Crocheting device of sewing machine

A sewing machine and hook needle technology, applied in the field of sewing machines, can solve the problems of residual thread ends, the needle and the shuttle can not be aligned, the needle hook can not be hooked to the bottom thread, etc., and achieves neat and beautiful stitches, high thread hooking efficiency, and simple use and control. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

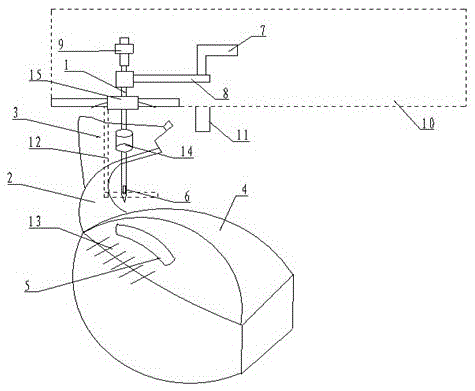

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0018] see figure 1 , the embodiment of the present invention includes:

[0019] The thread hooking device for a sewing machine includes three components: a hook rod body, a shuttle mechanism and a thread pay-off device, wherein the hook rod body includes an alloy vertical needle rod, and the alloy vertical needle The lower end of the rod is provided with a needle point structure, and a needle port is provided at the junction of the alloy vertical needle rod and the needle point structure. The needle port is an elliptical structure. through the needle.

[0020] The thread pay-off adopts a cylindrical structure, and the thread pay-off is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com