Patents

Literature

53 results about "Block needle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

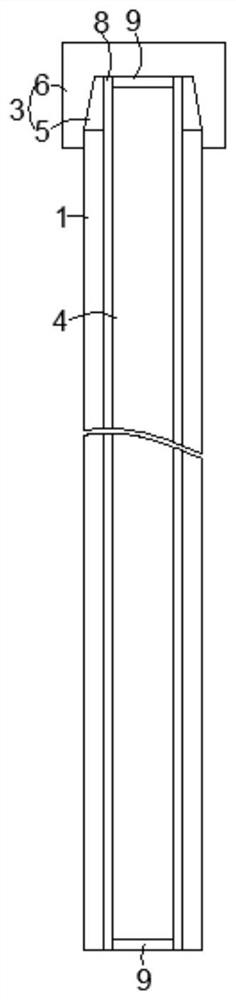

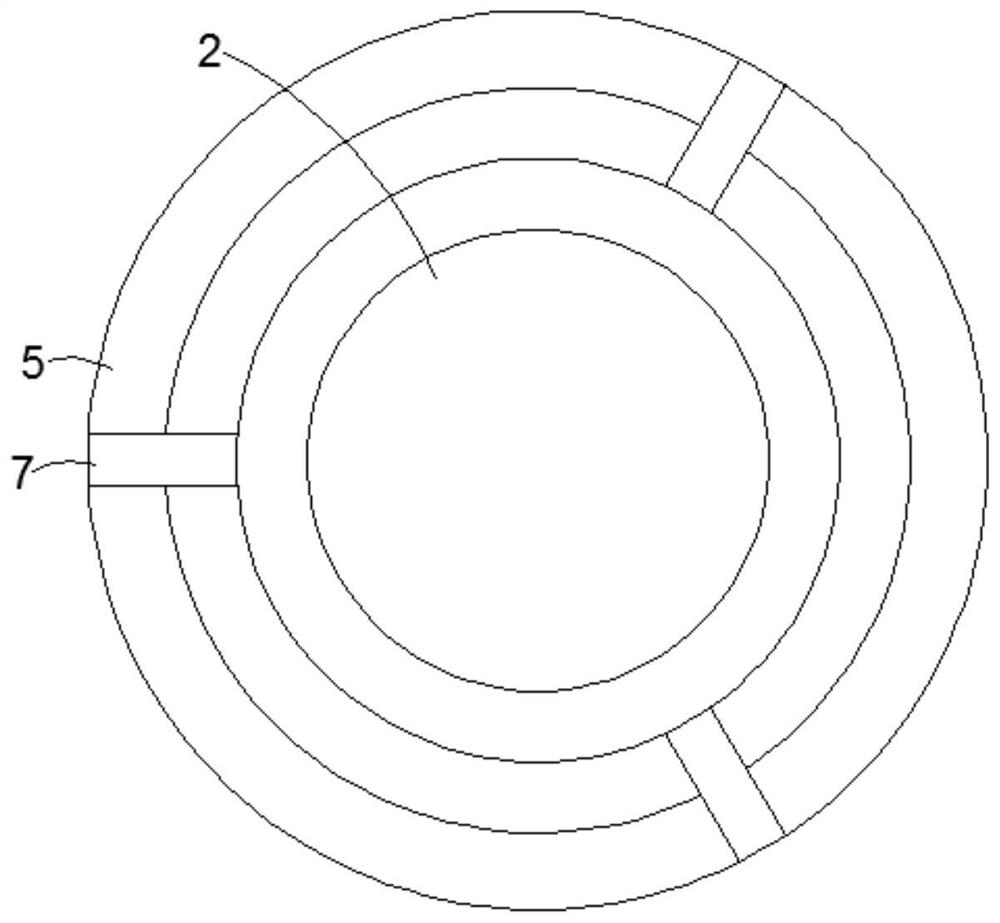

Novel spray head for 3D printer

ActiveCN105965888ASimple structureEasy and fast operation and replacementAdditive manufacturing apparatusSpray nozzleEngineering

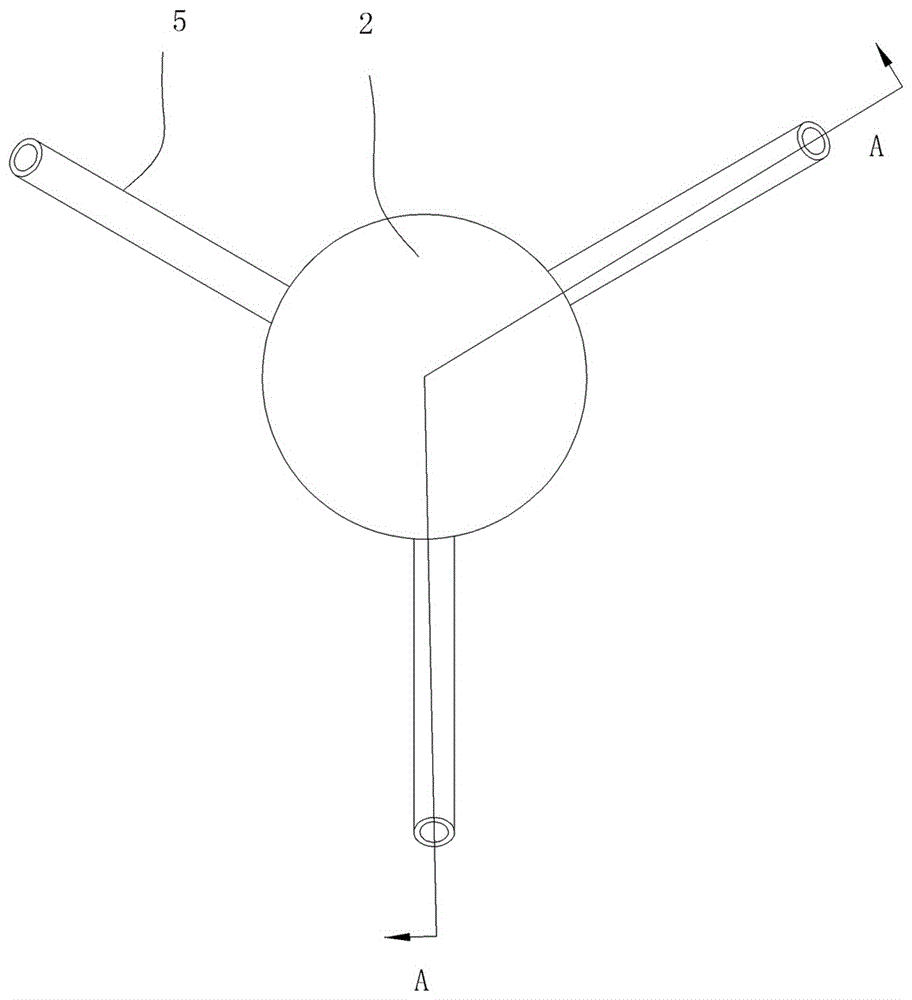

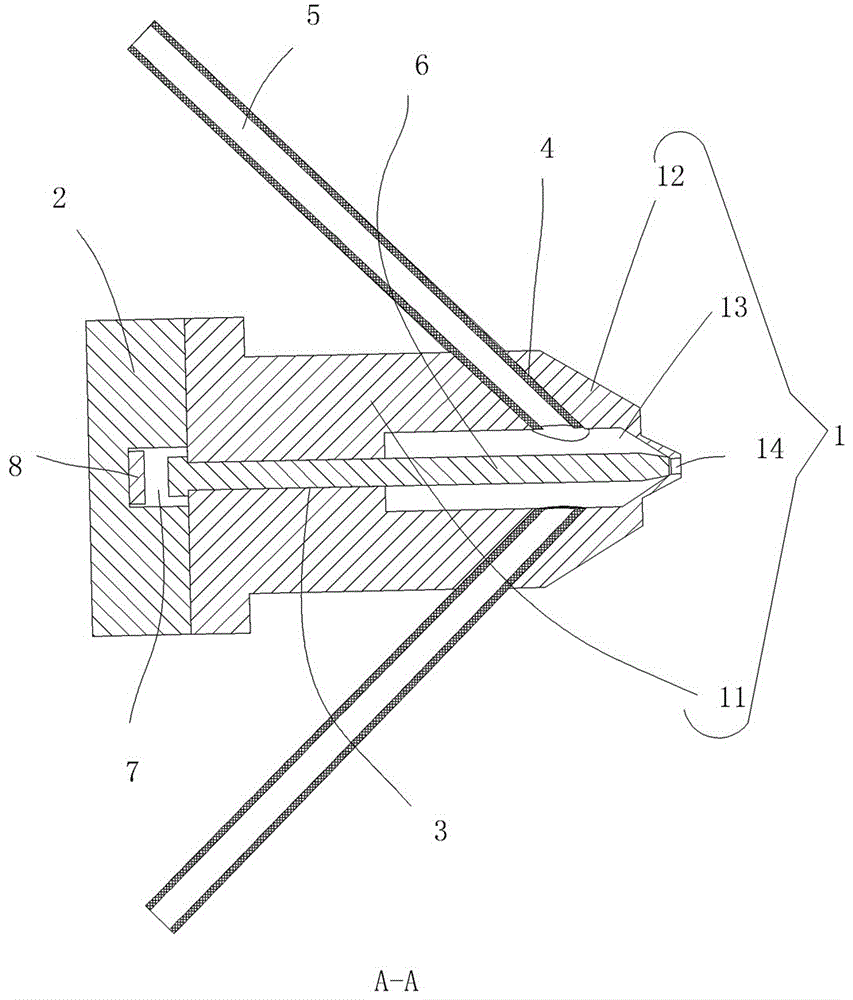

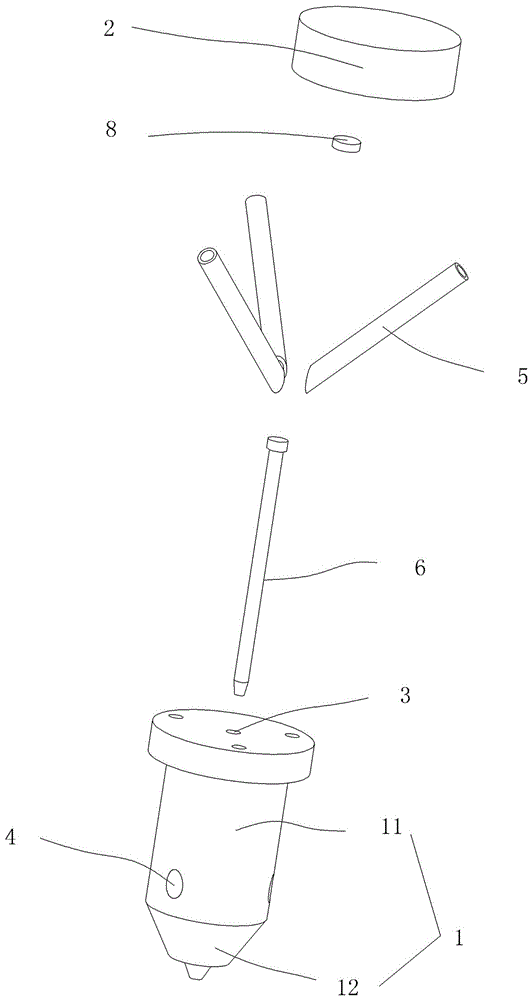

The invention discloses a novel spray head for a 3D printer. The novel spray head comprises a spray nozzle and an upper cover arranged on the top surface of the spray nozzle, wherein the spray nozzle comprises a cylindrical spray nozzle body and a conical spray nozzle head arranged at the bottom end of the cylindrical spray nozzle body; a spraying cavity is arranged in the cylindrical spray nozzle body; a material blocking hole is formed in the center of the cylindrical spray nozzle body; three feeding holes are uniformly formed in the side wall of the cylindrical spray nozzle body; feeding tubes are arranged in the feeding holes; a material blocking needle is arranged in the material blocking hole; a concave cavity with an opening in bottom surface is formed in the upper cover; an electromagnet is arranged in the concave cavity; and under the action of the electromagnet, the top of the material blocking needle lifts in the material blocking hole, so that the bottom end of the material blocking needle is movably blocked in a spray nozzle hole of the conical spray nozzle head. The novel spray head is simple in structure; by virtue of three feeding tubes, three base-color raw materials can be simultaneously fed, operation and replacement are simple, convenient and quick, and therefore, printing efficiency is greatly improved; and moreover, the material blocking needle is arranged, so that drainage and wire-drawing can be prevented, and therefore, use stability is greatly improved, applicability is high and practicability is high.

Owner:广州市文搏智能科技有限公司

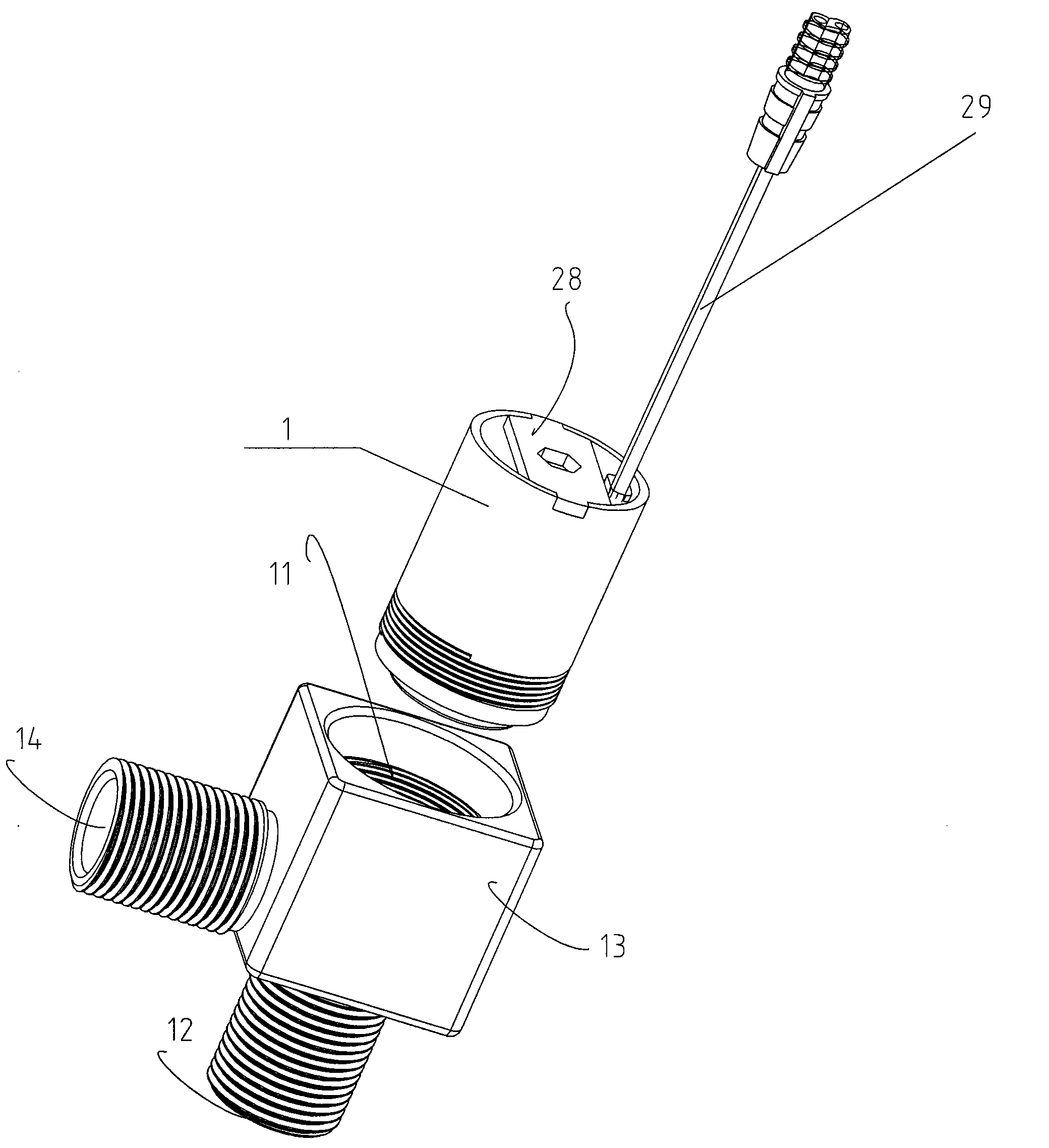

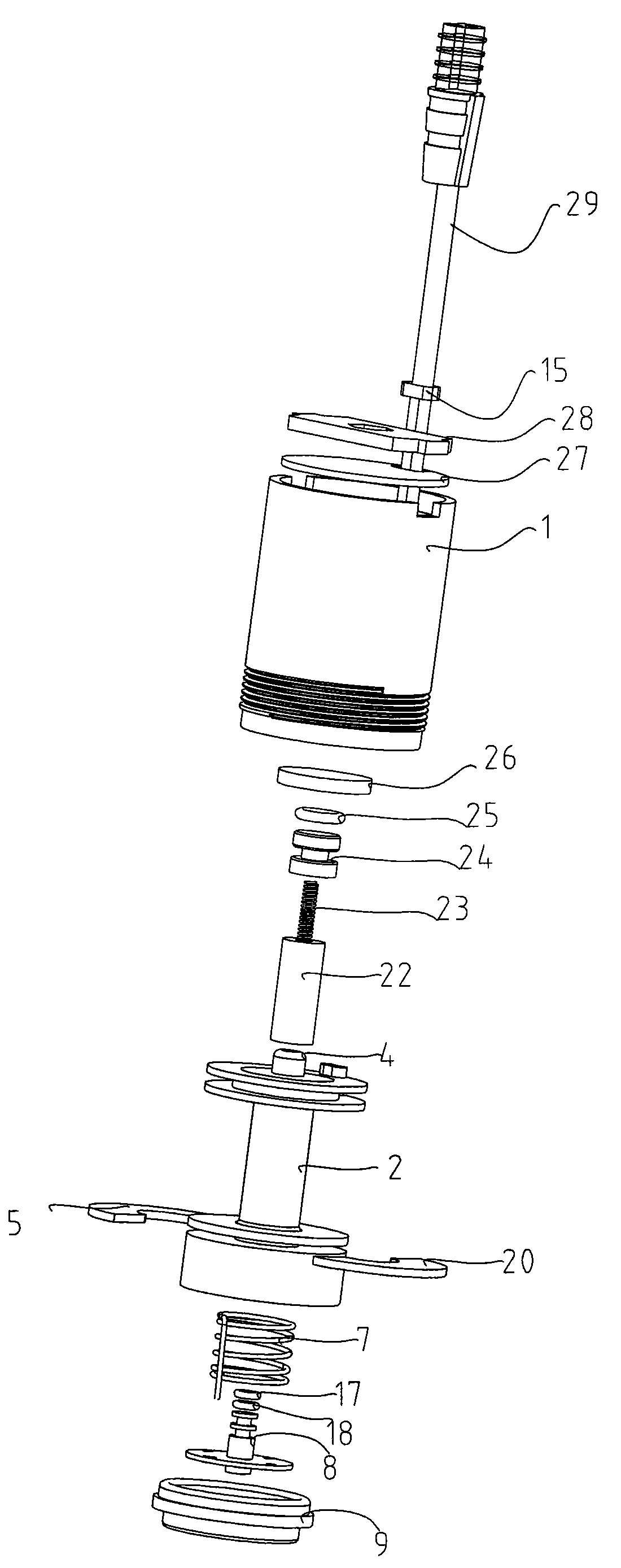

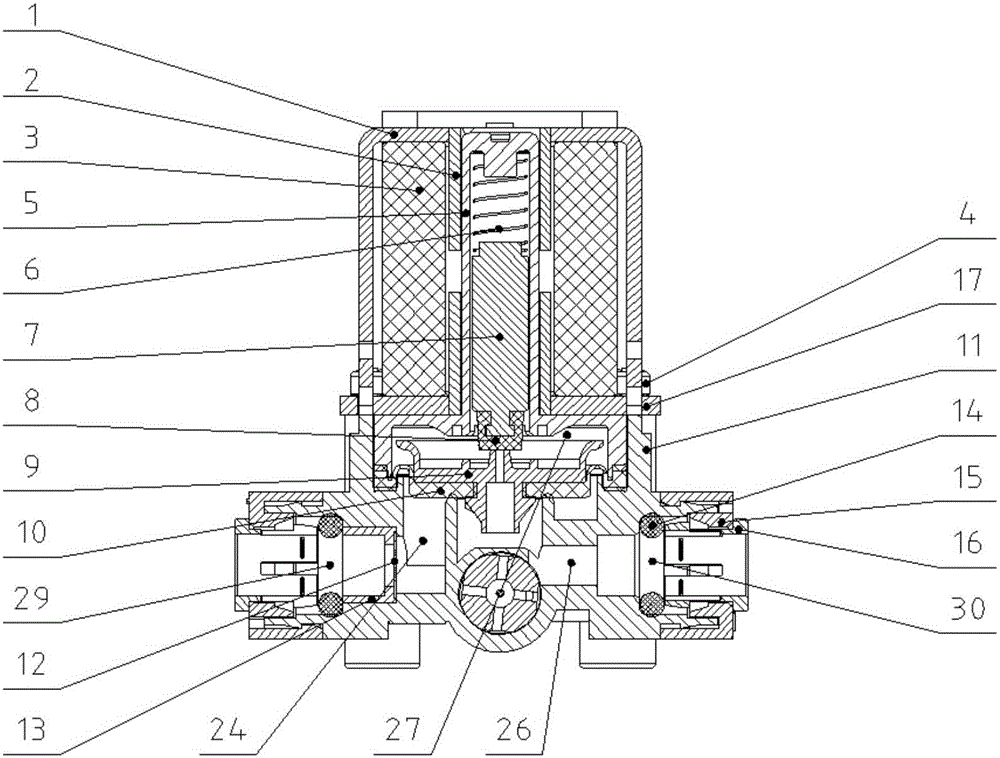

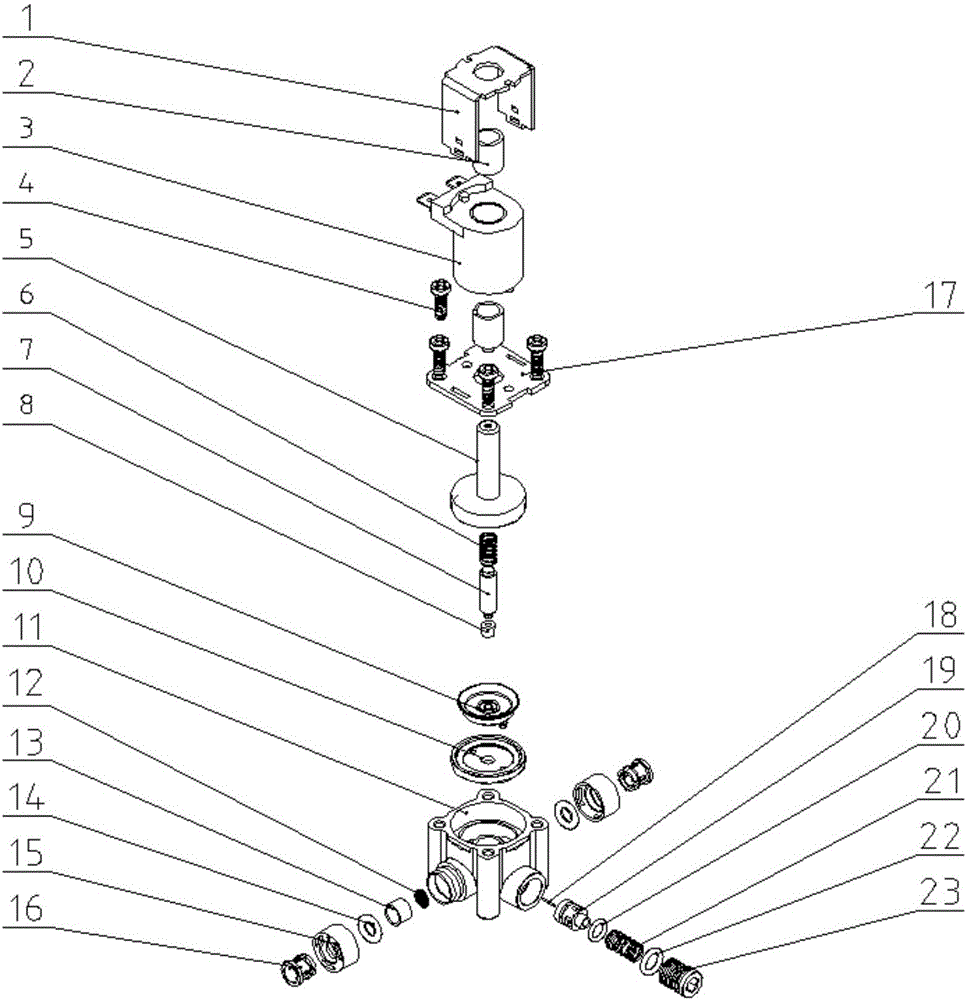

Integrated bistable solenoid valve

ActiveCN101551024AReduce impact noiseImprove performanceDiaphragm valvesOperating means/releasing devices for valvesSolenoid valveEngineering

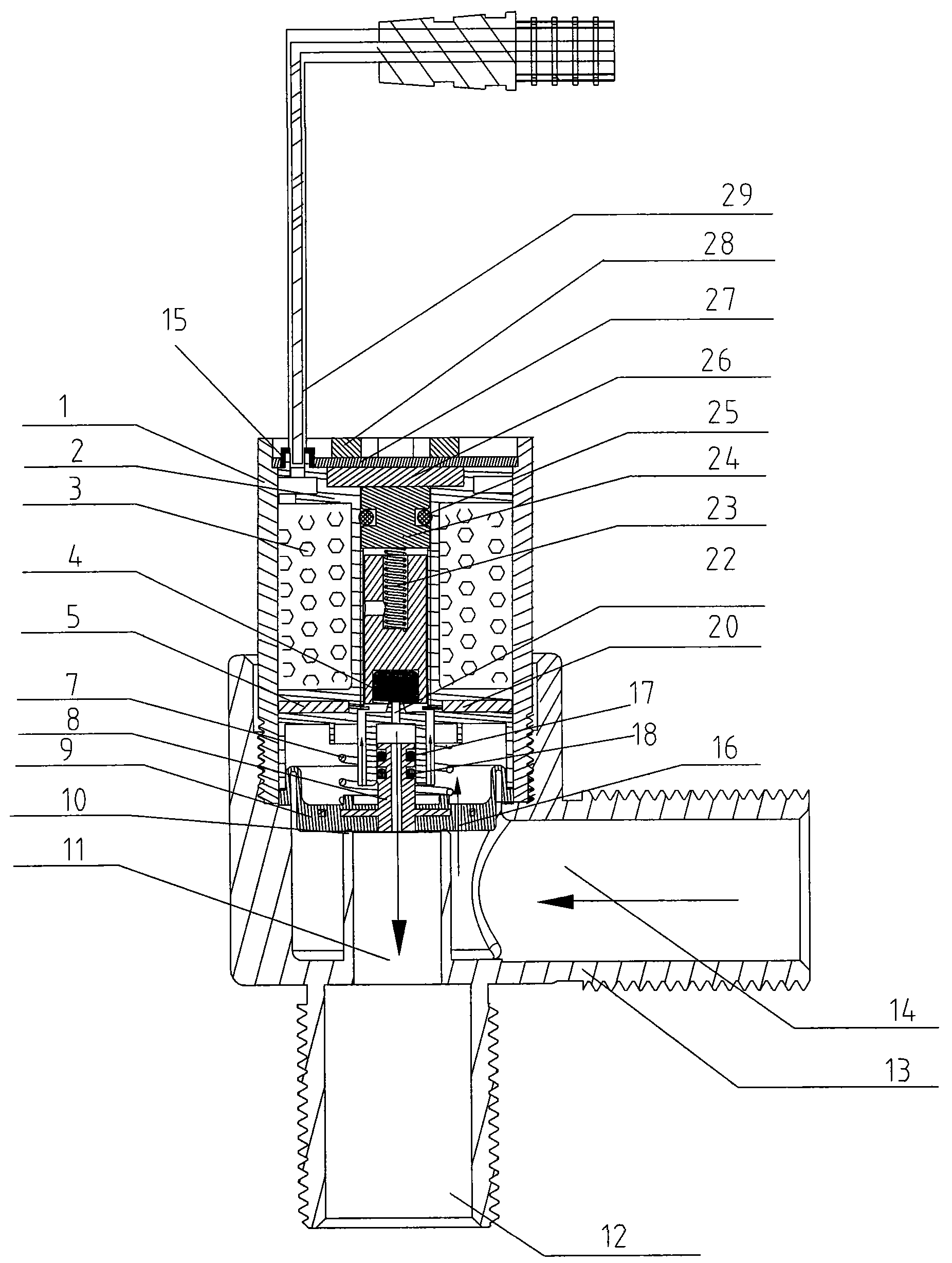

The integrated bistable solenoid valve in the invention comprises a electromagnetic valve head mounted on valve body; the electromagnetic valve head comprises a cover casing formed with external thread; the cover casing is in threaded connection with a valve body formed with internal thread; a coil frame is equipped in the inner cavity of the cover casing; a coil is disposed on the waist of the coil frame; a fixed iron core, a moving iron core with a built-in adhesive spring and a plug are disposed in sequence in the inner upper cavity of the coil frame; a first O-shaped sealing ring is disposed in the ring groove of the fixed iron core; an anti-blocking needle spring, a piston film core and a rubber film are disposed in sequence in the inner lower cavity of the coil frame; the coil frame is equipped with a first and a second shielding iron plate which form a shielding space together with the coil outer cap; the rubber film is clamped on the lower port of the cover casing by sealing; a magnet is disposed on the top of the coil frame; a coil casing cover is disposed on the cover casing opening, and is fixed by a casing locking plate; an anti-reverse inserting wire with enclosed coil sheath is lead out from the coil; the coil sheath is positioned on the coil casing cover; and the piston film core is assembled with the rubber film to compose a direct acting piston type structure.

Owner:宁波展鹰智能厨卫科技有限公司

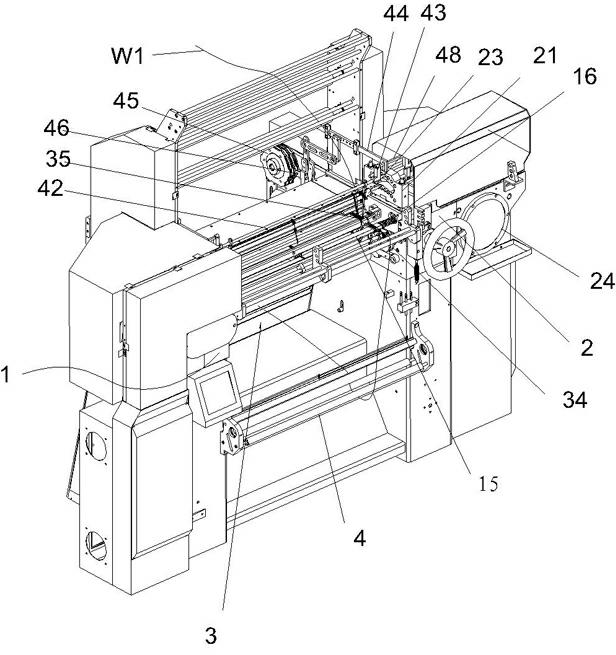

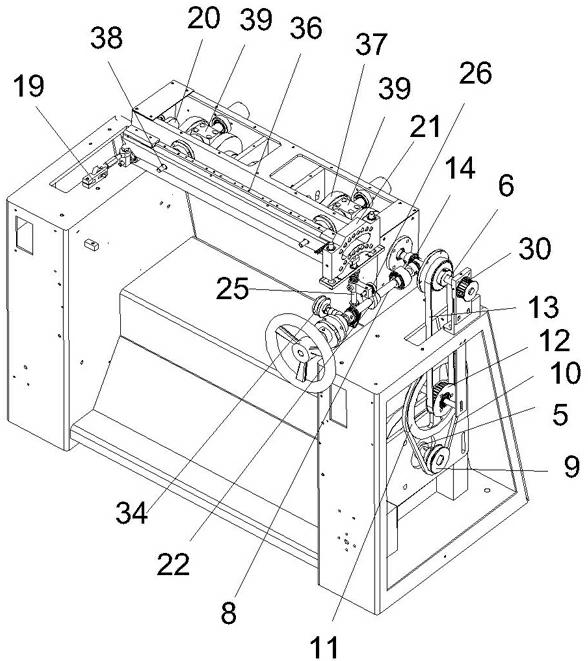

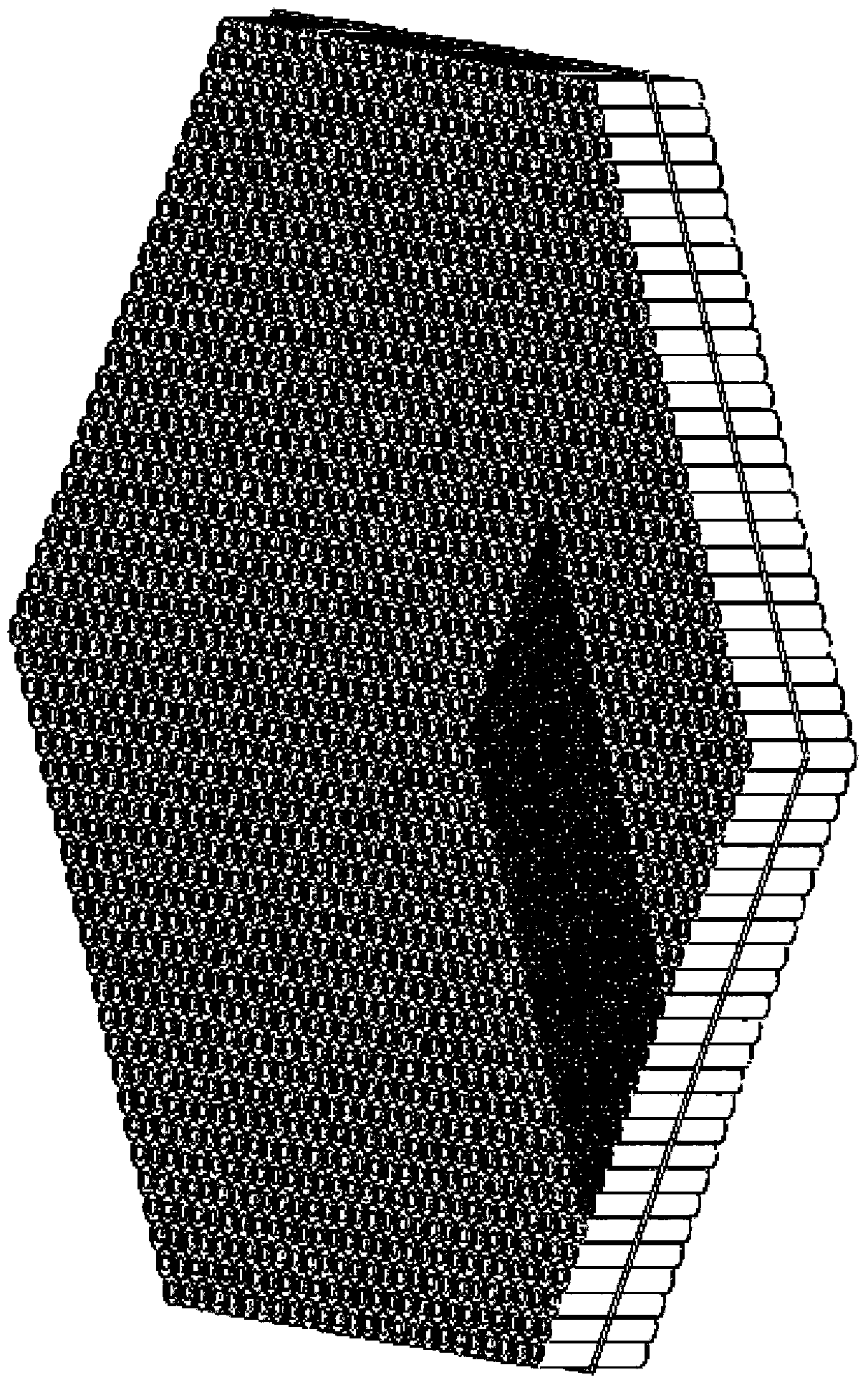

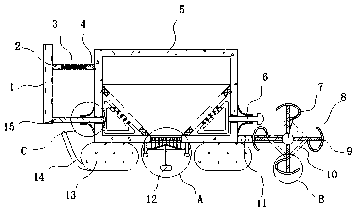

Multifunctional lace crochet machine

ActiveCN102154780ACollaborate closely with each otherSmooth power transmissionCrochetingSprocketEngineering

The invention mainly discloses a multifunctional lace crochet machine which comprises a power transmission device, a warp yarn mechanism, a weft yarn mechanism, a needle withdrawing mechanism, a needle blocking mechanism and a crossing mechanism. The needle blocking mechanism comprises a swing shaft, a blocking needle, a blocking needle drive arm and a needle blocking cam; one end of the needle blocking drive arm leans against the needle blocking cam driven by the power transmission device, and the other end of the needle blocking drive arm is fixedly connected with the swing shaft which rotates with the swing shaft of the needle blocking drive arm; and the swing shaft is fixedly connected with the blocking need which turns over inwards and outwards at the outer side of a needle bed with the swing shaft. The crossing mechanism comprises a weft yarn shaft, a swing arm, a shift fork and a floret chain transmission device, wherein the weft yarn shaft is mounted on the weft yarn mechanismand fixed with a weft yarn tube; the swing arm is fixedly sleeved on the weft yarn shaft; the shift form shifts the swing arm to swing; the floret chain transmission device supplies power to the shift fork; and a floret chainwheel in the floret chain transmission device is driven by the power transmission device. The multifunctional lace crochet machine disclosed by the invention is suitable for crocheting various flower forms, remarkably shortens the knitting time and has high production efficiency.

Owner:SHAOXING SANFANG MACHINERY

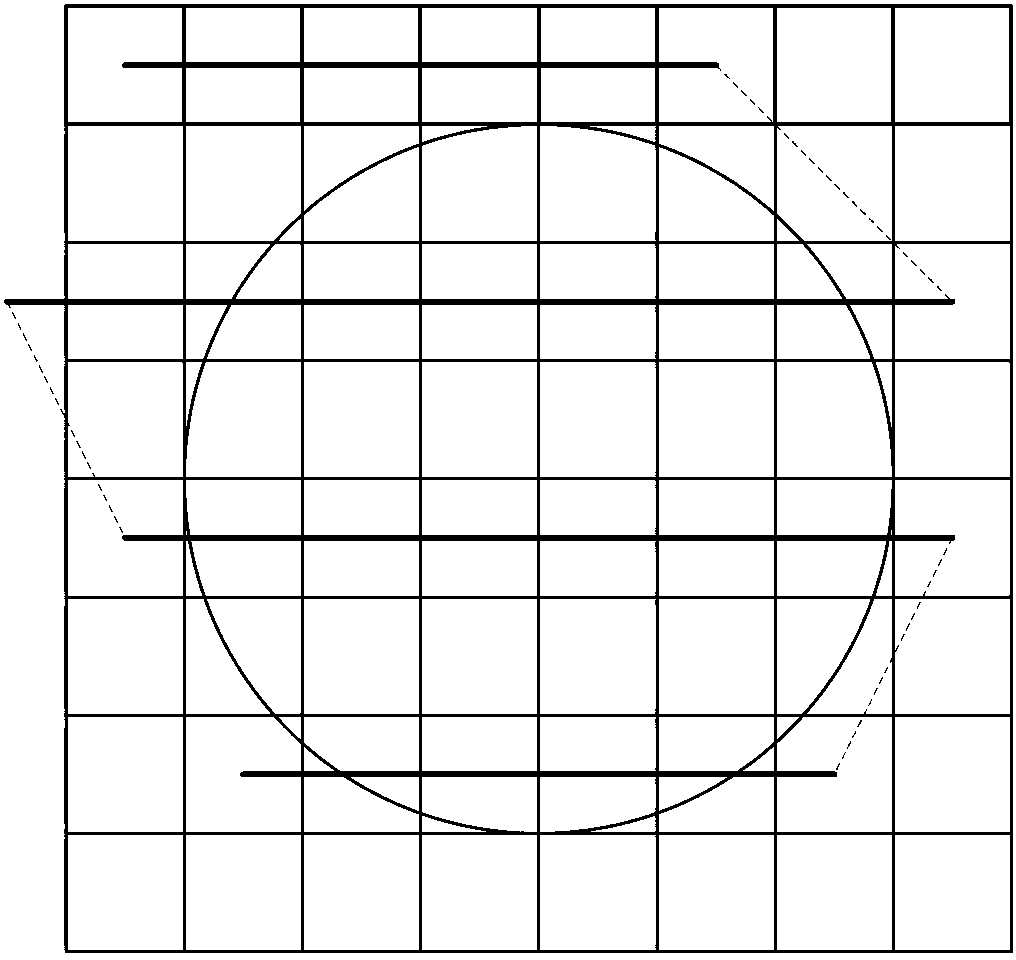

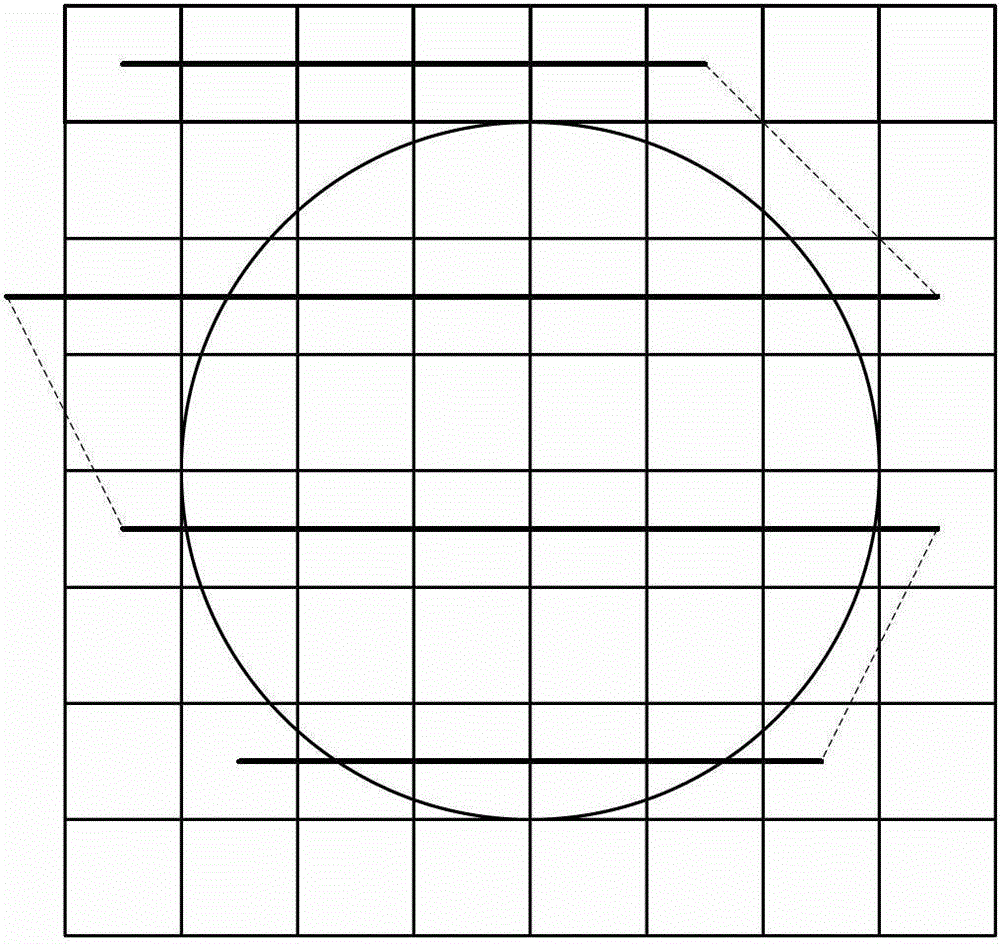

Test path selection method and corresponding wafer test method

ActiveCN103344896AAvoid testingReduce distanceSemiconductor/solid-state device testing/measurementIndividual semiconductor device testingComputer hardwareElectricity

The invention provides a test path selection method which includes the first step of forming valid dies and invalid dies on an arranged wafer, the second step of forming a wafer mapping picture, the third step of marking the positions of the valid dies and the invalid dies on the wafer mapping picture according to the positions of the valid dies and the invalid dies, the fourth step of enabling multi-circuit-block needle card pictures to be arranged repeatedly on the dies of the wafer mapping picture and filling the wafer mapping picture, wherein the multi-circuit-block needle card pictures at least comprise a first needle card identification mark and a second needle card identification mark, the fifth step of eliminating the multi-circuit-block needle card pictures fully occupying the invalid dies on the wafer mapping picture and reserving the multi-circuit-block needle card pictures at least occupying one valid die, and the sixth step of enabling the dies corresponding to the first identification marks in each multi-circuit-block needle card picture reserved on the wafer mapping picture to be connected into a straight line, and obtaining a test path. The invention further provides a wafer test method. The test path selection method and the corresponding wafer test method shorten the distance of needle card displacement in the testing process, save needle card displacement time, and improve testing efficiency of wafers.

Owner:HANGZHOU SILAN MICROELECTRONICS

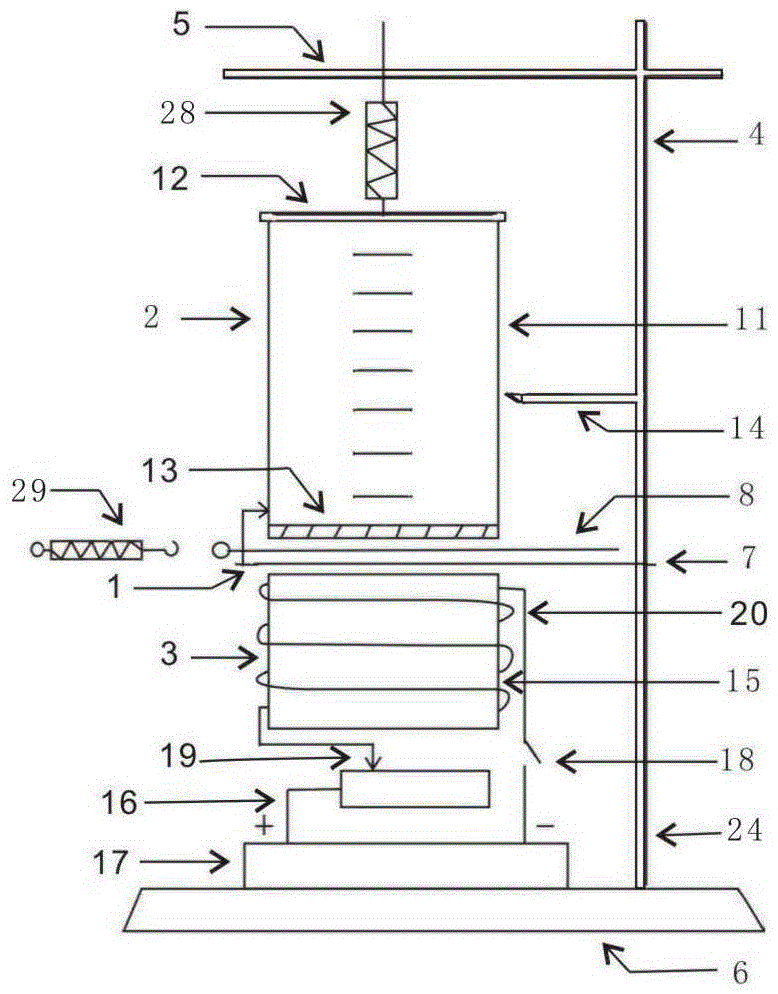

Residual heat recycling device

ActiveCN109589700AImplement automatic cleanupImprove cleaning efficiencyGas treatmentDispersed particle filtrationBottleElectrical and Electronics engineering

The invention relates to the field of glass bottle processing, and particularly relates to a residual heat recycling device. The device comprises a vent pipe, a heat collecting pipe, an ash tank communicated with the vent pipe, an air inlet and an air outlet, wherein the heat collecting pipe is positioned inside the vent pipe; a main filter screen is arranged in the smoke vent; the ash tank is positioned under the vent pipe; a rotary roller opposite to the air inlet is in rotating connection in the ash tank, and is provided with a fan blade; the rotary roller is coaxially connected with a crank shaft; a cleaning mechanism is in sliding connection with the side, far from the heat collecting pipe, of the main filter screen; a connecting rod is connected between the cleaning mechanism and thecrank shaft; two ends of the connecting rod are respectively in rotating connection on the cleaning mechanism and the crank shaft; a secondary filter screen opposite to the air outlet is arranged inthe ash tank; blocking needles are inserted in meshes of the secondary filter screen, and are connected with a press plate which enables the blocking needles to be drawn out from the meshes of the secondary filter screen; and a baffle is in sliding connection with the side, near the heat collecting pipe, of the main filter screen, and can be supported against the press plate.

Owner:CHONGQING HAOSHENG GLASS

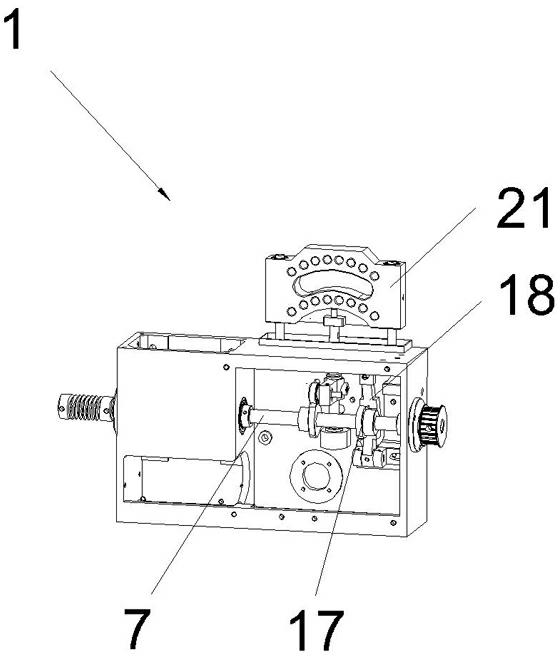

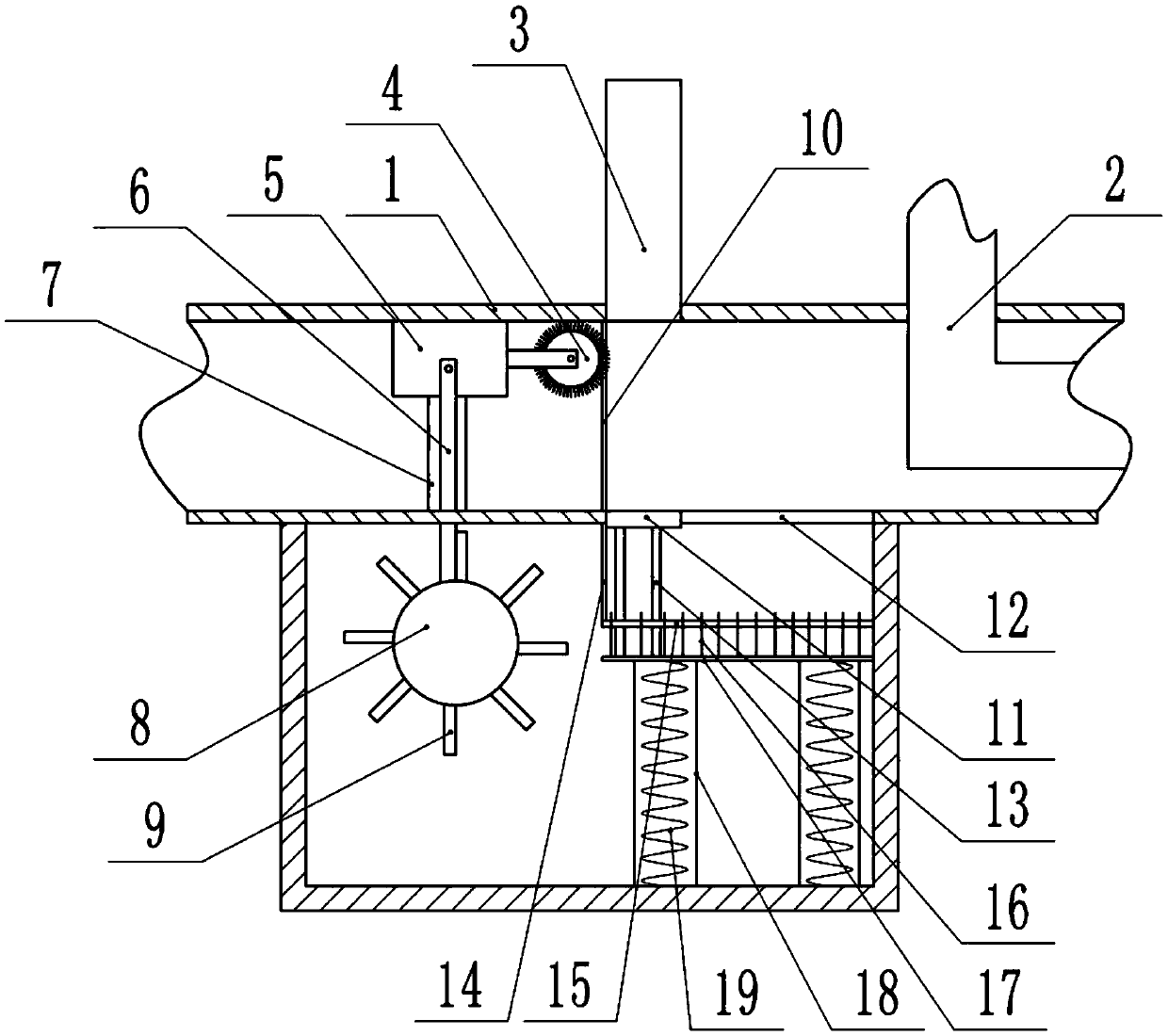

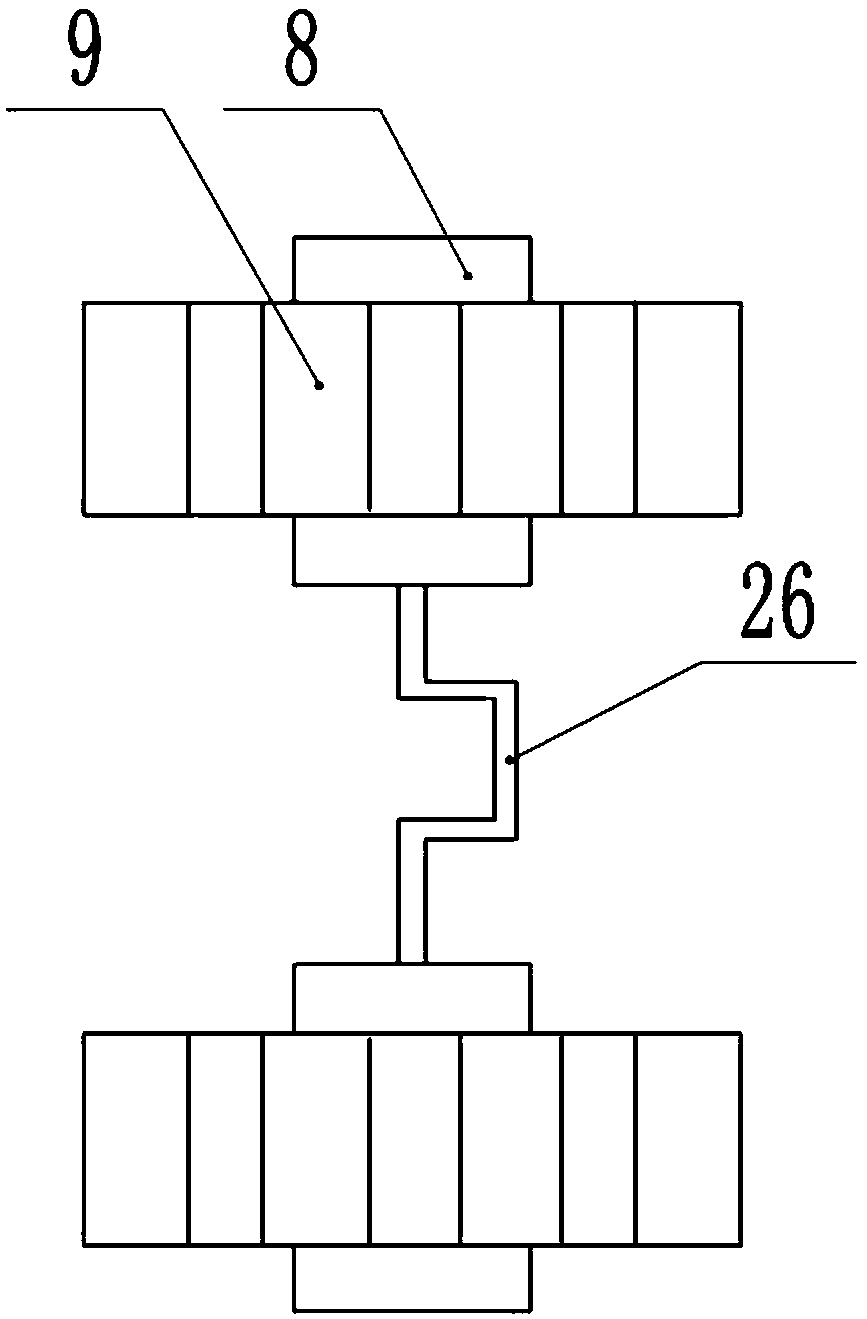

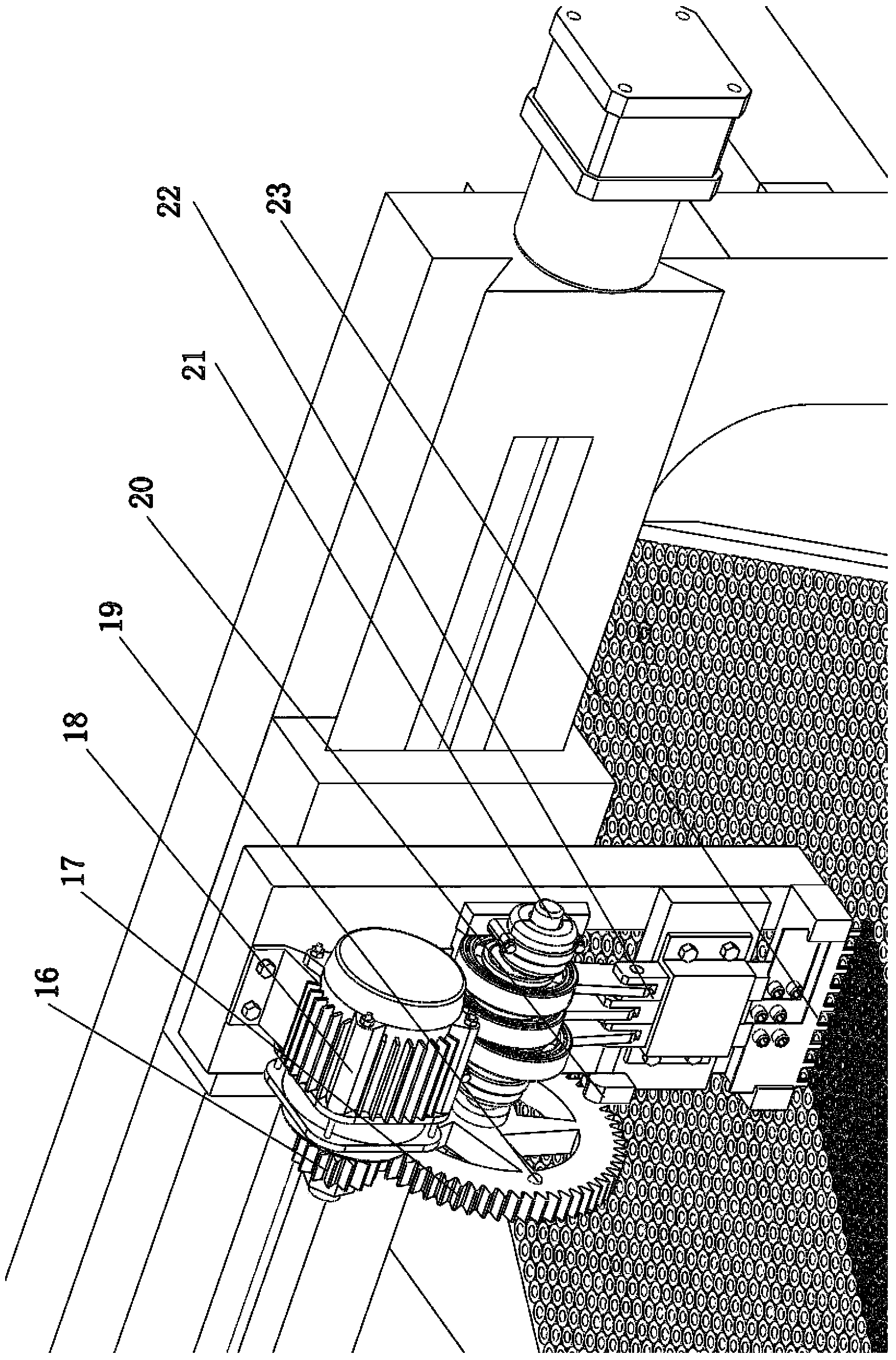

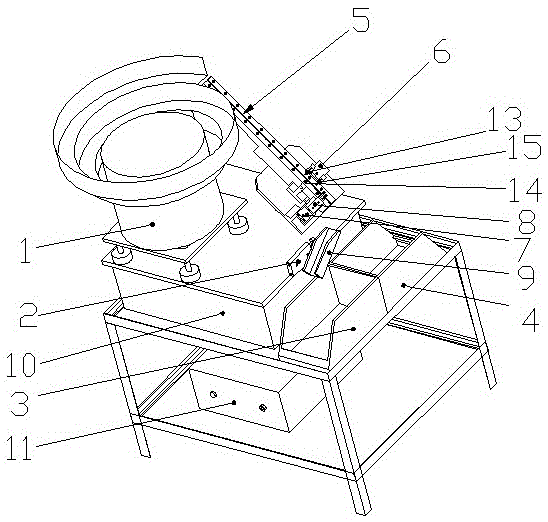

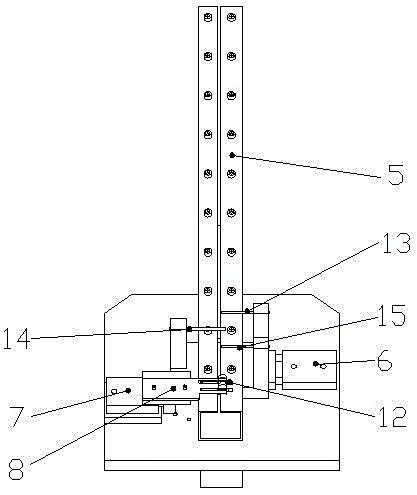

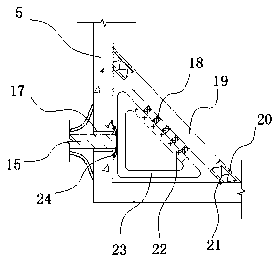

Numerical control firecracker binding and firecracker barrel tail blocking machine

ActiveCN103411481AReduce labor intensityImprove feed positioning accuracyFireworksFirecrackerNumerical control

The invention provides a numerical control firecracker binding and firecracker barrel tail blocking machine to overcome the defects that a large number of waste firecracker barrels are produced due to the fact that an existing hand-operated firecracker binding and firecracker barrel tail blocking machine is high in labor intensity and positioning is inaccurate due to manual feeding, and belongs to the technical field of firework and firecracker machinery. According to the scheme, some technical measures are taken, namely, mechanical power replaces manual power, and numerical control automatic feeding replaces manual feeding. According to numerical control automatic feeding, firecracker barrels are fixed, clamped and bound on a longitudinal sliding table, and an electric firecracker barrel tail blocking machine head is arranged on a transverse sliding table. Through a single board computer and the like, the longitudinal sliding table and the transverse sliding table are controlled to move synchronously, therefore, firecracker barrel tail blocking needles can be aligned with each row of firecracker barrels, and numerical control automatic feeding can be achieved. According to the scheme, due to the fact that manual power is replaced by an electromotor, labor intensity of workers is greatly relieved, and meanwhile the working speed is greatly raised. After manual feeding of the firecracker barrel tail blocking machine is replaced by the numerical control automatic feeding, the feeding positioning accuracy of the firecracker barrels is greatly improved, and the phenomenon of appearance of the waste firecracker barrels caused by inaccurate positioning is basically eliminated.

Owner:启东市天汾电动工具技术创新中心

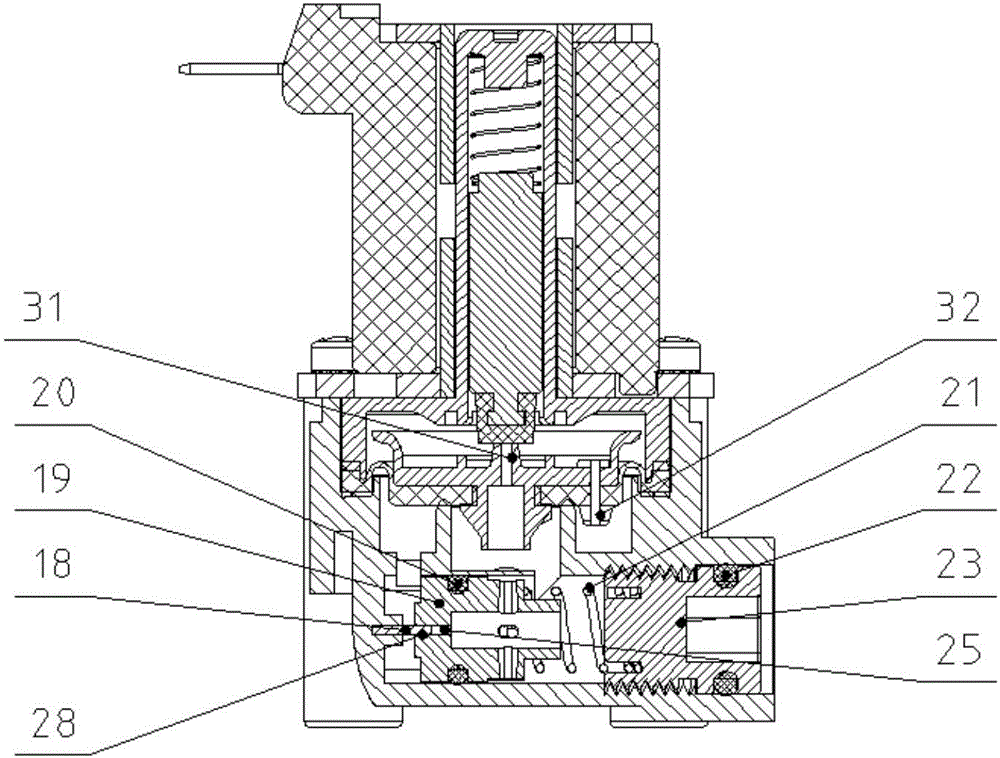

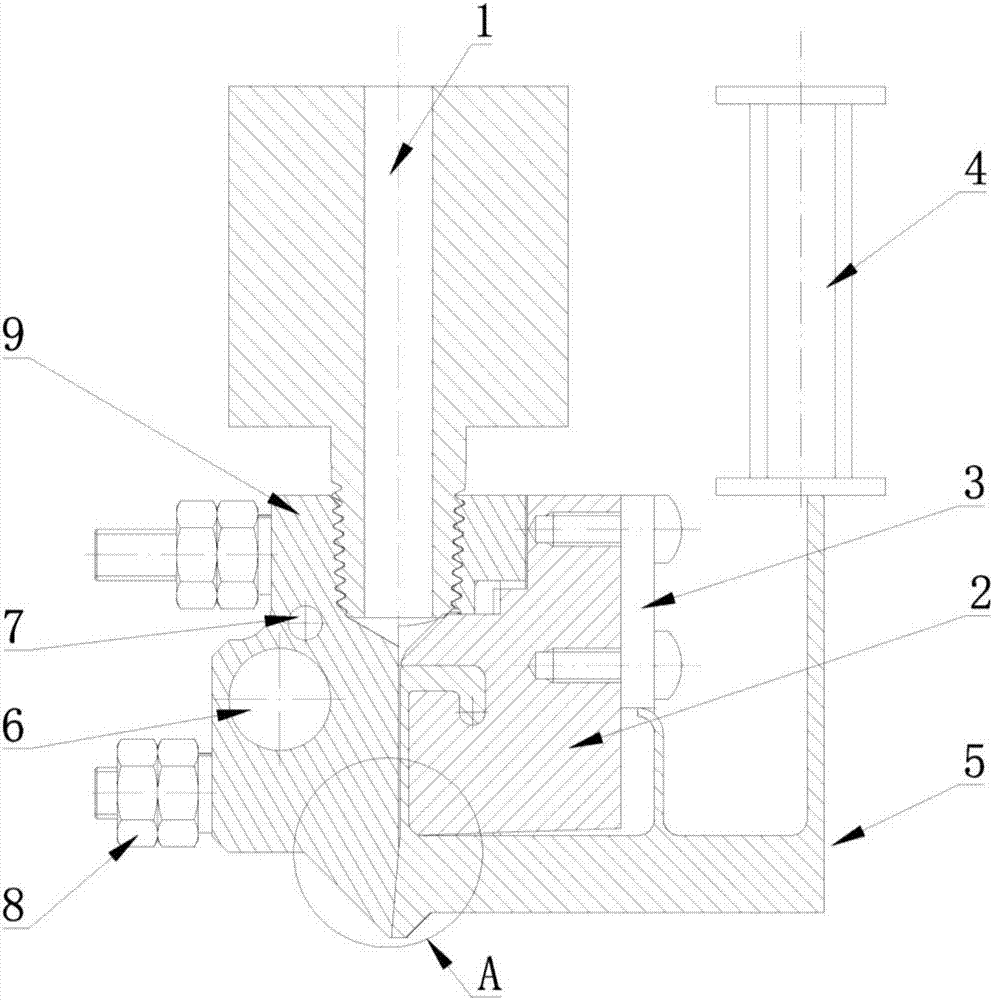

Anti-blocking and self-cleaning effluent proportional solenoid valve

InactiveCN106555900ASolve the clogging problemOperating means/releasing devices for valvesSolenoid valveWastewater

The invention provides an anti-blocking and self-cleaning effluent proportional solenoid valve comprising a valve body; valve diaphragms are arranged in the valve body; the inside of the valve body is defined into a water inlet chamber, a water outlet chamber and a water separation chamber by the valve diaphragms; the water inlet chamber is internally provided with a fixed anti-blocking needle, a movable anti-blocking sleeve and a fixed anti-blocking seat, wherein the fixed anti-blocking needle is fixedly arranged in the water inlet chamber, the fixed anti-blocking seat is fixedly arranged in the water outlet chamber, the movable anti-blocking sleeve is movably arranged between the fixed anti-blocking needle and the fixed anti-blocking seat, and the excircle of the movable anti-blocking sleeve is sealed together with the valve body to partition the water inlet chamber and the water outlet chamber; the movable anti-blocking sleeve is provided with an anti-blocking through hole corresponding to the fixed anti-blocking needle end; and an anti-blocking reset spring is arranged between the fixed anti-blocking seat end in the movable anti-blocking sleeve and the fixed anti-blocking seat. The anti-blocking and self-cleaning effluent proportional solenoid valve has the advantage that the problem of effluent hole blockage of the effluent proportional solenoid valve is solved.

Owner:ZHEJIANG DAWEI ELECTRONICS

Semi-conductor conveying device

InactiveCN102862811AAvoid material wasteReduce usageControl devices for conveyorsVacuum pumpingEngineering

Disclosed is a semi-conductor conveying device. A switching mechanism is arranged to switch the release of compressed air in a conveying track and perform vacuum pumping operation. Before a pick-up head moves forward to a pick-up position, semi-conductors are absorbed on the conveying track mainly through vacuum and are prevented from falling off; and when the pick-up head moves to a pick-up position, the vacuum absorption force is canceled, the semi-conductors at the front end are blown to a groove of the pick-up head through the compressed air, then the semi-conductors at the back end are absorbed to the conveying track through switching the compressed air to the vacuum absorption, and the pick-up head moves to an original position simultaneously. According to the device, a product blocking needle and a center trigger of the existing device are omitted, parts are saved, falling off waste of the semi-conductors is avoided, the production cost is reduced, simultaneously, operation of the semi-conductors is achieved through the switching function between the compressed air and the vacuum absorption, and the working efficiency is high.

Owner:JIANGYIN GLORY TECH

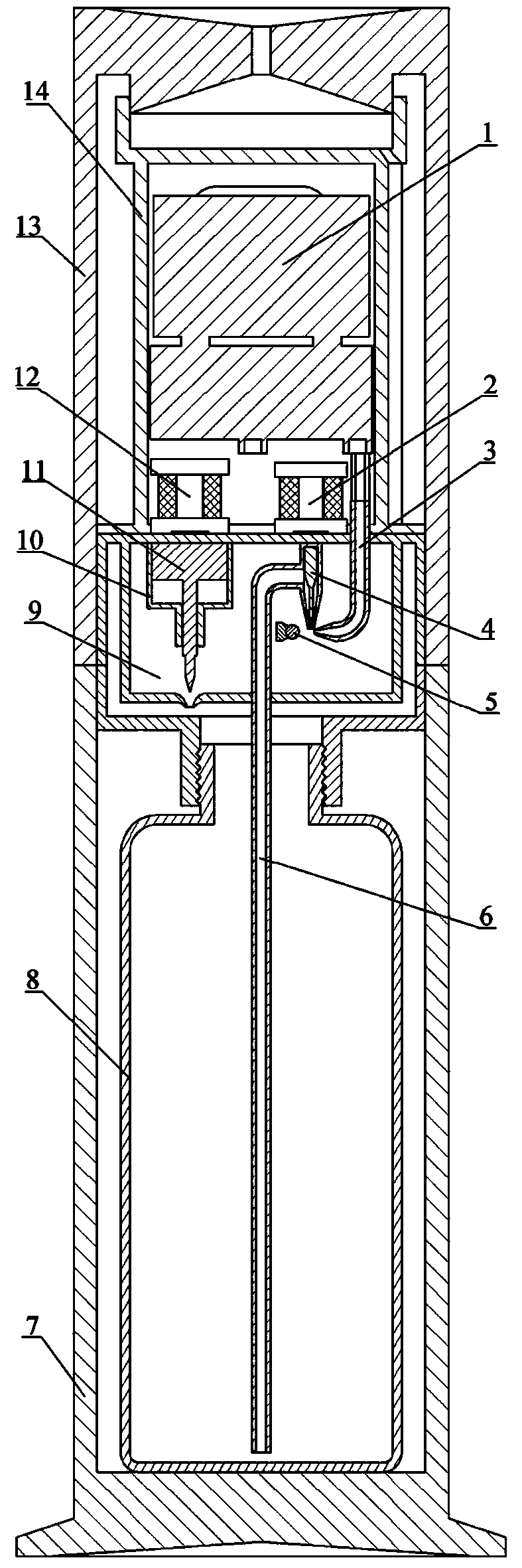

Siphoning type essential oil atomization aromatherapy equipment

The invention discloses siphoning type essential oil atomization aromatherapy equipment which comprises an upper cover and a base, wherein a motor is installed inside the upper cover; an air outlet of the motor is connected with an atomization chamber; and a first electromagnetic iron is arranged at the top of the atomization chamber. An essential oil storage device is installed on the base; the lower part of an essential oil tube is positioned inside the essential oil storage device; the upper part of the essential oil tube is positioned in the atomization chamber; and a first anti-block needle is installed at the tail end on the upper part of the essential oil tube in an interference fit mode. By utilizing the siphoning type essential oil atomization aromatherapy equipment, the essential oil is atomized in a siphoning mode, the essential oil components are uniformly diffused, and the purity of the essential oil grains diffused out is ensured to the maximum extent.

Owner:上海百芬环境科技有限公司

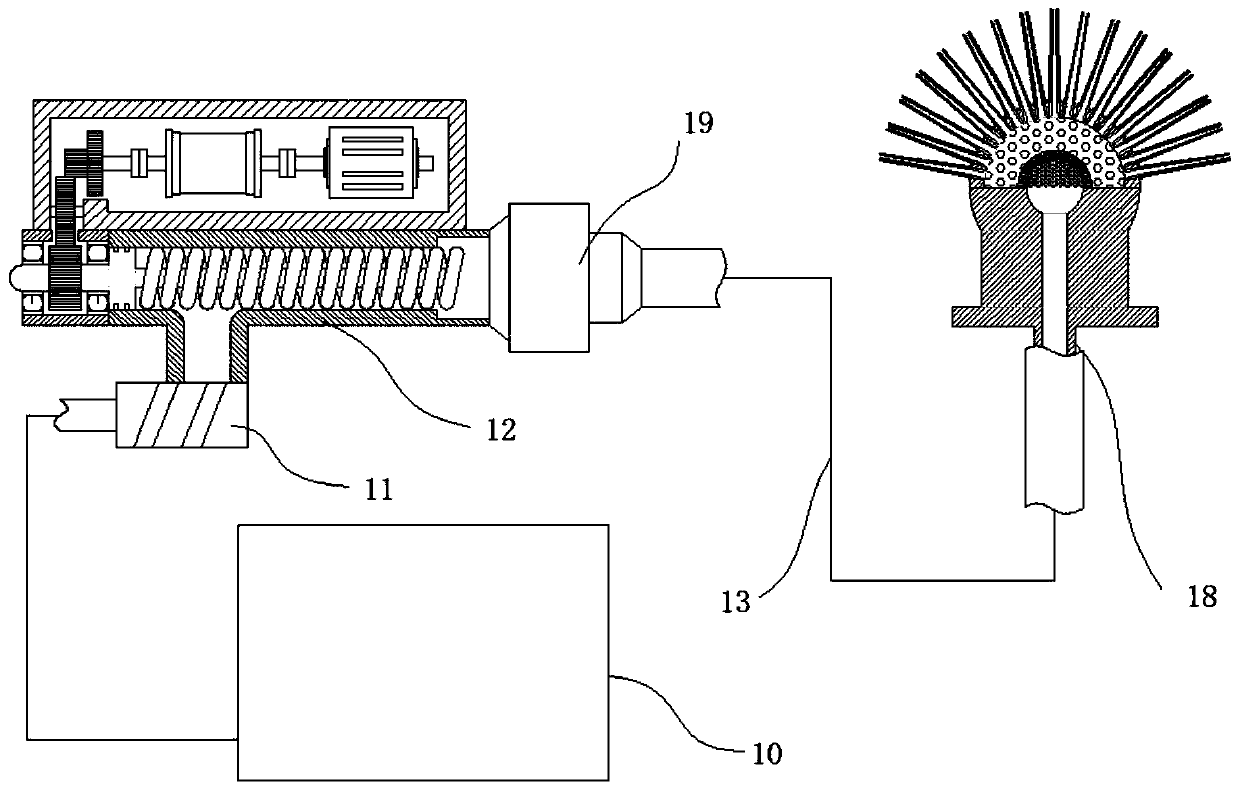

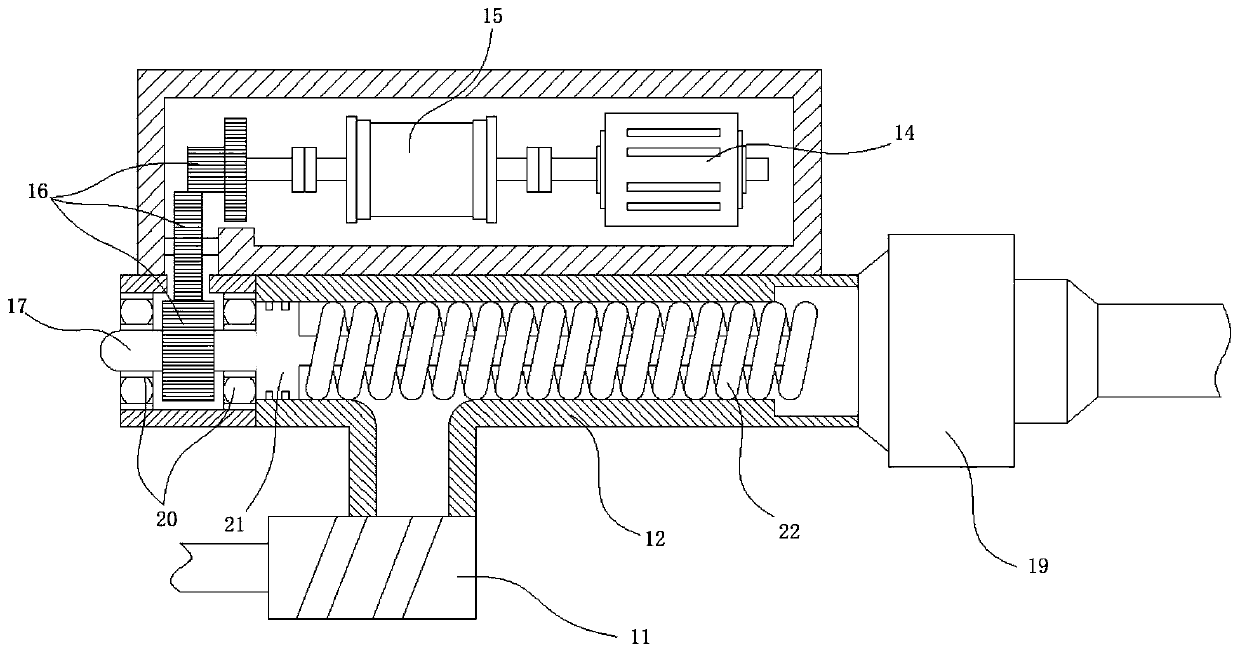

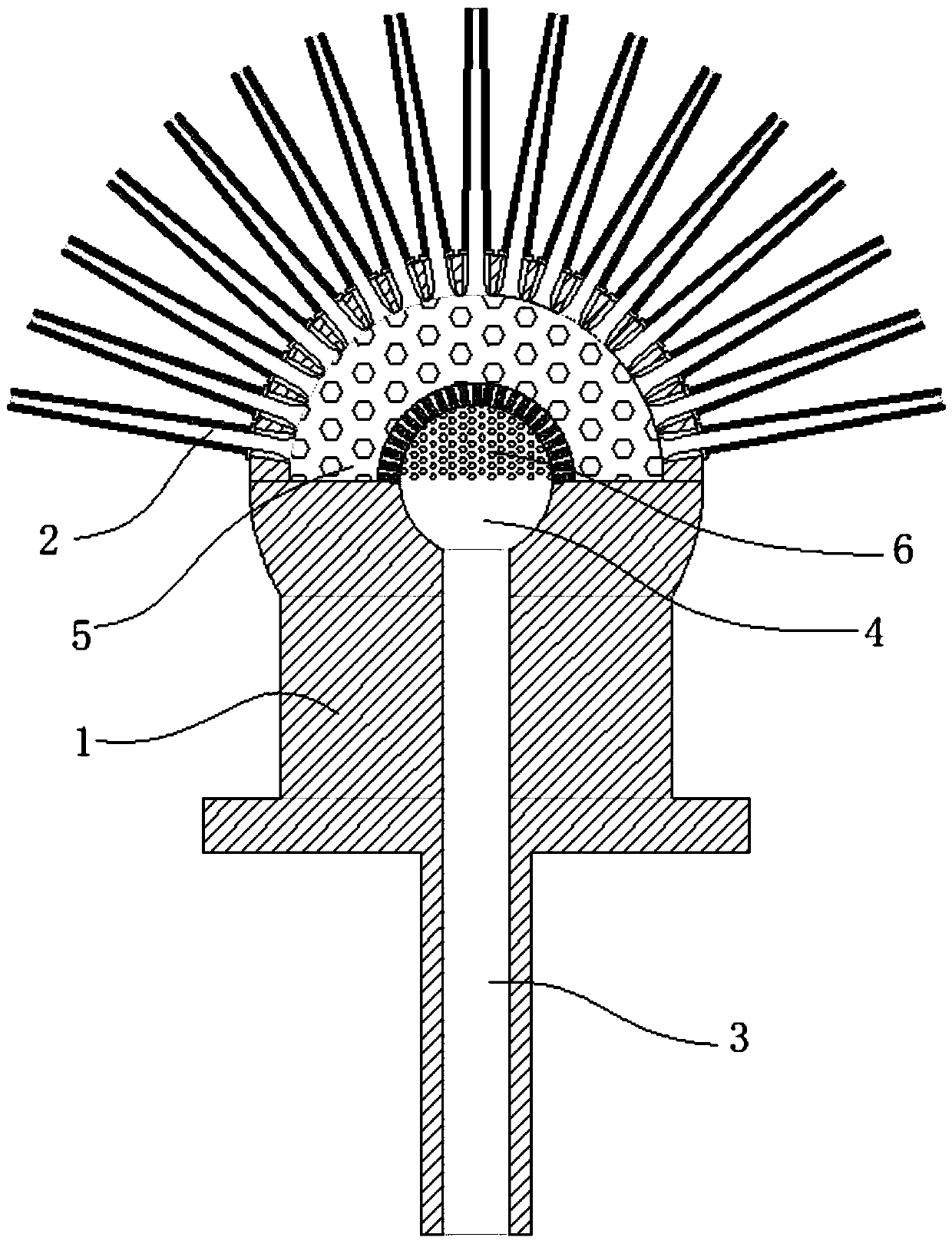

Polymer spraying mechanism for static spinning nanofiber

ActiveCN110205686AIncrease productivityPressure is easy to controlSpinning head liquid feederFilament/thread formingElectrospinningNanofiber

The invention discloses a polymer spraying mechanism for static spinning nanofiber. The polymer spraying mechanism comprises a polymer feeding mechanism and a spinning needle head, the polymer feedingmechanism comprises a polymer storage tank, a metering pump, a quantitative feeding pipe and a polymer feeding pipeline, the spinning needle head comprises a nozzle pipe and detachable needle head units, and a nozzle pipeline, a nozzle distributor and a nozzle inner cavity are arranged in the nozzle pipe. The polymer spraying mechanism is simple in principle and reasonable in design, feeding accuracy of a polymer solution can be ensured effectively, and spraying stability of the spinning needle head is improved, so that quality of produced nanofiber is improved indirectly; the spinning needlehead is improved, and the needle head units can adjust spinning direction along with position changing; the needle head units are proper in number, so that time for stopping for maintenance is reduced, and nanofiber production efficiency is improved; polymer pressure in the nozzle inner cavity is controllable, the circumstance that polymer is sprayed dramatically and blocks needle heads is eradicated, quick and stable spinning is realized, spinning efficiency can be improved effectively, and spinning uniformity is improved.

Owner:北京英鸿光大科技有限公司

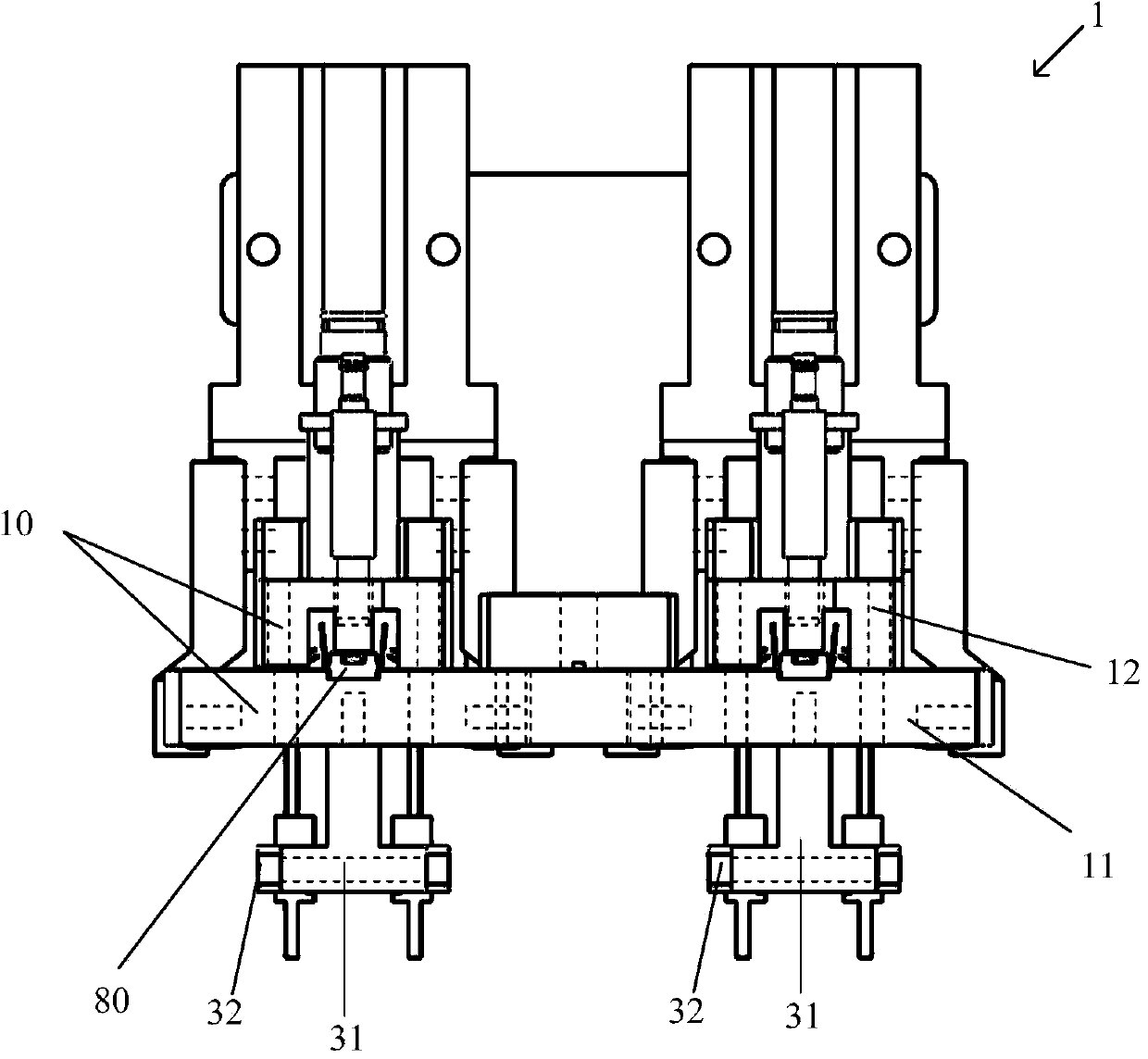

Automatic testing device for integrated circuit

ActiveCN103630827AImprove positioning accuracyImprove installation accuracyElectronic circuit testingMeasurement instrument housingEngineeringAutomatic testing

The invention discloses an automatic testing device for an integrated circuit. The device comprises a testing region which is located on one part of a rail component and is used for testing an integrated circuit chip, wherein a gold finger fixing device used for fixing a gold finger and a blocking device used for blocking the integrated circuit chip from moving to the downstream place under the effect of gravity are arranged in the testing region; the blocking device comprises a blocking base, a blocking needle, a blocking air cylinder and a blocking shifting block; the blocking base is arranged on the rail component of the testing region; the blocking needle is capable of moving relative to the blocking base, and can be operated to abut against the lower side edge of the integrated circuit chip so as to block the integrated circuit chip; the blocking air cylinder is used for providing the actuating force for the blocking needle; the blocking shifting block is mounted on the blocking base in a pivoting way; one end of the blocking shifting block is abutted against the blocking air cylinder and is actuated by the blocking air cylinder; the other end of the blocking shifting block is matched with the blocking needle to move the blocking needle. By using the automatic testing device for the integrated circuit, the position of the blocking needle is precisely controlled, and the phenomenon that the chip is clamped or malposed is avoided.

Owner:HANGZHOU YOUWANG ELECTRONICS

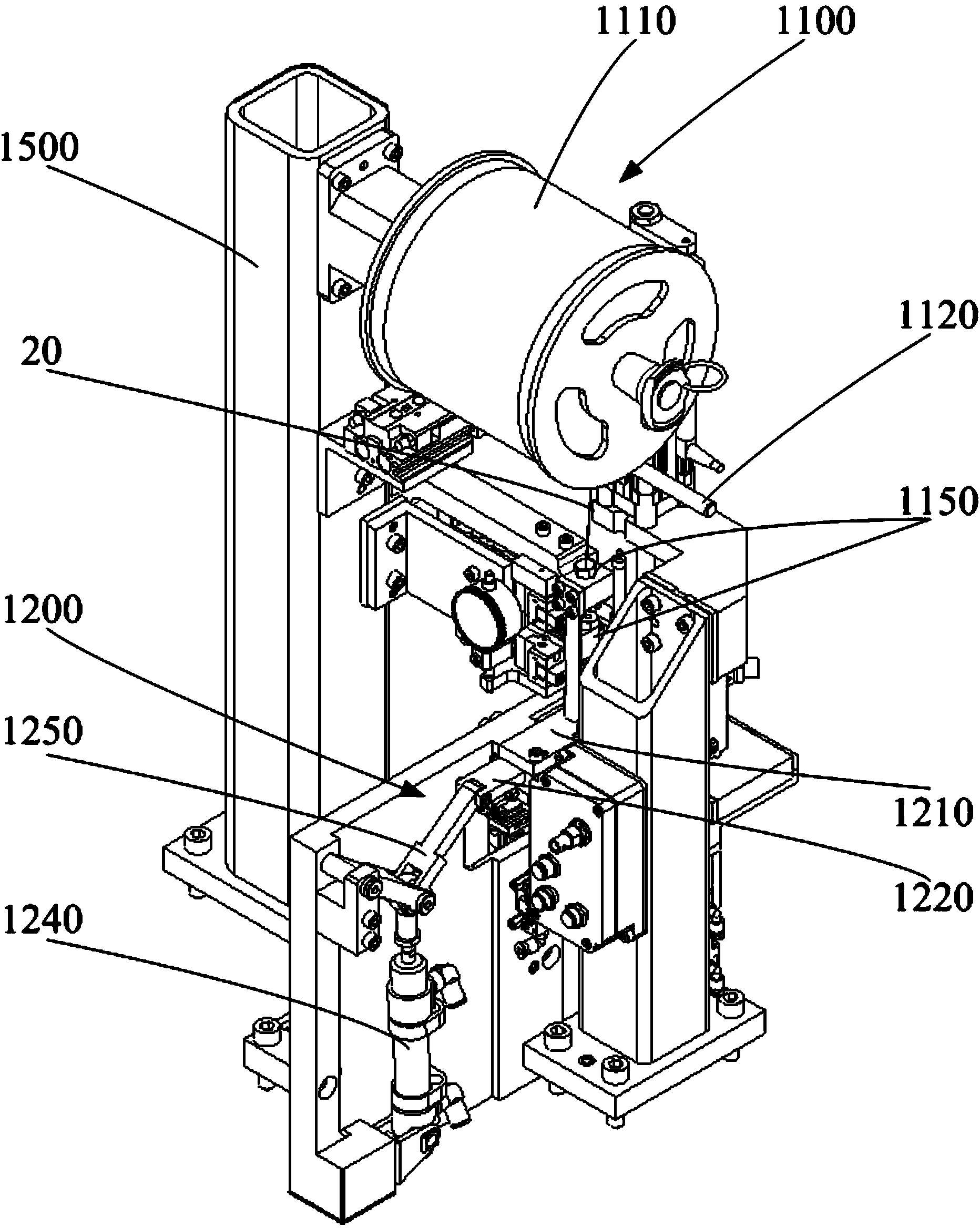

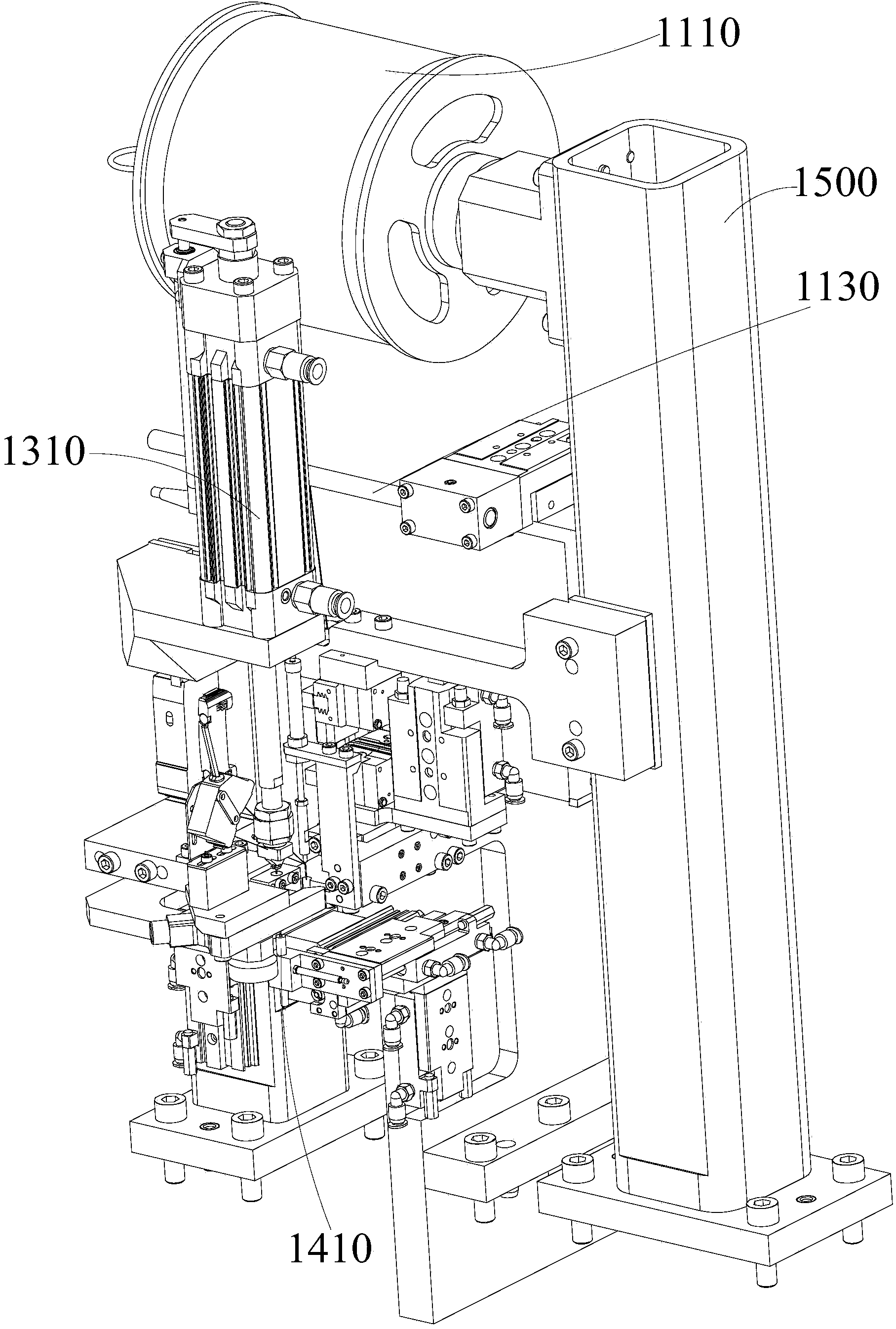

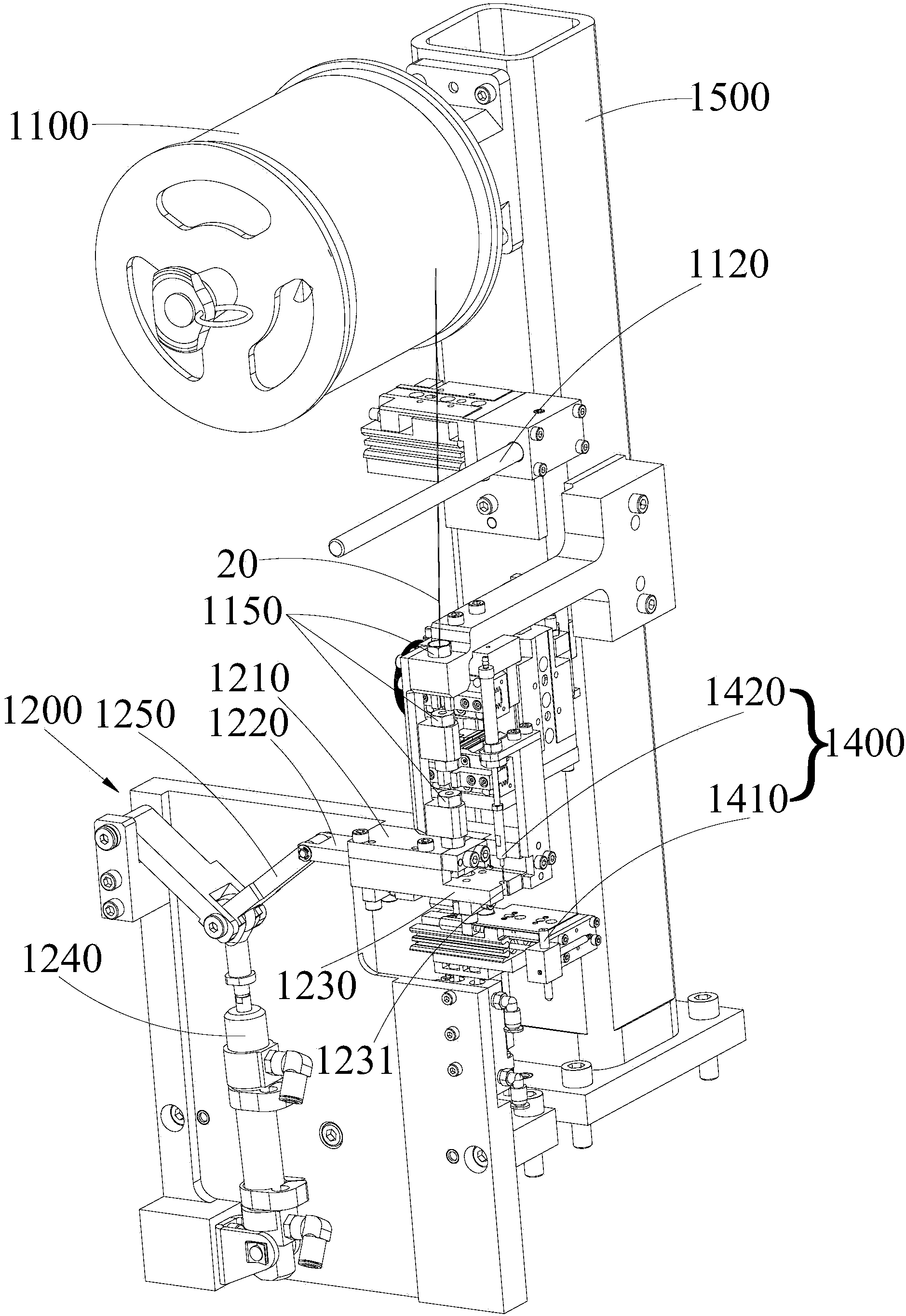

Automatic pin punching equipment

Automatic pin punching equipment comprises a wire feeding mechanism, a wire cutting mechanism, a pin punching mechanism and a wire transferring mechanism, wherein the wire feeding mechanism comprises a wire feeding plate, a tension rod, a first wire clamp and a second wire clamp, and the first wire clamp and the second wire clamp are located under the tension rod at an interval; the wire cutting mechanism comprises an upper wire cutting block, a lower wire cutting block and a wire cutting platform, the upper wire cutting block, the lower wire cutting block and the wire cutting platform are sequentially arranged under the wire feeding mechanism, the lower wire cutting block is arranged between the upper wire cutting block and the wire cutting platform in a sliding mode, the upper wire cutting block and the lower wire cutting block are respectively provided with a through hole, the through holes are communicated with each other, a notch is formed in the communicating portion of the two through holes, and the wire cutting platform is provided with a blanking hole at the finishing point of the sliding route of the lower wire cutting block; the pin punching mechanism comprises a pin punching cylinder, a punching pin and a pin punching platform; the wire transferring mechanism comprises a material collecting tube, a thimble and a moving device, the side faces of the material collecting tube are provided with blocking holes communicated with each other, a blocking needle is arranged in the blocking holes in a sliding mode, and the moving device is in transmission connection with the material collecting tube. According to the automatic pin punching equipment, automatic pin punching of products can be achieved, efficiency is relatively high, quality of the products is good, and cost is low.

Owner:上海乾享机电科技有限公司

Waterflow filtering device for water jet

InactiveCN101670207AEasy to disassembleEasy to disassemble and cleanNeedling machinesFiltration separationWater flowEngineering

The invention provides a waterflow filtering device for a water jet, which relates to a high-pressure water-jet generating device for non-woven fabric processing equipment. The lower part of a water jet body is provided with a water inlet, a water cavity and a water cavity plug; the upper part of the water jet body is provided with a water needle plate, an upper water cavity and an upper pressureplate; the upper pressure plate is provided with a water jet outlet; the water cavity is communicated with the upper water cavity through a plurality of water pipes; the inside of the water cavity isprovided with a circular filter; and an inner cylinder of the circular filter is connected with the water inlet, while an outer cylinder is connected with the water cavity. The waterflow filtering device cannot block needle holes on the water needle plate to avoid affecting the performance of the water needle plate, can be conveniently cleaned by removing the filter at a plug end, reduces the removal and the cleaning of the water needle plate, and can greatly prolong the service life of a sealing element on the water needle plate.

Owner:YIZHENG SIFANG LIGHT TEXTILE MACHINERY

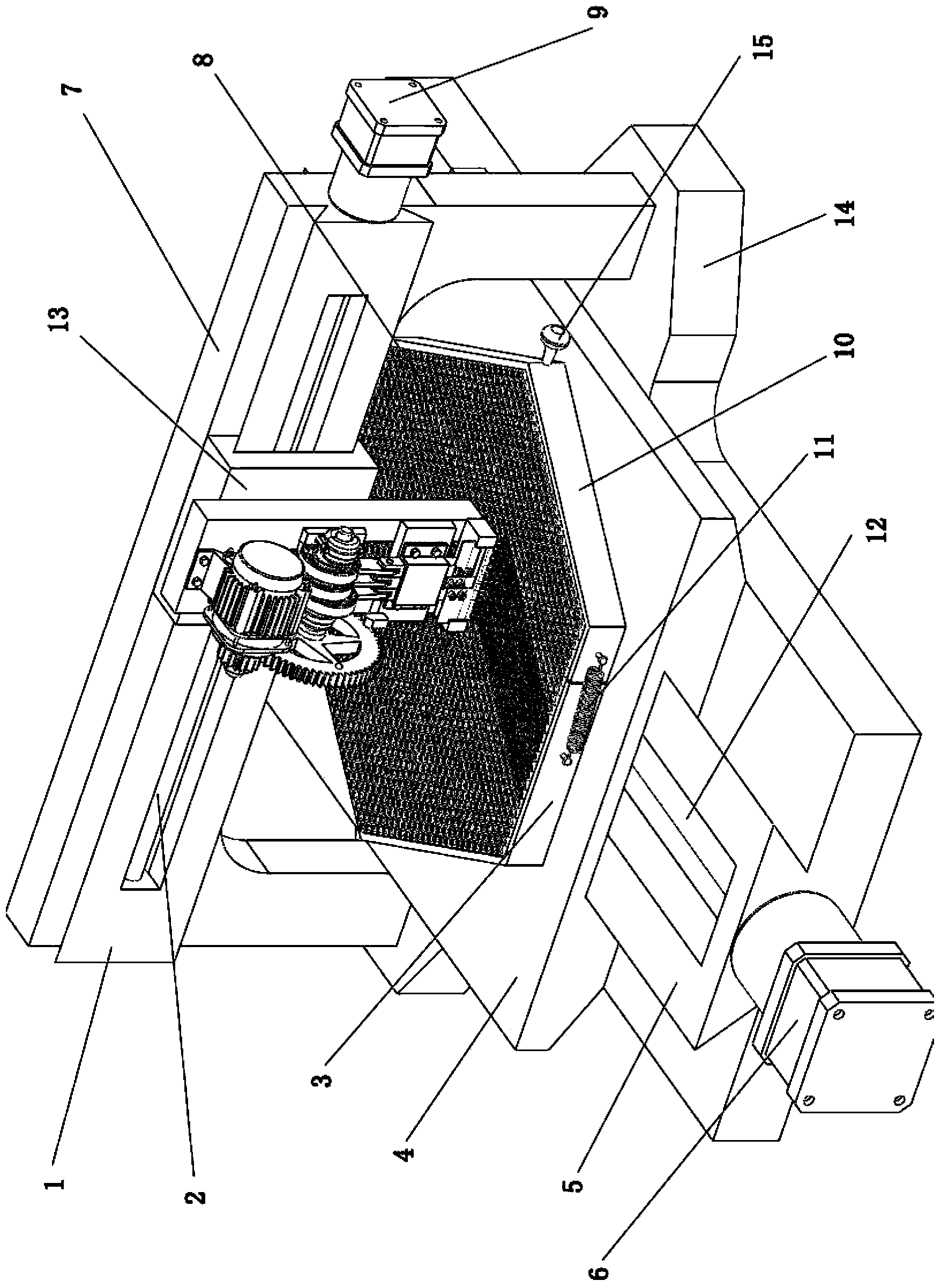

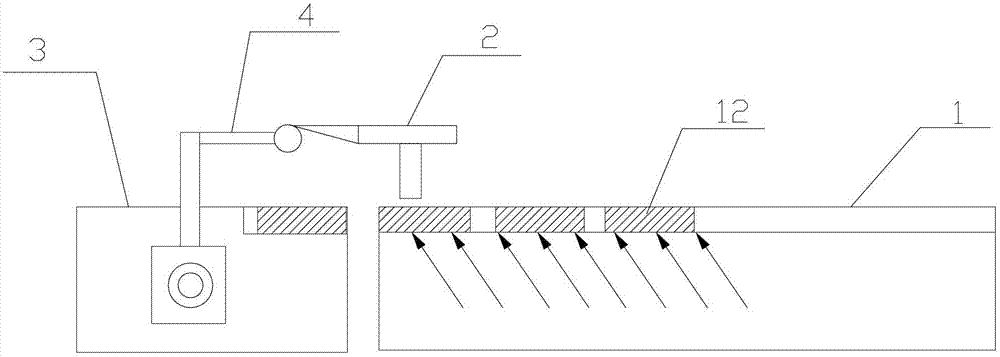

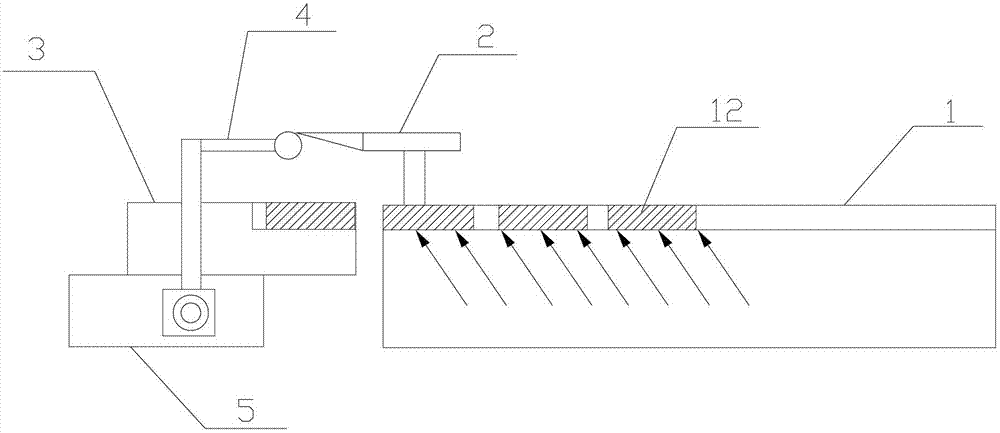

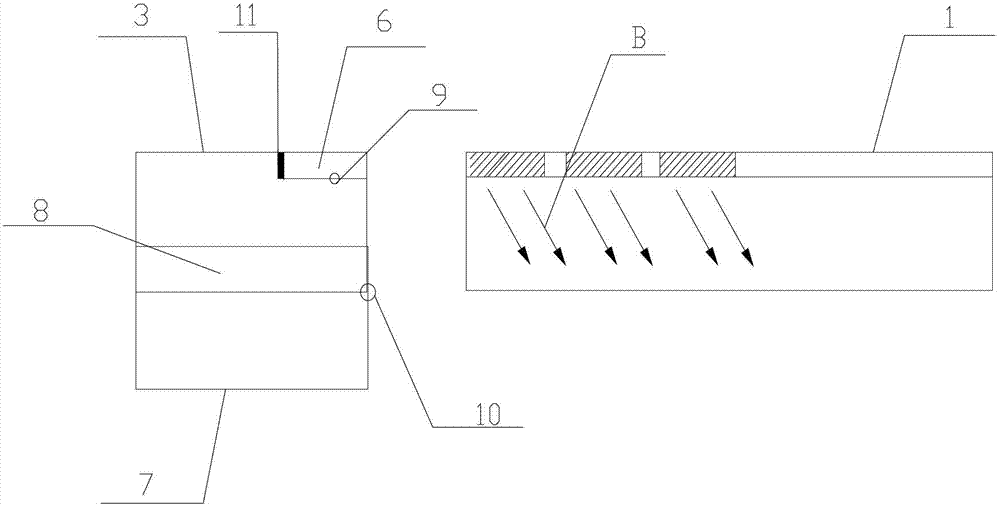

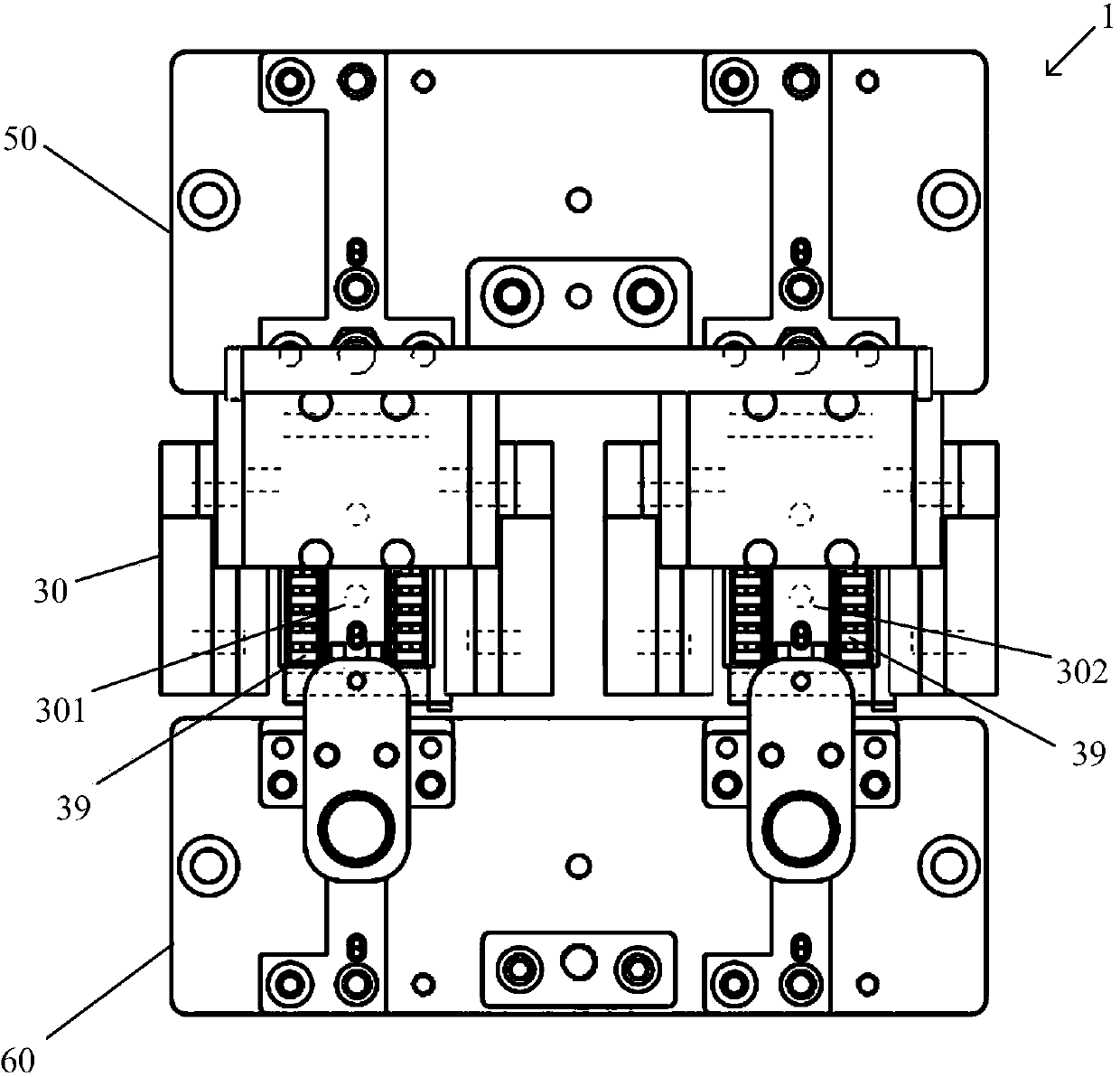

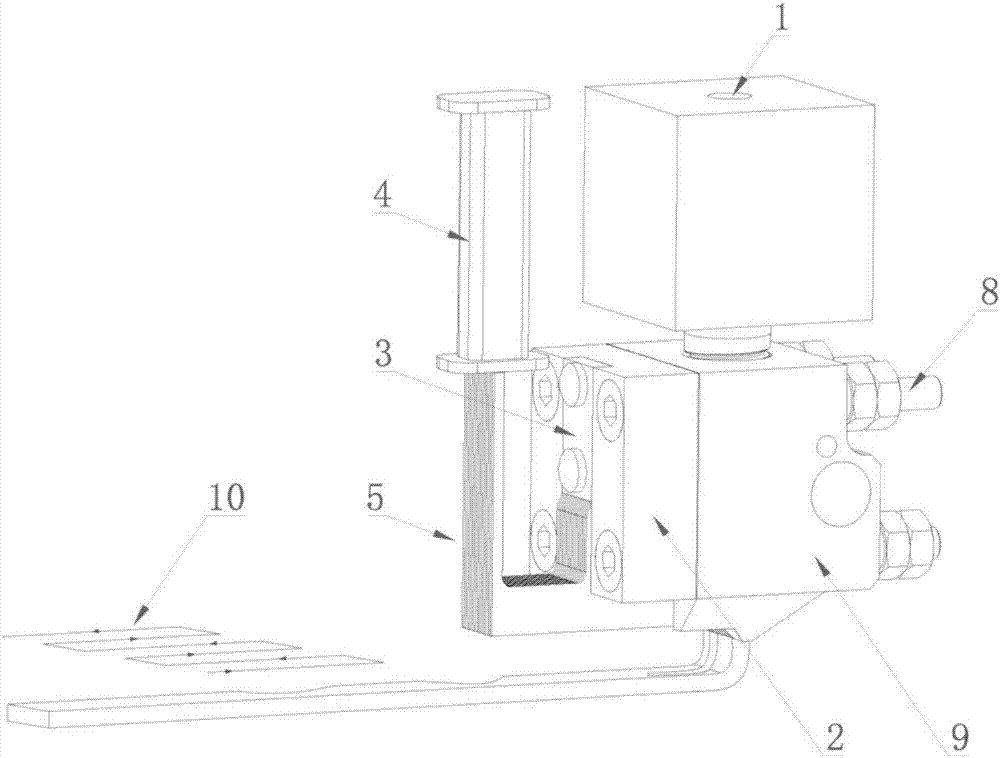

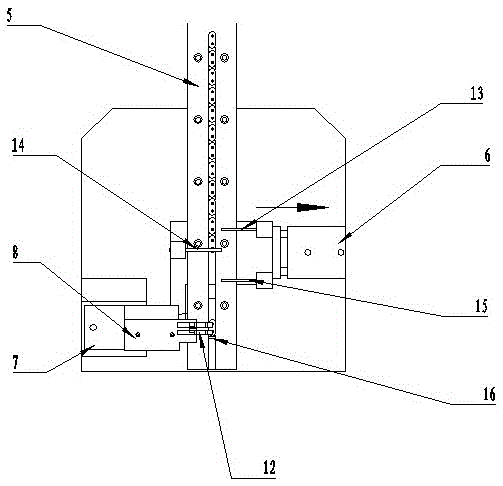

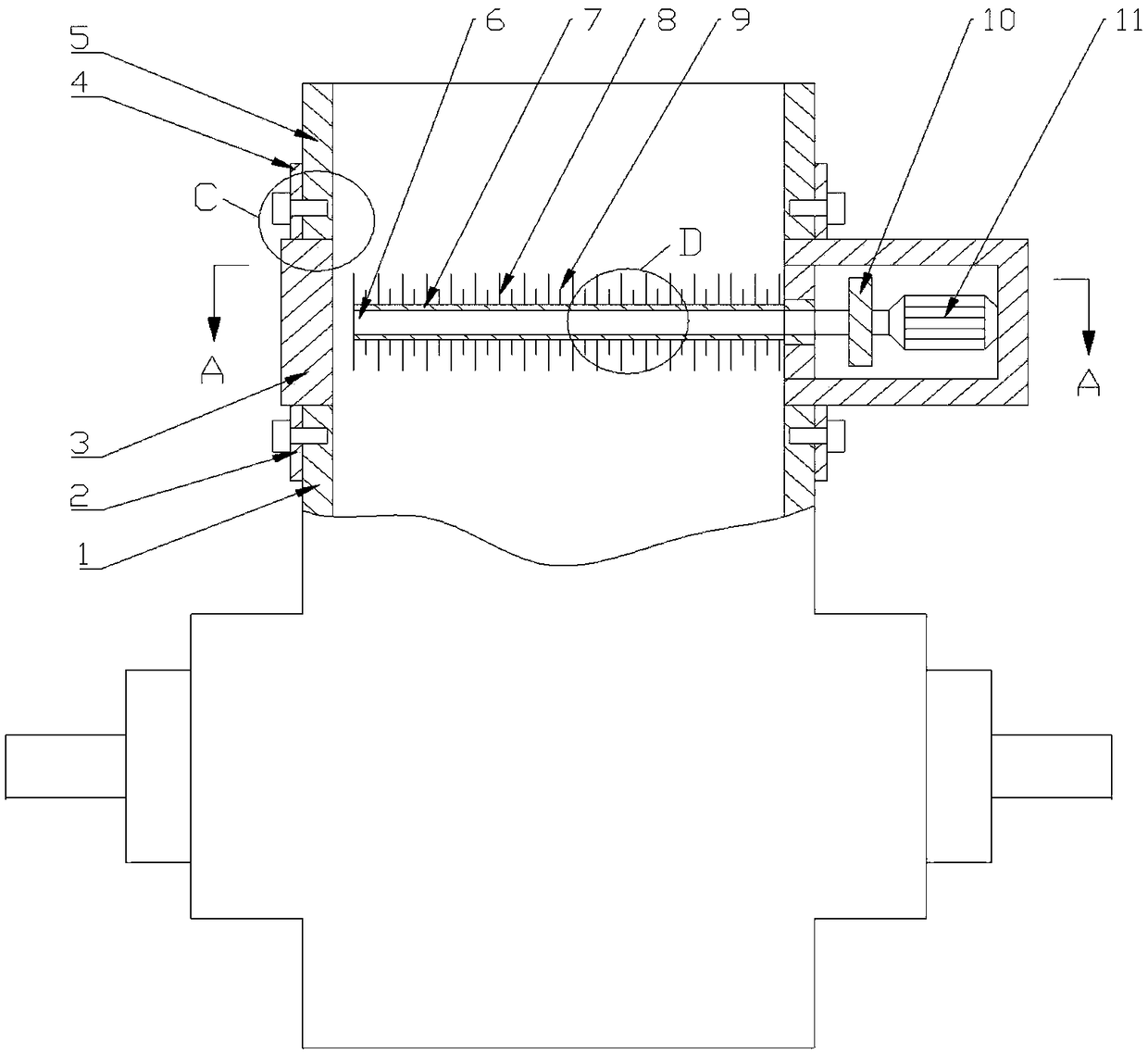

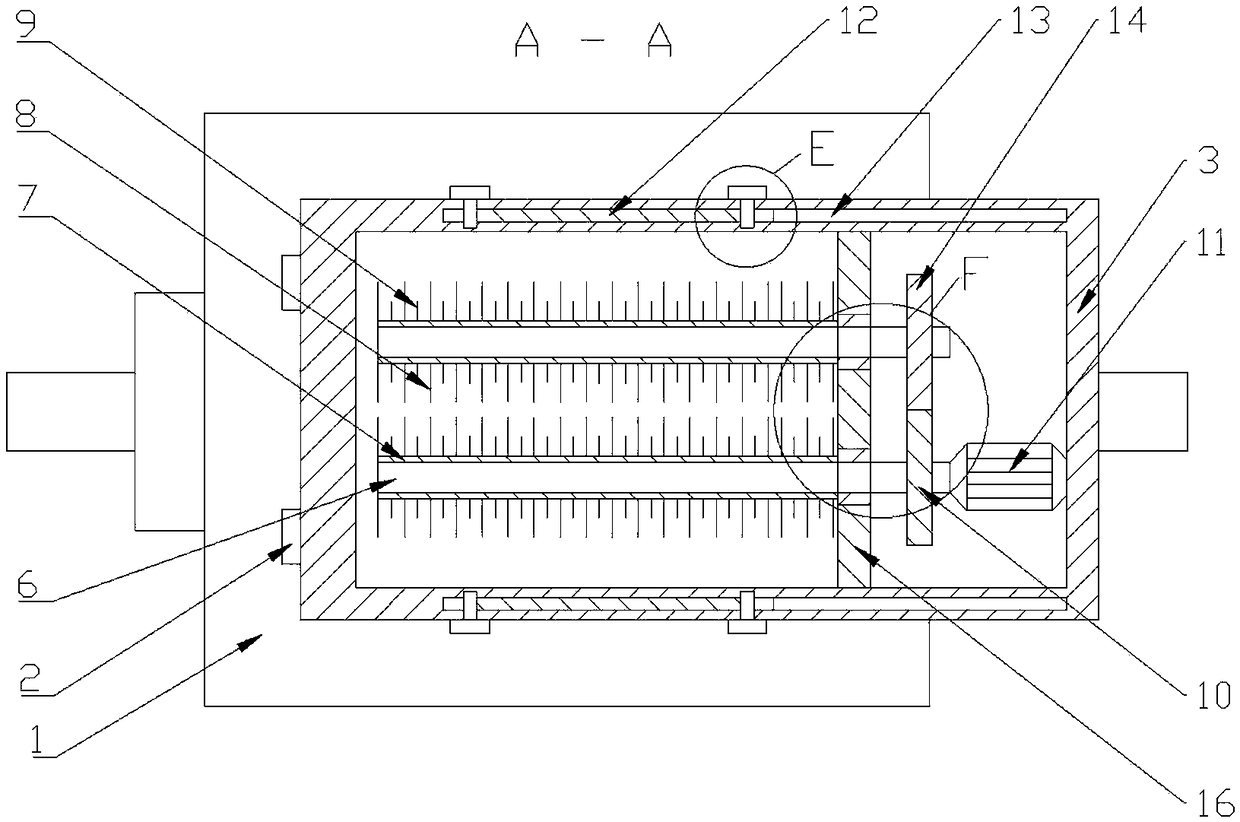

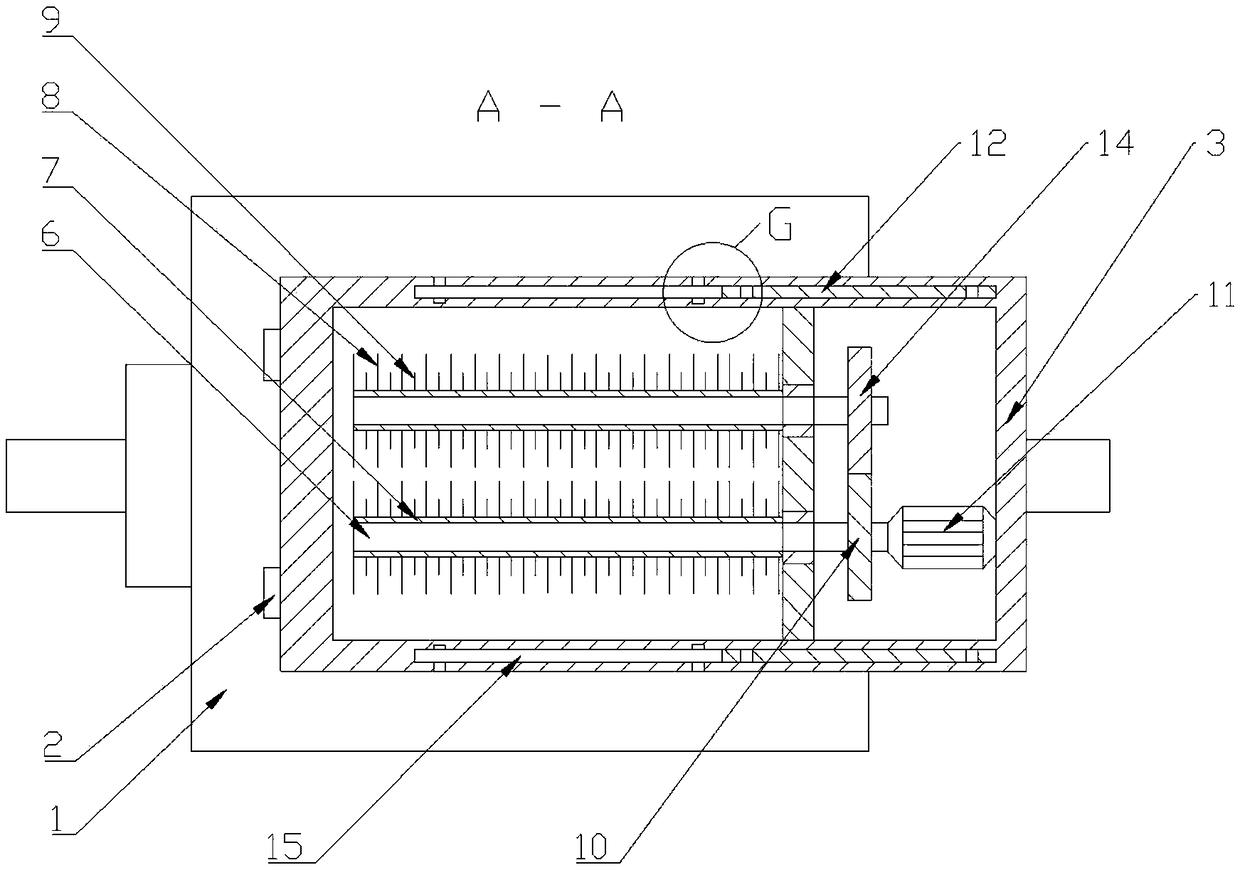

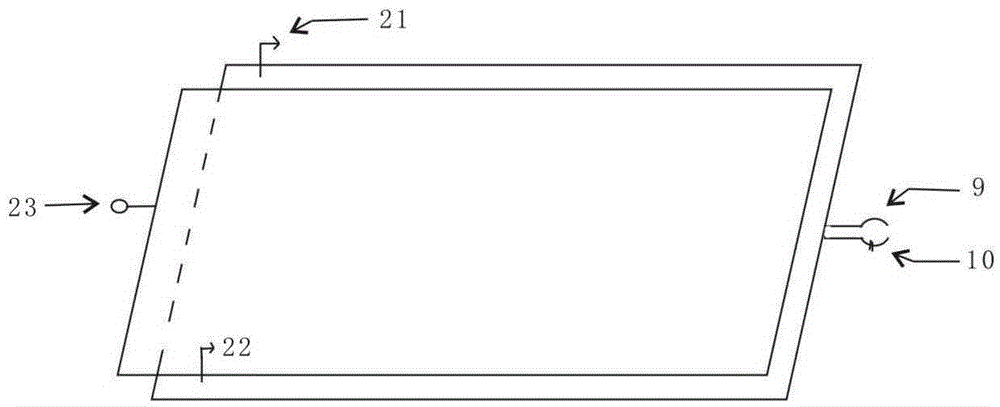

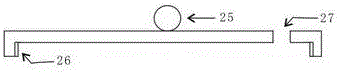

Linear array jet type FDM (fused deposition manufacturing) three-dimensional printing spray head and printing method

InactiveCN106945264AImprove work efficiencySuitable for printing3D object support structuresApplying layer meansChinese charactersJet flow

The invention discloses a linear array jet type FDM (fused deposition manufacturing) three-dimensional printing spray head and a printing method. The spray head comprises a spray head main body, a spray head mask, a sliced blocking needle array, a blocking needle pressure adjustment block and a blocking needle array drive device. A spray nozzle is internally provided with a long-narrow-seam-shaped molten printing material flowing-out opening, and flat molten plastic jet flow of a set width is formed; the sliced blocking needle array is formed by stacking a plurality of sliced blocking needles, and the planar structures of all the sliced blocking needles are the same in shape and the same or different in thickness; the blocking needle array drive device is used for driving any sliced blocking needle to swing front and back, and when the molten plastic jet flow of the width of the position where any sliced blocking needle is located is blocked or opened, the molten plastic jet flow is made to generate position-controllable comb-shaped gaps; and the three-dimensional printing spray head performs reciprocating linear movement according to the track shaped like a Chinese character 'ji', the comb-shaped controllable flat molten plastic jet flow is spread and laid on a worktable top to be deposited to form set patterns, and multiple layers of the patterns are piled to form a three-dimensional printing workpiece.

Owner:HUBEI UNIV OF TECH

Test path selection method and corresponding wafer test method

ActiveCN103344896BAvoid testingReduce distanceSemiconductor/solid-state device testing/measurementIndividual semiconductor device testingComputer hardwareElectricity

The invention provides a test path selection method which includes the first step of forming valid dies and invalid dies on an arranged wafer, the second step of forming a wafer mapping picture, the third step of marking the positions of the valid dies and the invalid dies on the wafer mapping picture according to the positions of the valid dies and the invalid dies, the fourth step of enabling multi-circuit-block needle card pictures to be arranged repeatedly on the dies of the wafer mapping picture and filling the wafer mapping picture, wherein the multi-circuit-block needle card pictures at least comprise a first needle card identification mark and a second needle card identification mark, the fifth step of eliminating the multi-circuit-block needle card pictures fully occupying the invalid dies on the wafer mapping picture and reserving the multi-circuit-block needle card pictures at least occupying one valid die, and the sixth step of enabling the dies corresponding to the first identification marks in each multi-circuit-block needle card picture reserved on the wafer mapping picture to be connected into a straight line, and obtaining a test path. The invention further provides a wafer test method. The test path selection method and the corresponding wafer test method shorten the distance of needle card displacement in the testing process, save needle card displacement time, and improve testing efficiency of wafers.

Owner:HANGZHOU SILAN MICROELECTRONICS

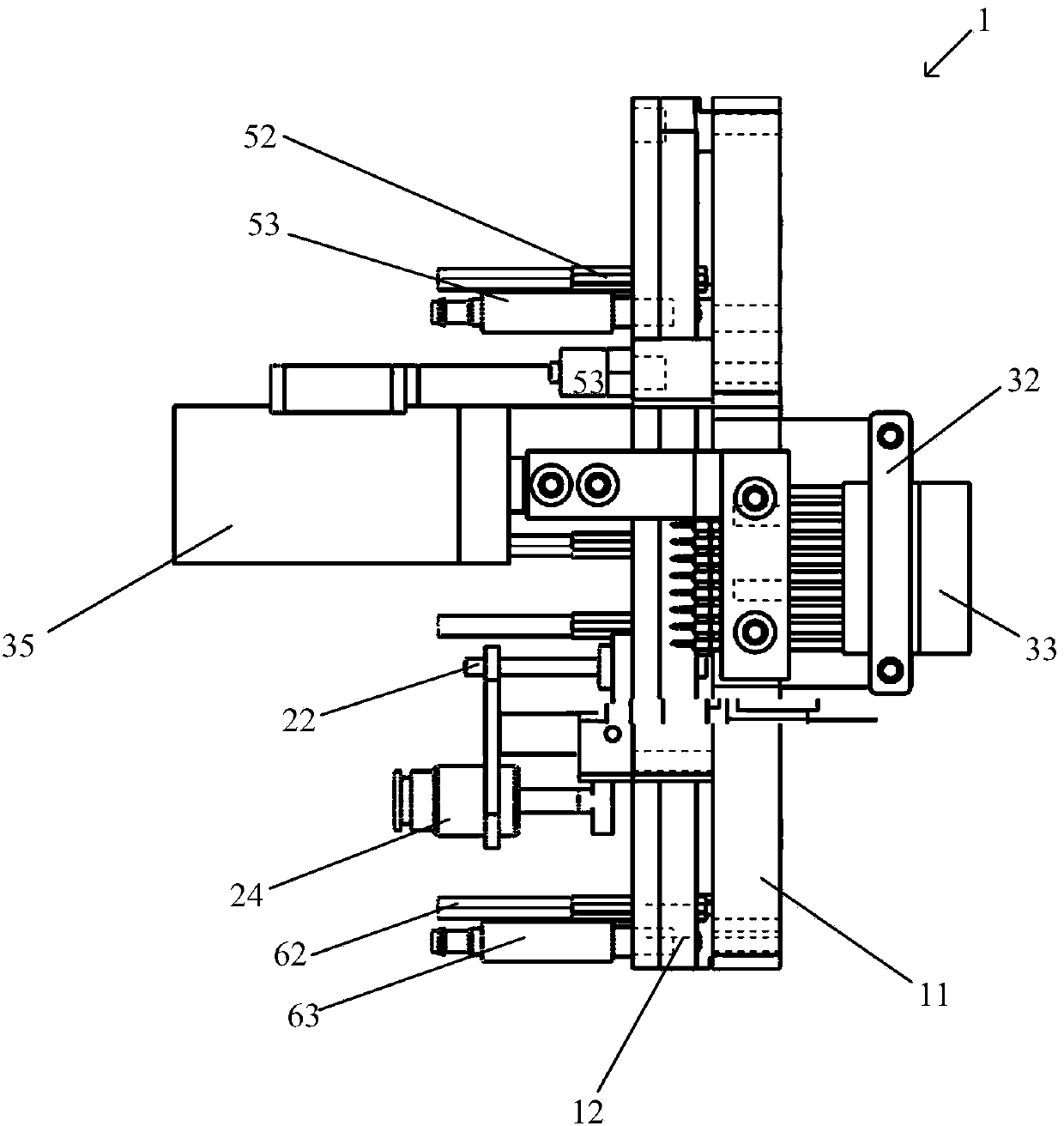

Crystal RPP (resistance pin-to-pin) electric performance parameter testing and sorting device and method

InactiveCN105642567AReasonable structureImprove test accuracySortingElectrical resistance and conductanceElectricity

The invention relates to a crystal RPP (resistance pin-to-pin) electric performance parameter testing and sorting device. The crystal RPP electric performance parameter testing and sorting device comprises a feeding device, a testing device, a sorting device and a control device, wherein the feeding device comprises a vibrating plate, the discharge outlet of the vibrating plate is provided with an inclined feeding rail, and the feeding rail is provided with a guide groove; a front blocking needle, a middle blocking needle, a lower blocking needle and a bottom blocking needle are sequentially arranged in the front of the guide groove, a testing head is arranged on the left of the feeding rail, and the rear of the testing head is connected with a testing head air cylinder; the front end of the testing head is provided with an elastic piece which is connected with an insulation resistance tester; the insulation resistance tester is connected with the main unit of the control device. The crystal RPP electric performance parameter testing and sorting device is reasonable in structure, high in testing precision, convenient to operate, and capable of increasing sorting efficiency, lowering sorting cost, increasing product yield and increasing production efficiency.

Owner:TANGSHAN GUOXIN JINGYUAN ELECTRONICS CO LTD

Red tide treatment device for protecting marine ecological environment

ActiveCN109231292AEasy to reciprocateMove quicklyWater cleaningSpecific water treatment objectivesEcological environmentEngineering

The invention discloses a red tide treatment device for protecting a marine ecological environment. The device comprises a tank body, wherein a fixed block is arranged at the top of the outer wall ofone side of the tank body, and connecting springs are distributed on one side, far from the tank body, of the fixed block in an equal interval manner; connecting rods are arranged at one ends, far from the fixed block, of the connecting springs, and a mounting plate is arranged at one ends of the connecting rods; second movable rods are arranged at two ends of the bottom of one side of the mounting plate, and extension sleeves are arranged at two ends of the bottoms of the outer walls of two sides of the tank body; and draining holes are formed in the inner walls of the bottoms of the extension sleeves in an equal interval manner, and the inner walls of the draining holes are obliquely arranged. According to the red tide treatment device, clay powder in the tank body is moved to an unloading hole, so that the clay powder is not accumulated in the tank body; discharging holes are dredged in a reciprocating manner by virtue of anti-blocking needles, so that the blockage of a dischargingnet plate is effectively prevented, the situation that the clay is accumulated on the mounting net plate is effectively avoided, the rapid settling of the clay is promoted, and the treatment efficiency of red tide is improved.

Owner:山东圣文环保科技有限公司

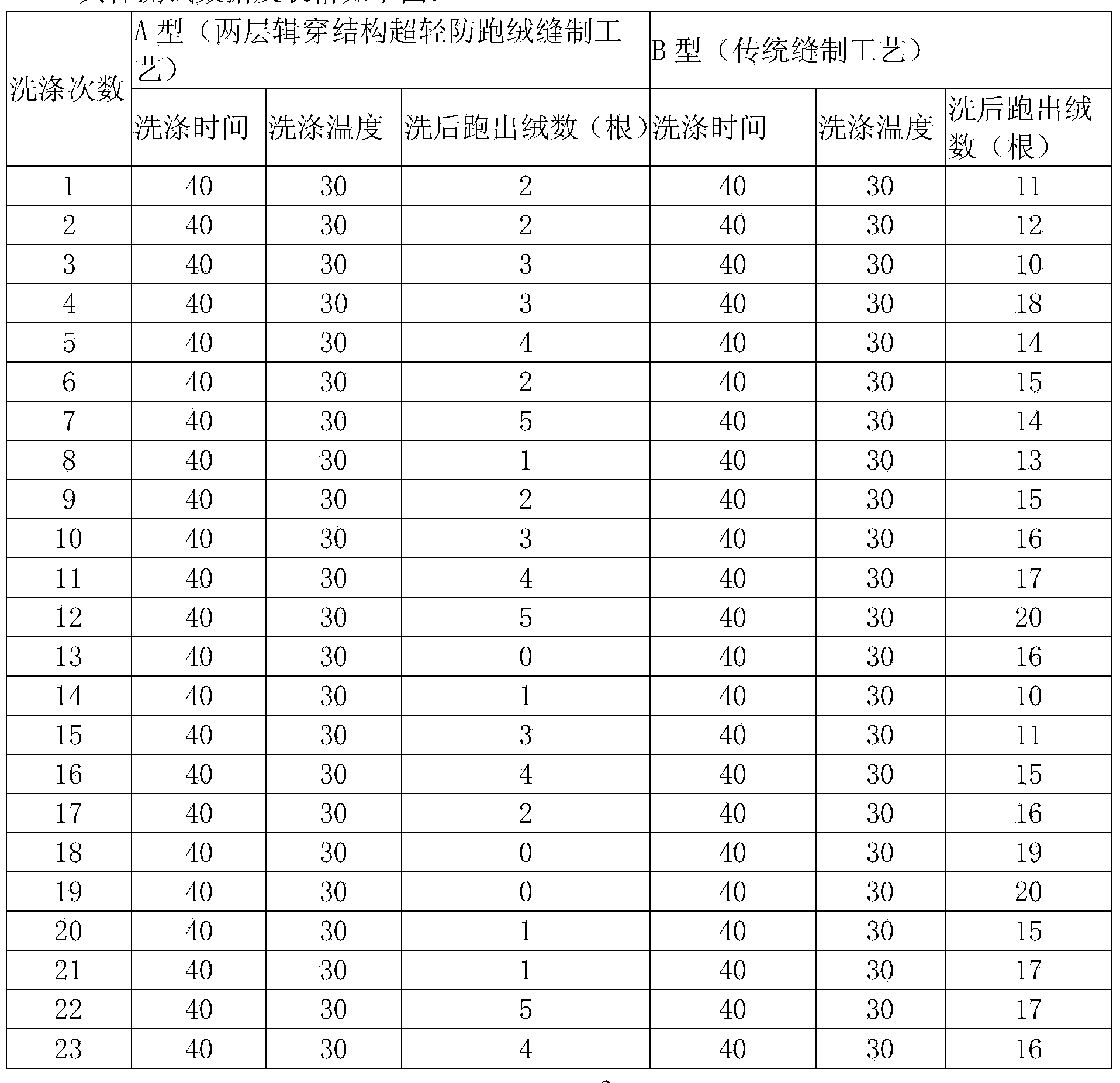

Ultralight down feather shifting preventing down jacket with two-layer basting through structure and sewing process

InactiveCN103919297AEfficient anti-running effectOvergarmentsClothes making applicancesFiberEngineering

The invention discloses an ultralight down feather shifting preventing down jacket with a two-layer basting through structure. The ultralight down feather shifting preventing down jacket with the two-layer basting through structure comprises shell fabric, lining and down feathers, down feather preventing strips are arranged at the sewing positions of the shell fabric and the lining, and the width of the down feather preventing strips is 0.8 cm. A sewing process comprises the following steps of cutting the shell fabric and the lining according to requirements for using, thread sewing is carried out on the cut shell fabric and the cut lining according to requirements, the down feather preventing strips are arranged at all sewing positions of the shell fabric and the lining, the down feather preventing strips are clamped in the middle of stitching, and the characteristics of expansion and contraction of the fibers of the down feather preventing strips are utilized to block needle holes fast. The space between the shell fabric and the lining with the thread sewing finished is filled with the down feathers, and the shell fabric and the lining which are filled with the down feathers are sewed according to requirements. According to the ultralight down feather shifting preventing down jacket with the two-layer basting through structure and the sewing process, the down feather preventing strips are arranged at all the sewing positions of the shell fabric and the lining, the needle holes of the stitching are blocked fast by utilizing the characteristics of the expansion and contraction of the fibers of the down feather preventing strips, and therefore an efficient down feather shifting preventing effect is achieved.

Owner:YANGZHOU JIUCHENG OUTDOOR GOODS

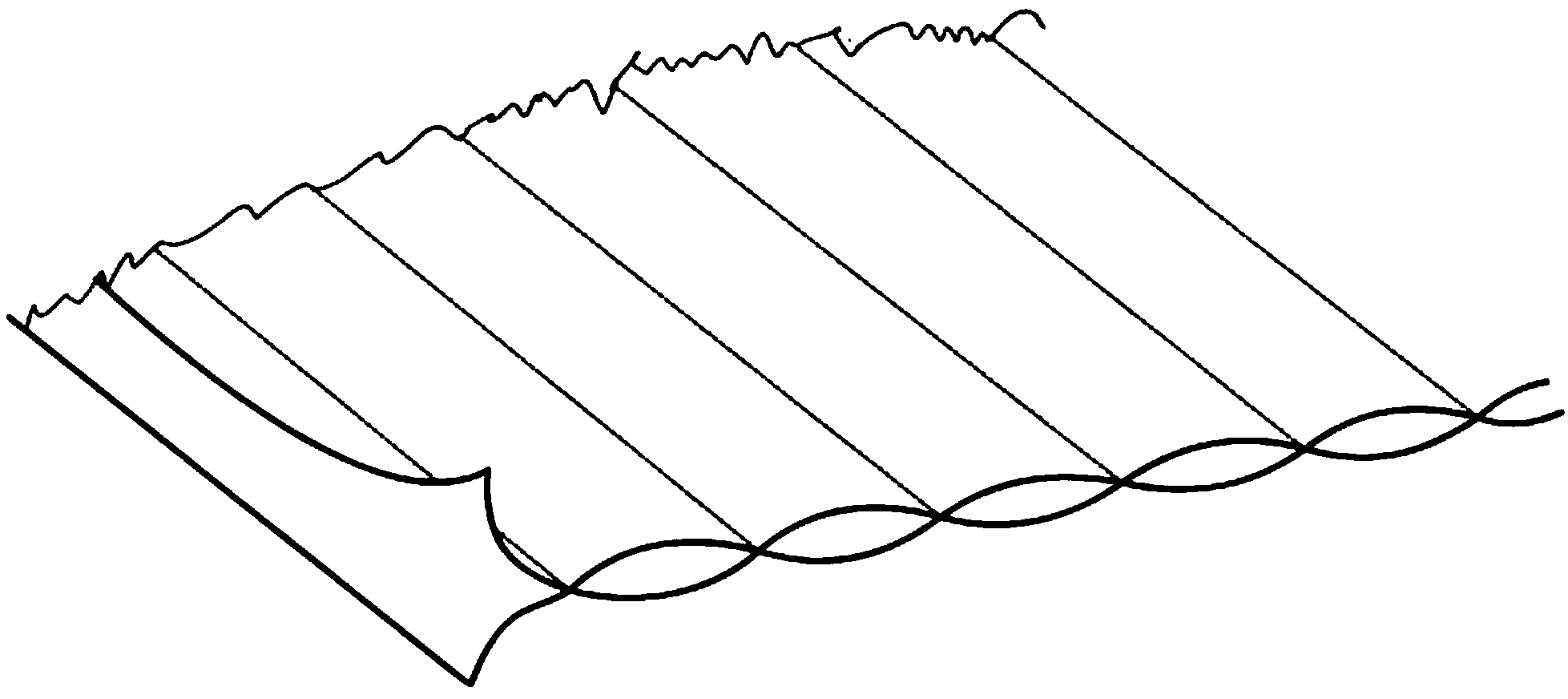

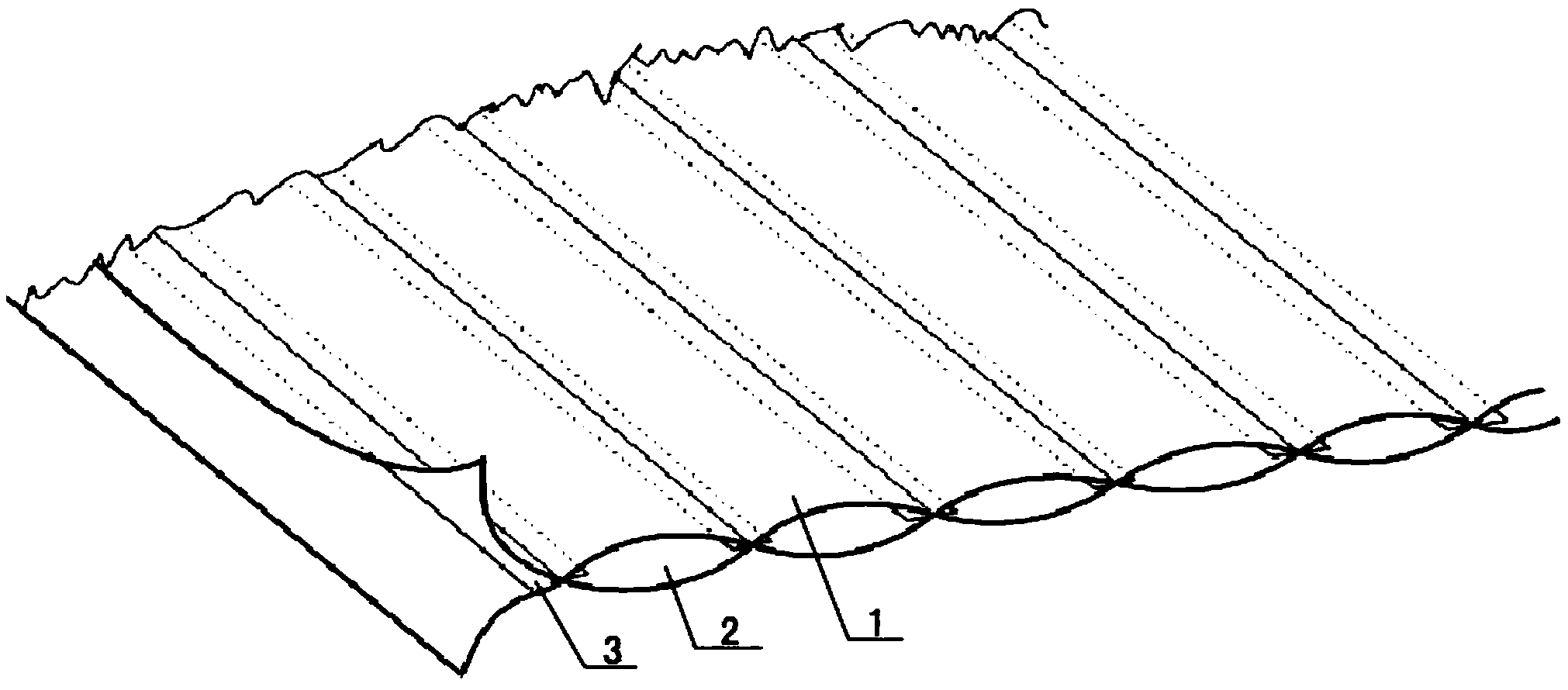

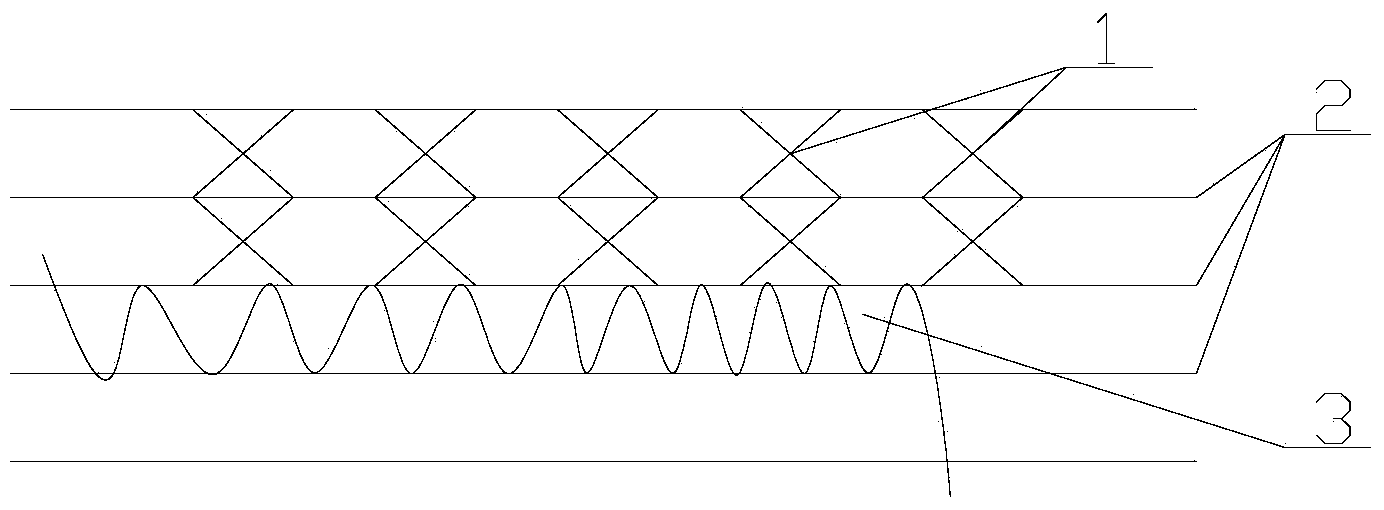

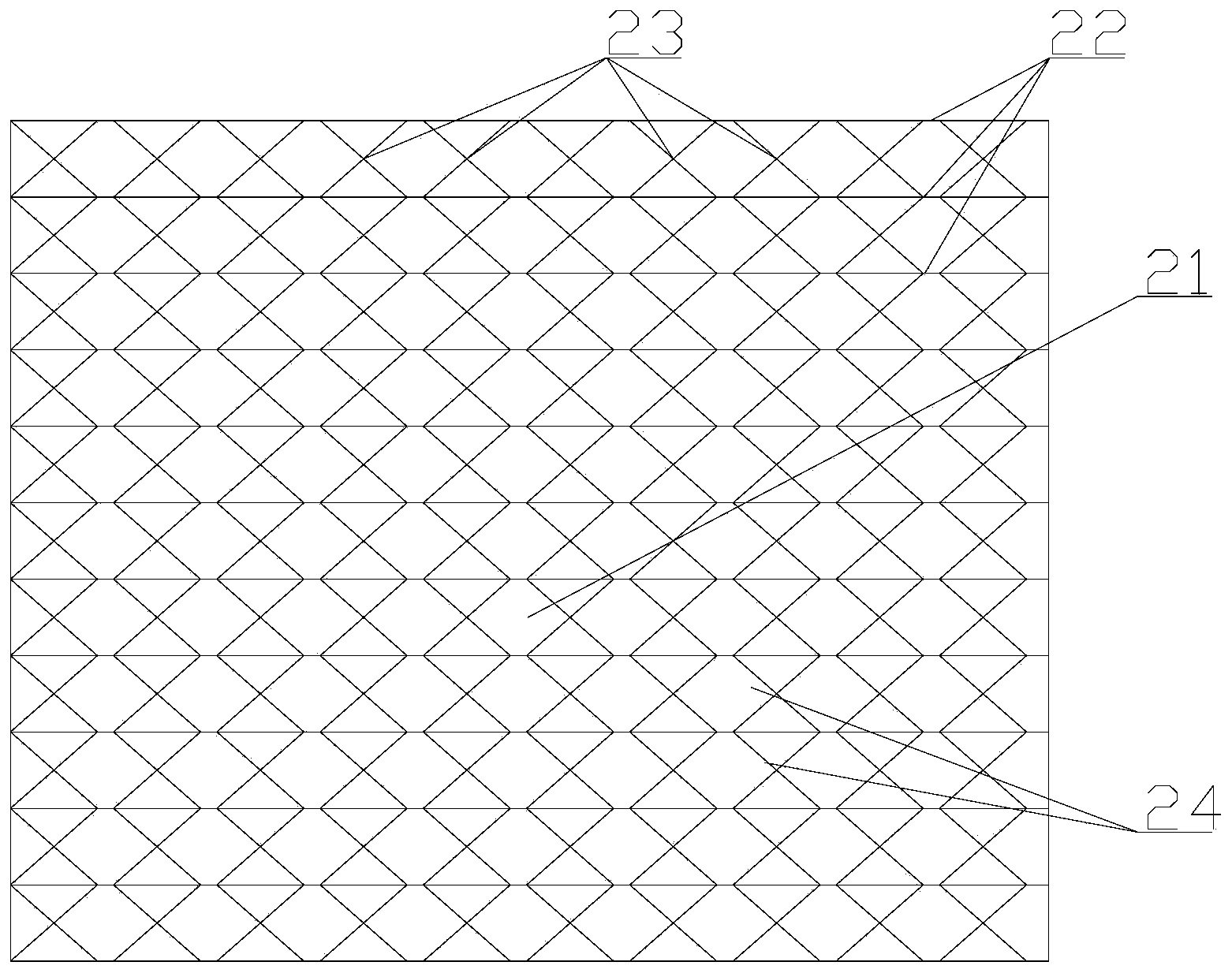

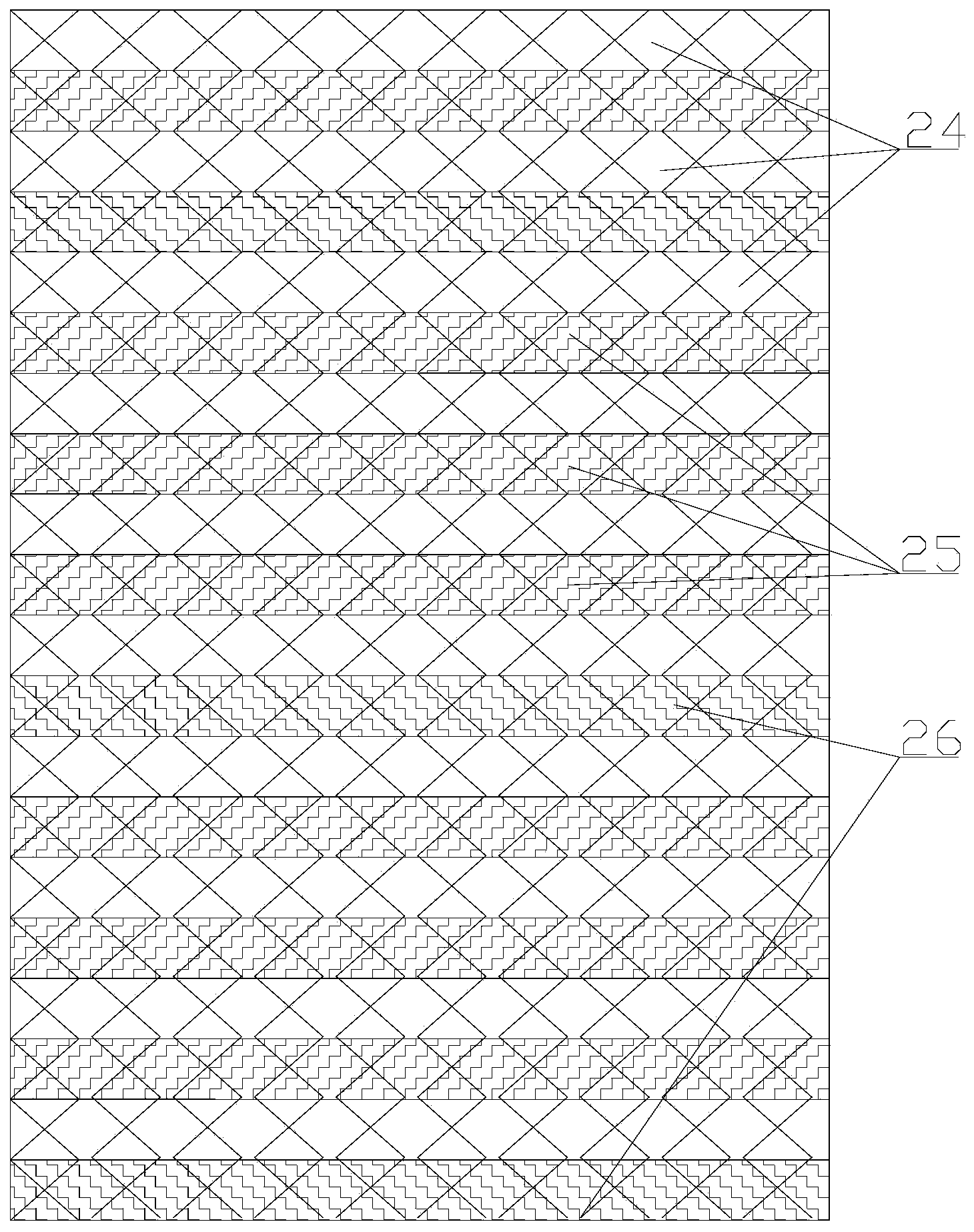

Method for knitting bath towel cloth and bath towel cloth

ActiveCN103924378AIngenious knitting methodSoft fabricCrochetingBathroom accessoriesBiomedical engineeringBlock needle

The invention discloses a method for knitting bath towel cloth and the bath towel cloth which is durable and soft in fabric. The bath towel cloth is knitted by a crochet machine. The method for knitting the bath towel cloth comprises the steps that a plurality of bottom threads are distributed at intervals uniformly and parallelly, a bottom needle and a surface needle pass through three needle tubes on the crochet machine, a blocking needle performs knitting on the bottom threads, the bottom needle is positioned between the two connected bottom threads to perform cross-shaped knitting on the two adjacent bottom threads through the needle tubes, the blocking needle does not move and performs knitting of the surface needle, and the surface needle is wound on the two adjacent bottom threads.

Owner:吴云升

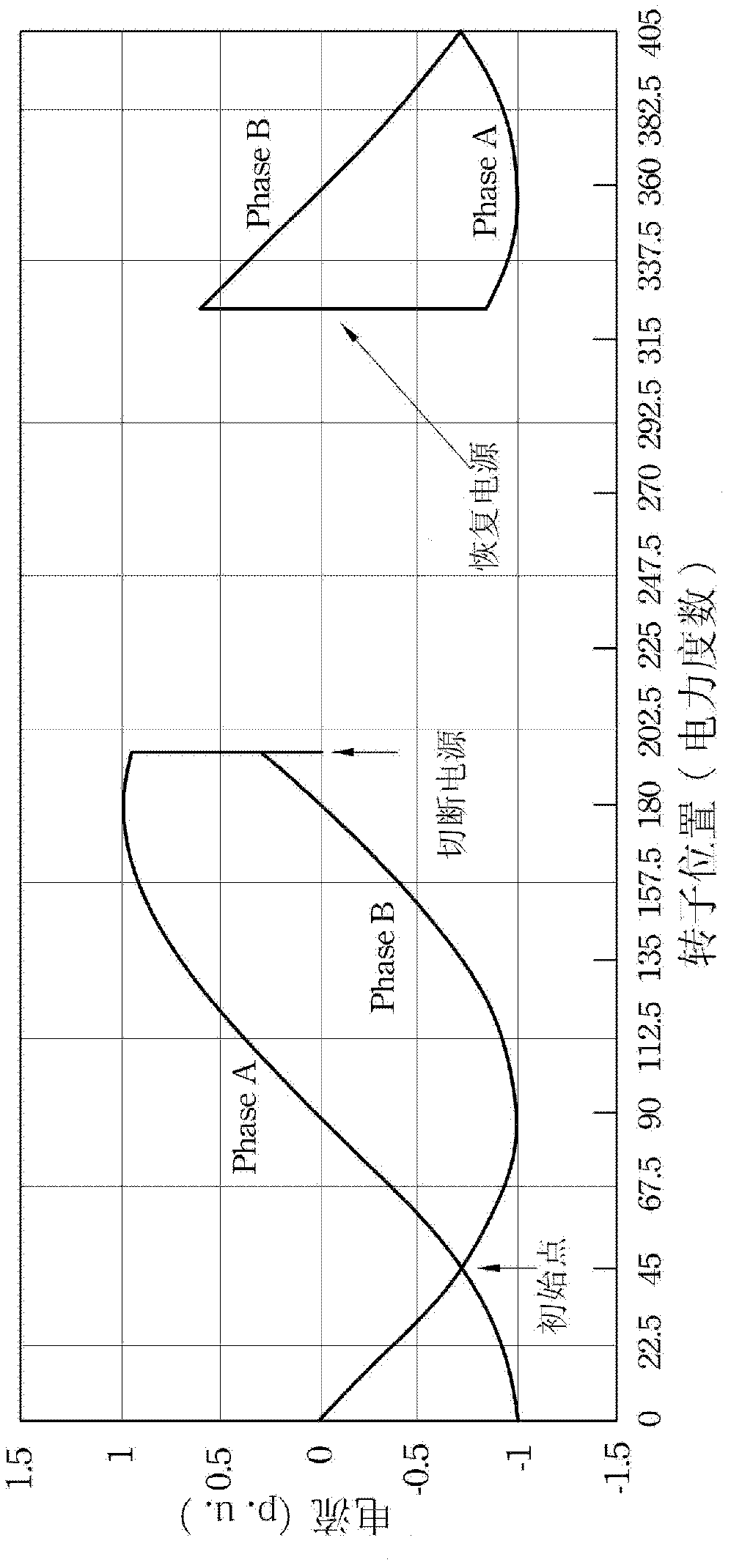

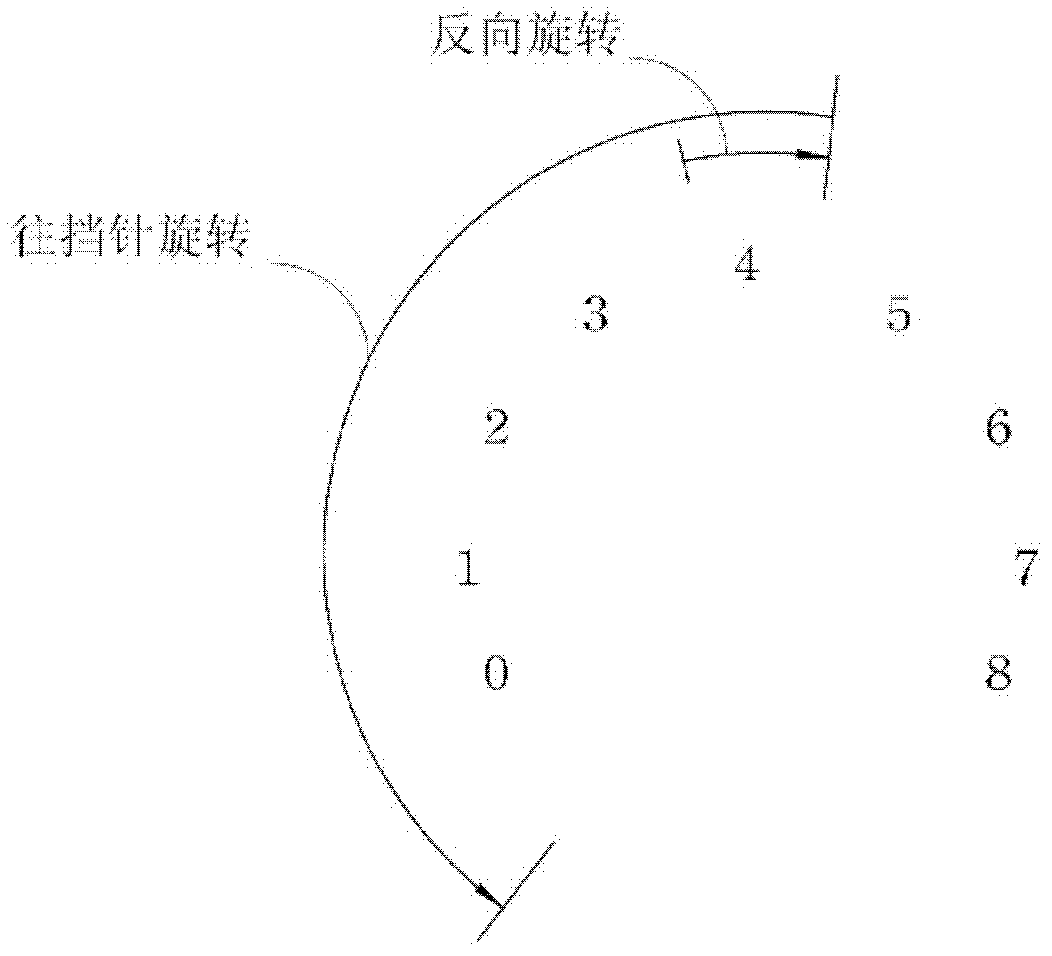

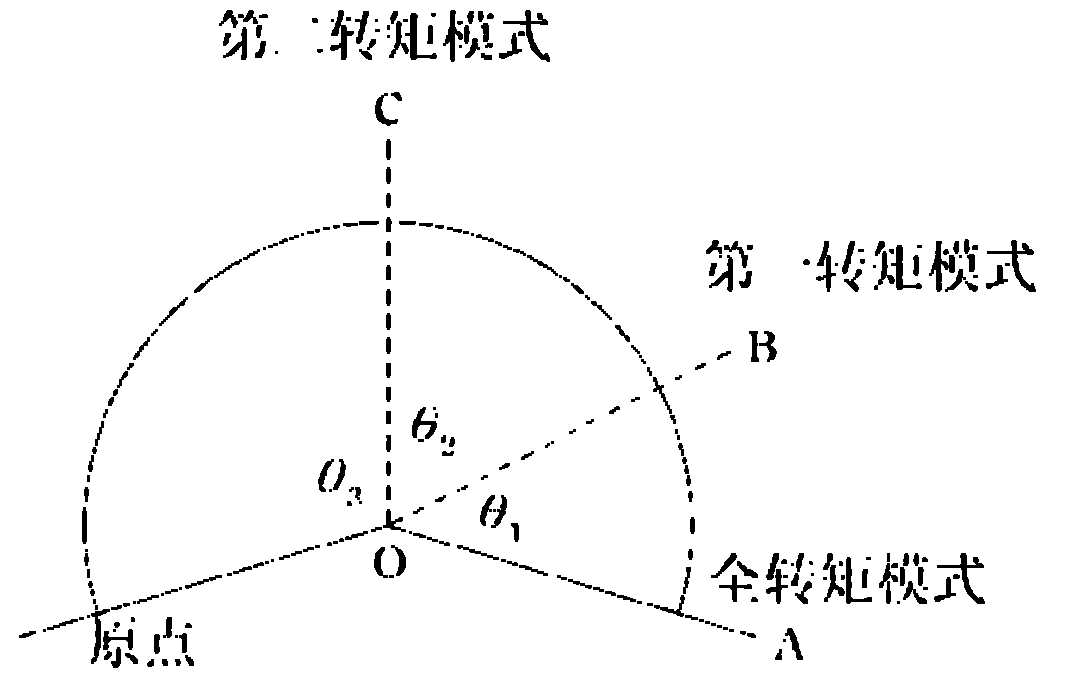

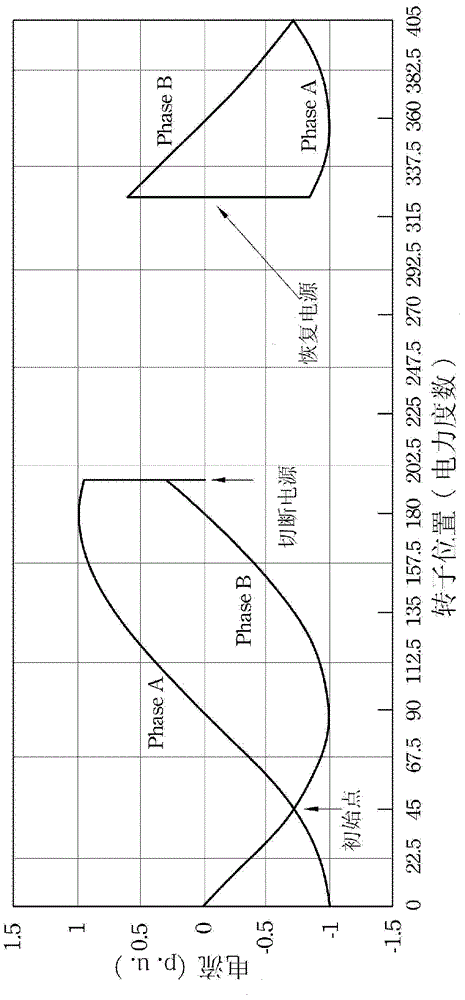

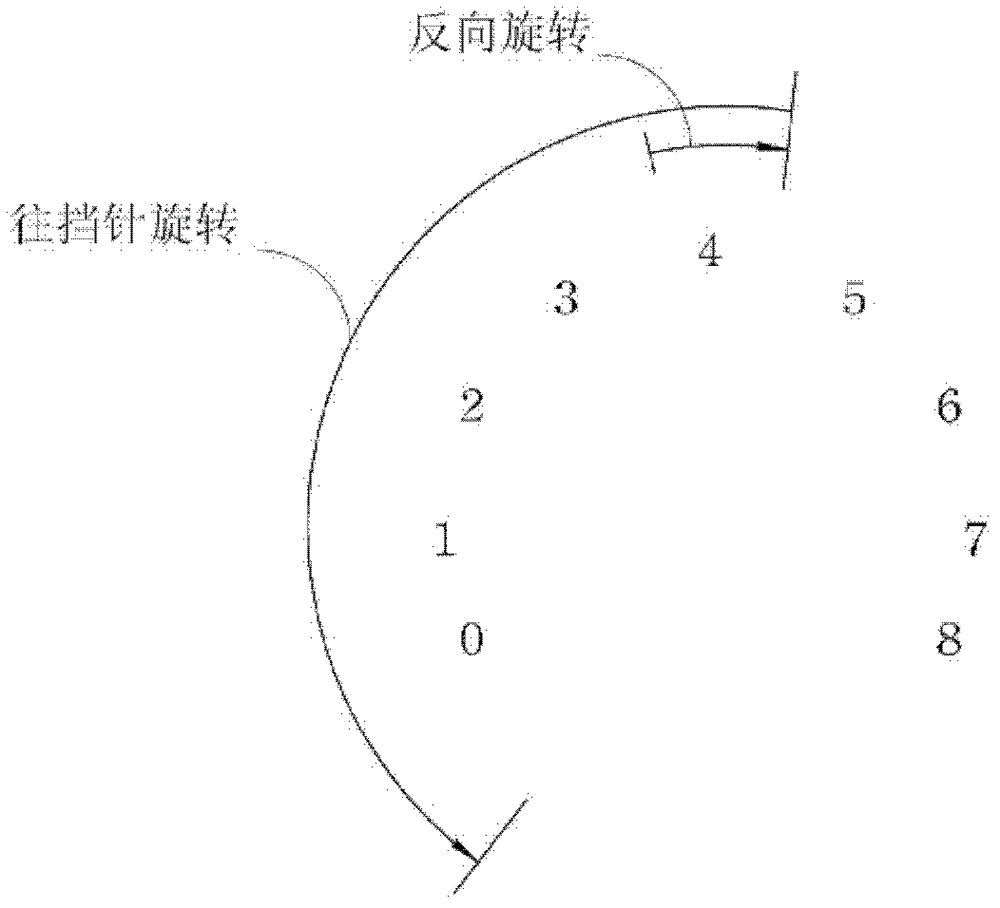

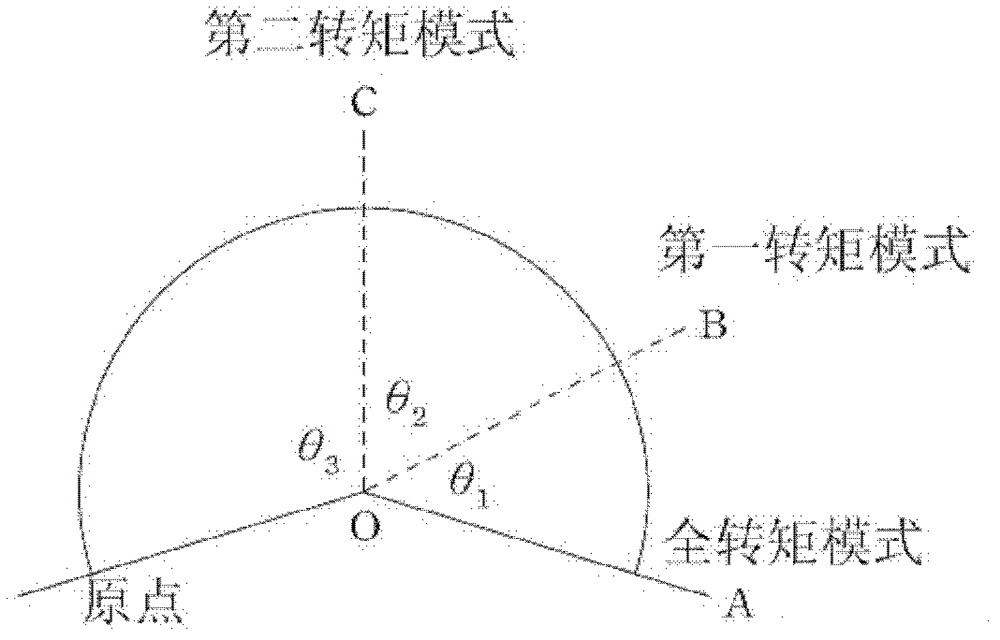

Control method of stepping motor

InactiveCN103166553ASmooth runningAvoid zeroing procedure failureDynamo-electric converter controlUltrasound attenuationDashboard

A control method of a stepping motor is used for controlling the stepping motor of a dashboard. The control method of the stepping motor comprises the following steps of enabling the stepping motor to rotate a first angle to the origin of the dashboard through a full torque mode; enabling the stepping motor to rotate a second angle to the origin through a first torque mode, wherein the first torque mode is a first attenuation amount of the full torque mode, and the first attenuation amount is the minimum attenuation amount for continue rotation of the stepping motor; and enabling the stepping motor to rotate a third angle to the origin through a second torque mode, wherein the second torque mode is a second attenuation amount of the first torque mode, and the second attenuation amount is the minimum attenuation amount of continue rotation for the stepping motor. According to the control method of the stepping motor, a failure of returning to zero caused by too big strength of a pointer impacting a block needle and a failure of returning to zero caused by a big pointer reversing when the power is cut off can be avoided, and smooth operation of the pointer can be realized under the condition that the cost is not increased.

Owner:DELTA ELECTRONICS INC

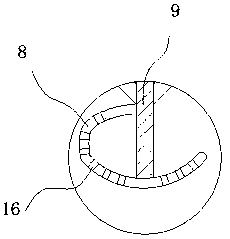

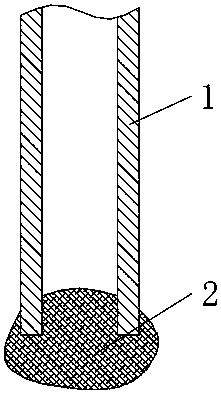

Ultrasonic retardation needle with good developing effect

ActiveCN113171161AExcellent developabilityPrecise positioningSurgical needlesMedical devicesHuman bodySound wave

The invention relates to an ultrasonic retardation needle with a good developing effect. The ultrasonic retardation needle comprises a puncture needle, a developing core is arranged in the puncture needle in a penetrating manner; a fixing assembly is used for fixing the developing core and the puncture needle together; the developing core is provided with a developing cavity; the inside of the developing cavity is vacuum; the developing core and the puncture needle are fixed together through the fixing assembly, when the puncture needle enters a human body, the developing core enters the human body along with the puncture needle, and due to the fact that sound waves in vacuum cannot be conducted, when the position of the retardation needle is detected through ultrasound, the developing core provided with the developing cavity with the vacuum interior can improve the developing effect of the ultrasound blocking needle; and therefore, the positioning of the ultrasonic retardation needle is more accurate.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

Air seal machine with anti-blocking mechanism

The invention relates to the technical field of an air seal machine, in particular to an air seal machine with an anti-blocking mechanism. The air seal machine with the anti-blocking mechanism comprises a gear No. 1, a gear No.2, a shell and a feeding pipe, wherein the anti-blocking mechanism with an anti-blocking box is arranged between the shell and the feeding pipe; the gear No. 1 and the gearNo.2 are both connected a rotating shaft passing through a baffle plate in a horizontal direction; a dust collection cover is sleeved on the outer surface of the rotating shaft; anti-blocking needlesare arranged on the outer surface of the dust collection cover; the distance between the two adjacent anti-blocking needles is greater than the diameter of the maximum cross section of a material; andthe anti-blocking box communicates with the interiors of the shell and the feeding pipe. By arranging the anti-blocking mechanism between the shell and the feeding pipe, the material fed in from thefeeding pipe firstly passes through the anti-blocking needles in the anti-blocking mechanism, so that sheet-like or fibrous sundries in the material such as hair and thin lines is wound on the anti-blocking needles, so as not to seriously affect the rotation of impellers, thus, the working efficiency of the air seal machine is improved, and the service life of the air seal machine is prolonged.

Owner:郑州金诚信筛网设备有限公司

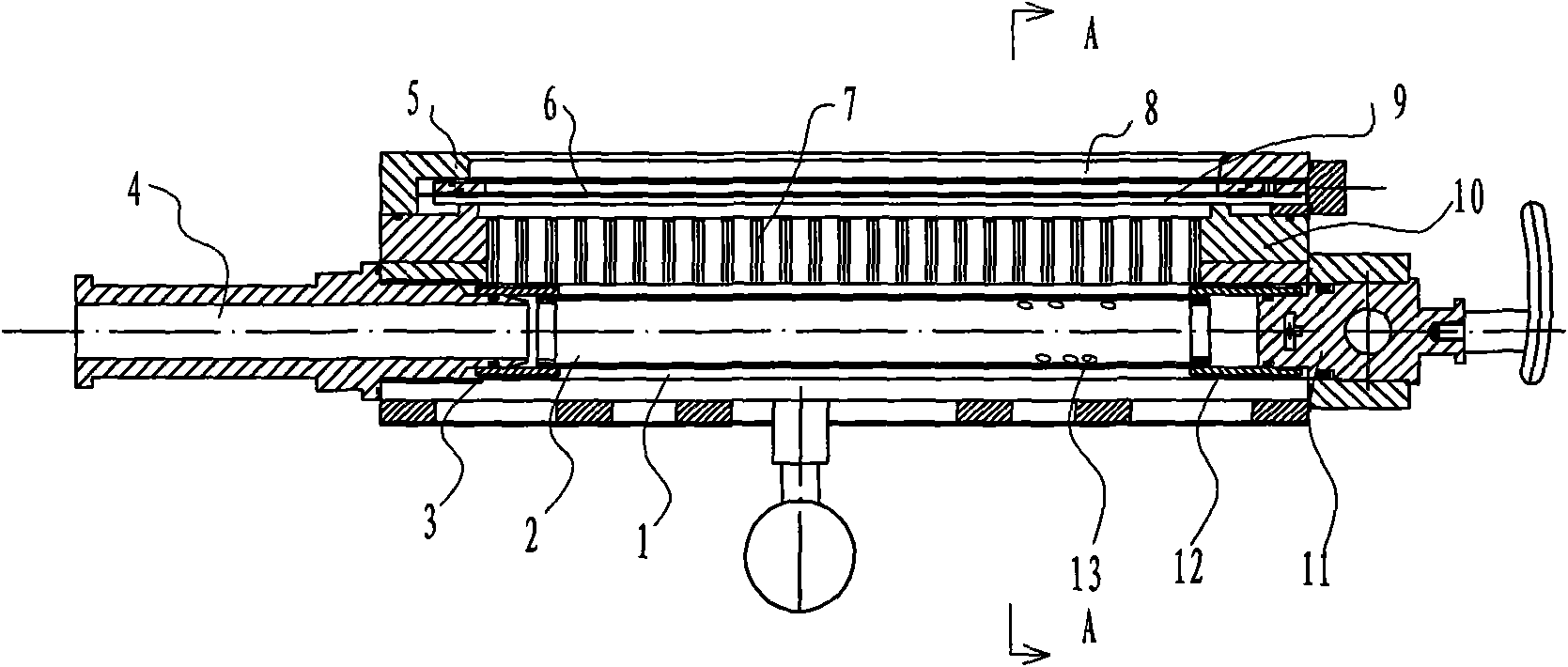

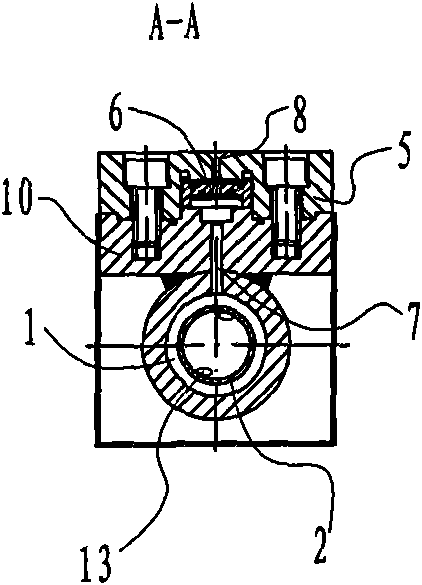

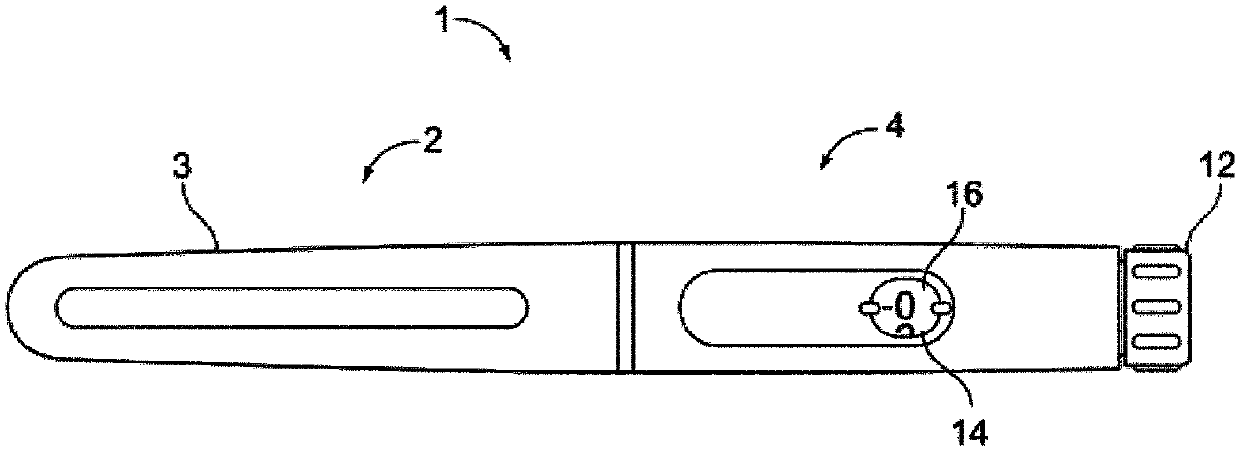

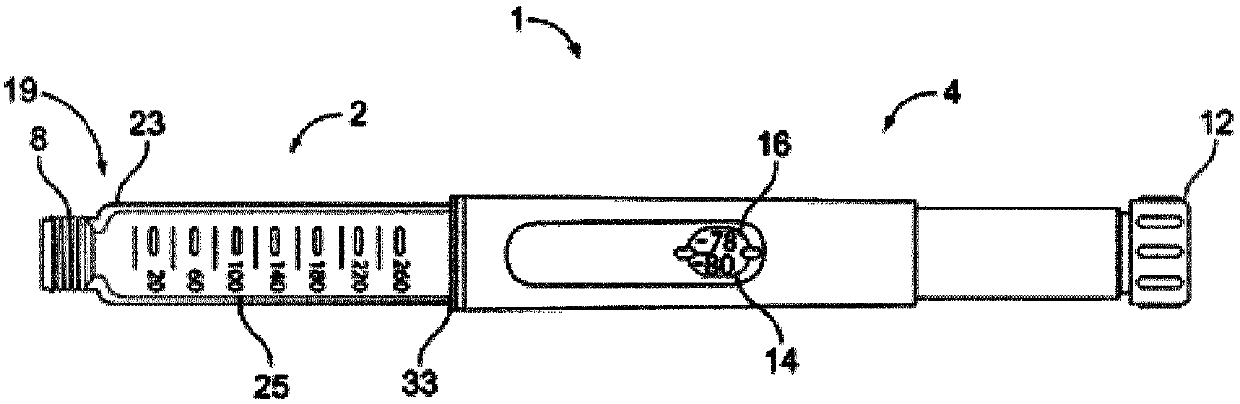

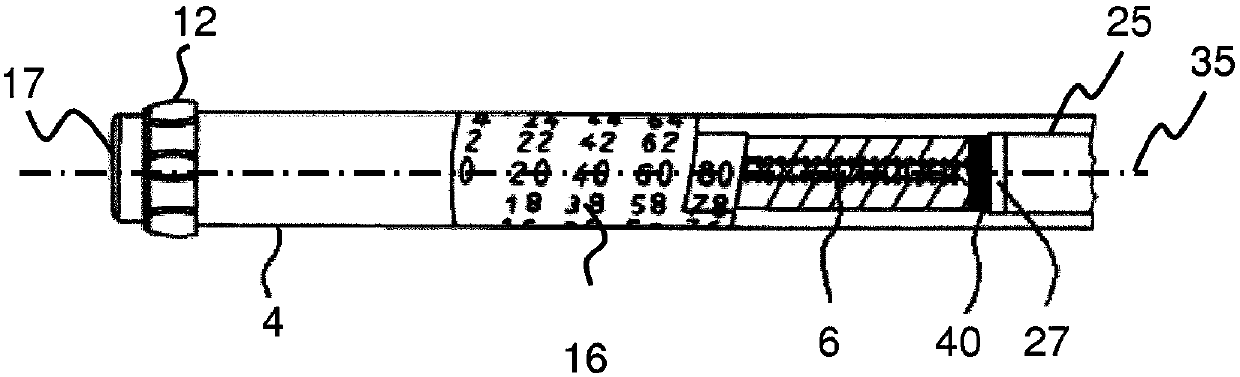

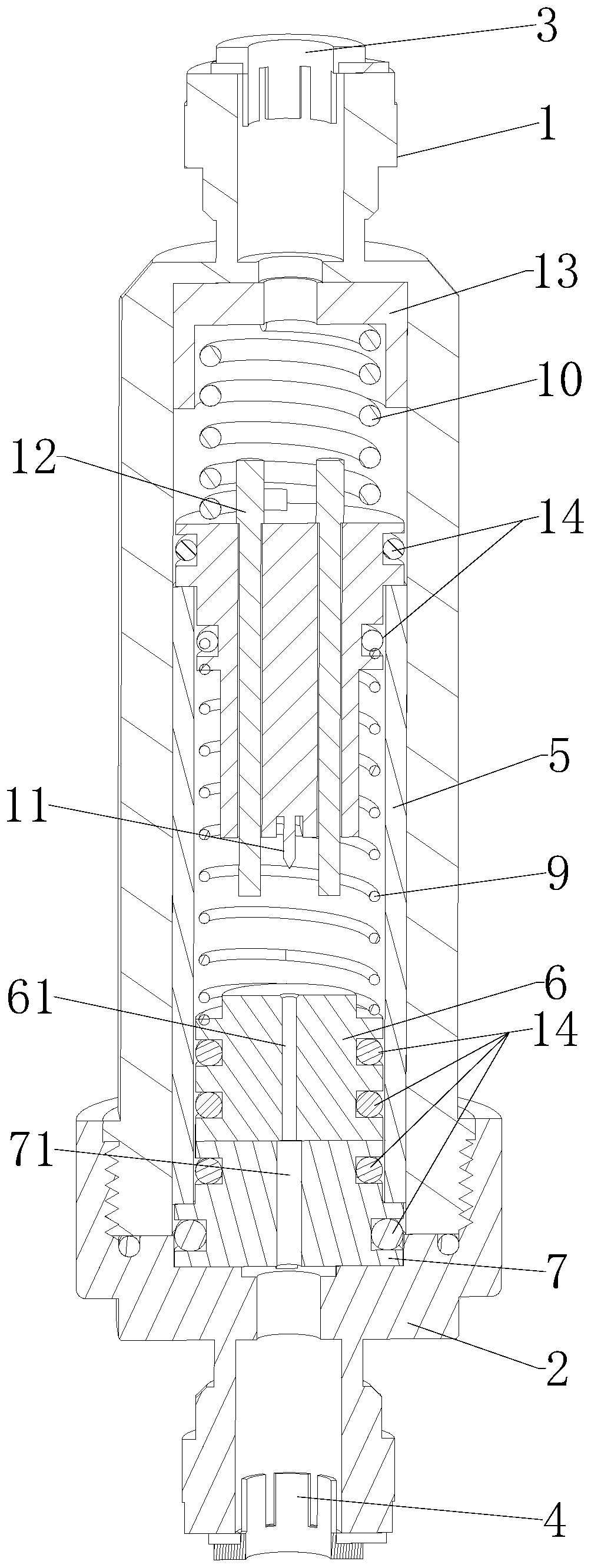

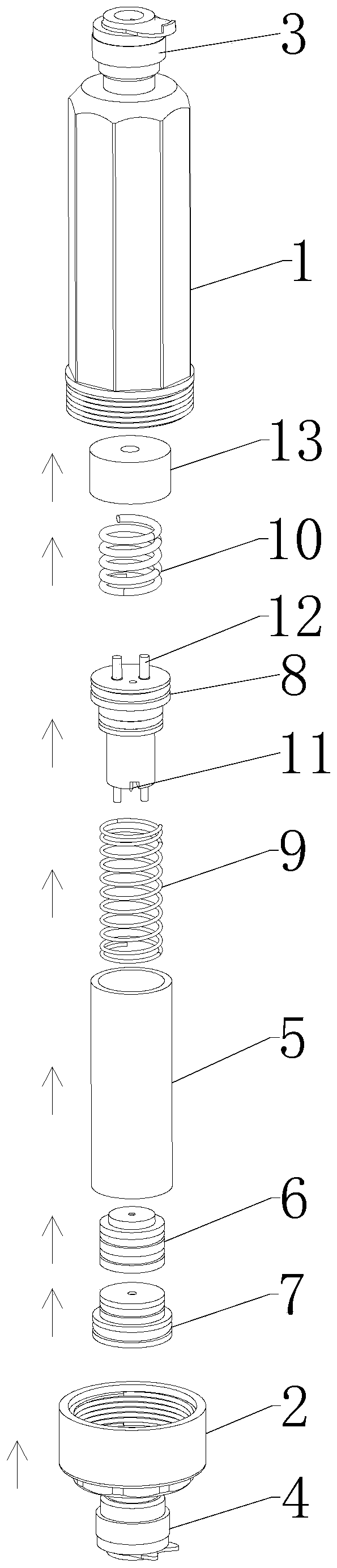

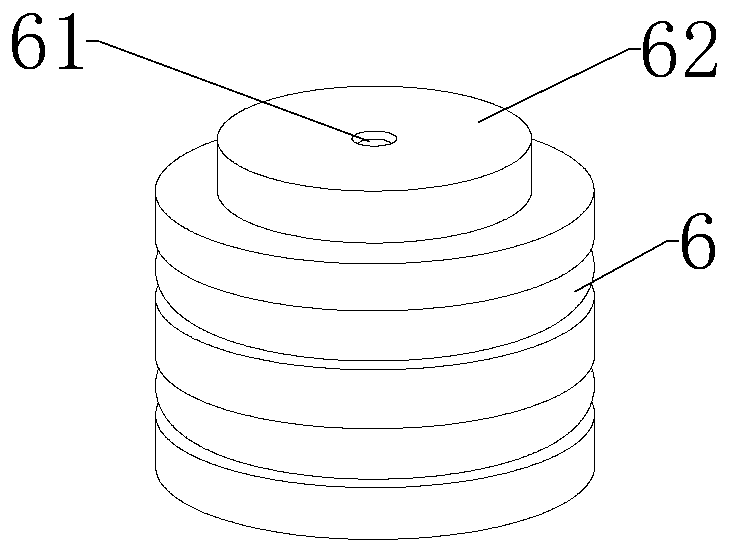

Drug delivery device with load indicator

The invention discloses a drug delivery device with load indicator. The invention refers to a drug delivery device (1) with a piston rod (6) which extends along a longitudinal axis of the drug delivery device (1), wherein the piston rod (6) is adapted to apply an axial load in the distal direction to a cartridge bung (27) in order to dispense a medicament contained in the cartridge (25). In orderto improve the convenience of the injection process and to mitigate the risk of underdosing due to a blocked needle a cartridge bung load indicator (40, 60, 70) is provided, located at the distal endof the piston rod (6) and adapted to abut against the cartridge bung (27), wherein the cartridge bung load indicator (40, 60, 70) comprises an indicator element (53, 62, 71) that audibly, tangibly and / or visually indicates a load state of the piston rod (6) to the user.

Owner:SANOFI SA

Gravity and friction relationship test device

InactiveCN105654816AImprove cognitive abilityEasy to learnEducational modelsGravitational forceEngineering

The invention discloses a gravity and friction relationship test device. The device comprises a support device installed on a stand column, a gravity device placed on a light pull sheet and a variable force device assembled on a pedestal. The support device comprises a support sheet, a light pull sheet, a bayonet and a fastening bolt. The gravity device comprises a container, a container cover and a magnet. The variable force device comprises an electromagnet, a slide rheostat, a power supply, a switch, a slip sheet and a wire. Left block needle and right block needle are symmetrically arranged on the support sheet of the support device. A container cover button, a container cover thread and a container cover hole are formed on the container cover. According to the invention, the gravity and friction relationship test device has the advantages that test purpose is achieved, the structure is simple, the effect is visual, the stability is good, the repeatability is strong, the conclusion is clear and the physical knowledge learning of students is facilitated.

Owner:王义金

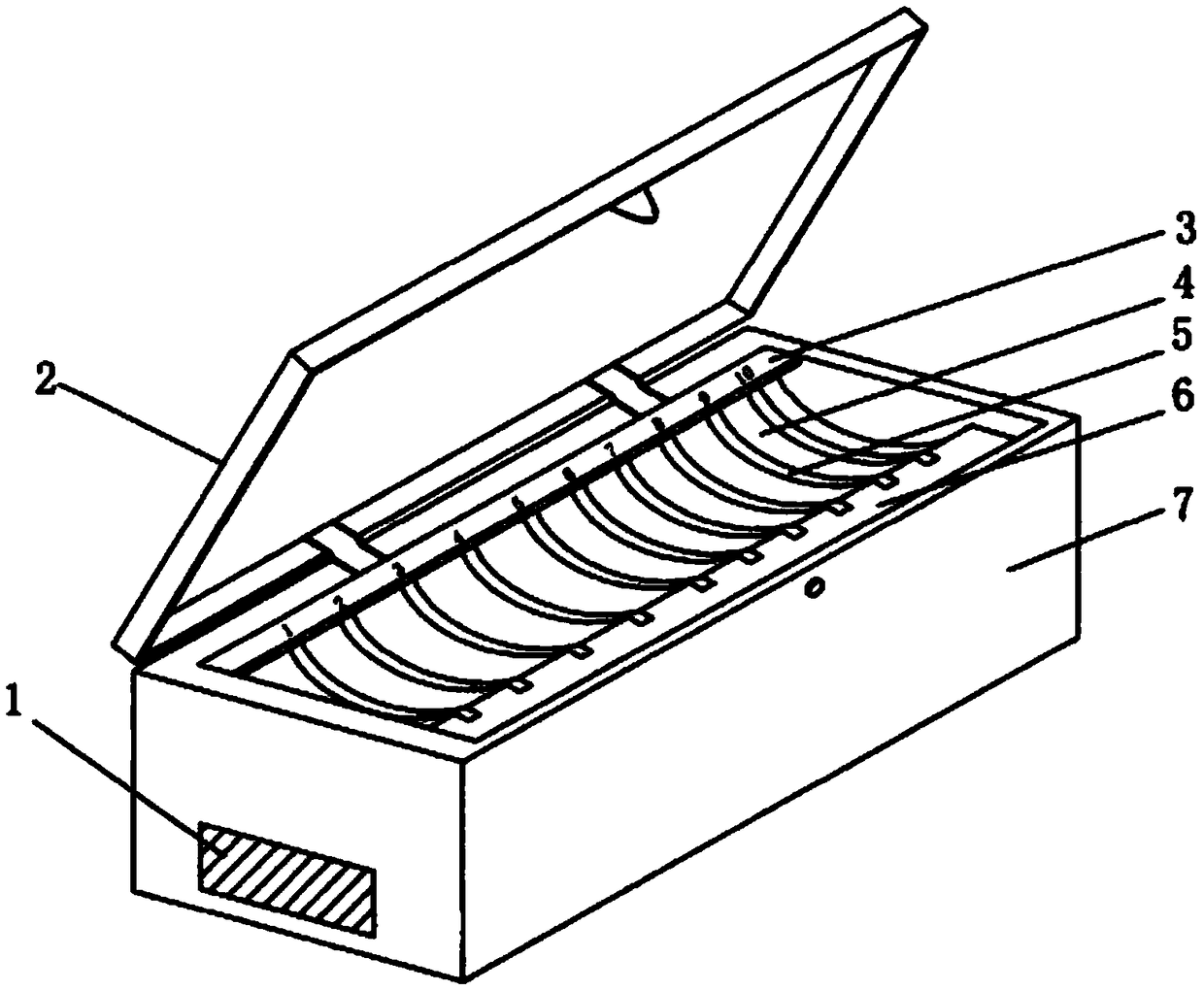

Magnetic needle case for surgery

InactiveCN108095786AAvoid stabbingPrevent fallingSuture equipmentsSurgical needlesBiomedical engineeringBlock needle

The invention relates to a magnetic needle case for surgery. The magnetic needle case comprises a case body and a case cover, wherein a magnetic stripe is arranged at the bottom of the case body, a needle seat is arranged on the magnetic stripe in the magnetic case, the needle seat is provided with multiple arc-shaped sunk needle grooves corresponding to the shape of surgical needles, the left endof each needle groove on the needle seat is provided with a needle tip guard plate, the needle tip guard plate can block needle tips and the fingers can be protected from being stabbed when the needles are taken. The magnetic needle case has the advantages that the magnetic stripe at the bottom of the needle case can adsorb the needles, thereby effectively preventing the needles from falling or losing; the needle tip guard plate can block the needle tips and prevent the fingers from being stabbed when the needles are taken; the shape of the needle grooves corresponds to that of the needles, and therefore the station keeping is good, the placement is neat, and the storage and access are more convenient and safer. The magnetic needle case is mainly used to store various surgical needles, and can be also used to store other similar shaped curved needles.

Owner:徐州复立医疗器械有限公司

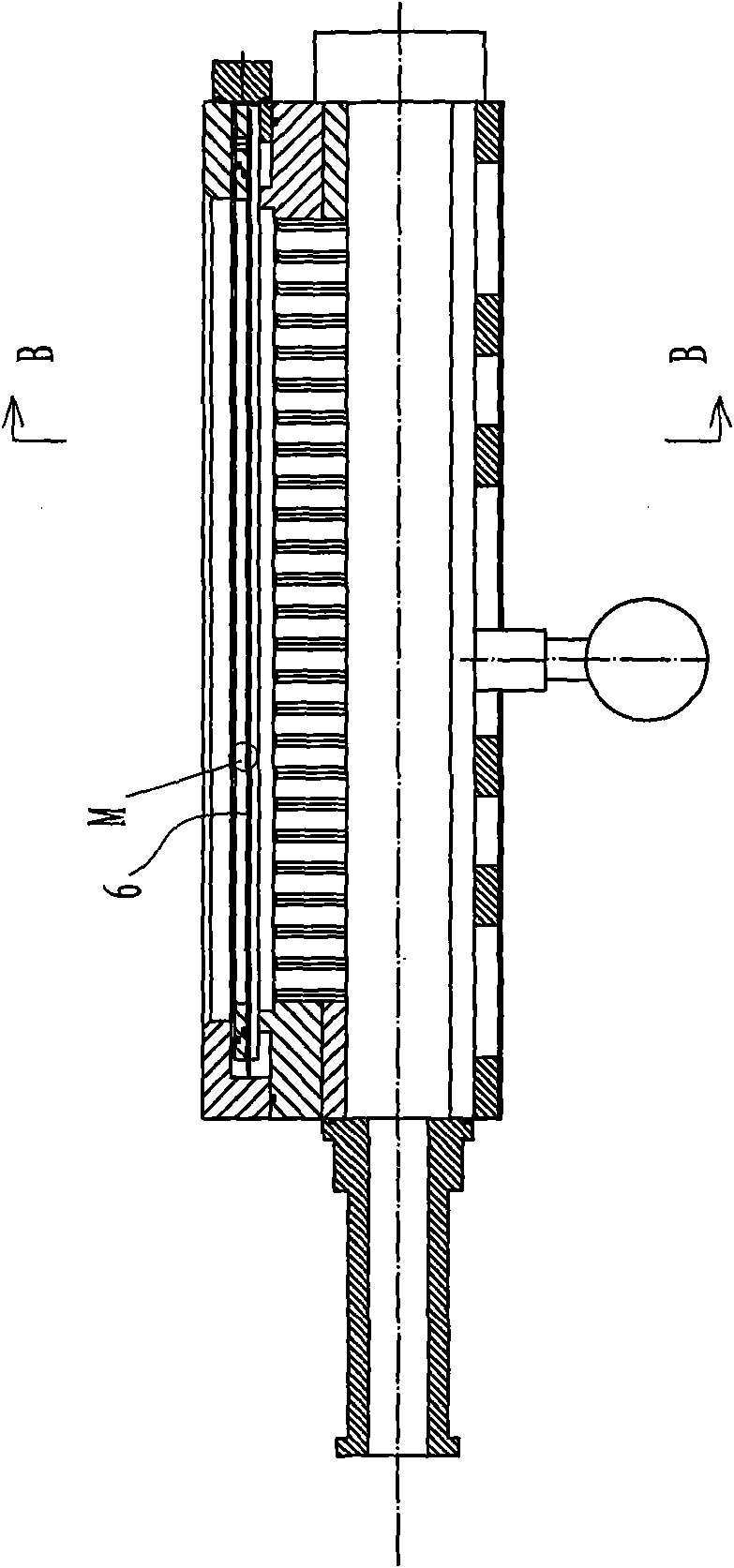

Spinning apparatus with circular extruding function

ActiveCN109837596AAvoid affecting productivityEasy to cleanFilament/thread formingElectrospinningEngineering

The invention discloses a spinning apparatus with a circular extruding function and belongs to the technical field of electrostatic spinning. The spinning apparatus comprises a mounting box; an injection pipe is fixedly communicated with the top center of the mounting box; the bottom of the mounting box is fixedly communicated with a plurality of needles; the top of the mounting box is fixedly connected with cleaning mechanisms corresponding to the needles; the cleaning mechanisms comprises an ejector pin coaxial to the needles, a fixing box and a linear driving device, the fixing boxes are fixedly connected with the top of the mounting box, the linear driving devices comprise a fixed end and a moving end, the fixed ends of the linear driving devices are fixedly connected with the tops ofthe fixing boxes, the ejector pins are positioned in the fixing boxes, the tops of the ejector pins are fixedly connected with the moving ends of the linear driving devices, and the bottoms of the ejector pins are extended into the mounting box. The spinning apparatus has the advantages that the blocked needles can be automatically cleaned; stopping the apparatus during cleaning is not required, so that labor intensity is reduced for workers and production efficiency is improved.

Owner:苏州申久高新纤维有限公司

Control method of stepper motor

InactiveCN103166553BSmooth runningAvoid zeroing procedure failureDynamo-electric converter controlDashboardUltrasound attenuation

A control method of a stepping motor is used for controlling the stepping motor of a dashboard. The control method of the stepping motor comprises the following steps of enabling the stepping motor to rotate a first angle to the origin of the dashboard through a full torque mode; enabling the stepping motor to rotate a second angle to the origin through a first torque mode, wherein the first torque mode is a first attenuation amount of the full torque mode, and the first attenuation amount is the minimum attenuation amount for continue rotation of the stepping motor; and enabling the stepping motor to rotate a third angle to the origin through a second torque mode, wherein the second torque mode is a second attenuation amount of the first torque mode, and the second attenuation amount is the minimum attenuation amount of continue rotation for the stepping motor. According to the control method of the stepping motor, a failure of returning to zero caused by too big strength of a pointer impacting a block needle and a failure of returning to zero caused by a big pointer reversing when the power is cut off can be avoided, and smooth operation of the pointer can be realized under the condition that the cost is not increased.

Owner:DELTA ELECTRONICS INC

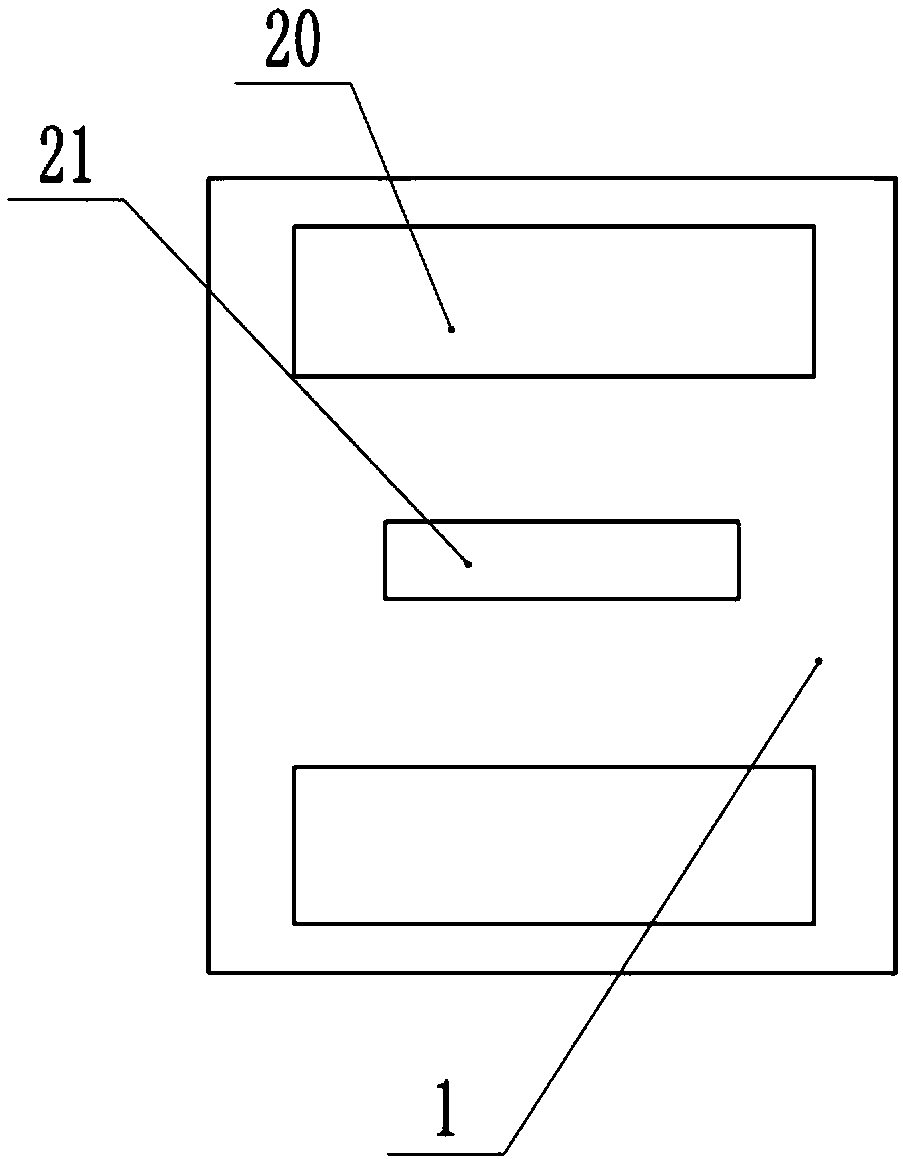

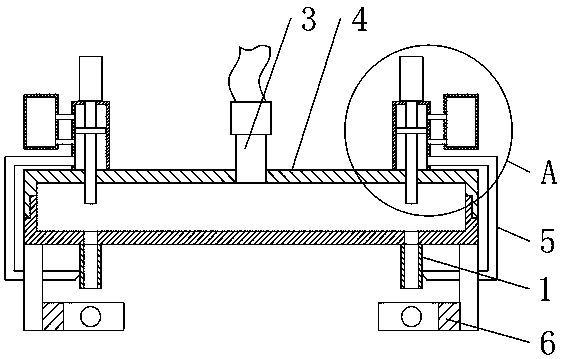

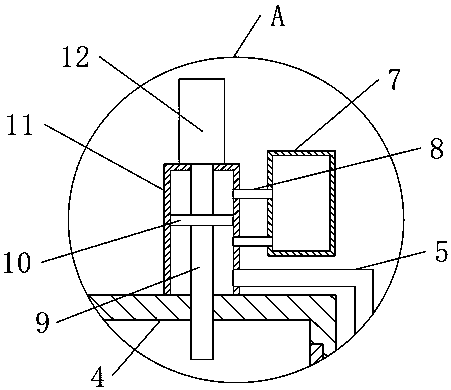

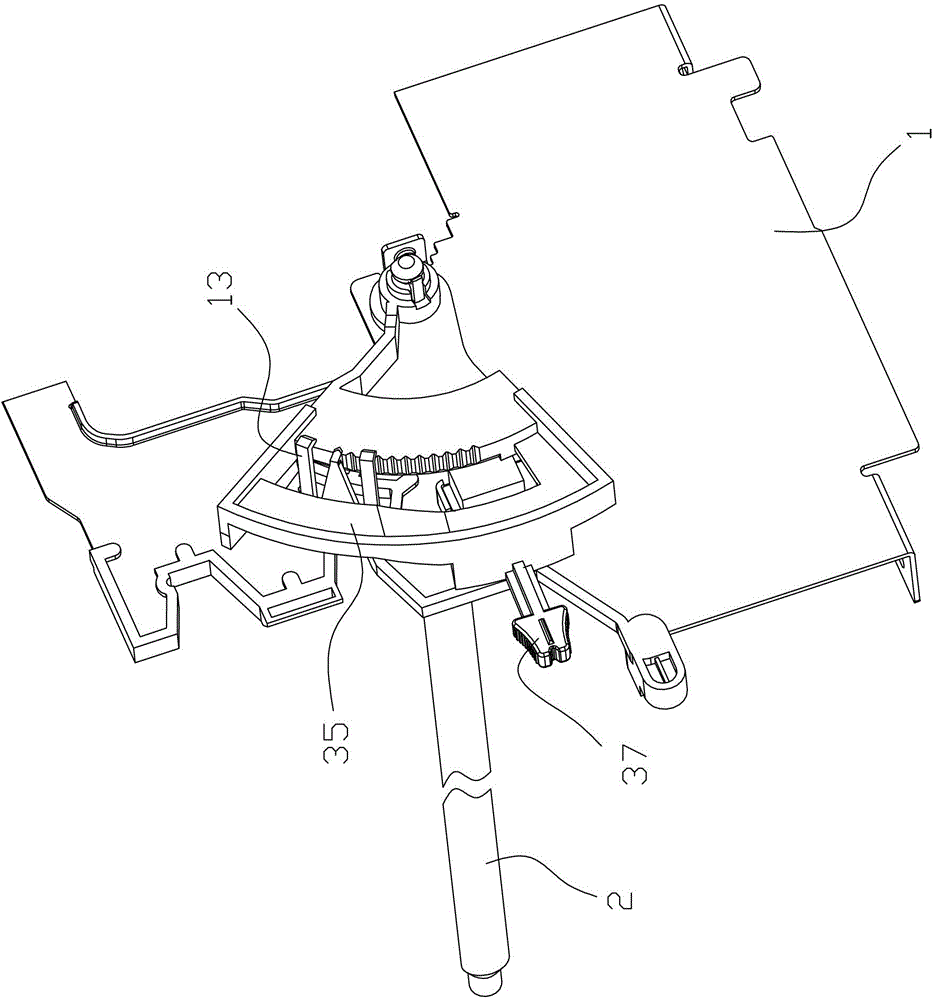

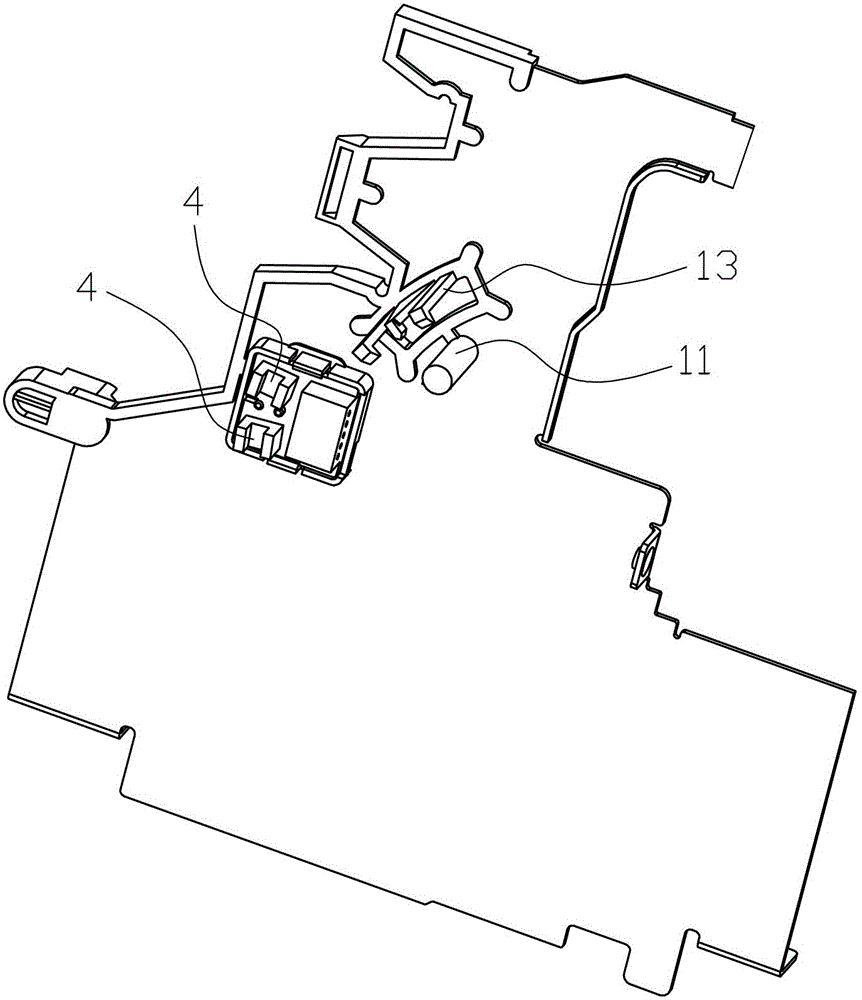

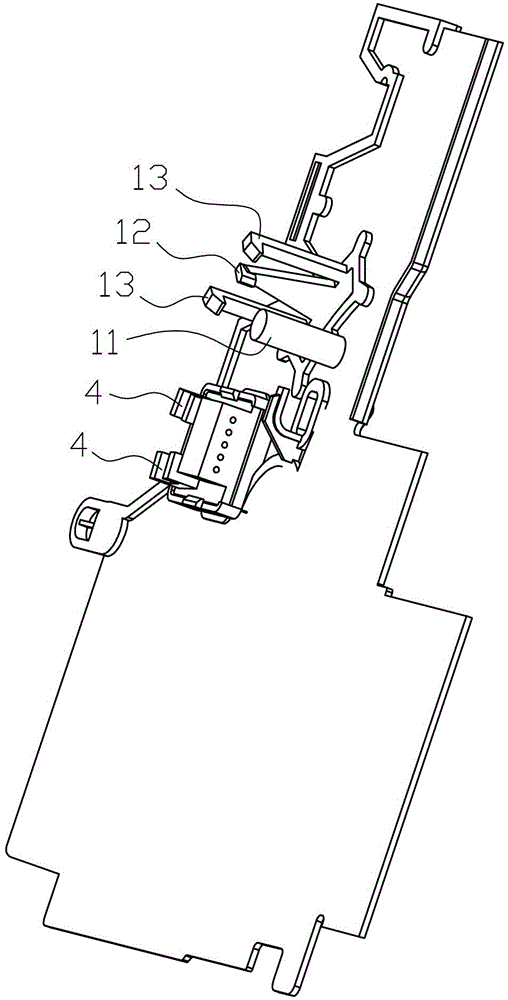

Duplication dynamics automatic adjustment structure assembly of stylus printer

ActiveCN103101321BSimple structureSimple, reasonable and compact structureOther printing apparatusElectricityLight beam

The invention discloses a duplication dynamics automatic adjustment structure assembly of a stylus printer. The duplication dynamics automatic adjustment structure assembly of the stylus printer comprises a support and a paper-thickness regulating shaft of an eccentric shaft, wherein one end of the paper-thickness penetrates through the support, and then a paper-thickness slection lever is fixedly installed at a tail end of the paper-thickness regulating shaft. The paper-thickness selection lever is in a sector structure, and a surface of the selection lever is divided into an inner sector shape and an outer sector shape. File position teeth are arranged on one end surface of the inner sector shape along diameter direction of the inner sector. Blocking needles locked in the file position teeth are arranged on the support. A U-shaped photo-electricity sensor is installed on the end surface of the support nearby the paper-thickness selection lever. Blocking slices capable of sheltering beams of the U-shaped photo-electricity sensor are arranged on the paper-thickness selection lever. A duplication dynamics state of the automatic adjustment stylus printer is capable of abandoning a duplication dynamics adjustment manner of manually regulating the duplication dynamics through a panel press button in the traditional technology. The duplication dynamics automatic adjustment structure assembly of the stylus printer is simple in structure, reasonable and compact, saving in bill material and high in printing efficiency.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

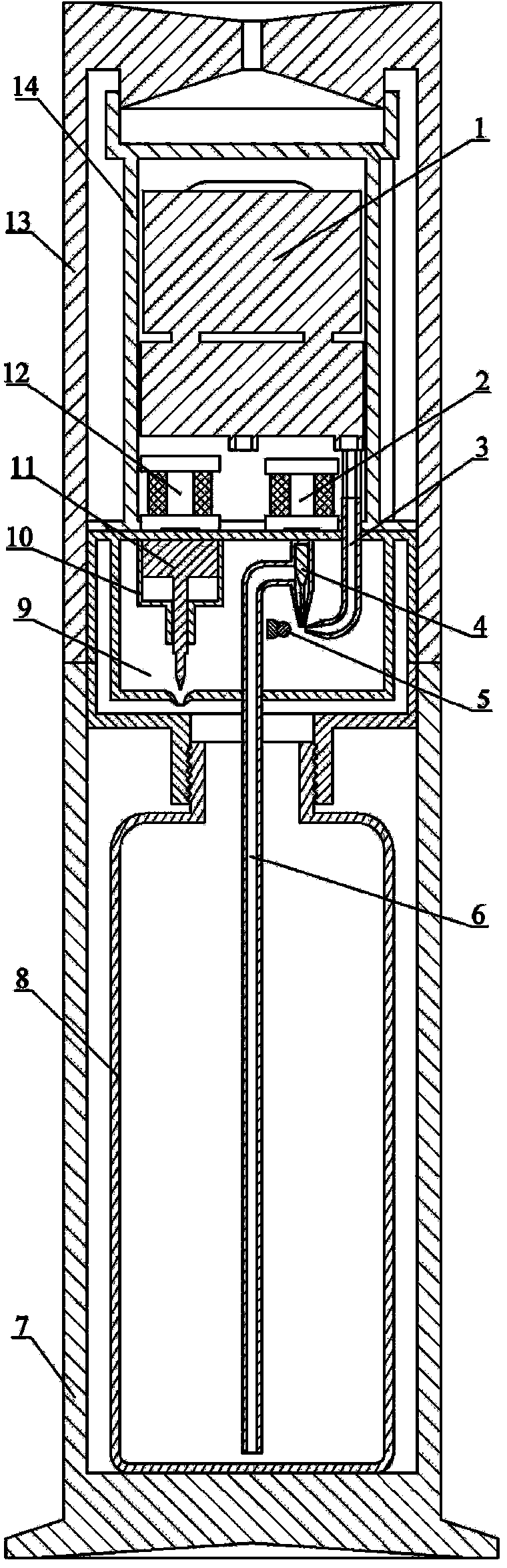

Self-flushing anti-blocking waste water jar

PendingCN109944971AGood controllabilityImprove featuresEqualizing valvesWater/sewage treatment bu osmosis/dialysisPistonBlock needle

The invention discloses a self-flushing anti-blocking waste water jar. The self-flushing anti-blocking waste water jar comprises a shell and a shell cap arranged at the lower end of the shell, whereinthe upper end of the shell is provided with a water outlet end, and the lower end of the shell cap is provided with a water inlet end. The shell is internally provided with an inner pipe barrel, a lower plug, an upper plug, a first spring and a second spring, wherein a piston is arranged in the inner pipe barrel, and the piston is provided with a vertically-through first through hole; the lower plug is arranged at the lower end of the inner pipe barrel, a vertically-through second through hole is formed in the lower plug, and water flows out of the second through hole to push the piston to move upwards; the upper plug is arranged at the upper end of the inner pipe barrel and is provided with a vertically-through third through hole; the first spring is contained in the inner pipe barrel and is clamped between the upper plug and the piston; the second spring is pressed on the top end of the upper plug; the bottom of the upper plug is provided with a blocking needle, and the first through hole is used for allowing the blocking needle to be inserted in; and the upper plug is also provided with a thimble used for blocking the piston. A waste water discharging device of a pure mechanical structure is adopted, no circuit system is needed, and good self-control and anti-blocking characteristics are achieved.

Owner:YUYAO SANSHUN WATER PURIFICATION TECH CO LTD

An essential oil siphon atomization aromatherapy device

The invention discloses siphoning type essential oil atomization aromatherapy equipment which comprises an upper cover and a base, wherein a motor is installed inside the upper cover; an air outlet of the motor is connected with an atomization chamber; and a first electromagnetic iron is arranged at the top of the atomization chamber. An essential oil storage device is installed on the base; the lower part of an essential oil tube is positioned inside the essential oil storage device; the upper part of the essential oil tube is positioned in the atomization chamber; and a first anti-block needle is installed at the tail end on the upper part of the essential oil tube in an interference fit mode. By utilizing the siphoning type essential oil atomization aromatherapy equipment, the essential oil is atomized in a siphoning mode, the essential oil components are uniformly diffused, and the purity of the essential oil grains diffused out is ensured to the maximum extent.

Owner:上海百芬环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com