Pole-ear folding device for cast-welding storage battery

A battery and tab technology, which is applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of affecting the flow of lead liquid in casting and welding, the tab cannot be pinched, and the labor intensity is high. It is beneficial to casting and welding forming, improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

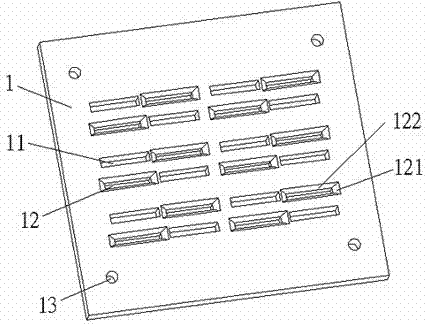

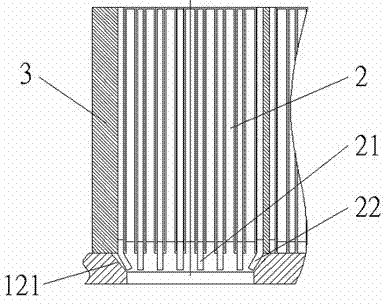

[0018] Such as figure 1 , figure 2 As shown, the device of the present invention is a folded pole lug plate 1, and the folded pole lug plate 1 is provided with several positive pole lug positioning grooves 11, negative pole lug positioning grooves 12, two short side walls 121 of the negative pole lug positioning groove 12 The two long side walls 122 of the negative tab positioning groove 12 are inclined 15 to 25° toward the center of the slot, and the side walls of the negative tab positioning slot 12 are not inclined and extend to the bottom of the slot. The upper part of the ear positioning groove 12 is trumpet-shaped with the opening upward, and the lower part is rectangular.

[0019] The length of the upper opening of the positive tab positioning groove 11 is 2-4 mm longer than the total length of the positive tab row, and the width of the upper opening is 2-3 mm larger than the width of the positive tab; the length of the upper opening of the negative tab positioning gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com