fabric folding machine

A technology for folding machines and fabrics, applied in the directions of folder, folding thin materials, textiles and papermaking, etc., can solve the problems of fabric accumulation, jamming, difficult for operators to eliminate, etc., and achieves low cost, simple structure, high efficiency and high efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

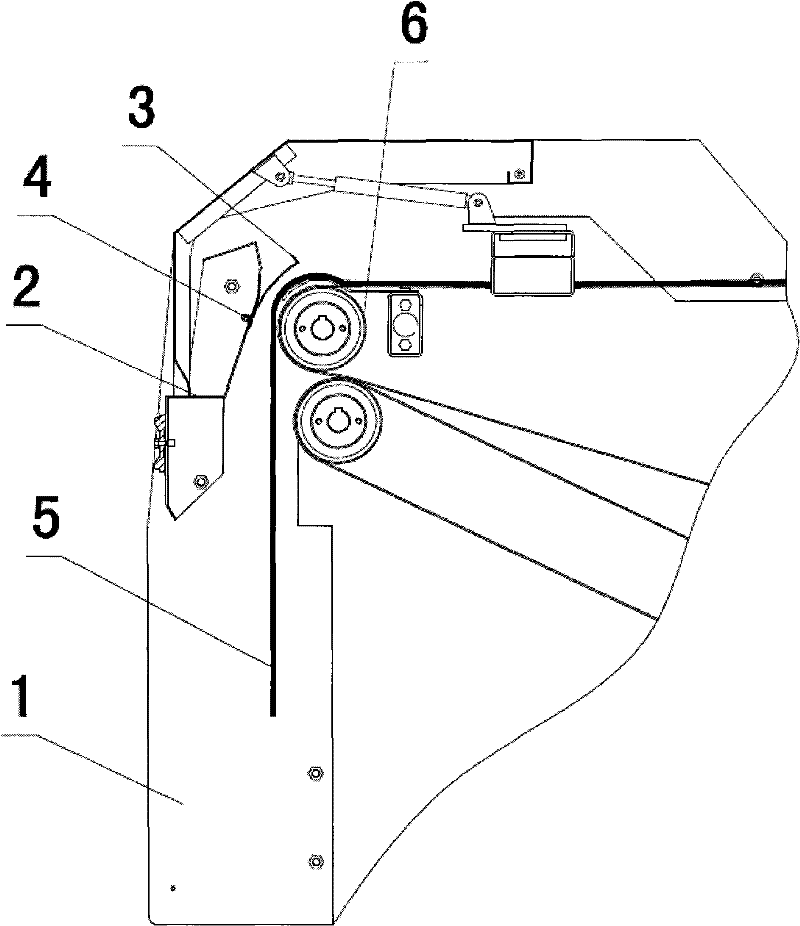

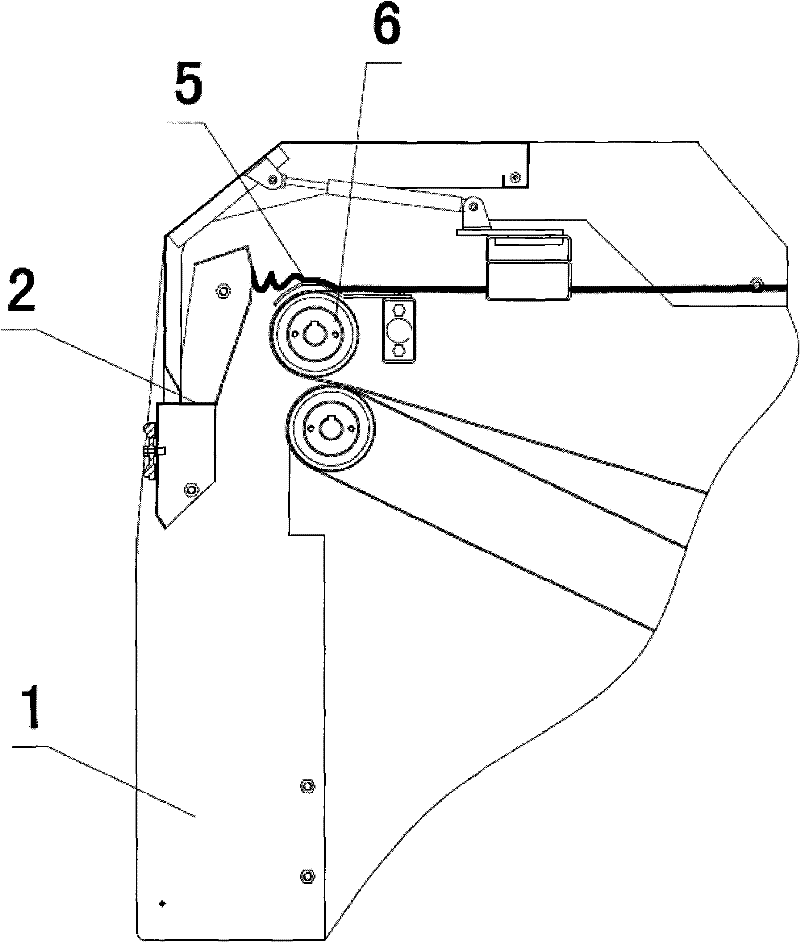

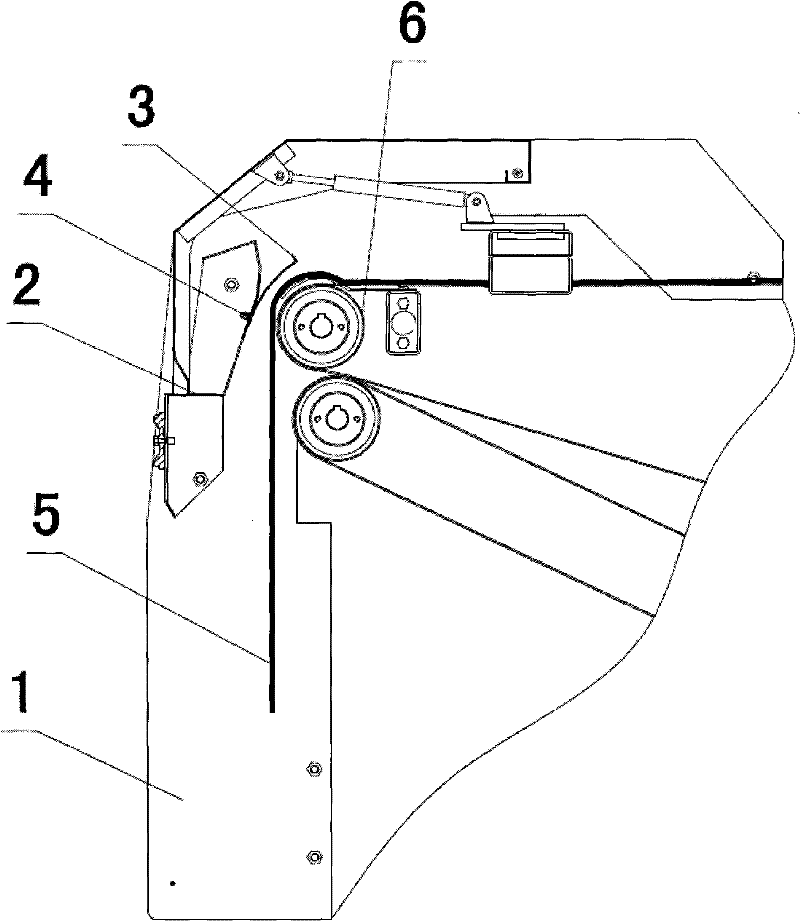

[0015] like figure 1 As shown, the fabric folding machine of the present invention includes a frame 1 , a first folding assembly 6 fixedly connected to the frame 1 , and an air blowing pipe support 2 arranged at the output end of the first folding assembly 6 and fixedly connected to the support 1 . The fabric folding machine also includes three arc-shaped anti-jam plates 3 arranged in parallel, the anti-jam plates 3 are fixedly connected to the blowing pipe 2, and the opening direction of the anti-jam plates 3 faces the output end of the first folding assembly 6 , when the fabric 5 to be folded is conveyed to the output end of the first folding assembly 6, the front end of the fabric 5 to be folded contacts the arc-shaped inner wall of the anti-jamming plate 3, thereby playing the role of bending, so that the fabric 5 to be folded can be Swing down smoothly, avoiding its accumulation or jamming at the first folding assembly 6. The threaded connector 4 includes bolts and nuts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com