Connection structure of motor rotor and bearing

A technology of connecting structure and motor rotor, applied in the direction of casing/cover/support, magnetic circuit shape/style/structure, electrical components, etc. Increase the weight of the motor and other issues to achieve the effect of reducing weight, improving power density and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

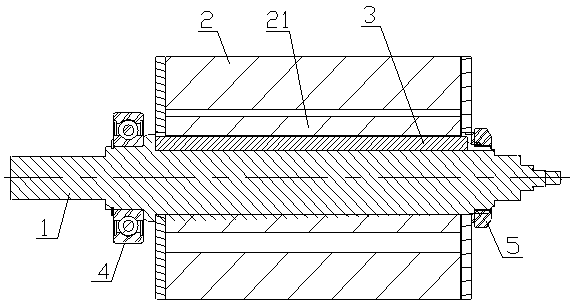

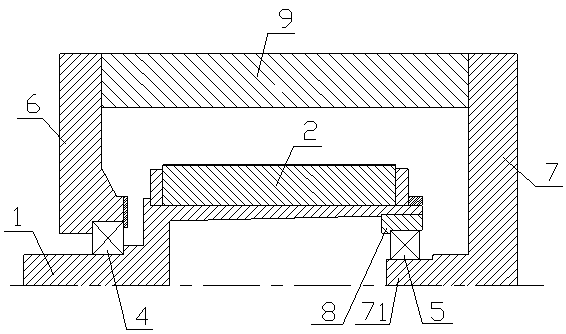

[0013] Example figure 2 As shown, the connecting structure of the motor rotor and the bearing of the present invention includes a motor shaft 1, a rotor core 2, a front bearing 4, a rear bearing 5, a front end cover 6 and a rear end cover 7, and the motor shaft 1 is a hollow with an open rear end. cup-type rotating shaft, the rotor core 2 is arranged on the outer ring of the hollow cup-type rotating shaft, the inner ring of the front bearing 4 is arranged on the outer ring of the front end of the hollow cup-type rotating shaft, and the outer ring of the front bearing 4 is arranged on the outer ring of the hollow cup-type rotating shaft In the bearing hole of the front end cover 6, the inner surface of the rear end cover 7 is provided with a cantilever shaft 71, and the inner ring of the rear bearing 5 is arranged on the cantilever shaft 71 on the inner surface of the rear end cover 7. The rear bearing The outer ring of 5 is arranged on the inner ring of the rear end of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com