Special western style pants under front hooking template for automatic template sewing machine

A sewing machine and template technology, applied in sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of rising defective rate, improper fixing, inaccurate positioning, etc. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

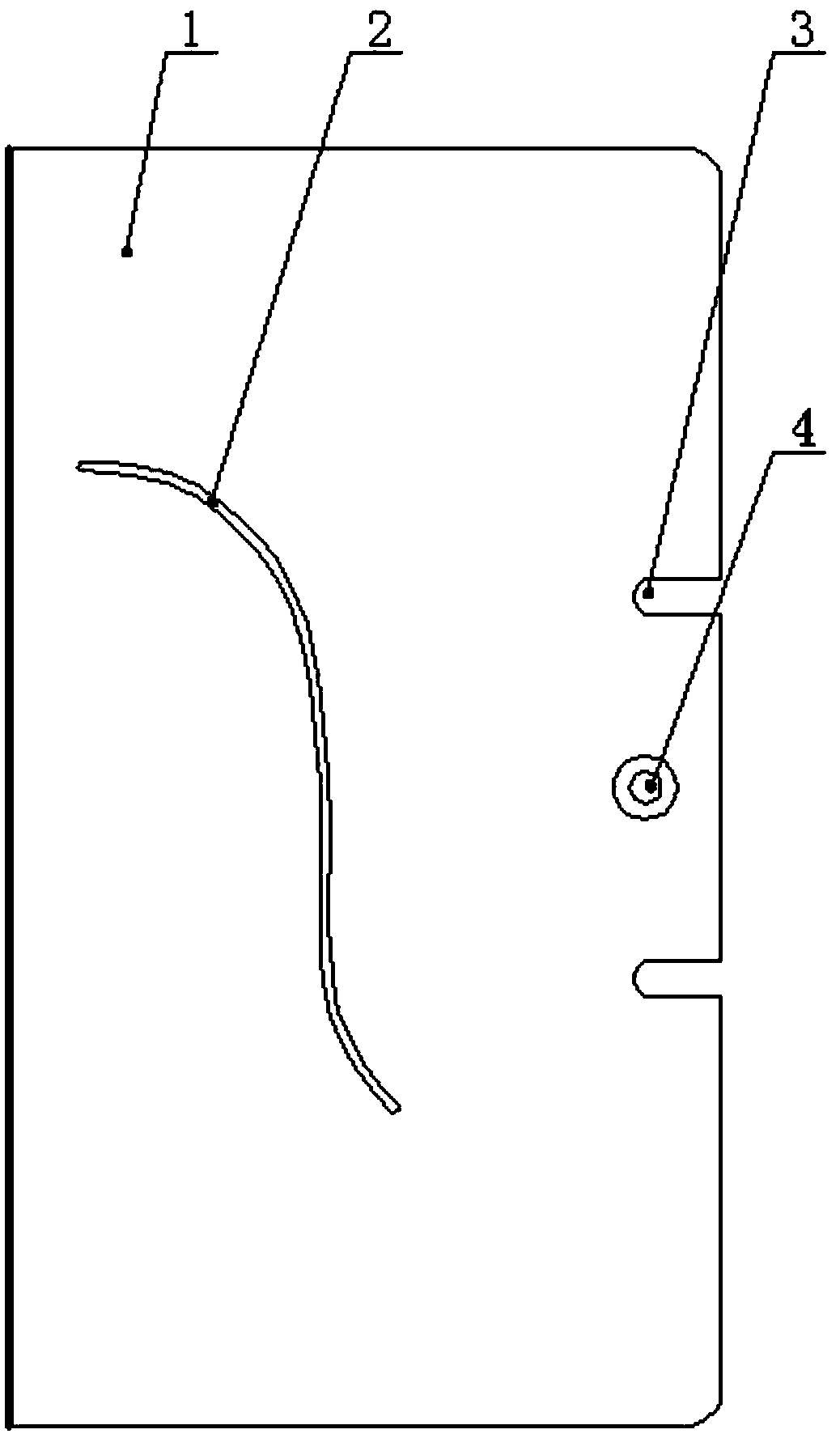

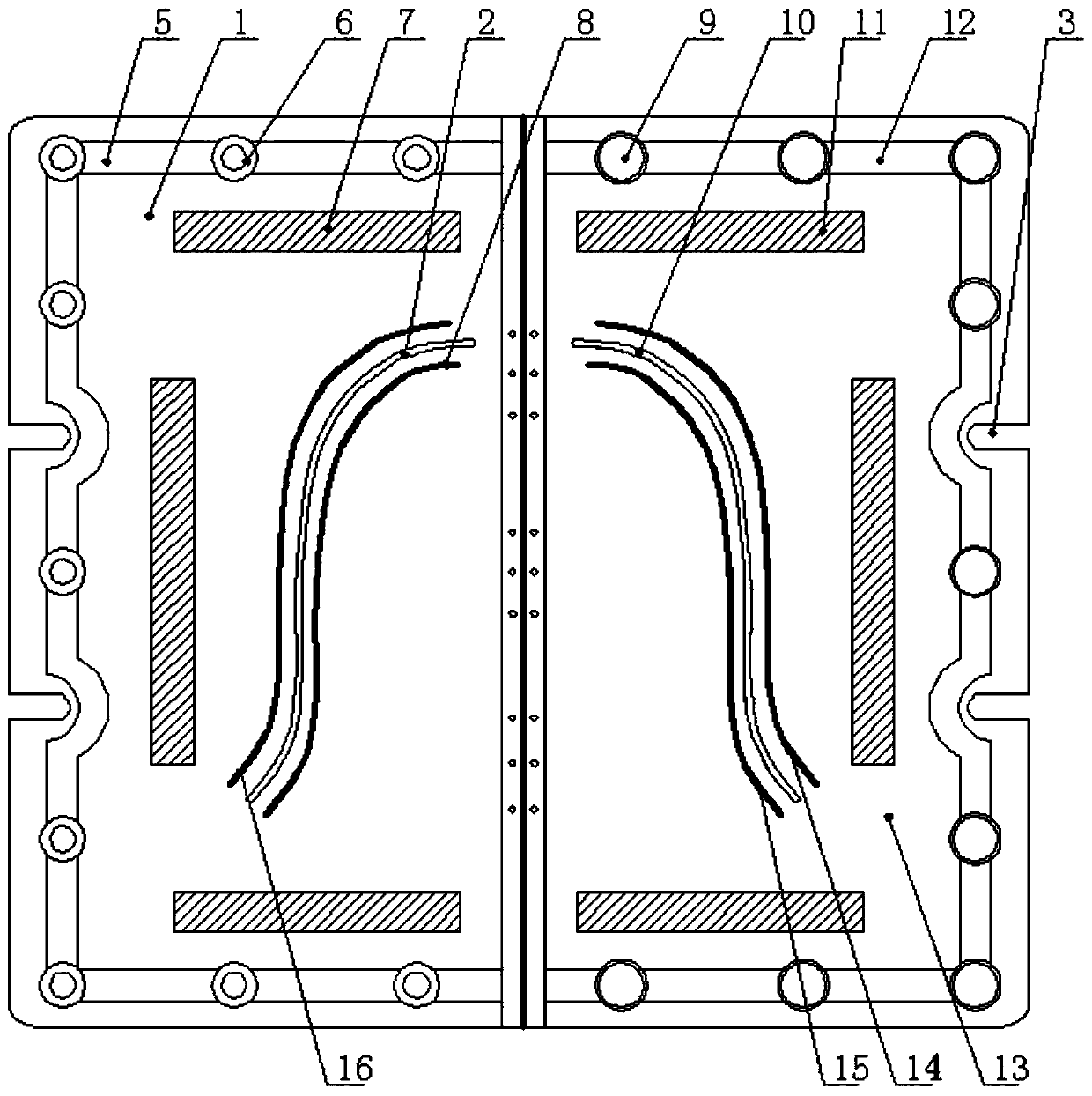

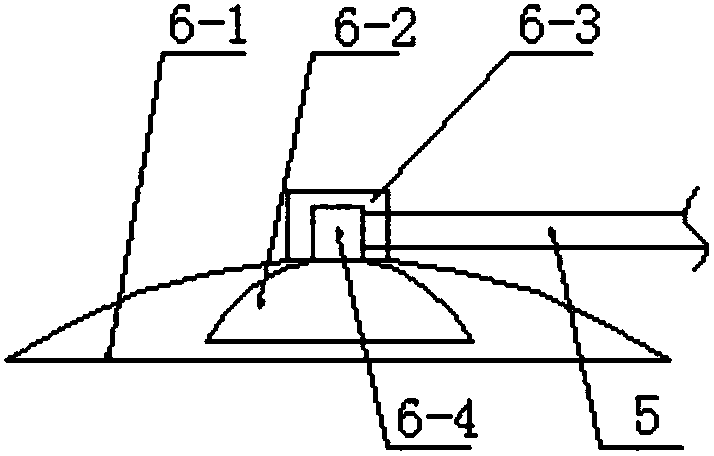

[0020] An automatic template sewing machine special hook trousers bottom placket template, which is composed of a bottom plate 13 and a cover plate 1. A cover plate is hinged on one side of the bottom plate. Bottom plate suture through groove 10 and cover plate suture through groove 2 that match the machining allowance; the outer periphery of the cover plate is evenly distributed with a plurality of adsorption devices 6, and the adsorption devices are connected through air pipes 5, and the outer periphery of the bottom plate is uniformly distributed. There are a plurality of adsorption tanks 9, and the adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com