Direct-reading and storage integrated noise logging instrument

A logging tool and noise technology, applied in the field of direct reading and storage integrated noise logging tools, can solve the problems of single working mode, unable to judge well condition in time, unable to store logging data, etc. Single working method, the effect of making up for technical gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

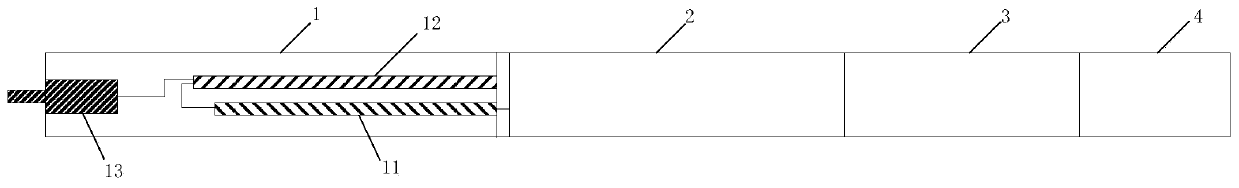

[0042] See figure 1 , figure 1 It is a schematic structural diagram of a direct-reading storage integrated noise logging tool provided by an embodiment of the present invention. figure 1 The noise logging tool in includes a circuit assembly 1 , a sensor assembly 2 , an adjustment assembly 3 and a single-core plug assembly 4 connected in sequence.

[0043] Specifically, the sensor assembly 2 is used to collect relevant data in the well, and transmit the collected data to the circuit assembly 1 . The circuit component 1 realizes the storage, processing and output of the collected data. The output end of the circuit component 1 is connected to a high-speed remote transmission, and the high-speed remote transmission sends the data output by the circuit component to the ground numerical control to realize direct reading of the data. The main function of the regulating assembly 3 is to balance the pressure change inside the sensor assembly 2 due to the temperature change. The sin...

Embodiment 2

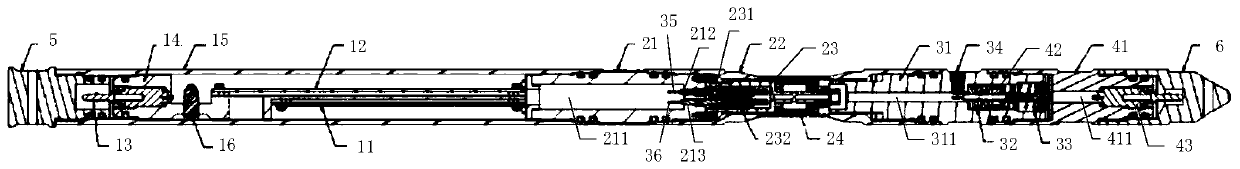

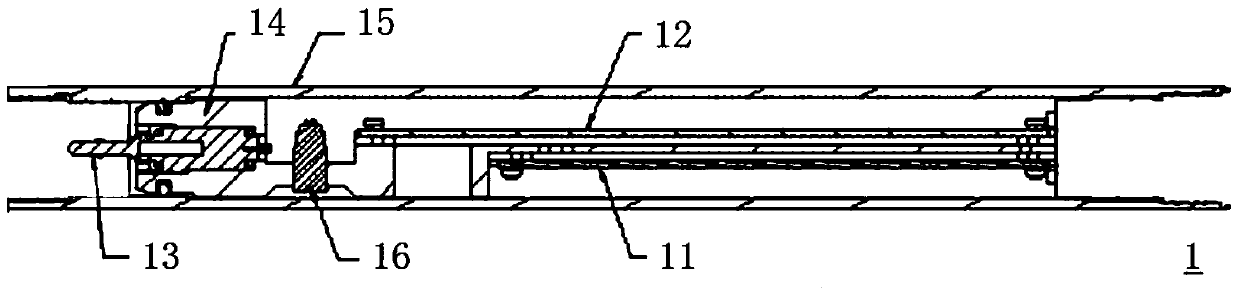

[0050] See figure 2 and image 3 , figure 2 It is a schematic structural diagram of another direct-reading storage integrated noise logging tool provided by the embodiment of the present invention, image 3 for figure 2 Schematic diagram of the circuit components of the medium noise logging tool. image 3 The circuit assembly 1 includes a first circuit board 11 , a second circuit board 12 , an adjustable pin 13 , a circuit frame 14 , an outer protective tube 15 of the circuit frame and a Remo plug 16 .

[0051] Please refer to Embodiment 1 for the connection relationship and functions among the first circuit board 11 , the second circuit board 12 , and the adjustable pin 13 .

[0052] The circuit skeleton 14 has a first end and a second end opposite to each other, the first end is columnar, and the second end is flat. The central axis position inside the first end is provided with a first groove, one end of the adjustable pin 13 is embedded in the first groove, and the...

Embodiment 3

[0058] On the basis of Example 2, combining figure 2 and Figure 4 , Figure 4 for figure 2 Schematic diagram of the sensor assembly of a medium-noise logging tool. Figure 4 The sensor assembly 2 includes a sensor joint 21, a sensor outer protective tube 22, a sensor frame 23 and a sensor 24.

[0059] The sensor connector 21 is mainly used to connect the sensor 24 with the circuit assembly 1 . The sensor connector 21 has opposing third and fourth ends. The third end is connected with the circuit skeleton 14, and its junction is provided with a plurality of screws to fix; Connection, the connection method is bolt connection. A cavity 211 is also provided inside the third end of the sensor joint 21 , and the cavity 211 extends from the end of the third end along the central axis of the sensor joint 21 until approaching the fourth end. The inside of the fourth end is provided with a first channel 212 and a second channel 213 juxtaposed to each other, the first channel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com