Sock production device

A production device and sock technology, which is applied to the jointing machine of knitted fabrics, textiles and papermaking, high-pressure cleaning, etc., can solve the problems of equipment use impact, increase the burden of equipment, and difficult placement, so as to ensure air quality and improve production Efficiency and the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

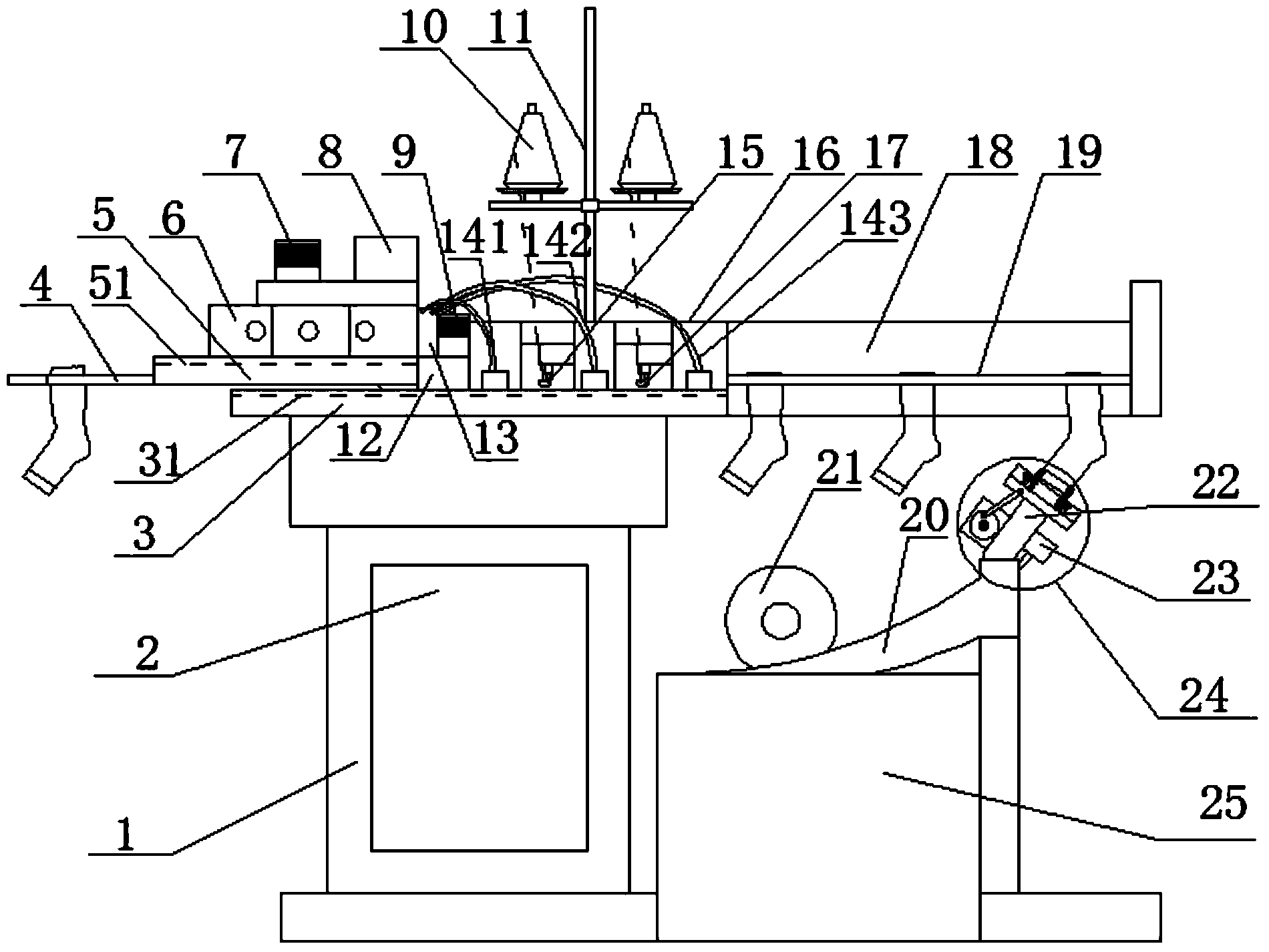

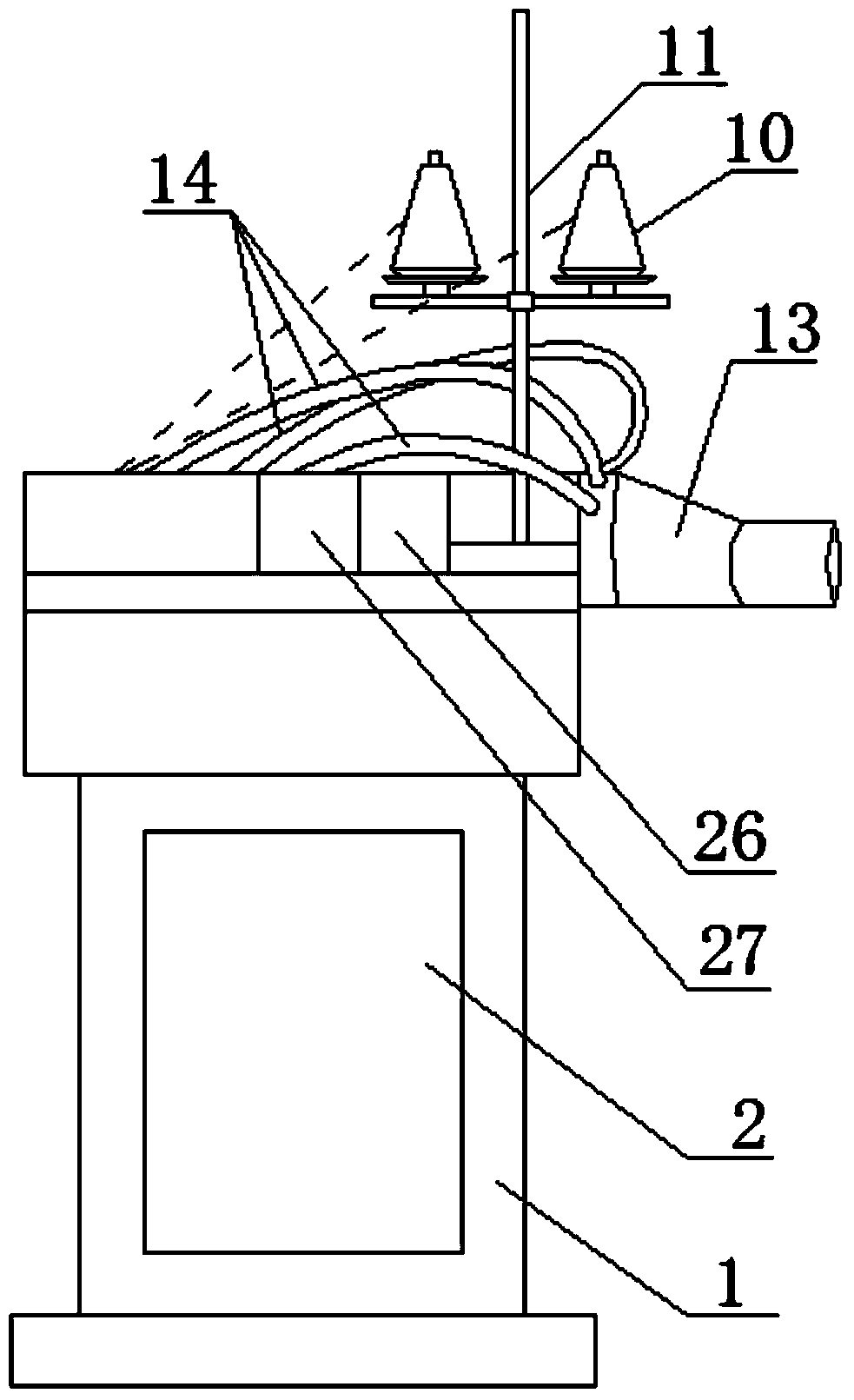

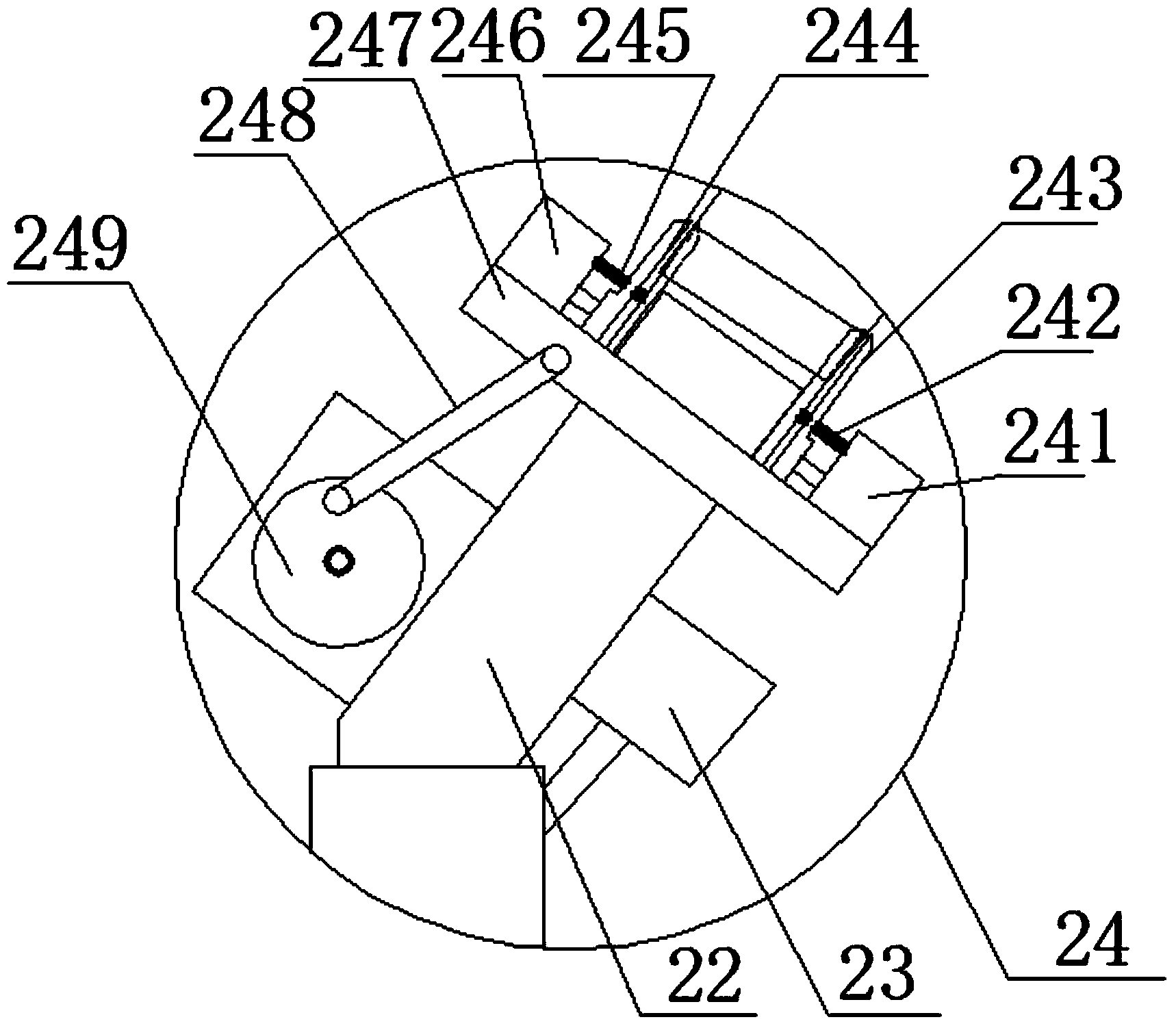

[0022] refer to Figure 1 ~ Figure 4, a kind of sock production device of the present invention, comprises frame 1, feeding device, waste material recycling device, seam end box 16, discharging device 18, hosiery turning device 24; Said feeding device comprises guide rail 4, guide frame 6, guide box 5. Feeding box 3, the first motor assembly 8, a guide frame 6 is installed on the frame 1, the first motor assembly 8 is installed on the guide frame 6, the guide frame 6 is connected with the guide box 5, and the guide box 5 is provided with Guide chain 51, guide rail 4 is installed on the left end of guide box 5, feed box 3 is installed on the left end of frame 1, is provided with feed chain 31 in the feed box 3, feed box 3 is connected with guide box 5 by sprocket wheel; Described waste recycling The device comprises a negative air pressure suction device 13 and a pipeline 14, the negative air pressure suction device 13 is installed on the frame 1, and one end of the pipeline 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com