Pocket double gripper opening template

A template and pocket technology, used in textiles and papermaking, cloth feeding mechanisms, sewing equipment, etc., can solve problems such as the inability to guarantee the regular appearance of the double opening of the pocket, the inability to guarantee the processing specifications of the double opening of the pocket, and the uneven processing allowance. Solve the cumbersome processing method, simple structure, and ensure normative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

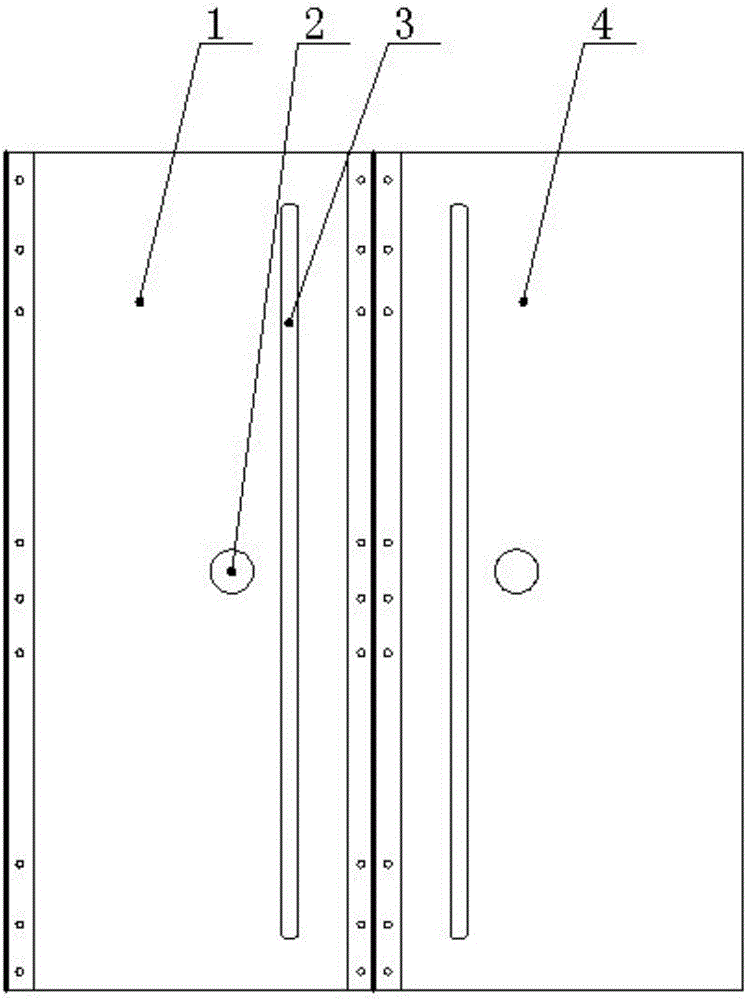

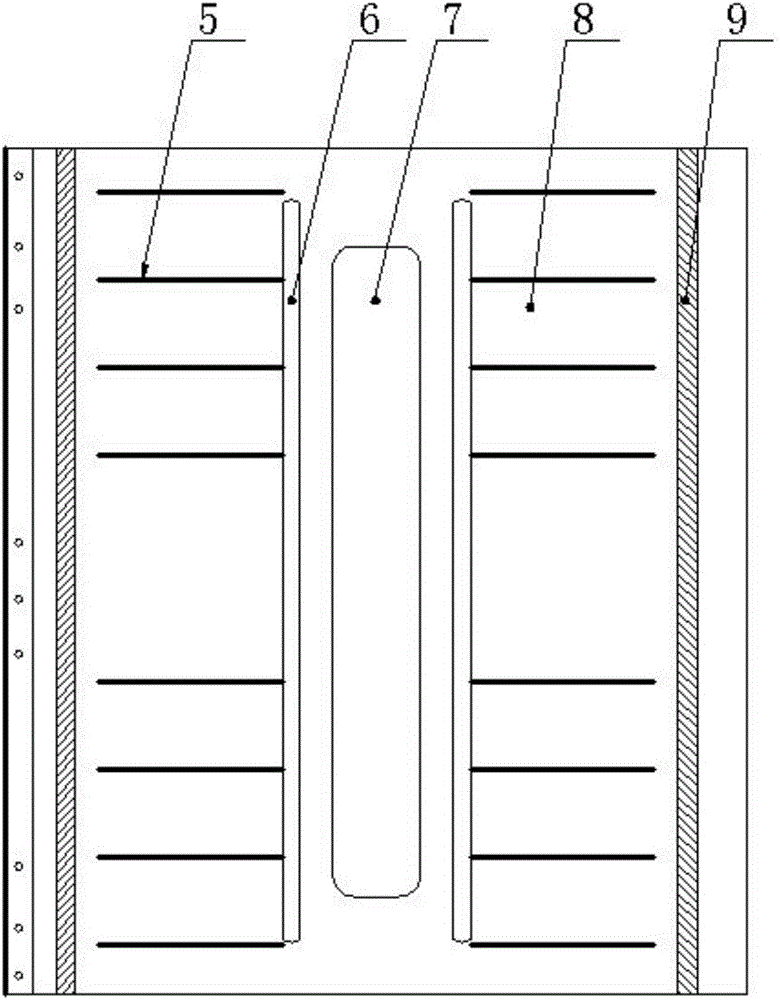

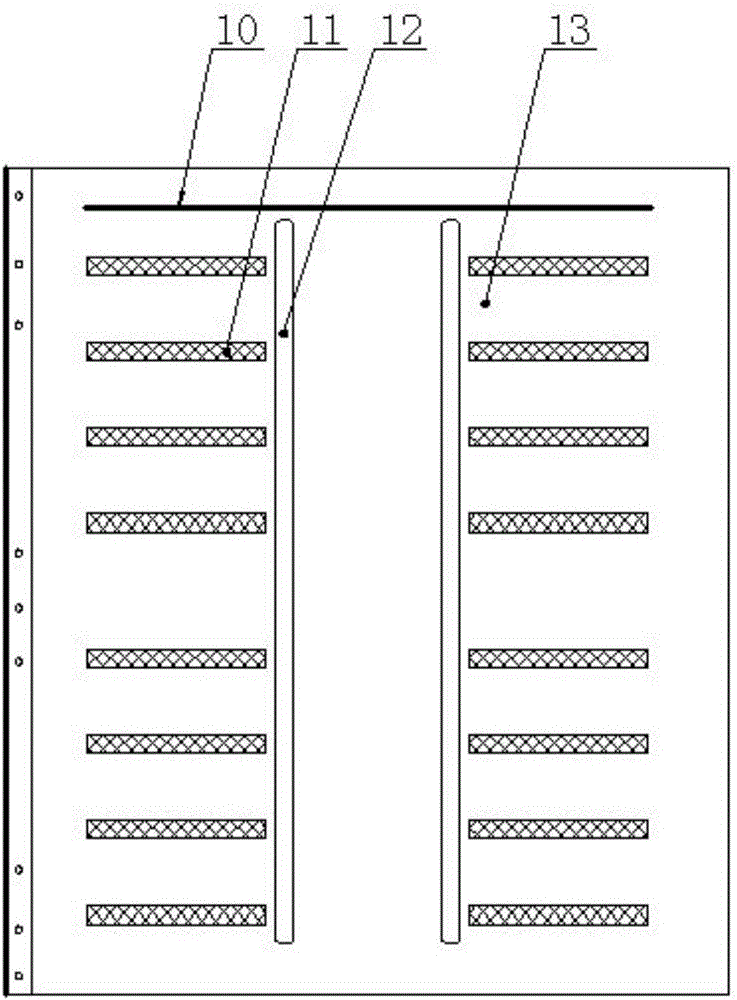

[0017] A pocket double-opening formwork, which is composed of a base plate 13, a backing plate 8 and a cover plate, the cover plate and the bottom plate are coaxially hinged on one side of the backing plate, and the backing plate, the bottom plate and the cover plate are respectively formed with mutually overlapping Backing plate suture through groove 6, bottom plate suture through groove 12 and cover plate suture through groove 3; The middle part of the backing plate is shaped on a strip-shaped extraction through groove 7, and the cover plate is composed of left cover plate 1, right The cover plate 4 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com