Duplication dynamics automatic adjustment structure assembly of stylus printer

A needle-type printer and automatic adjustment technology, applied in the direction of printing device, printing, etc., can solve the problems of increasing the structural complexity of the needle-type printer, limiting the design of the shape and structure, and increasing the tedious operation, so as to reduce the operation labor and improve the aesthetics. Improve and speed up the effect of printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

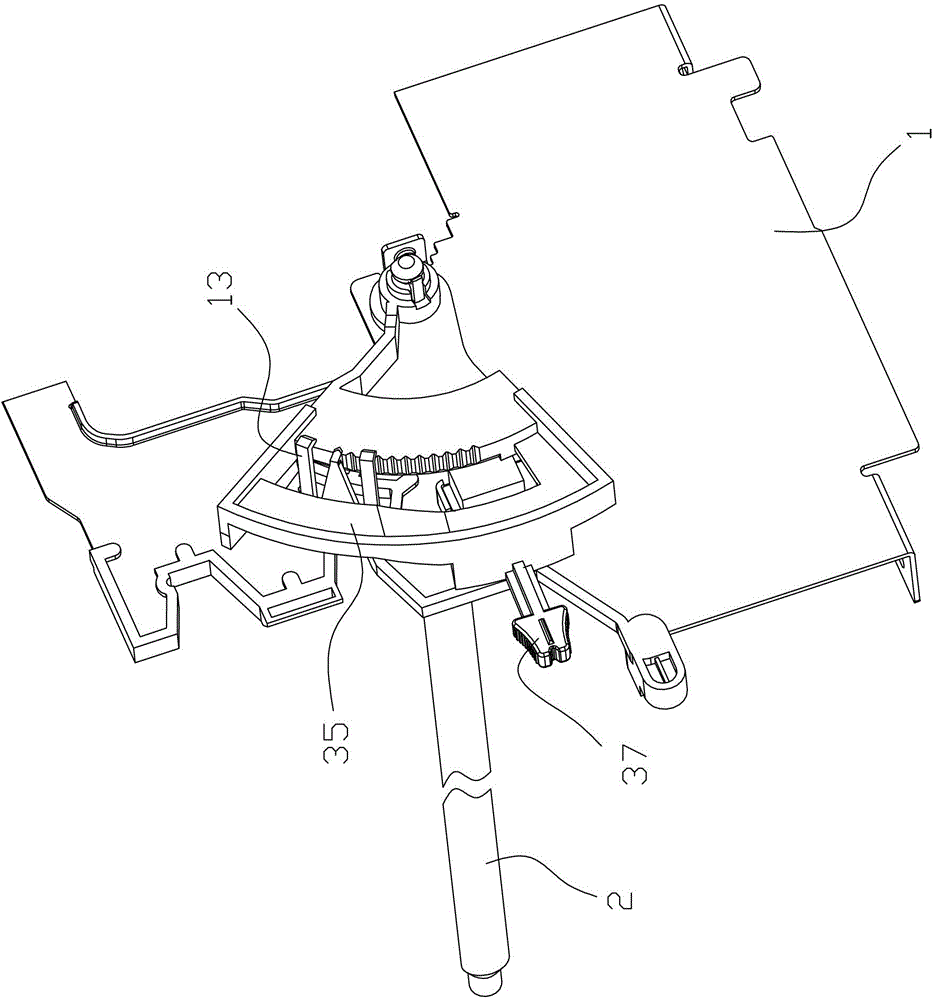

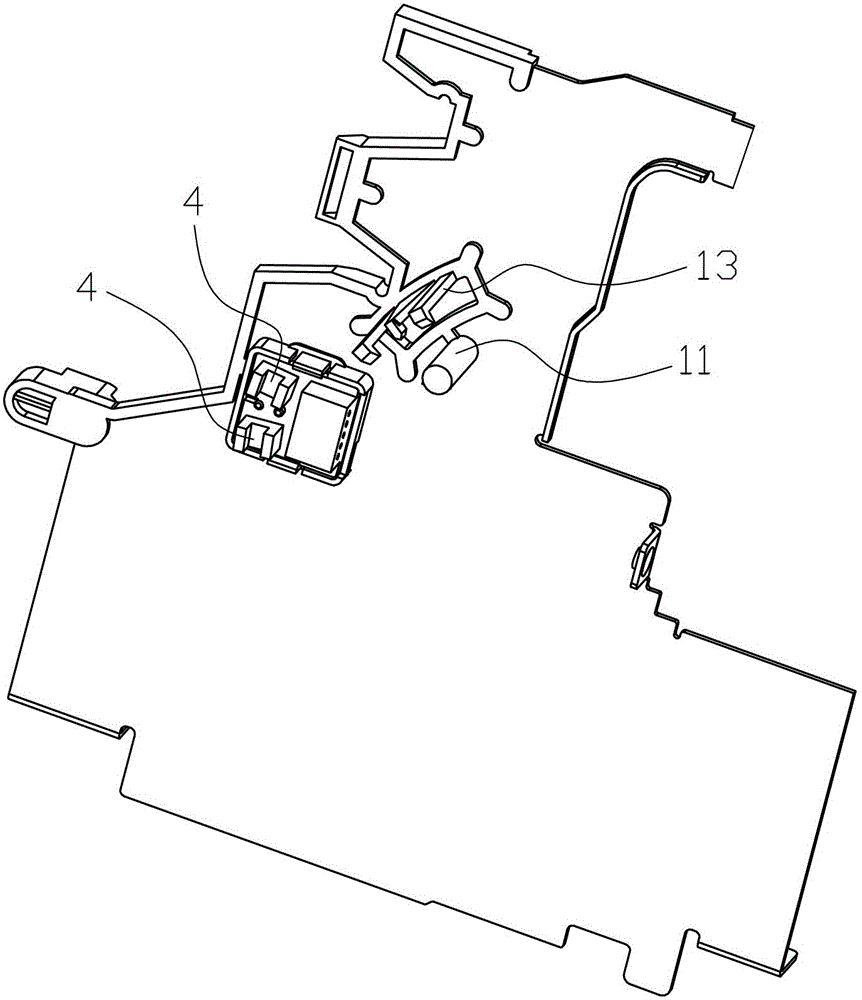

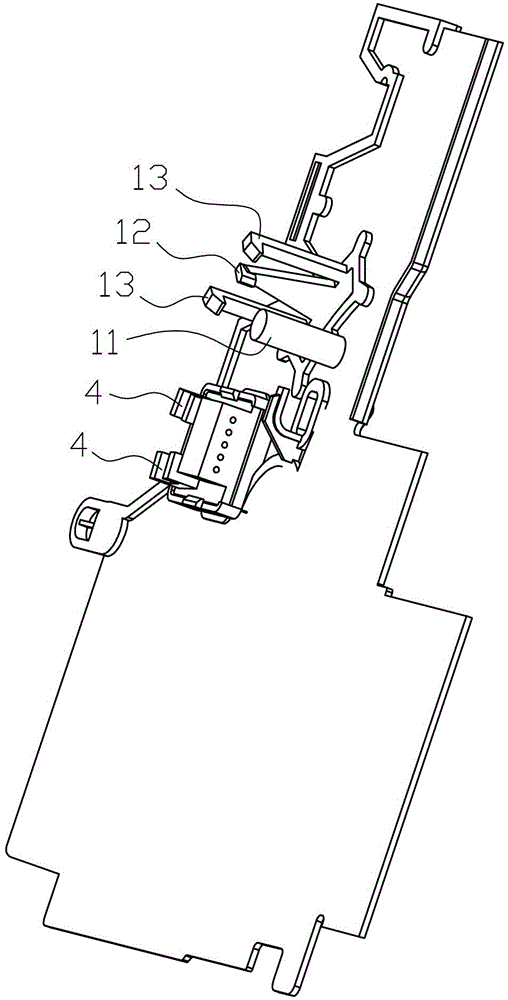

[0025] refer to Figure 1~Figure 10 , a structural assembly for automatically adjusting the copying force of a dot matrix printer of the present invention, which includes a bracket 1 and a paper thickness adjusting shaft 2 that is an eccentric shaft, and the paper thickness adjusting shaft 2 is an eccentric shaft, and an ordinary round shaft can also be used to suit the eccentric Sleeve structure, the paper thickness adjustment shaft 2 is an eccentric shaft, so that the paper thickness adjustment shaft 2 can adapt to printing media of different thicknesses when it rotates, and one end of the paper thickness adjustment shaft 2 passes through the bracket 1, and its end is fixed with a paper thickness The selection rod 3, preferably, the paper thickness adjustment shaft 2 is provided with a D-shaped surface 21 and an annular groove 22 on one end of the paper thickness selection rod 3, and the shaft hole of the paper thickness selection rod 3 has a D-shaped shape with the paper thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com