Automatic winding and dog-ear folding machine for packaging boxes

A packaging box, automatic technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low efficiency, poor winding quality, high manual labor intensity, etc., and achieve the effect of high cornering accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

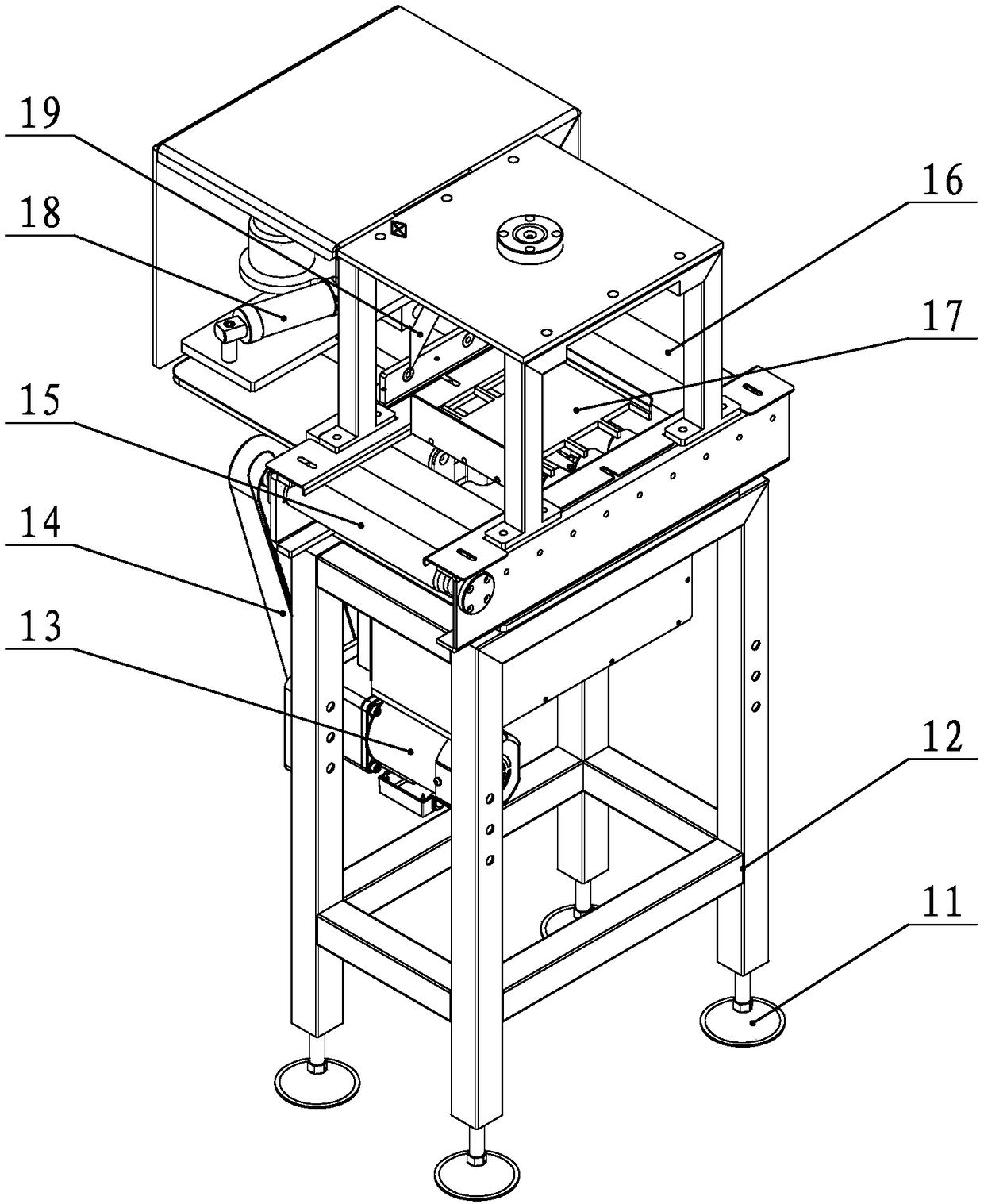

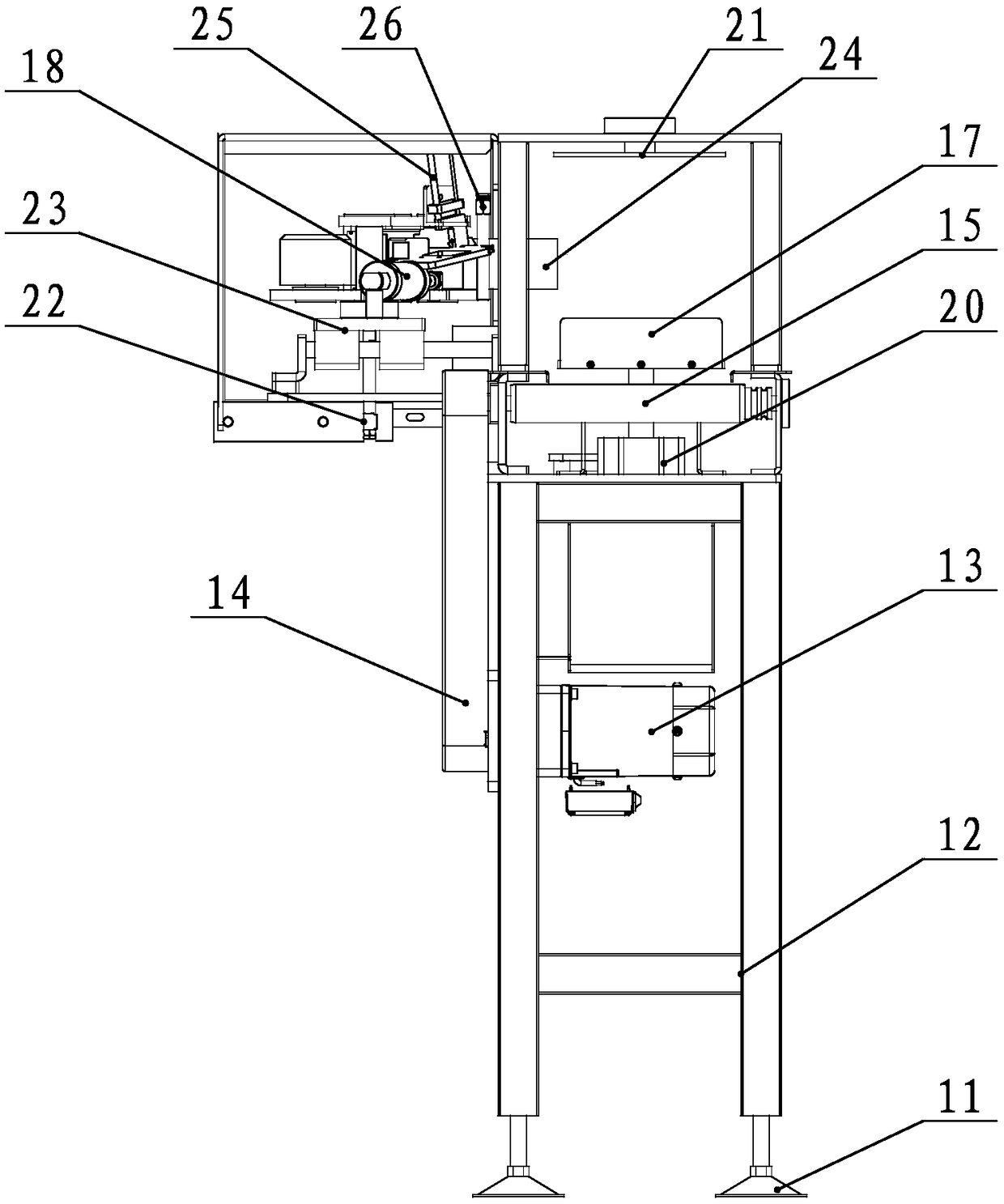

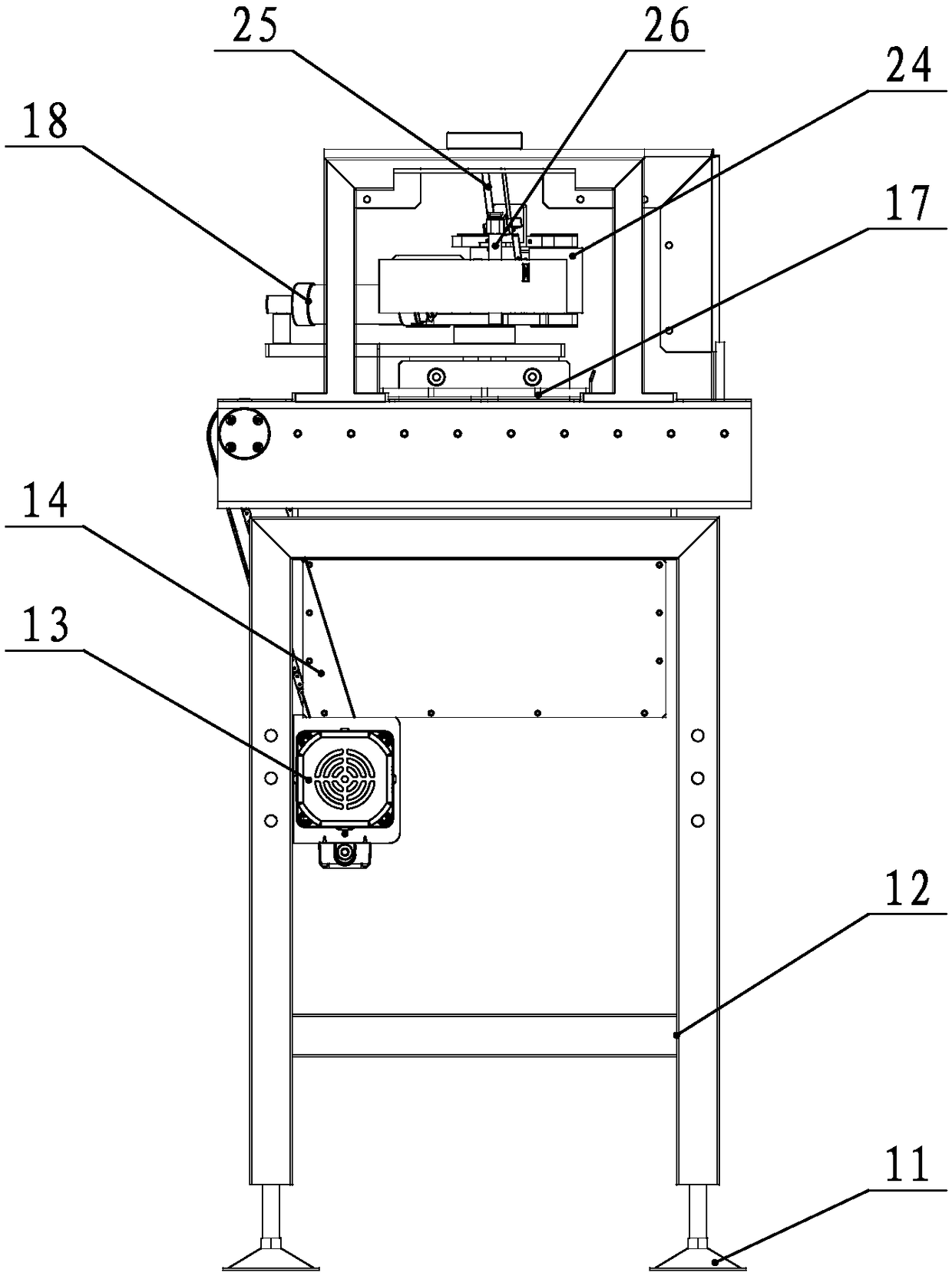

[0036] refer to Figure 1-4 , the packaging box automatic winding and knurling machine provided by the present invention includes: a base bracket 12 equipped with an adjustment foot cup 11, and a feed conveying roller 16, a positioning sensor, a jacking positioning mechanism 17, and a pressing mechanism 21 are installed on the base bracket 12 , Tape Roller 27, Tape Rolling Mechanism 24, Winding Rotation Mechanism 20, Cutter Telescoping Mechanism, Vacuum Suction Pipe Mechanism 25, Pinhole Air Tube, Air Brush 26, Outfeed Conveying Roller 15 and PLC Module Control System; Jacking and Positioning Mechanism 17 corresponds to the pressing mechanism 21 up and down, the winding rotating mechanism 20 is driven up and down by the jacking positioning mechanism 17 and driven to rotate by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com