A new type of small head sewing machine

A sewing machine and small head technology, applied in sewing machine components, thread cutting mechanisms in sewing machines, sewing equipment, etc., can solve problems such as poor sewing quality, improve sewing efficiency, overcome manual thread trimming, and improve sewing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

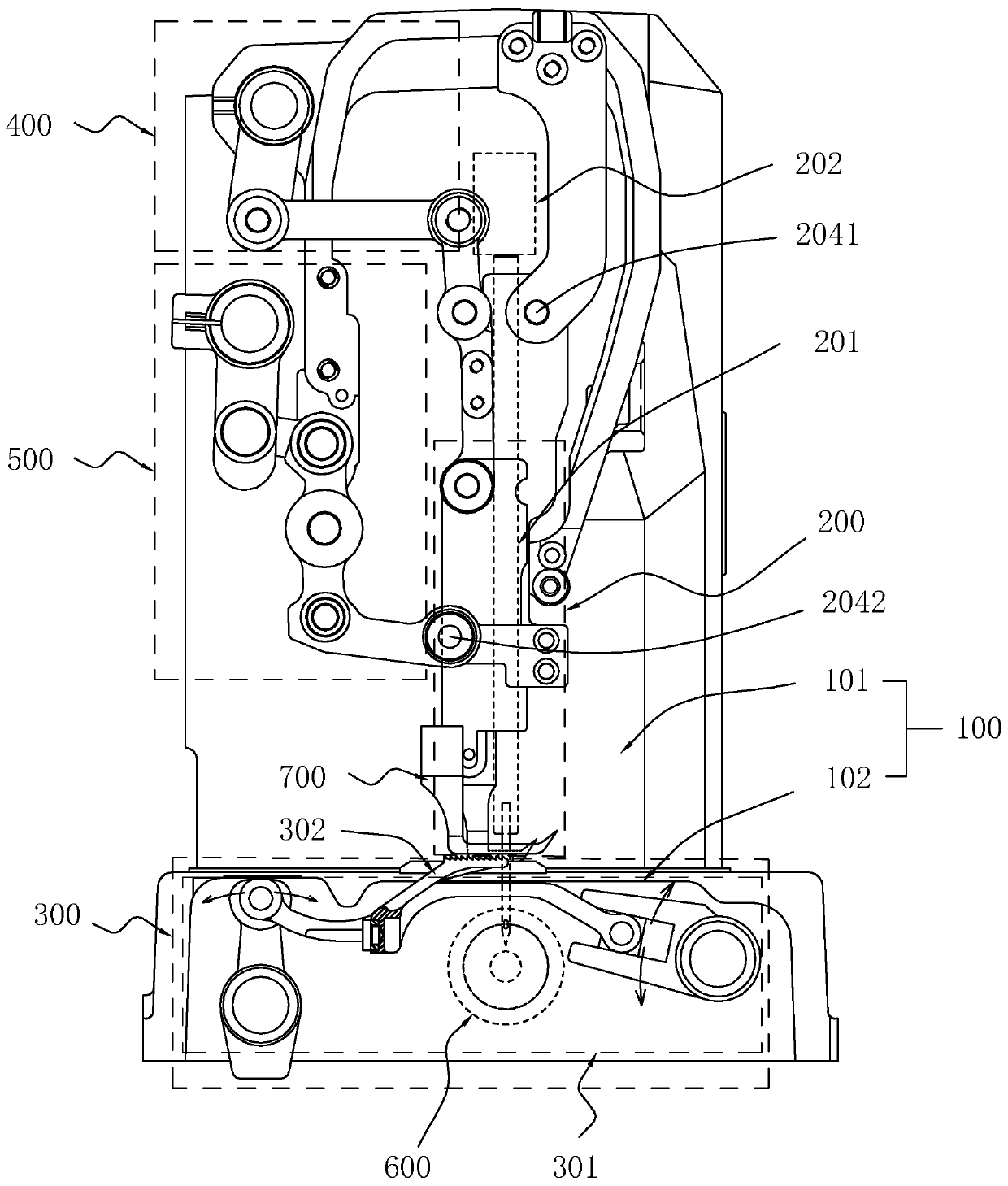

[0056] A new type of small head sewing machine, see figure 1 , including a casing 100, the casing 100 is provided with a vertical installation wall 101 and a sewing table 102, the installation wall 101 is located above the sewing table 102, and a main presser foot 700 and a feeding mechanism are respectively arranged on the installation wall 101 200, thrust mechanism 500, lifting mechanism 400.

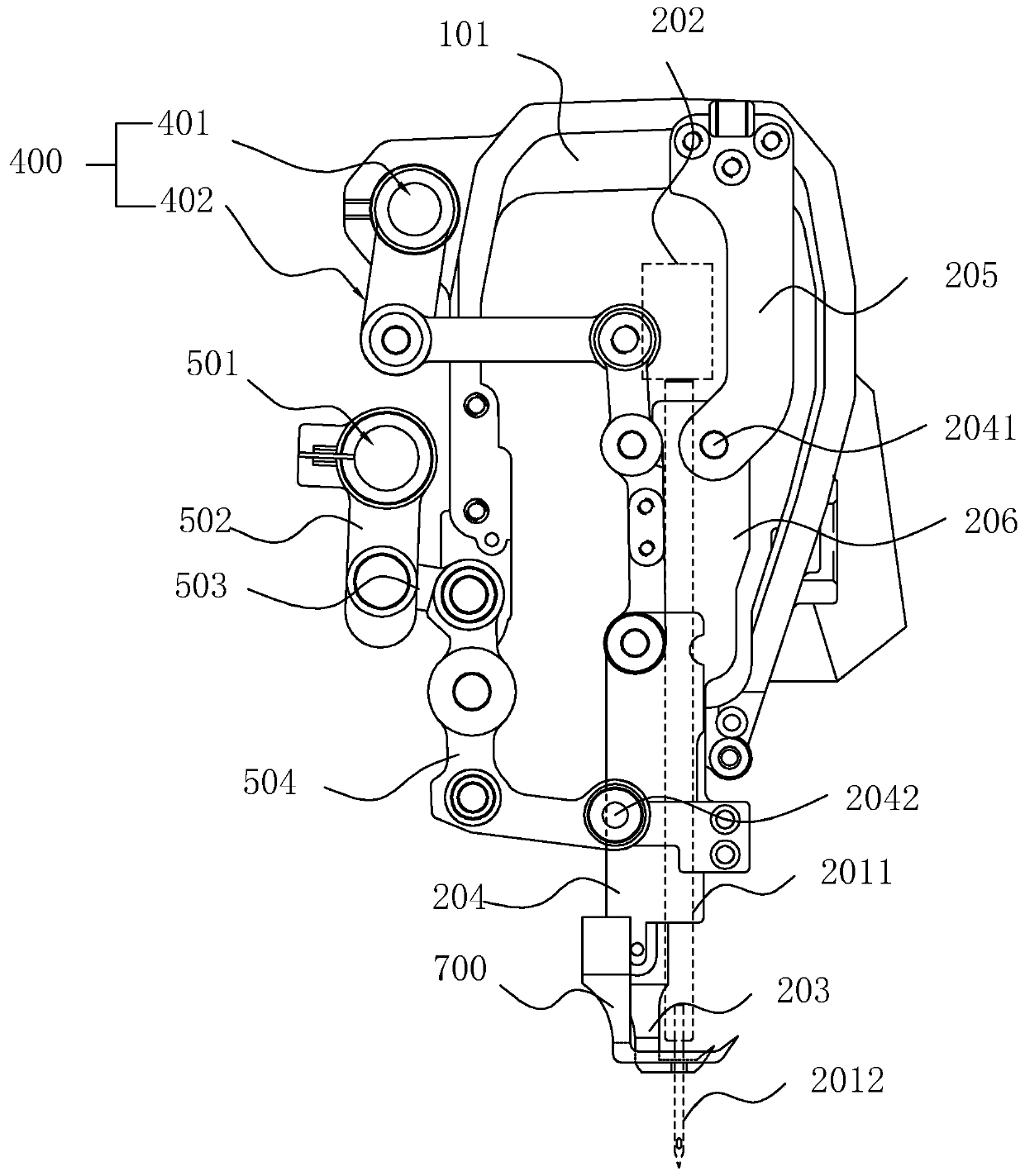

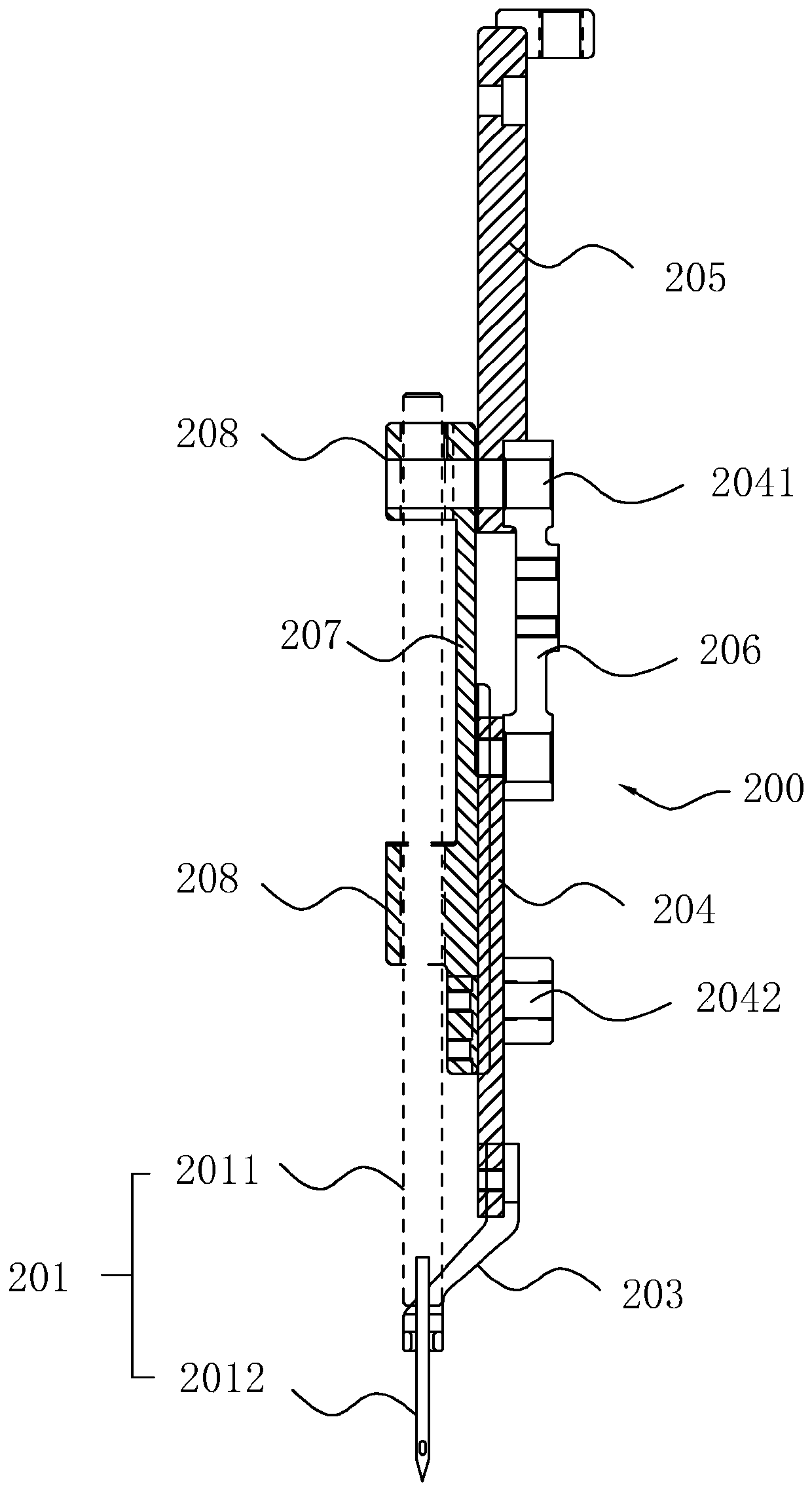

[0057] Among them, see figure 1 as well as figure 2 , the main presser foot 700 is used to press the fabric to be sewed on the upper table of the sewing table 102, the feeding mechanism 200 includes a sewing needle 201, a needle drive part 202, a swing presser foot 203, and a swing press connected to the end of the swing presser foot 203 Rod 204, sewing needle 201 is installed on the swing pressure rod 204 and the needle head of sewing needle 201 vertically penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com