Waterproof, anti-explosion and cutting-resistant high-strength double-layer toothed zipper and method for manufacturing same

A production method and tooth zipper technology, applied in the field of nylon zipper, can solve the problems of not being too fast, no waterproof air-tightness, explosion-proof, anti-cutting, and sewing needle breakage, etc., so as to improve sewing speed, anti-theft function, and overall strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

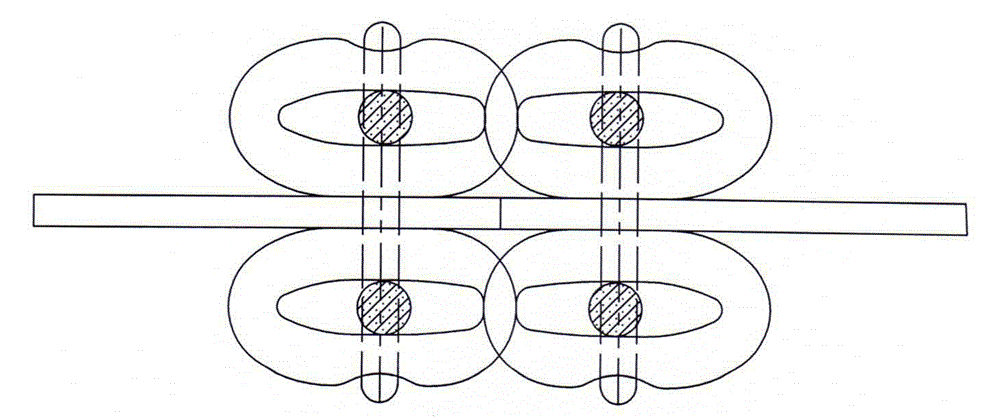

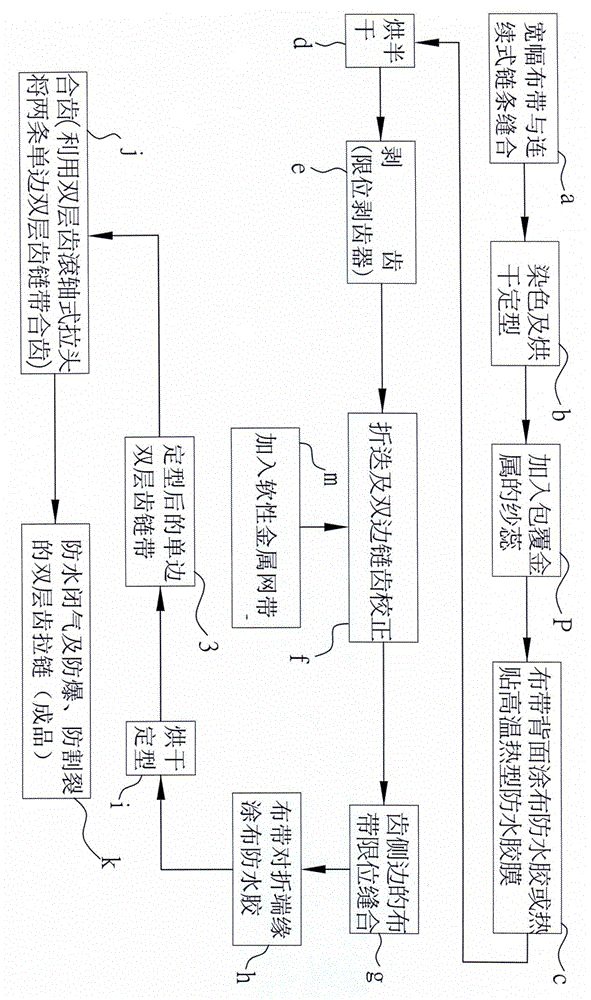

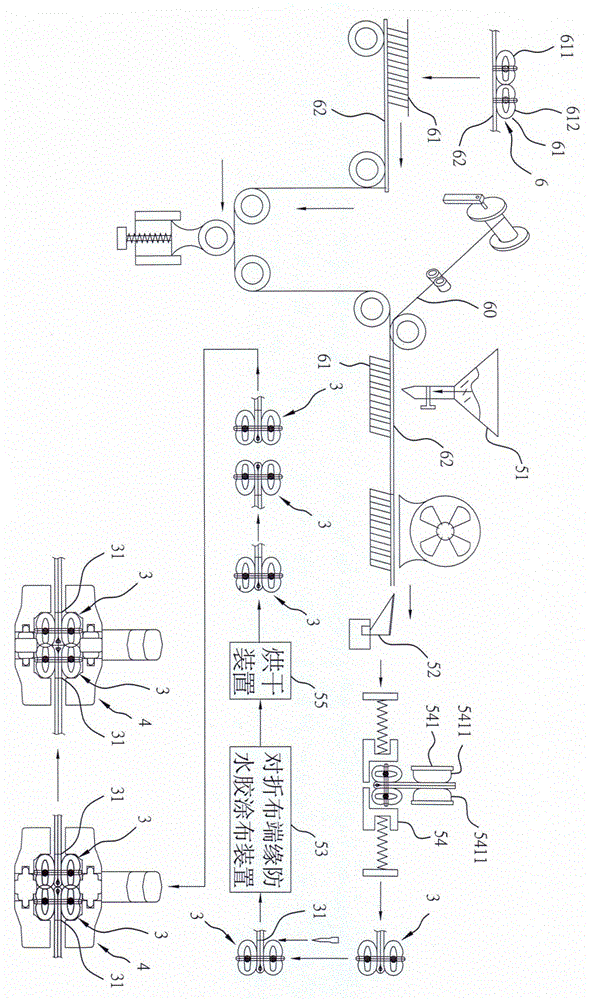

[0034] Such as Figure 2 to Figure 12 As shown, the present invention is a double-layer tooth zipper with high transverse strength that is waterproof, air-tight, explosion-proof, and anti-split and its manufacturing method. The technical thinking of the present invention only consists of a continuous nylon zipper chain 61 (refer to figure 2 ) is equipped with a thinner wide cloth belt 62 to achieve good conveying guidance and high stability stitching, and a continuous nylon zipper chain 61 is sewn on the middle a of a wide width cloth belt 62 (another refer to figure 2 ), become a chain belt 6 (referring to image 3 , Figure 4 ), and then go through the traditional dyeing and drying shaping process b (this can avoid the deformation and distortion of the chain teeth if the left and right chain teeth 611, 612 are separated before high temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com