A lithium battery automatic packaging equipment

A lithium battery, automatic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high labor cost, high labor intensity, and low work efficiency, so as to reduce labor cost, improve work efficiency, and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

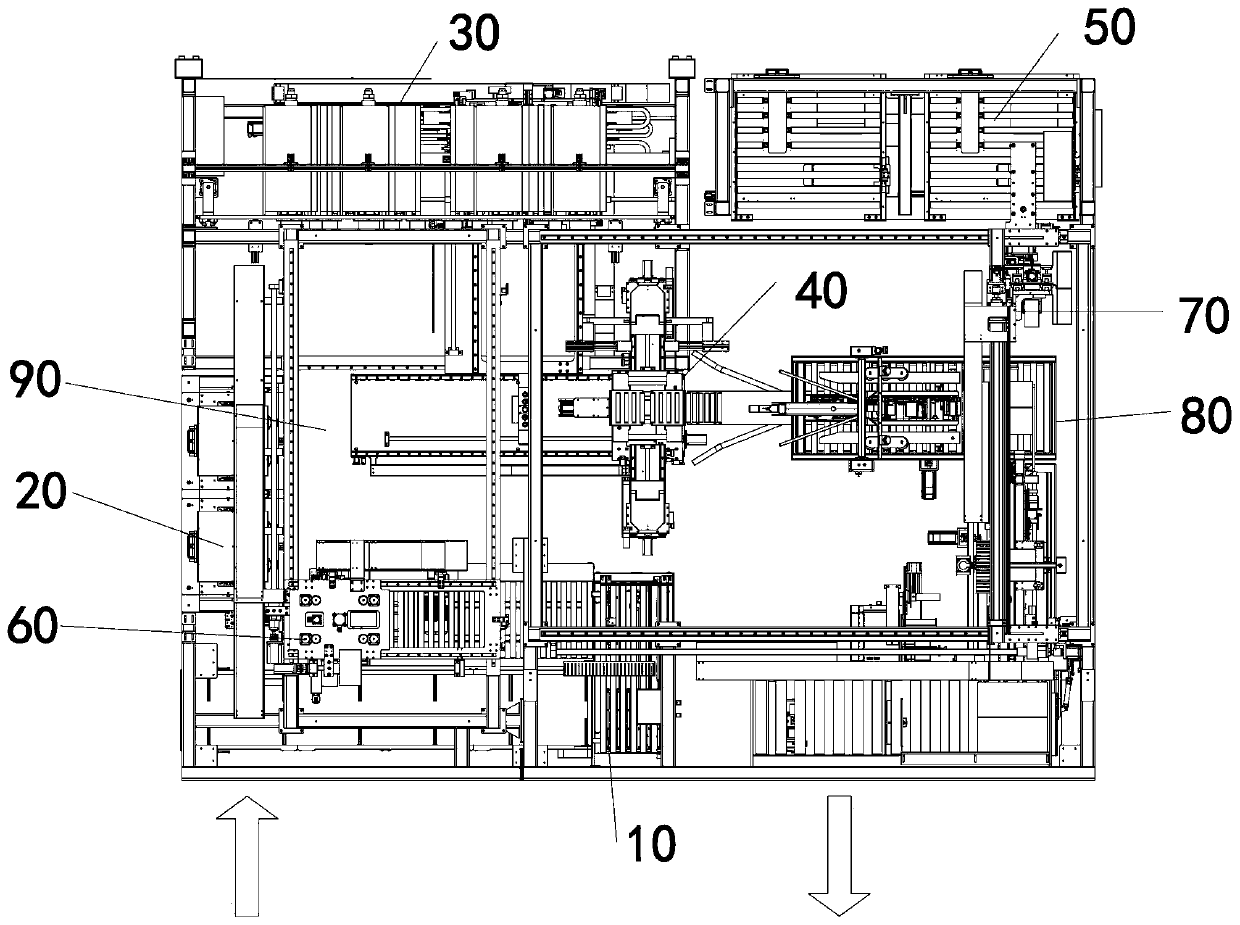

[0070] Such as figure 1 As shown, a lithium battery automatic packaging equipment described in this embodiment includes an automatic feeding device 10, a foam bin 20, a material transfer gantry device 60, a PE bag automatic packaging device 30, a carton bin 50, a carton Transfer gantry device 70, automatic transfer and folding device 40, automatic sealing and labeling device 80; PE bag automatic packaging device 30 and automatic feeding device 10 form the preliminary packaging of lithium battery materials packaged in PE bags together with foam In the primary packaging area 90 in the carton, a carton hopper 50 is set beside the PE bag automatic packaging device 30; a foam silo 20 is set on one side of the primary packaging area 90, and an automatic sealing and labeling device 80 is set on the other side; The transfer platform of the PE bag automatic packaging device 30 and the automatic transfer and ear folding device 40 are all installed in the primary packaging area 90, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com