Integrated bistable solenoid valve

A solenoid valve and bistable technology, applied in the field of solenoid valves, can solve the problems of complex water passage, disordered component layout, inconvenient maintenance, etc., and achieve the effects of improving work efficiency, simple performance and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

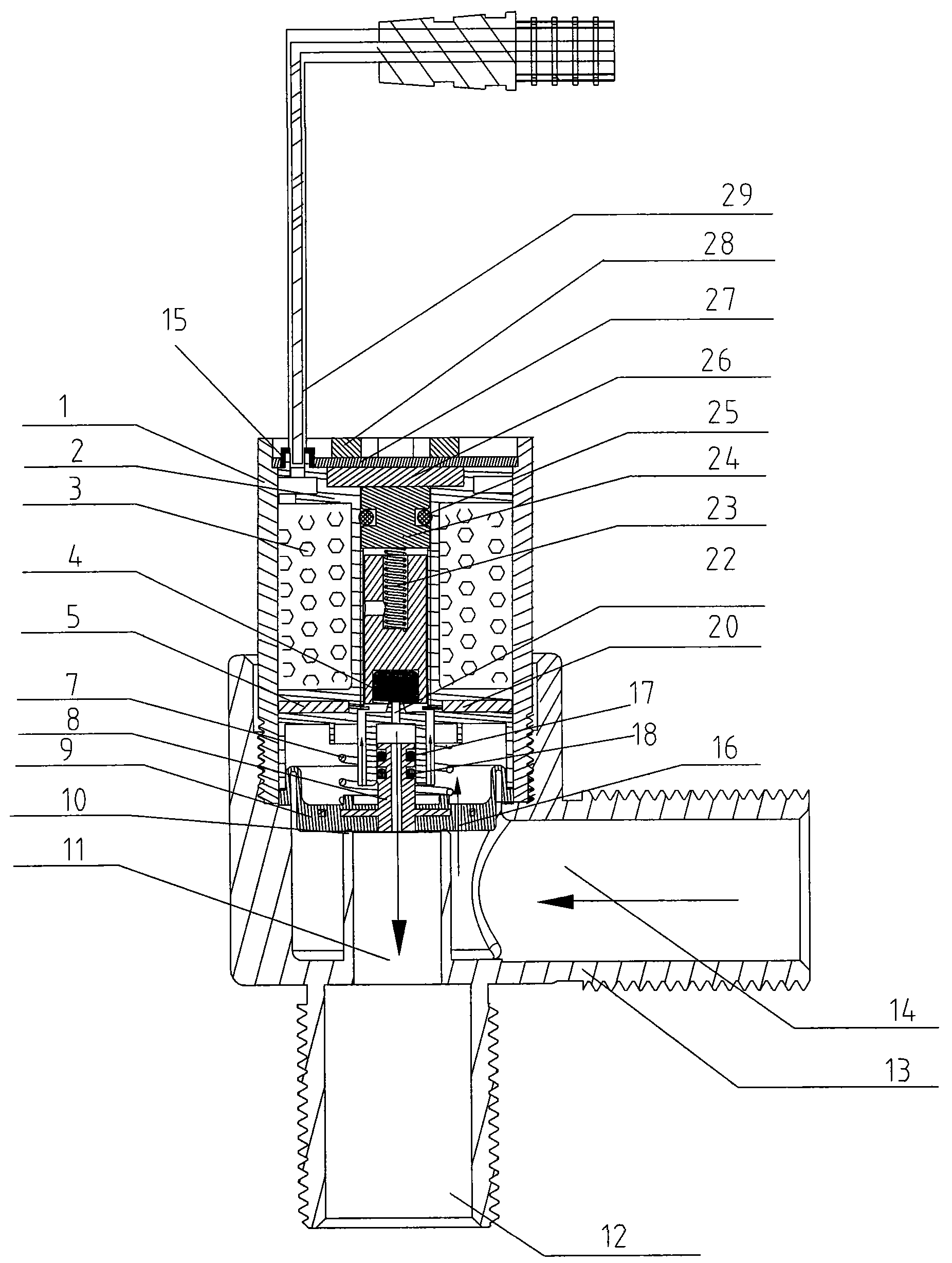

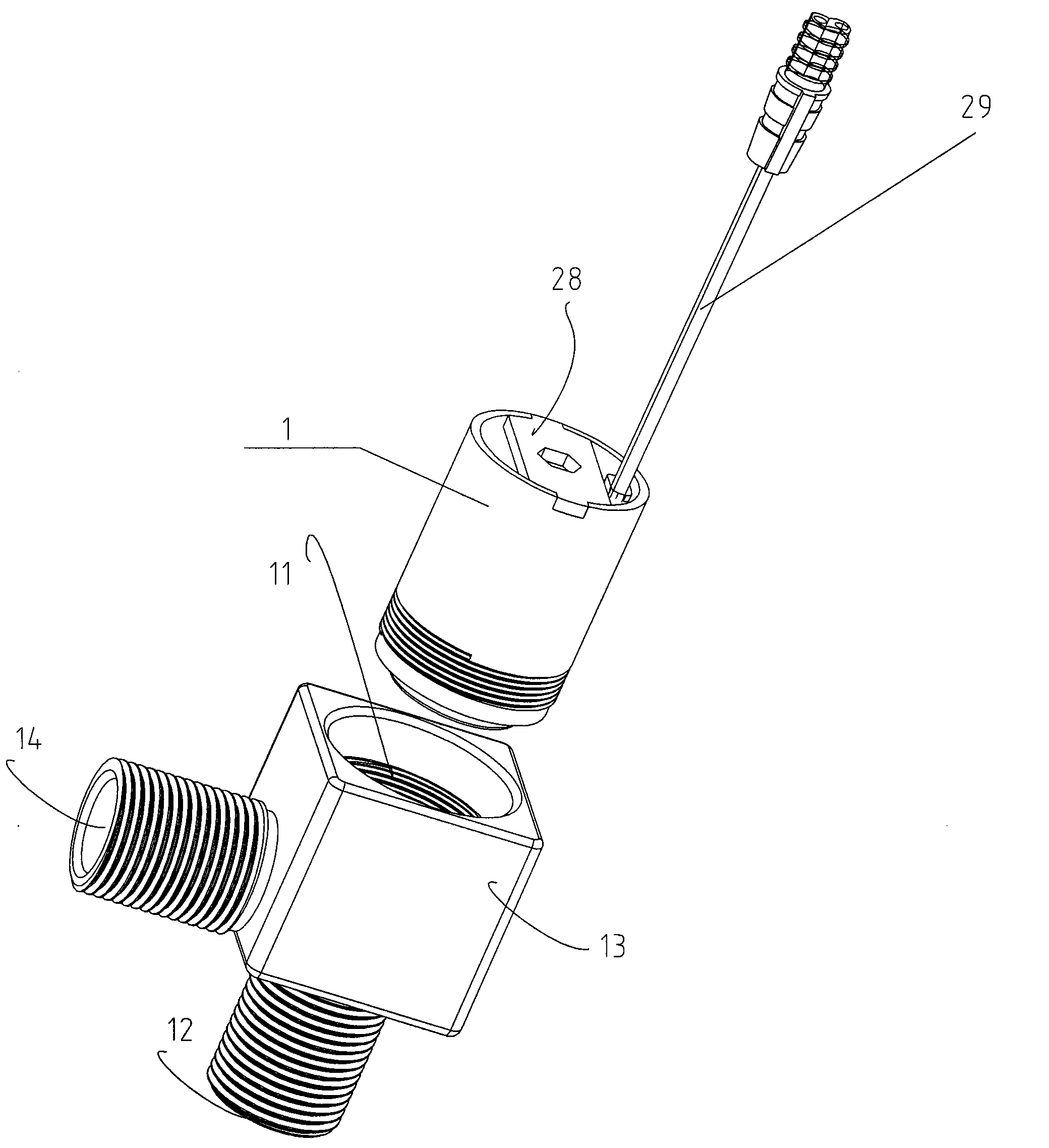

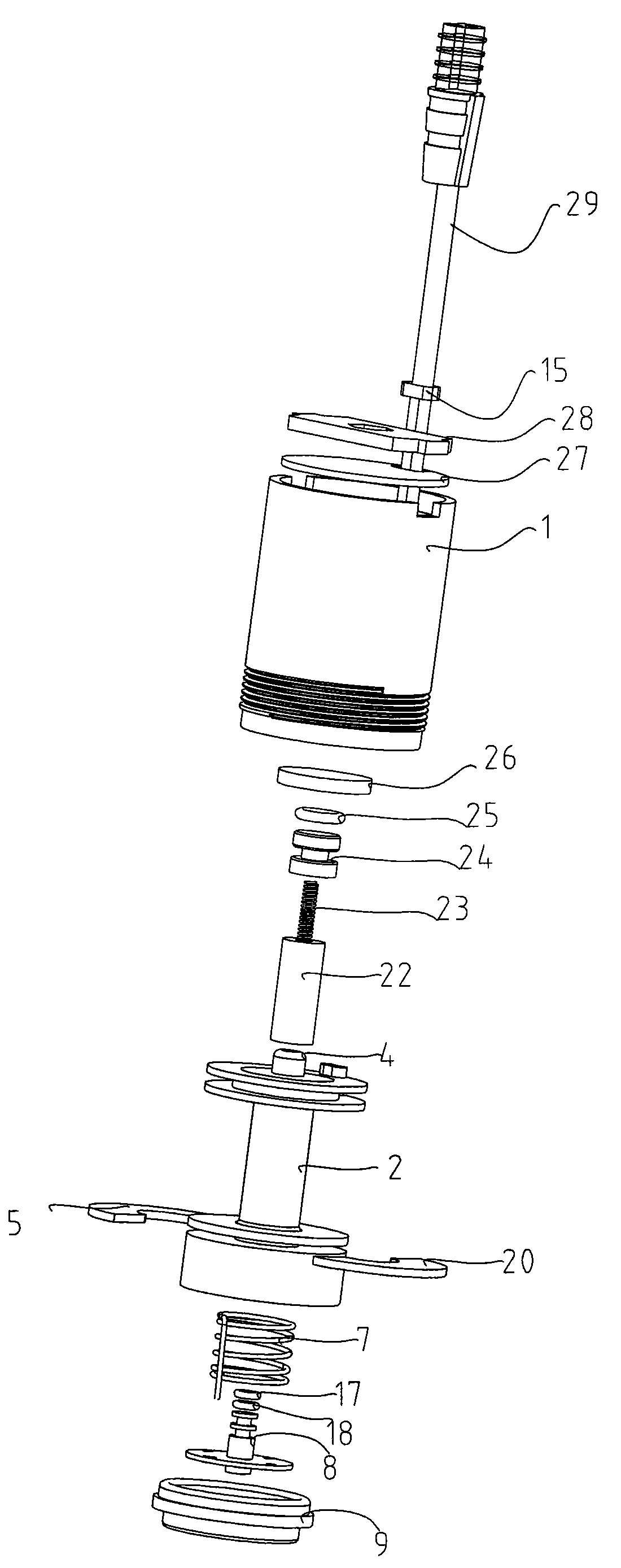

[0018] Such as Figure 1 to Figure 3 In the embodiment shown, the reference numbers indicate: casing 1, coil bobbin 2, coil 3, plug 4, first shielding iron plate 5, anti-blocking needle spring 7, piston membrane core 8, rubber membrane 9, valve body drain Pressure hole 11, valve body water outlet 12, valve body 13, valve body water inlet 14, coil sheath 15, booster hole 16, second sealing O-ring 17, third sealing O-ring 18, second shielding iron Plate 20, moving iron core 22, fixed iron core 24, first sealing O-ring 25, magnet 26, coil shell cover 27, shell locking plate 28, anti-opposite insertion line 29.

[0019] In the embodiment of the present invention, the bistable solenoid valve with integrated structure includes a solenoid valve head fitted on the valve body 13, and is characterized in that: the solenoid valve head includes a casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com