Sewing machine thread passing structure and sewing machine

A sewing machine and thread passing technology, which is applied in the field of sewing, can solve problems such as unsmooth thread exit, unsightly appearance, and limited application range, and achieve the effects of smooth thread exit, improved quality, and smooth stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] During the use of the traditional overlock sewing machine, it was found that when overcoating thin materials, there are often problems such as unsmooth thread exit, uneven stitches and unsightly appearance. After investigation, it was found that the amount of thread storage and take-up of the upper and lower loopers was unstable. Related, and there is no good solution at present, which makes the traditional sewing machine structure cloth limited in scope of application.

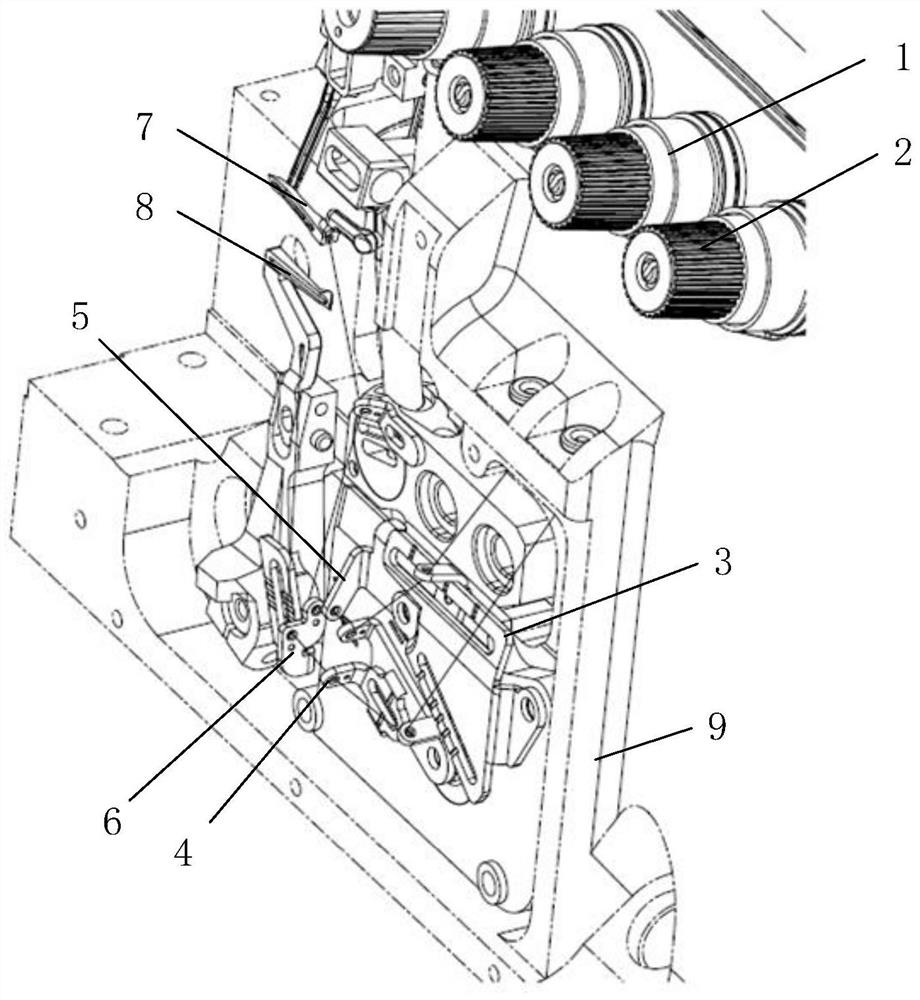

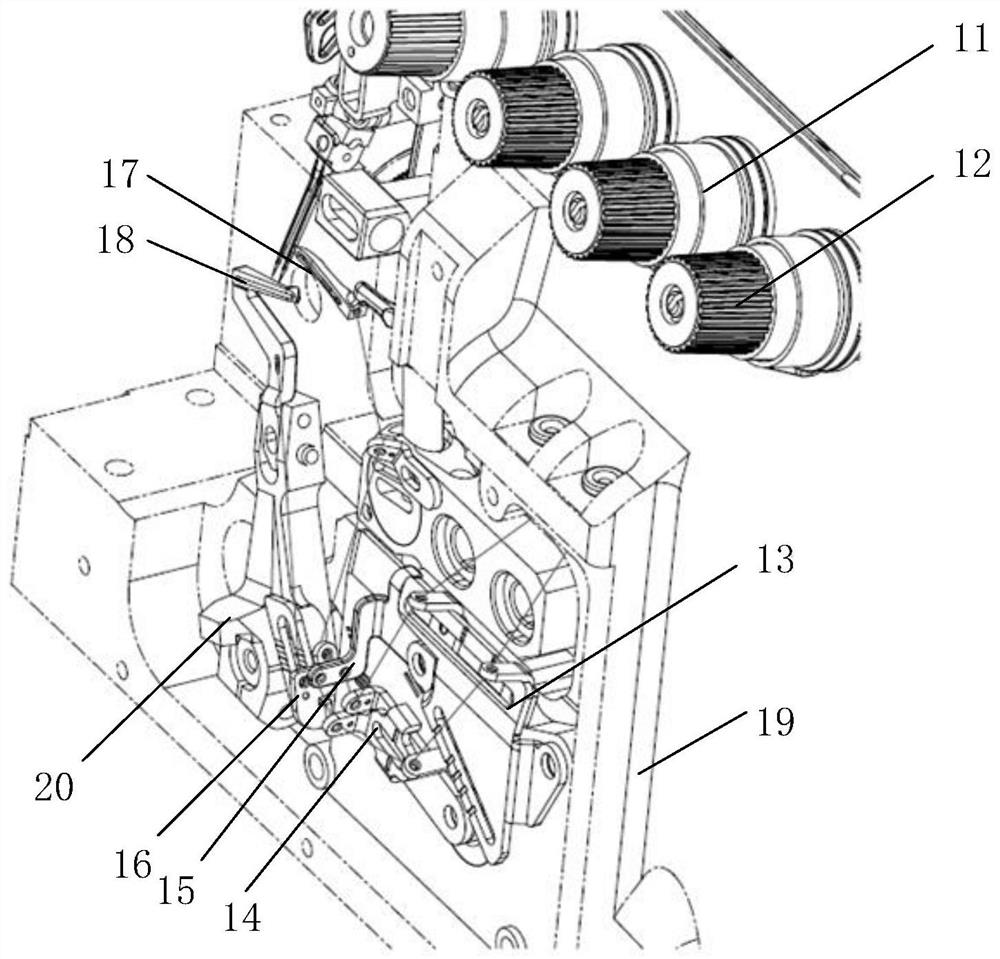

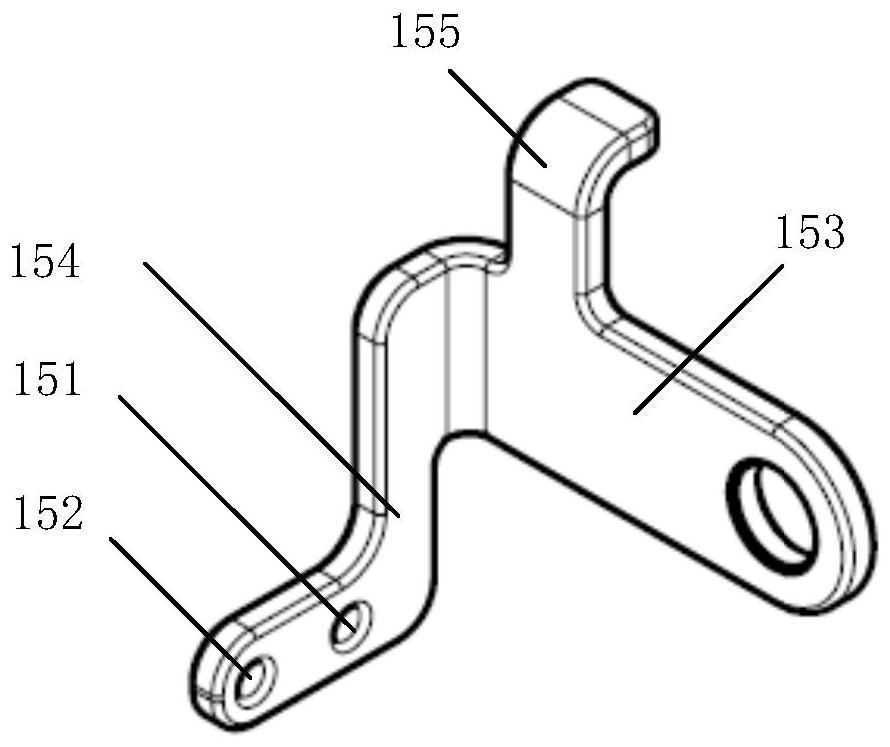

[0041] Specifically, please refer to figure 1 , figure 1 Schematic diagram of the traditional thread passing structure of the sewing machine. The thread passing structure of the sewing machine includes a first thread gripper 1, a second thread gripper 2, a first threading plate 3, a thread take-up plate 4, a thread passing plate 5, a second threading plate 6, an upper looper 7 and a lower looper Needle 8, the thread take-up plate 4 is rotatably connected with the body 9 of the sewing machine, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com