Programmable cylinder-driven carton machine with forming and inward-folding function

A cylinder-driven, carton machine technology, which is applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of inability to fold the inner edge to the bottom, fewer product specifications, and high equipment manufacturing costs, so as to improve efficiency, The effect of low production cost and large ear size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

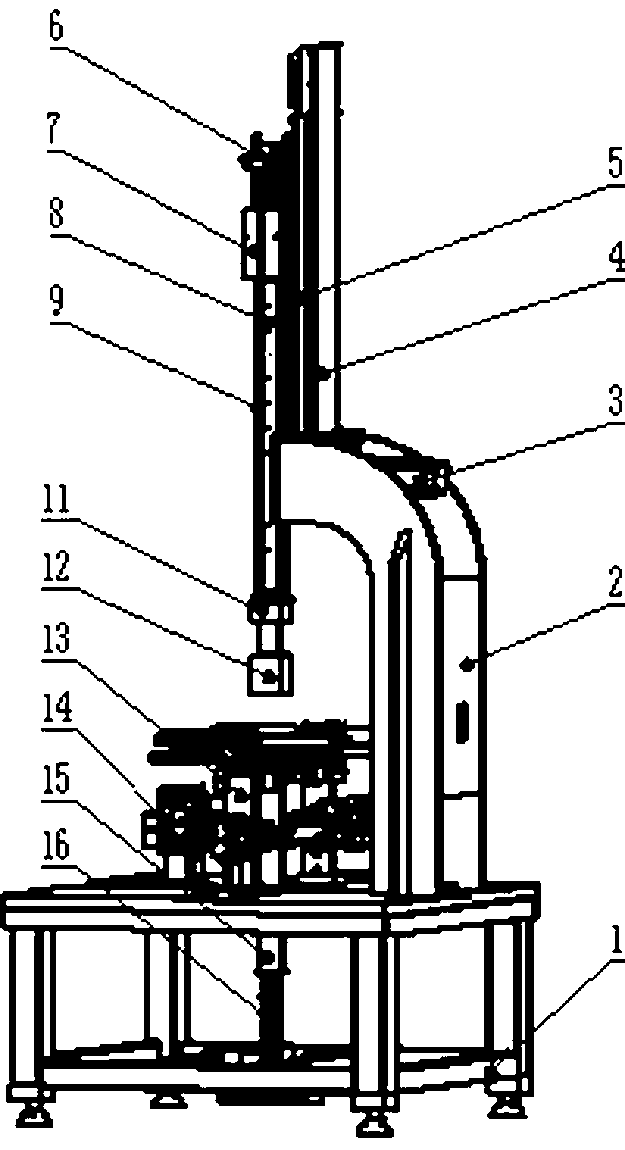

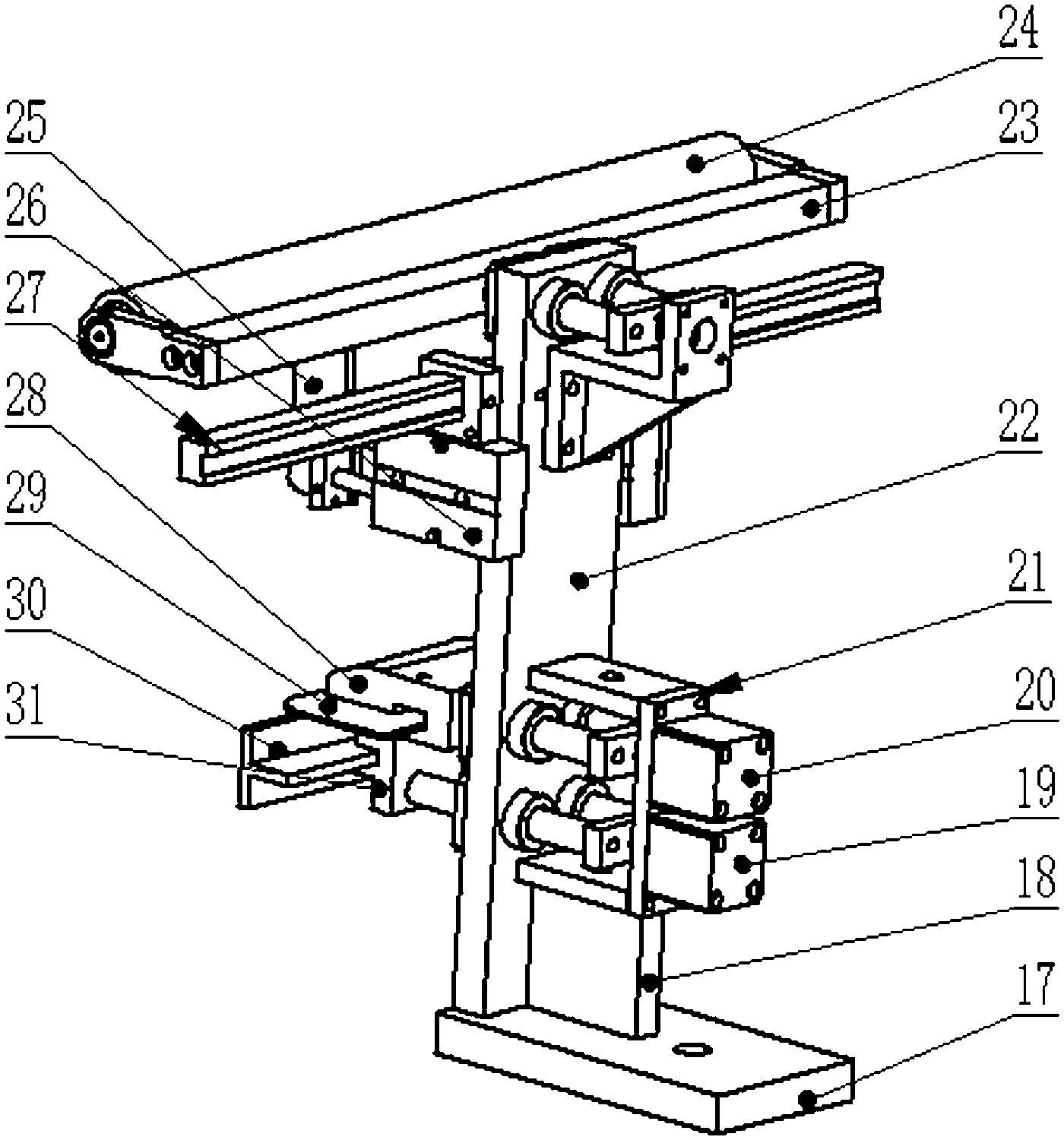

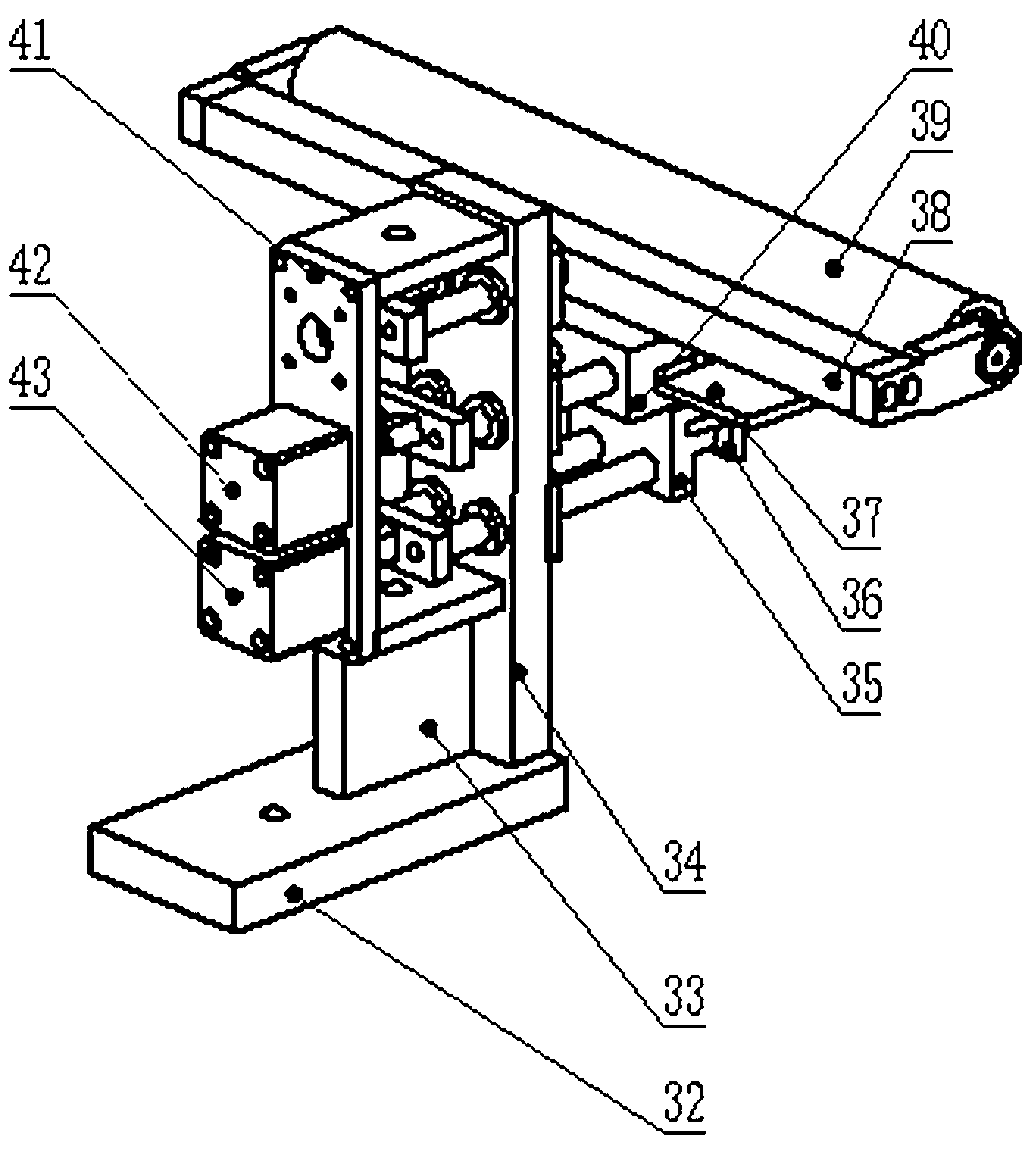

[0022] Frame 1 length 1022mm*width 922mm*height 570mm; tower 2 length 420mm*width 180mm*height 1108mm; servo motor 3 is a commercially available 750W power servo motor, column 4 length 280mm*width 121mm*height 950mm, power transmission belt 5 Length 2195mm*width 25mm*8 moulds, support frame 6 length 110mm*width 65mm*height 10mm, parting cylinder 7 is commercially available cylinder of TN32*90-S type, connecting column 8 length 1102mm*width 50mm*height 25mm, connecting frame 9 length 1130mm*outer diameter 20mm, upper mold 11 length 200mm*width 150mm*height 20mm, lower mold 12 length 199mm*width 149mm*height 19mm; spring tray connecting column 15 length 530mm*outer diameter 60mm, spring 16 length 1200mm*line Diameter 4mm*pitch 15mm; long side base 17 length 180mm*width 100mm*height 20mm, reinforcement plate 18 length 70mm*width 66mm*height 20mm, foam board cylinder 19 model is SDAS250020, side plate cylinder 20 model is SDAS250030, Foam board cylinder frame 21 length 107mm*width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com