Sewing machine

A sewing machine and machine needle technology, which is applied in the direction of sewing machine components, sewing machine needle holders, sewing machine housings, etc., can solve the problems of low work efficiency, low safety, cumbersome operation, etc., and achieve simple structure, neat and beautiful stitches , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

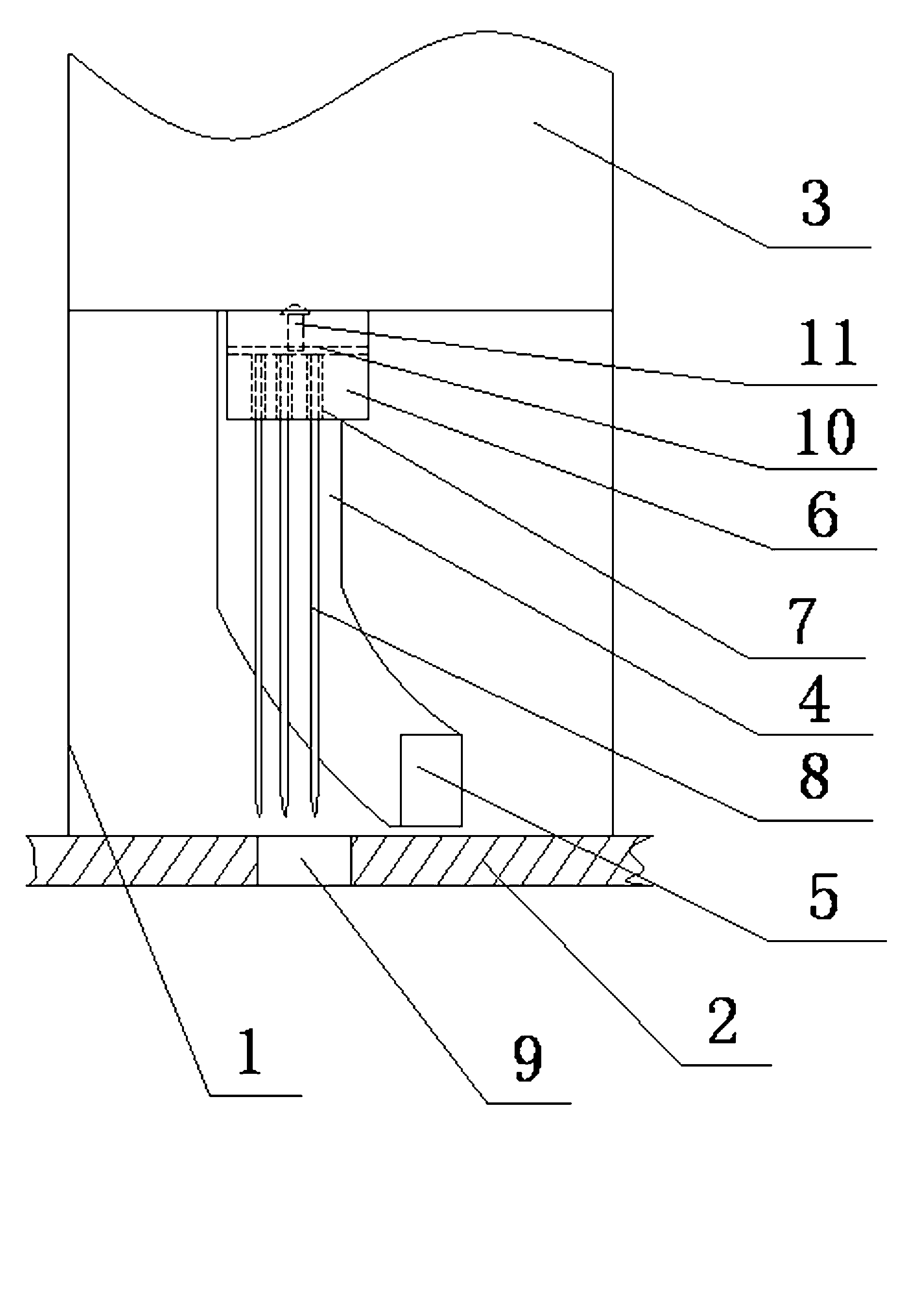

[0015] like figure 1 As shown, a sewing machine of the present invention comprises a frame 1, the bottom of the frame 1 is provided with a table top 2, the top of the frame 1 is provided with a power head 3, and the bottom of the power head 3 is fixedly provided with a hemming column 4. The bottom end of the crimping column 4 is connected to the crimping mechanism 5. The crimping mechanism 5 is at a certain distance from the table top 2 when the sewing machine is not in operation, and the crimping mechanism 5 is in contact with the table top 2 when the sewing machine is in operation. , the bottom of the power head 3 is also fixedly provided with a needle fixing mechanism 6, and the needle fixing mechanism 6 is provided with a plurality of needle placement holes 7, and three needle placement holes are horizontally arranged in the placement holes 7. Machine needle 8, the rear part of the machine needle 8 is movably fixed on the machine needle fixing mechanism 6, the head of the ...

Embodiment 2

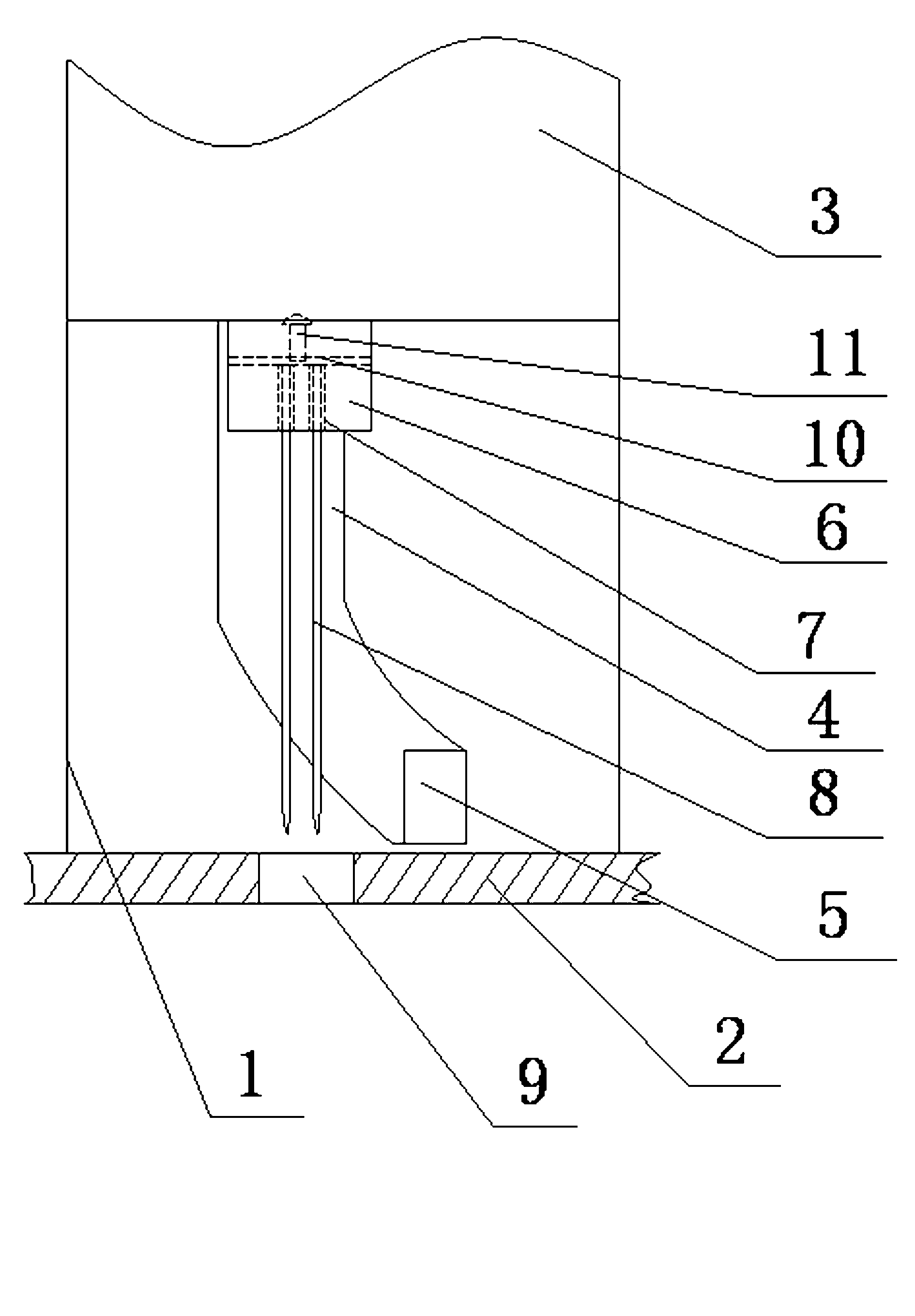

[0017] like figure 2 As shown, a sewing machine of the present invention comprises a frame 1, the bottom of the frame 1 is provided with a table top 2, the top of the frame 1 is provided with a power head 3, and the bottom of the power head 3 is fixedly provided with a hemming column 4. The bottom end of the crimping column 4 is connected to the crimping mechanism 5. The crimping mechanism 5 is at a certain distance from the table top 2 when the sewing machine is not in operation, and the crimping mechanism 5 is in contact with the table top 2 when the sewing machine is in operation. , the bottom of the power head 3 is also fixedly provided with a needle fixing mechanism 6, and the needle fixing mechanism 6 is provided with a plurality of needle placement holes 7, and the needle placement holes 7 are horizontally arranged with two A machine needle 8, the tail of the machine needle 8 is movably fixed on the needle fixing mechanism 6, the head of the machine needle 8 is close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com