Integrally-formed double-serrated-edge template

A technology of teeth and templates, which is applied in textiles and papermaking, cloth feeding mechanisms, sewing equipment, etc., can solve the problems that the symmetry of the double teeth of the hook pocket cannot be guaranteed, the appearance of the hook pocket cannot be guaranteed, and the processing margin of the double teeth is uneven. , to achieve the effect of easily completing the positioning work, protecting the fabric and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

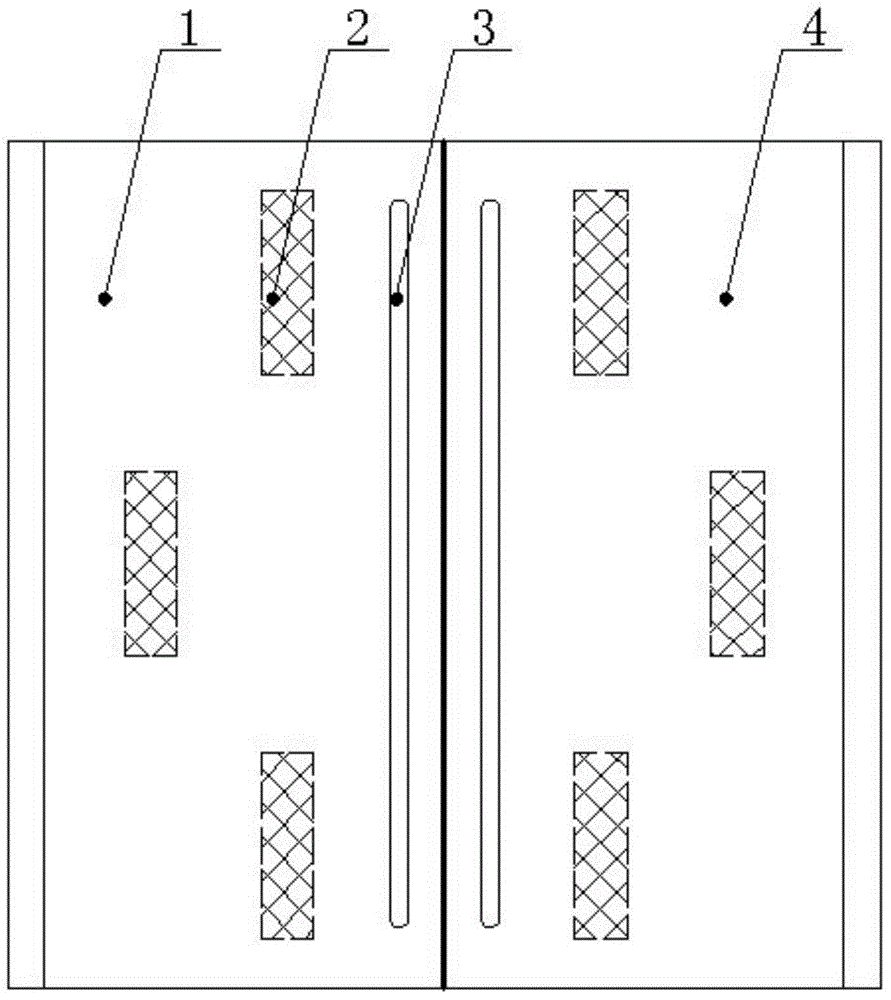

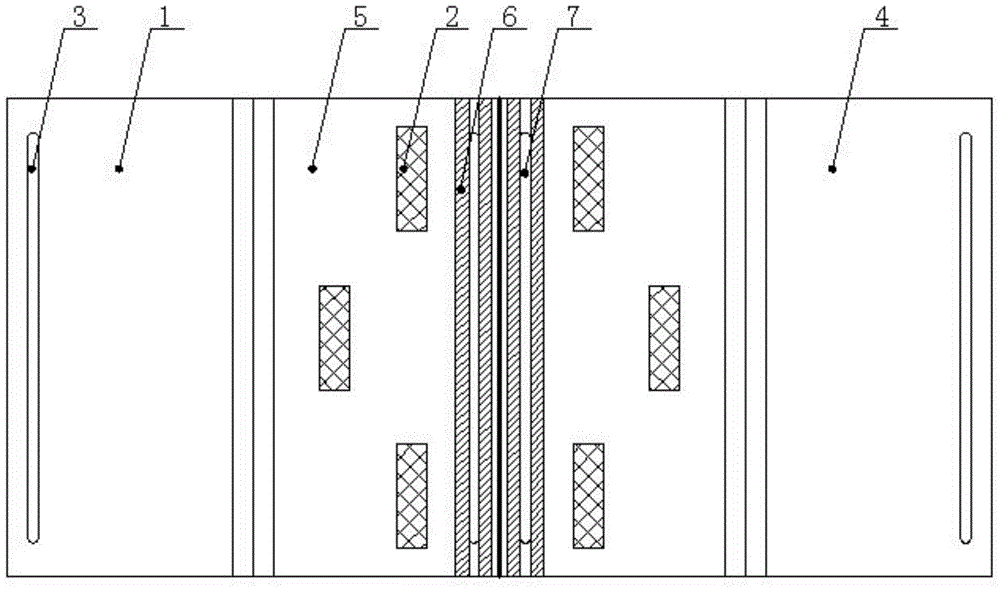

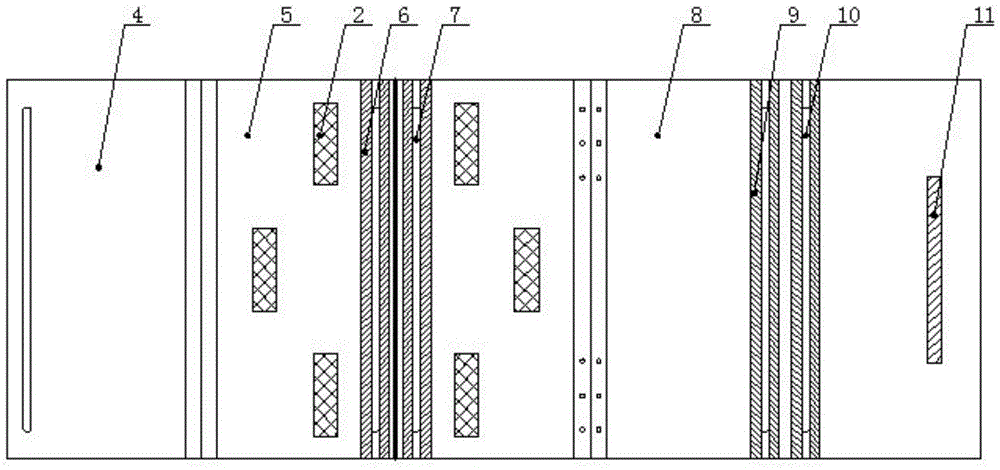

[0019] An integrally formed double-tooth sub-formwork, consisting of a cover plate, a backing plate 5 and a bottom plate 8, one side of the bottom plate is hinged to the backing plate, and the left cover plate 1 and the right cover plate 4 are respectively hinged on both sides of the backing plate. The left and right cover plates are provided with a cover plate tooth suture through groove 3, and the backing plate middle part is provided with a backing plate tooth suture through groove 7 suitable for the cover plate tooth suture through groove; the middle part of the backing plate is shaped on The bottom plate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com