Pole ear sort-out device of storage battery pole group

A technology of pole group tabs and finishing devices, which is applied to battery pack parts, circuits, electrical components, etc., can solve problems such as limited production efficiency, complex structure, and inconsistent height of pole group tabs, and achieve high work efficiency and mechanism The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

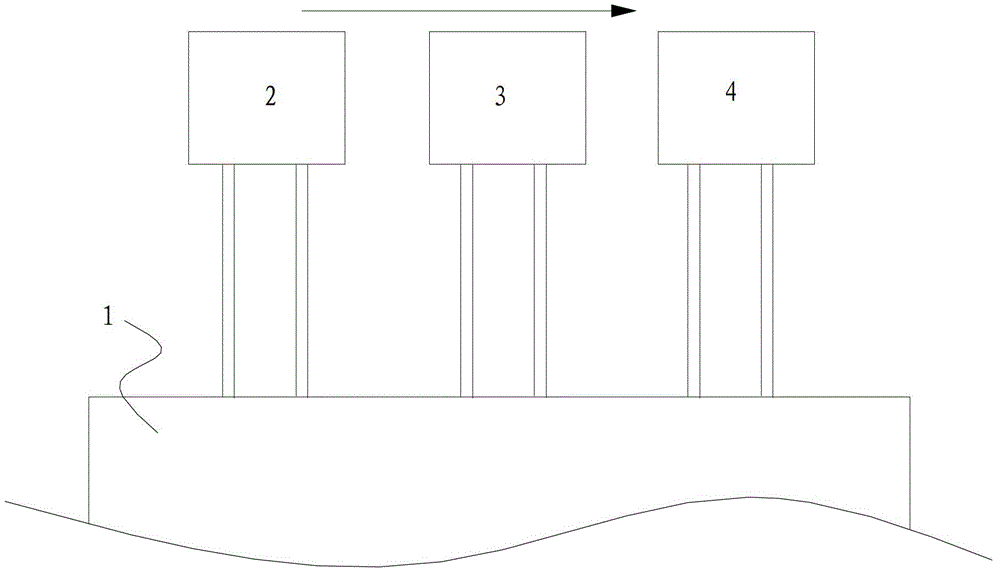

[0059] Such as figure 1 As shown in the figure, a device for arranging tabs of battery pole groups includes an ear brushing mechanism 2 , an ear folding mechanism 3 , and an ear cutting mechanism 4 sequentially arranged on a machine 1 along the battery pole group conveying direction.

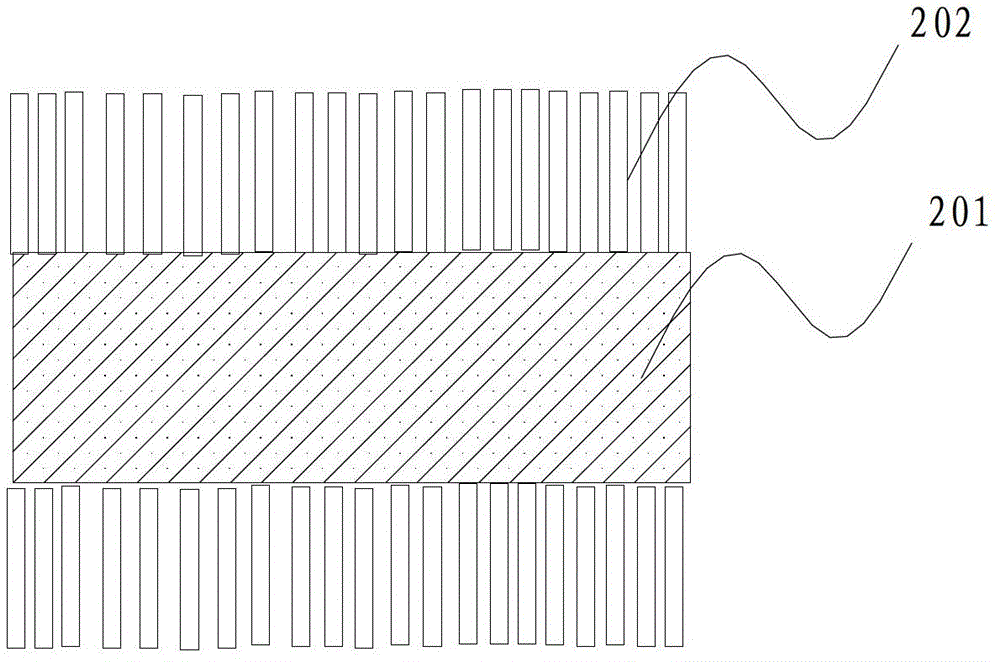

[0060] Such as figure 2 Shown is a structural schematic diagram of the brush ear mechanism 2 in the present invention, the brush ear mechanism 2 is composed of a cylinder 201 and bristles 202 fixed on the outer wall of the cylinder 201, and the machine table 1 is provided with a driving mechanism for driving the rotation of the cylinder 201 (in the figure not shown). The direction of the roller 201 forms an included angle of 5-20° with the direction of the arrangement of the battery tabs, which can increase the contact area between the bristles and the tabs when brushing the ears, and enhance the effect of brushing the ears while preventing the tabs from being damaged due to an excessive angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com