Sewing machine

A technology for sewing machines and objects to be sewn, applied in the field of sewing machines, can solve problems such as difficulty in evenly tightening stitches and inability to obtain beautiful stitches, so as to improve sewing efficiency, beautiful stitches, and prevent knotted needles trace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

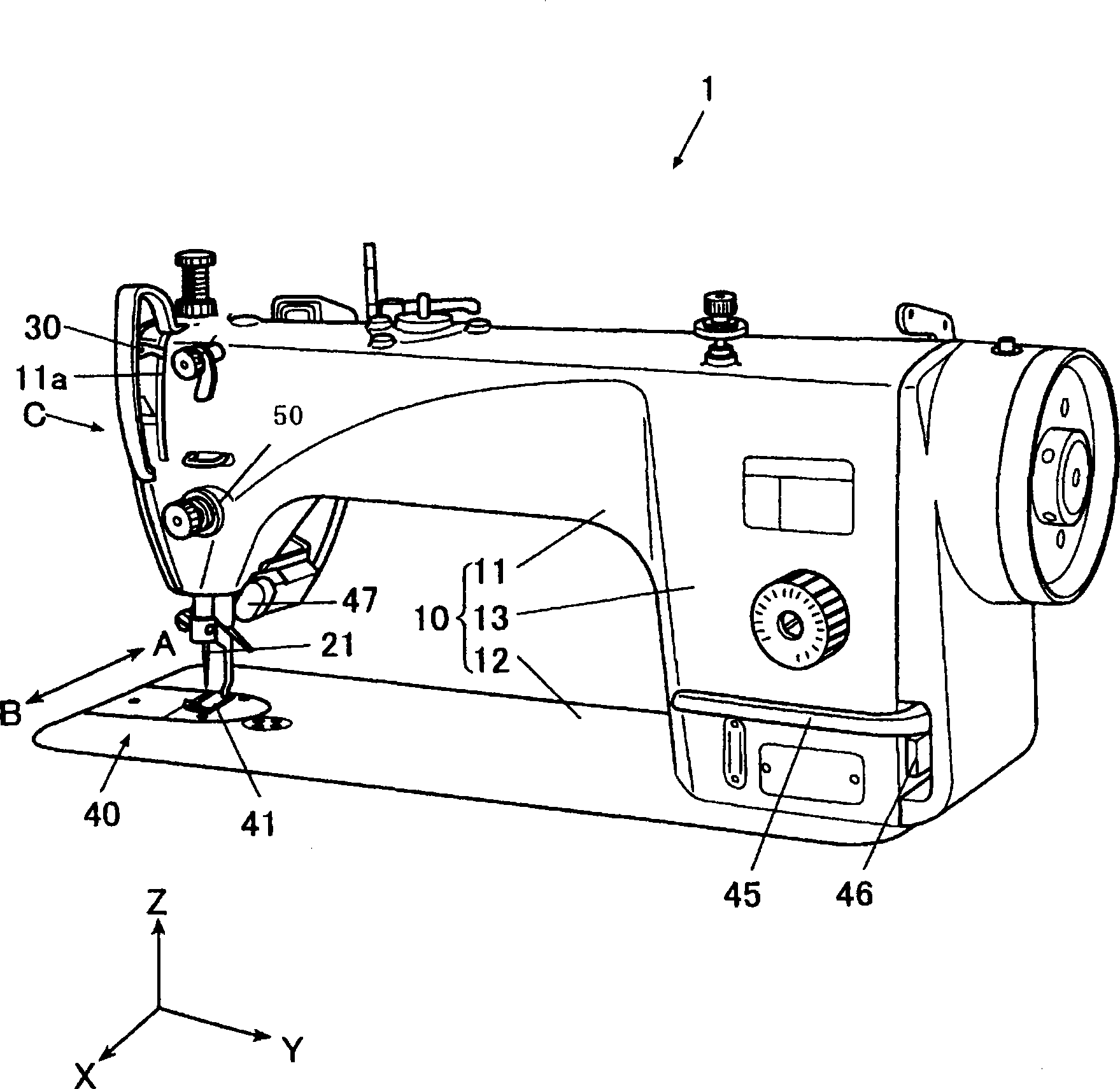

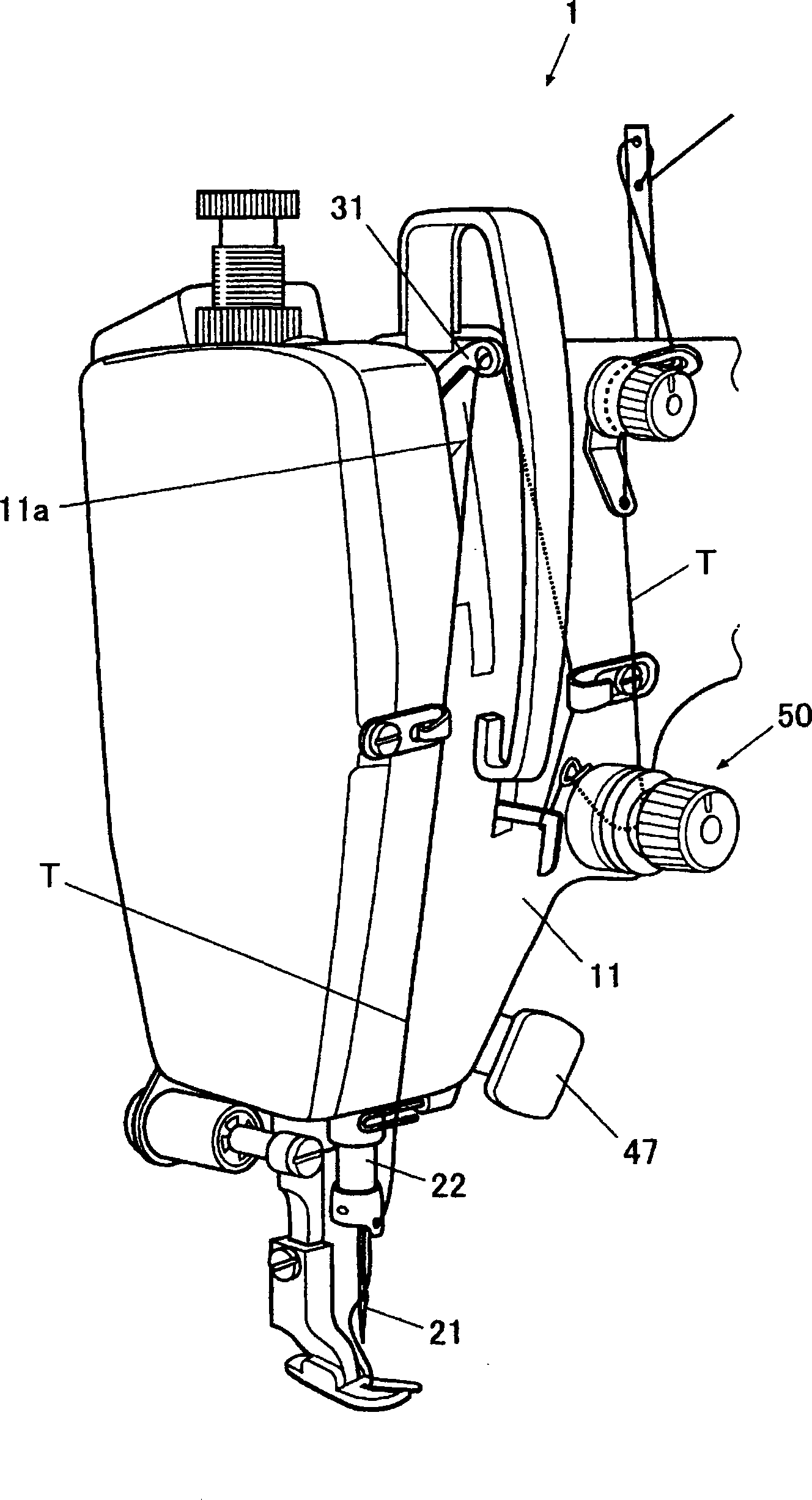

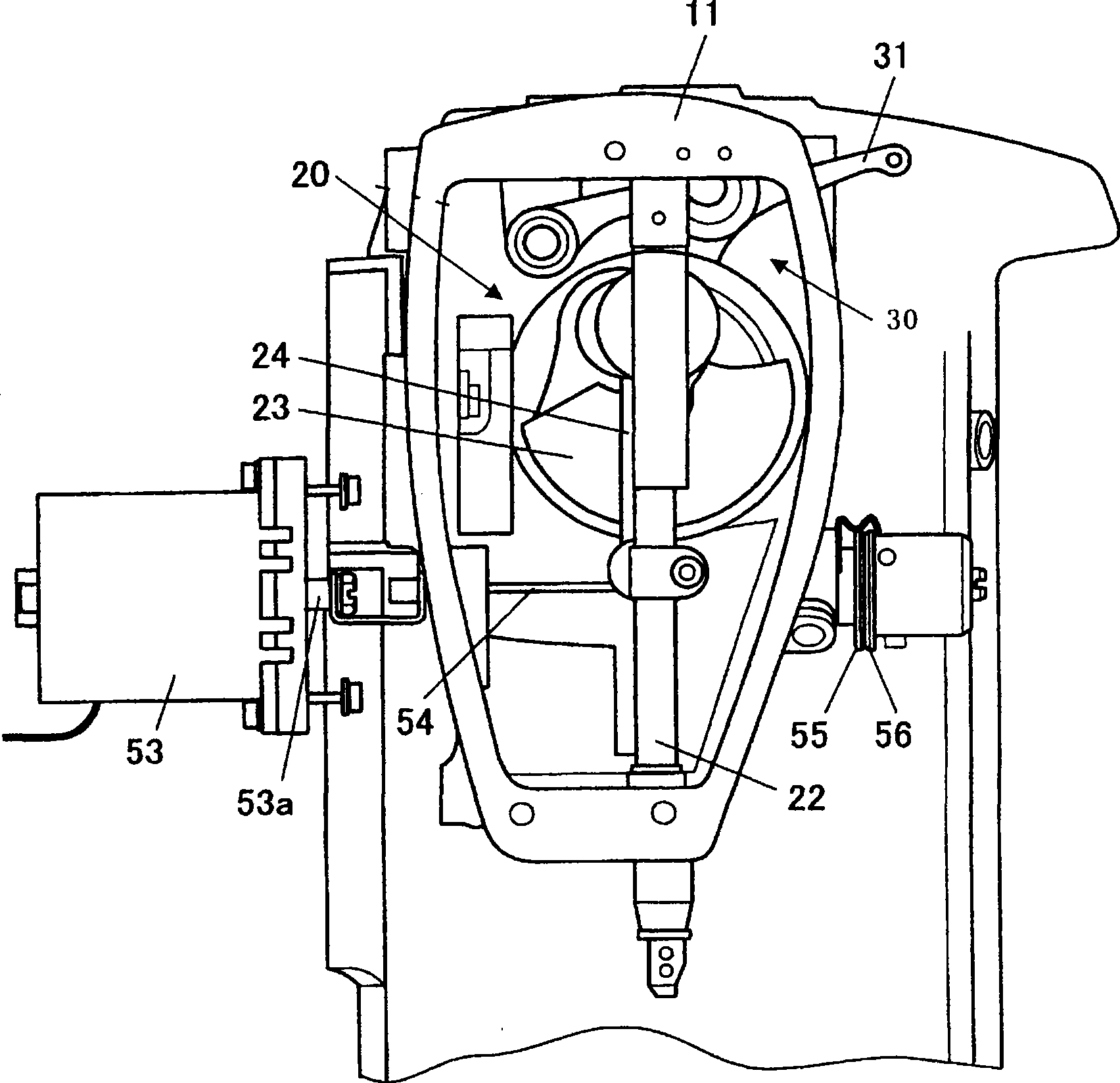

[0026] The following reference Figure 1 to Figure 6 Specific embodiments for carrying out the present invention will be described in detail. In addition, in this embodiment, the direction of each part of the sewing machine 1 is determined based on the XYZ axes shown in each figure. In the state where the sewing machine 1 is installed on a horizontal surface, the Z-axis direction represents the vertical direction, the Y-axis direction represents the left-right direction that coincides with the longitudinal direction of the sewing machine arm 11, and the X-axis direction represents the horizontal direction that is parallel to the Y-axis direction. The direction is orthogonal to the front-back direction.

[0027] (the whole frame)

[0028] (sewing frame)

[0029] Such as figure 1 As shown, the sewing machine frame 10 consists of a sewing machine arm 11 extending along the longitudinal direction (Y-axis direction) of the sewing machine table, a sewing machine base 12 opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com