A typesetting method for positioning, dashing, and typesetting

A line segment and fur technology, applied in the field of positioning and scribing typesetting, can solve the problems of not easy to draw straight, huge workload, etc., and achieve the effects of good durability, high sewing quality and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

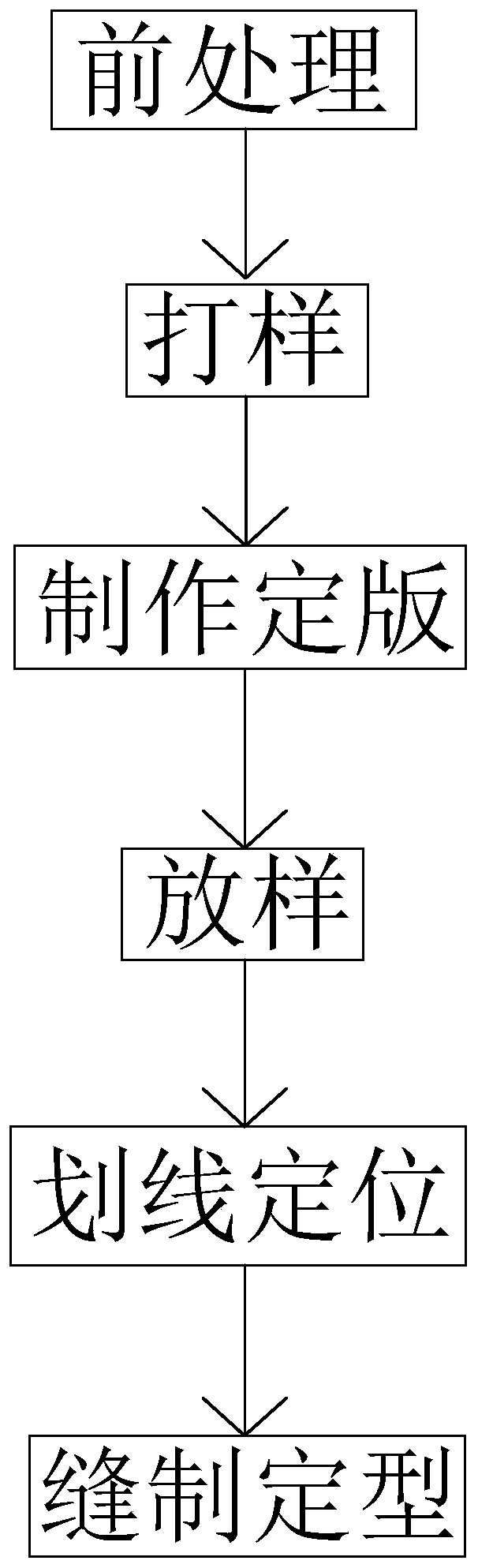

[0031] A typesetting method for positioning lines, such as figure 1 shown, including the following steps:

[0032] Step a pre-treatment: First, in order to prevent the fur from being torn when it is stretched, the operator sprinkles water on the raw fur and let the raw fur wet for 15 minutes; then fix the raw fur on the work panel with long nails horizontally Stretch, so that the original fur tissue is deformed in the transverse direction; then use 1810 cutting machine to cut the original fur along the direction of the hair; In the case of destroying the original organization of the fur piece, an expanded fur piece that is longer than the original fur is obtained, and then the direction along the fur of the original fur becomes the longitudinal direction, and the operator manually stretches and expands the lengthwise to obtain the expanded fur piece; Then comb the expanded fur parts along the direction of the hair, and then dry them with a model LH-900 hair dryer after fluffy...

Embodiment 2

[0039] A positioning, marking and typesetting method, the differences from Embodiment 1 mainly include: the wetting time and drying method of the original fur, the processing method of seaming the edge of the fur piece, the method of measuring the distance between parallel lines and the use The method of invisible chalk marking includes the following steps:

[0040] Step a pre-treatment: First, in order to prevent the fur from being torn when it is stretched, the operator sprinkles water on the raw fur, let the raw fur wet for 18 minutes, and then use long nails The original fur is fixed on the work panel and stretched horizontally, and then the artificial fur laser cutting machine model TSC-190140LD is used to cut the original fur along the direction of the fur, and then the operator manually stretches and expands the lengthwise to obtain the expanded fur. Fur pieces; then comb the expanded fur pieces along the direction of the hair, and then dry them naturally after fluffing...

Embodiment 3

[0047] A typesetting method for positioning, scribing, and typesetting. The differences from Embodiment 1 mainly include: the wetting time of the original fur, the stretching method of the original fur, the drying method of the original fur, and the processing of seaming the edge of the fur piece A method, a method of measuring the distance between parallel lines and a method of marking lines using invisible chalk, comprising the following steps:

[0048] Step a pre-treatment: First, in order to prevent the fur from being torn when stretched, the operator sprinkles water on the raw fur, let the raw fur wet for 20 minutes, and then fix the raw fur on the working panel longitudinally with air nails Stretching, followed by horizontal stretching and expansion, and then the operator uses a fur cutting machine of the model BK to cut the original fur along the direction of the fur to obtain the expansion fur piece; then the expansion fur piece along the Comb it along the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com