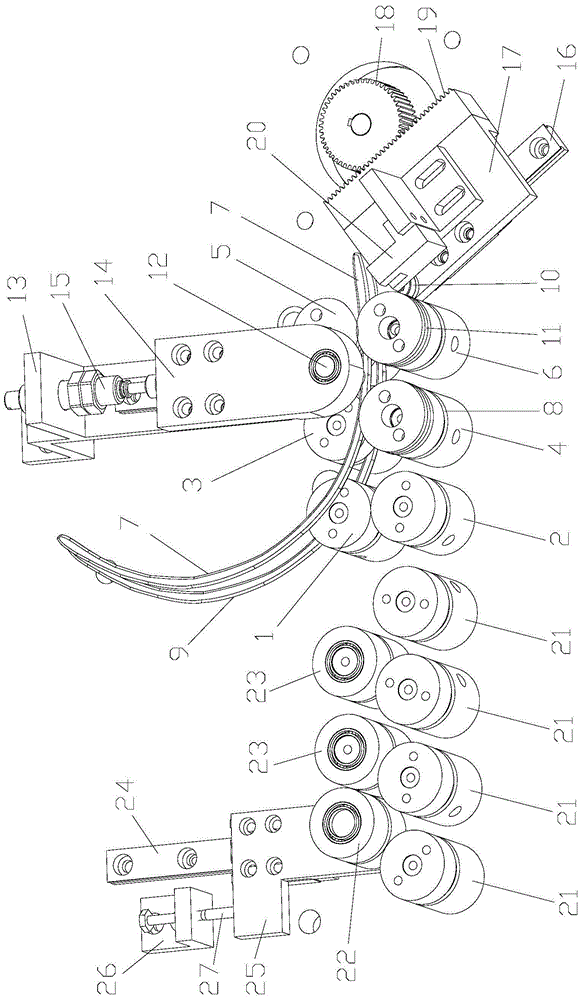

[0032] see image 3 In addition to the underwire bending part of the first embodiment, the bra underwire shaping device of the second embodiment also includes an underwire straightening part, and both the underwire straightening part and the underwire bending part are installed on On the same operating platform, the steel support 9 to be shaped can be roughly straightened by the straight part of the steel support, and then bent and formed by the bending part of the steel support. The straightening part of the steel support car includes a plurality of adjustment wheels 21 on the right side, a tensioning wheel 22 and a plurality of straightening transmission wheels 23 on the left side.

[0033] A plurality of adjustment wheels 21 are arranged at intervals from back to front along the same straight line, and the number of adjustment wheels 21 in this embodiment is four.

[0034] The tension wheel 22 is staggered and arranged on the left side between the two adjustment wheels 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com