Patents

Literature

130results about How to "Suitable for printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating composition for multiple hydrophilic applications

InactiveUS20030203991A1Tough and durable and printable surfaceImprove wettabilityOther chemical processesSynthetic resin layered productsColloidWear resistance

A coating composition is disclosed which comprises an aqueous polymeric matrix, a hydrophilic polymer, a colloidal metal oxide and a crosslinker. The coating composition when applied on medical devices is hydrophilic, shows improved lubricity, abrasion resistance and substrate adhesion on metallic or plastic substrates. The coating also shows improved water sheeting thus providing the coated substrates with anti-fog properties. The coating absorbs aqueous dye or stain solutions making the substrate suitable for printing.

Owner:HYDROMER INC

Coating composition for multiple hydrophilic applications

InactiveUS7008979B2Improve adhesionImprove the lubrication effectSurgerySynthetic resin layered productsColloidWear resistance

Owner:HYDROMER INC

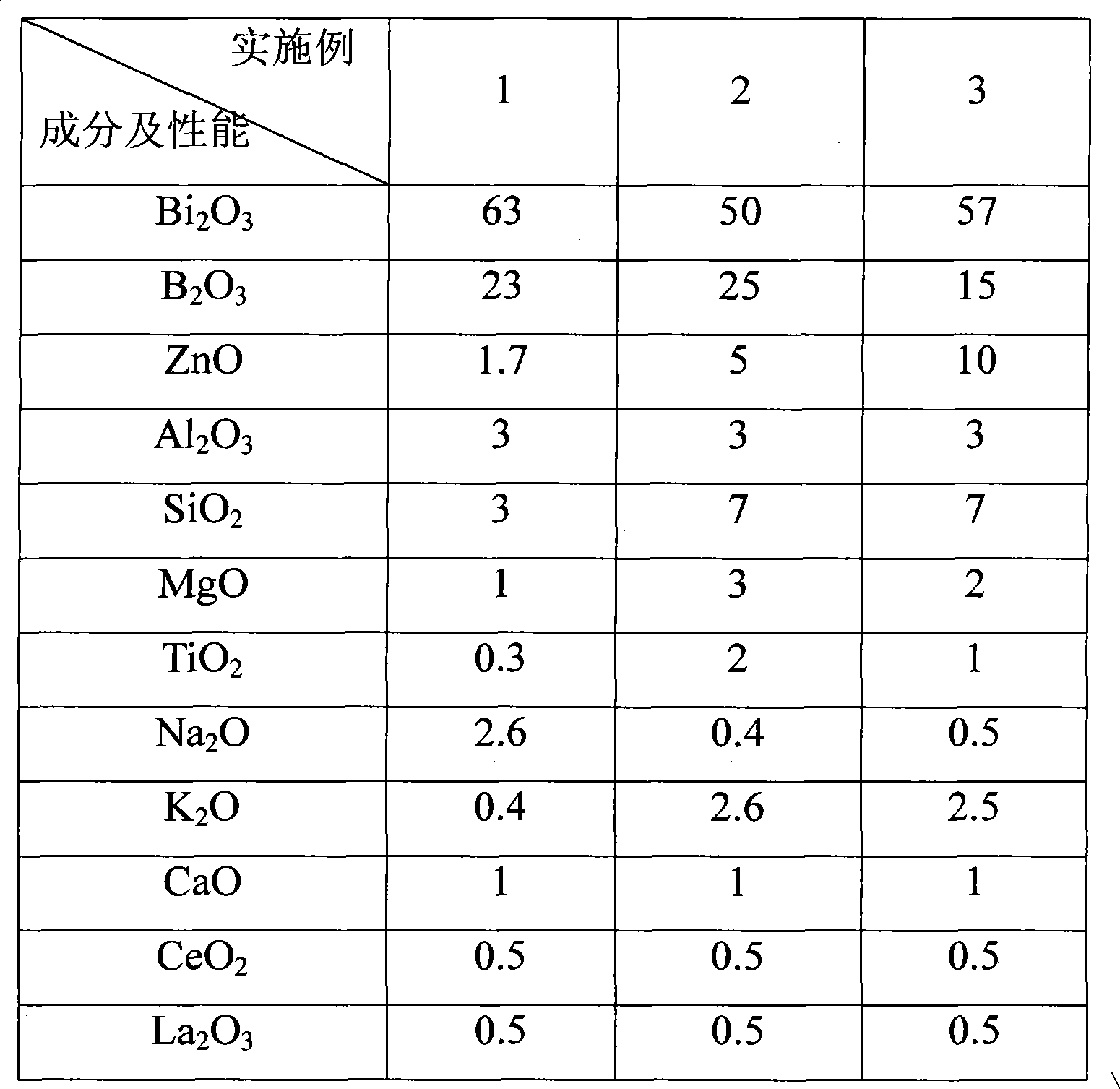

Low-melting point lead-less glasses powder for frit slurry, and preparation and use thereof

The invention discloses lead-free glass dust with low melting point used for glass frit slurry, as well as the preparation method and the application thereof. The lead-free glass dust is characterized in that the compositions have the following weight percentages: 50%-70% of bismuth oxide, 0.1%-30% of boric oxide, 0.1%-30% of zinc oxide, 0.1%-10% of aluminium oxide, 0.1%-10% of silicon oxide, 0.1%-10% of magnesia magnesium oxide, 0.1%-10% of titania titanium dioxide, 0.1%-5% of sodium monoxide, 0.1%-5% of potassium oxide, 0.1%-5% of calcium oxide, 0.1%-2% of cerium oxide, and 0.1%-2% of cerium oxide. The preparation method comprises the following steps: all raw materials are fully mixed; the mixed mixture is put into a crucible, and is then put into an electric furnace at the furnace temperature of 1200-1450 DEG C; the melted glass slurry is poured into a tablet machine for being pressed into sheets or poured into cold water; the flaky or granule glass and dye are put into a ball mill together for ball milling; the glass dust after the ball milling process is screened and bagged; and the glass dust is applicable to the glass frit slurry field of the dielectric layers of plasma displays, fluorescent displays and the like. The invention has the advantages that the glass dust has good insulation and high dielectric constant, and is applicable to screen printing.

Owner:陈培

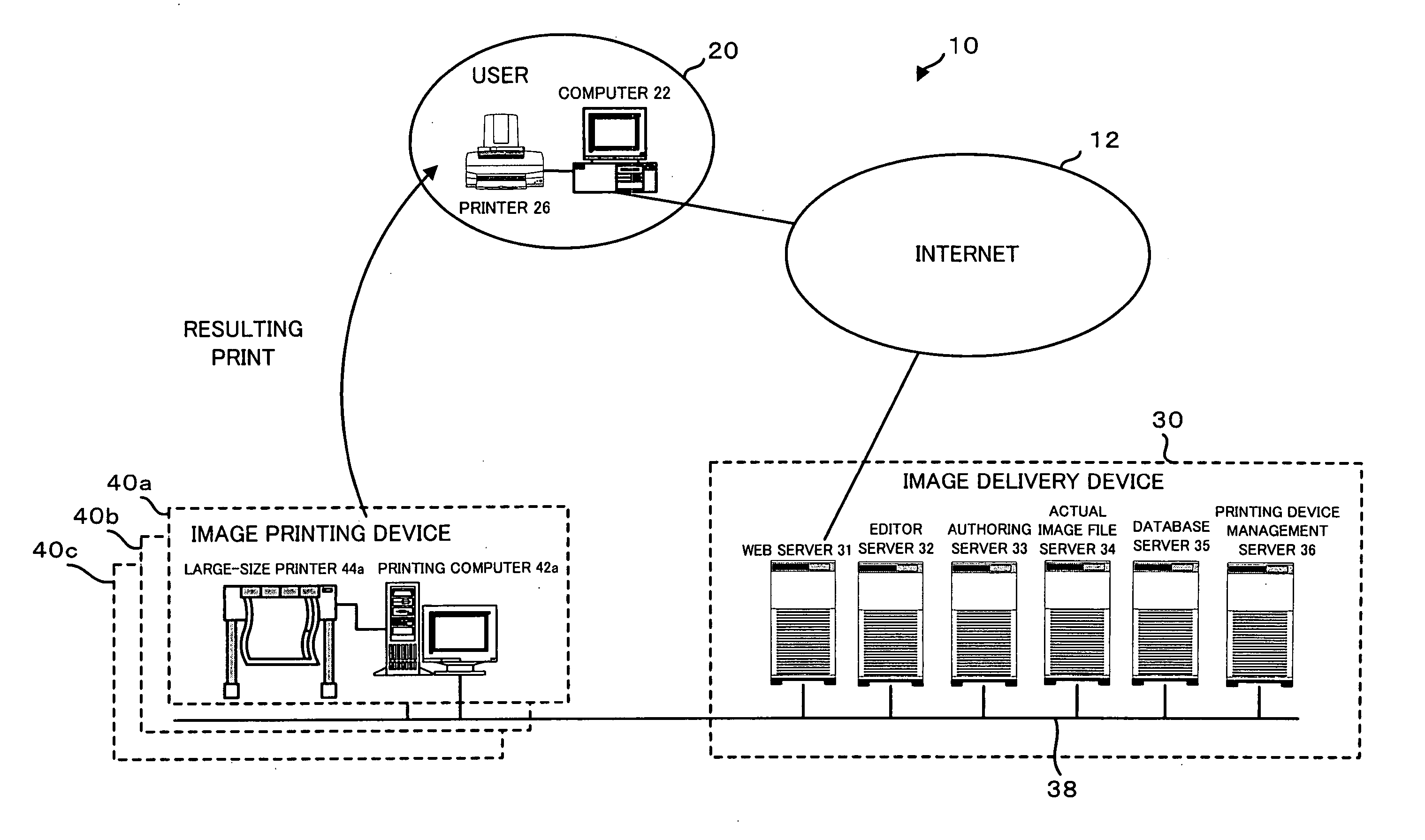

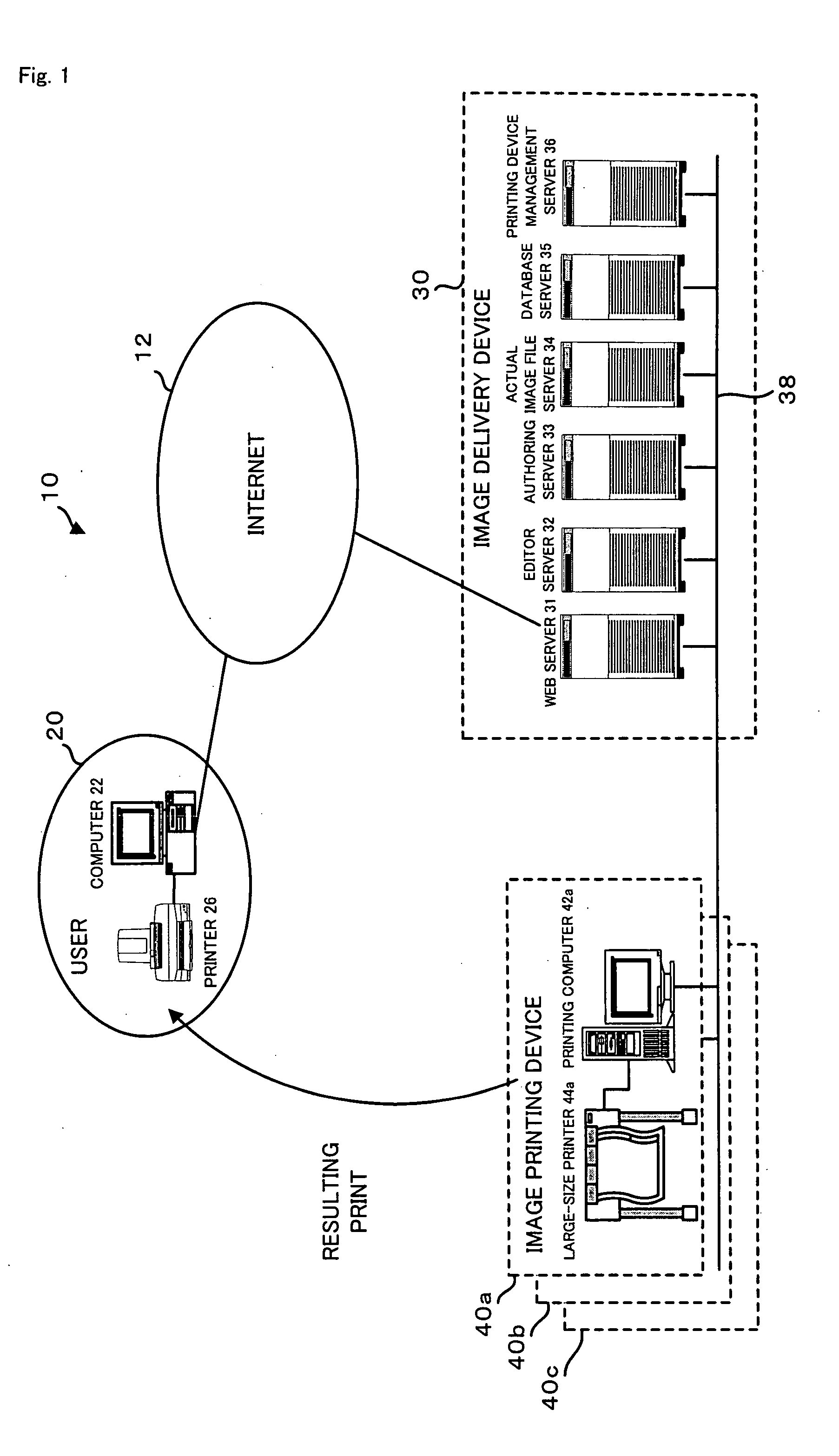

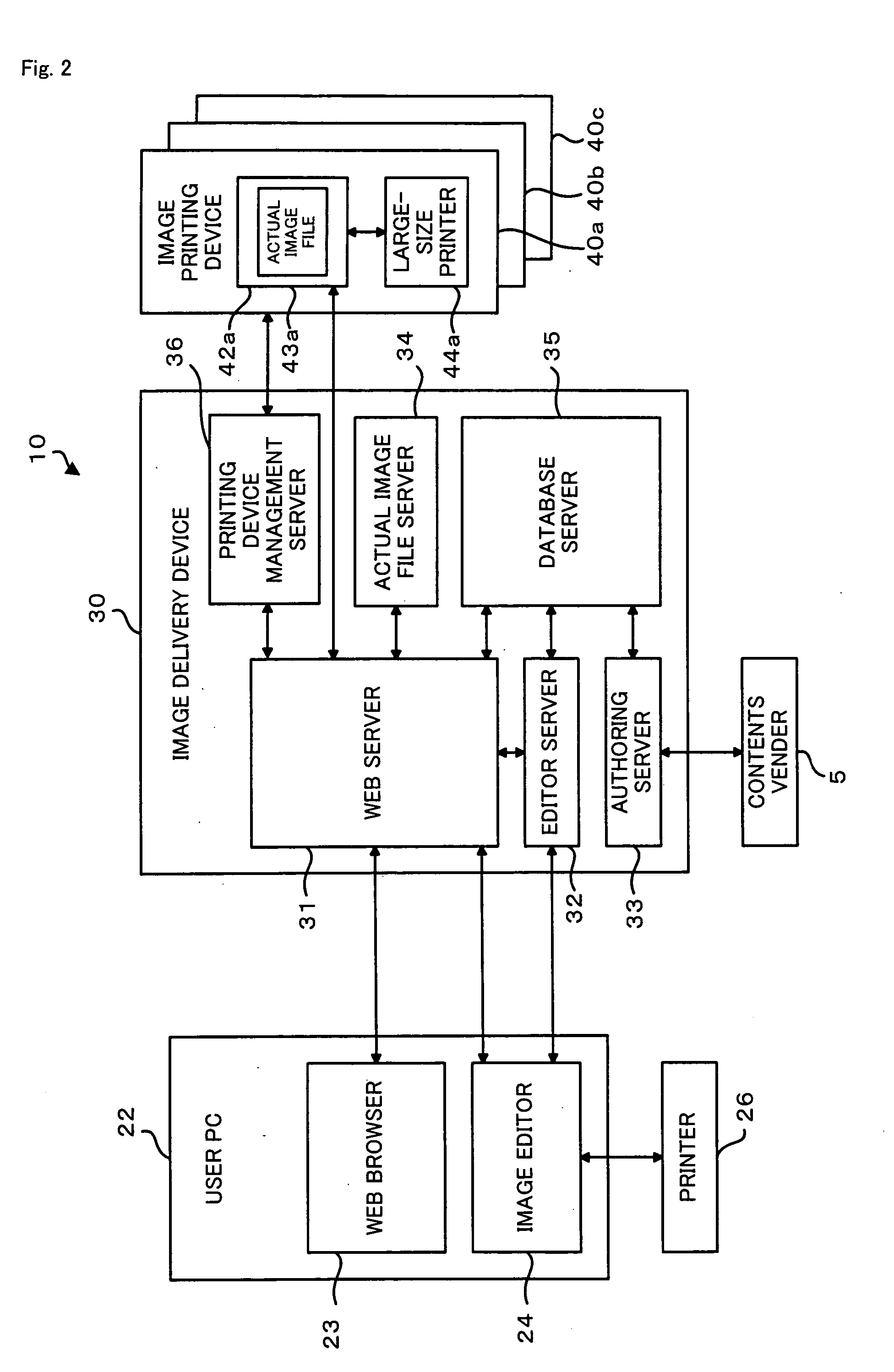

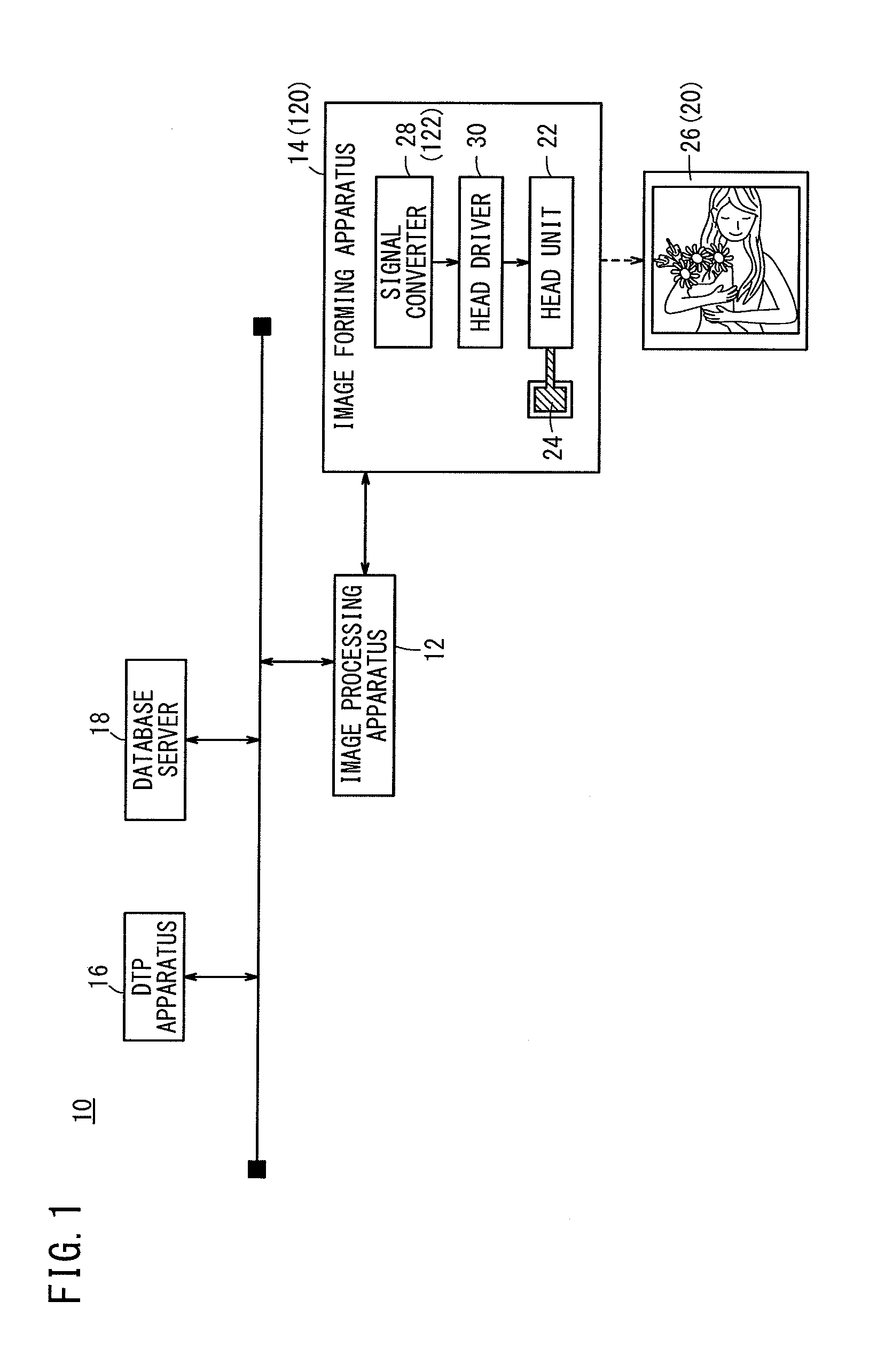

Image printing system and image delivery device and image printing device used therein

InactiveUS20050002058A1Improve reliabilityEasy and accurate determinationDigital computer detailsVisual presentationWeb browserComputer graphics (images)

When the user gives a printing instruction of an image delivered in response to the user's selection and edited, the image printing system of the invention retrieves available printers for printing the image, based on the ink type suitable for printing the image and an input paper size, and displays a list of the retrieved available printers on the user's Web browser. In response to the user's selection of a desired printer out of the list, the image printing system inputs a captured image, which is obtained by capturing the edited image, as a check image and the user's settings of editing parameters via the Internet and sends the check image and the user's settings of the editing parameters to a computer in a printing center where the selected printer is located. The computer displays a resized edited image and the check image in a comparable manner to confirm their consistency, prior to printing the edited image.

Owner:SEIKO EPSON CORP

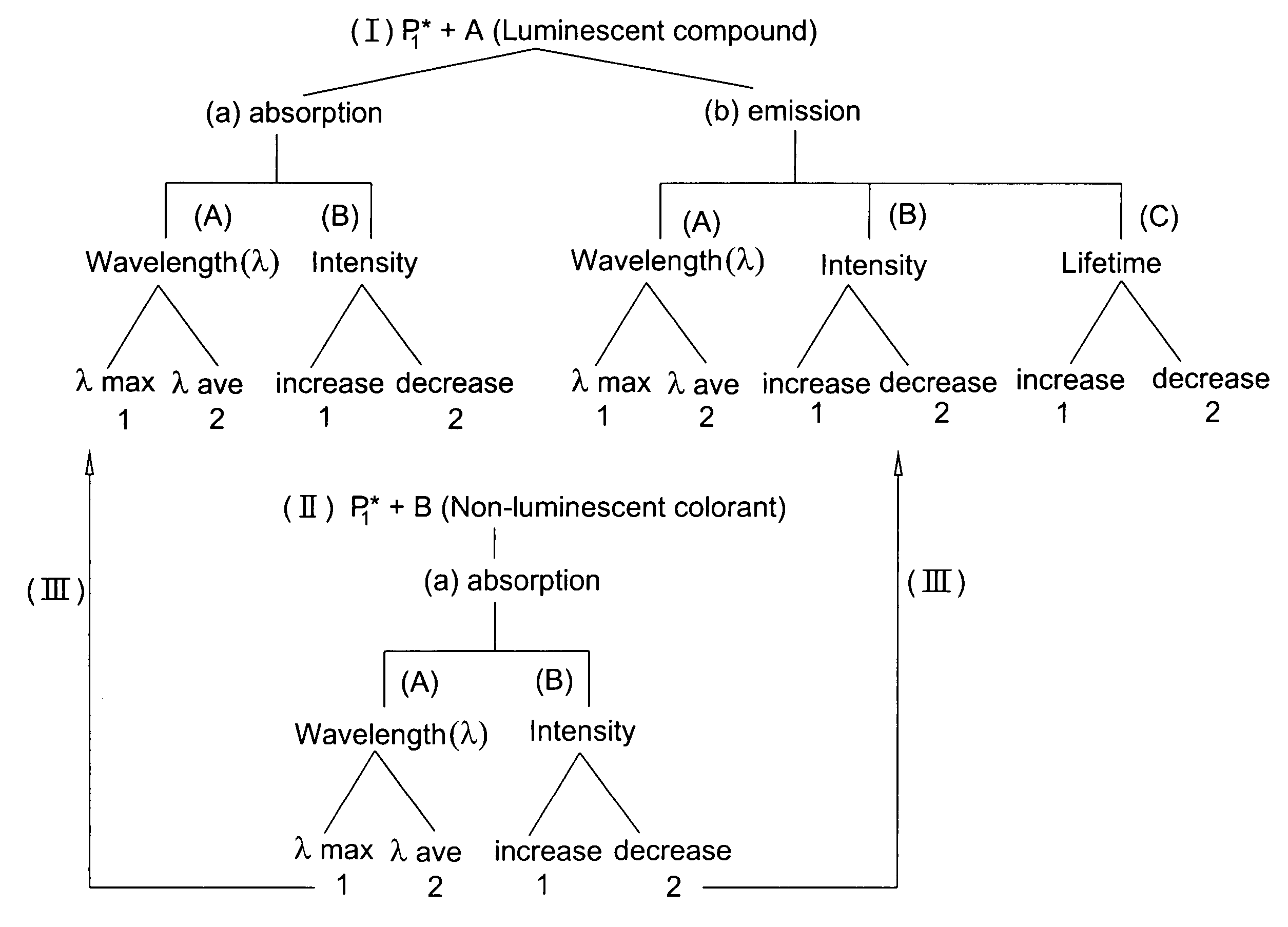

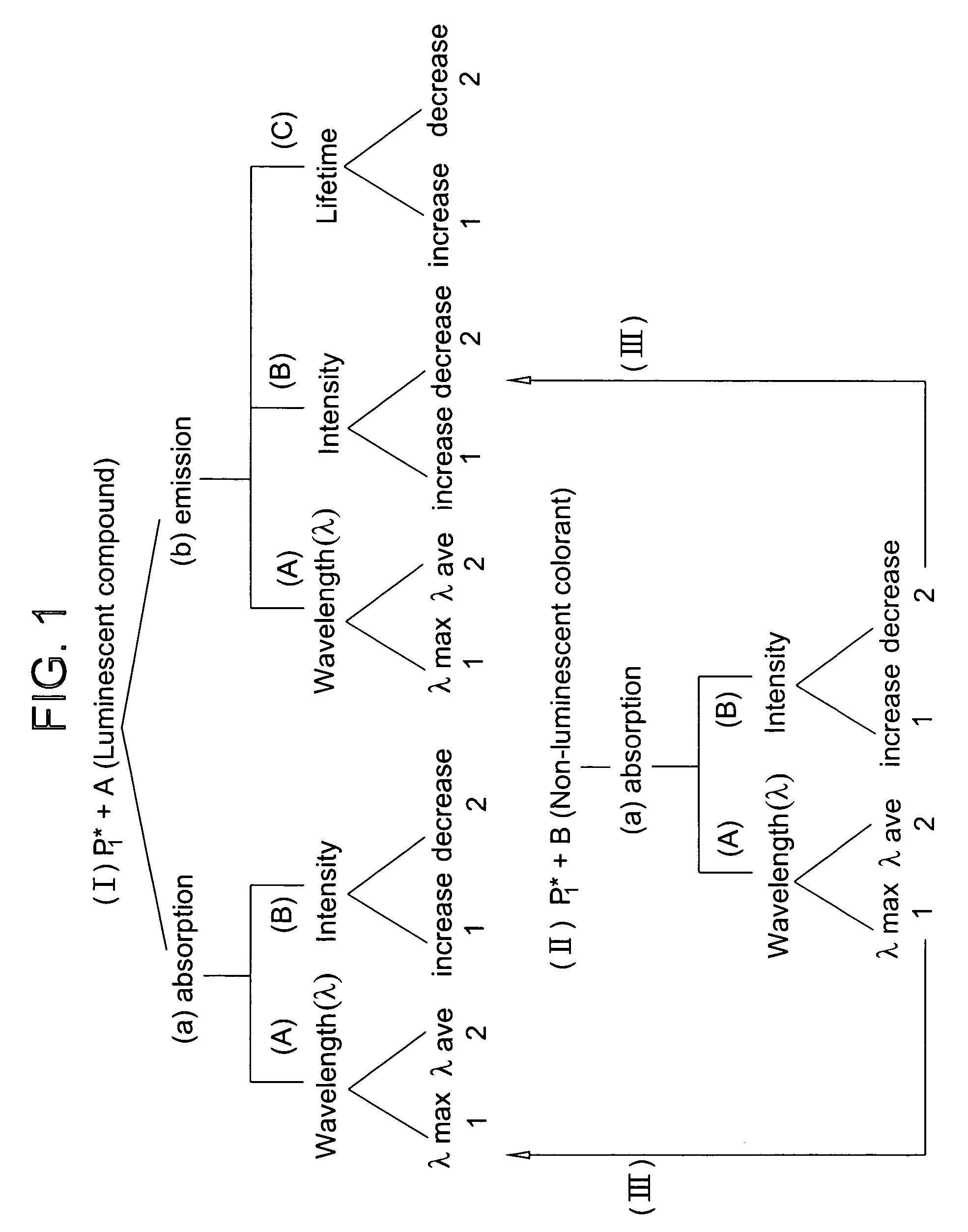

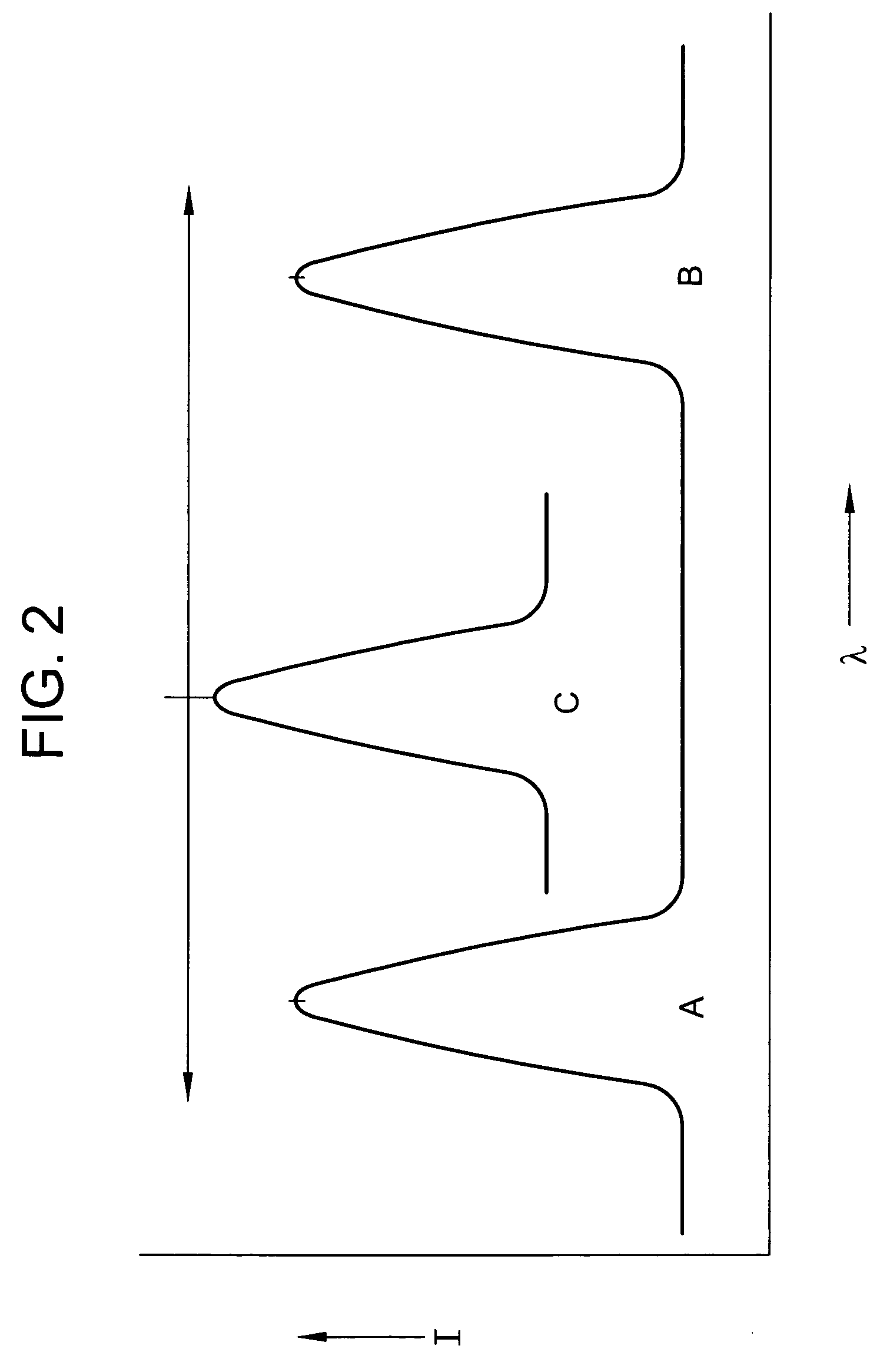

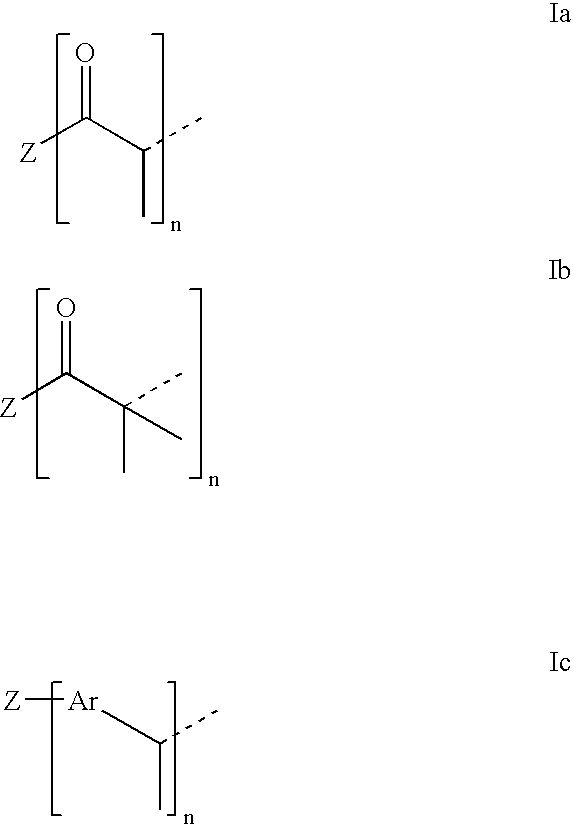

Ink jet ink composition and method for security marking

ActiveUS7147801B2Suitable for printingLuminescence quenchingNon-fibrous pulp additionLayered productsSolventLuminescence

Disclosed is an ink composition suitable for ink jet printing comprising a luminescent compound, a solvent, and an energy active compound, and optionally a non-luminescent colorant. The energy active compound, when exposed to energy, generates one or more active species that can react with the luminescent compound to alter one or more of the characteristics of the luminescent compound. The luminescent compound can be colored or colorless. Also disclosed is a method for marking substrates comprising providing a mark comprising a luminescent compound and an energy active compound. Further disclosed is a jet ink composition suitable for printing on substrates authentication or security marks which can be rendered unreadable. The luminescence of the mark is quenched and the visible color is changed when irradiated with a light.

Owner:VIDEOJET TECH INC

Multilayer acrylic film with improved optical and mechanical properties

InactiveUS20060008642A1Sufficient flexibilityHigh elongationSynthetic resin layered productsGlass/slag layered productsPolymer scienceEmulsion

A multiplayer acrylic film is presented having: a layer (A) made from a thermoplastic acrylic composition a layer (B) made from either a composition comprising a methacrylic (co)polymer and an impact modifying compound, or a composition prepared by sequential polymerization in aqueous emulsion of acrylate-based monomer systems, or a composition comprising a block copolymer, and a layer (C) made from a thermoplastic acrylic composition. The film is useful for coating a substrate (thermoplastic resin, thermosetting resin, etc.).

Owner:ARKEMA FRANCE SA

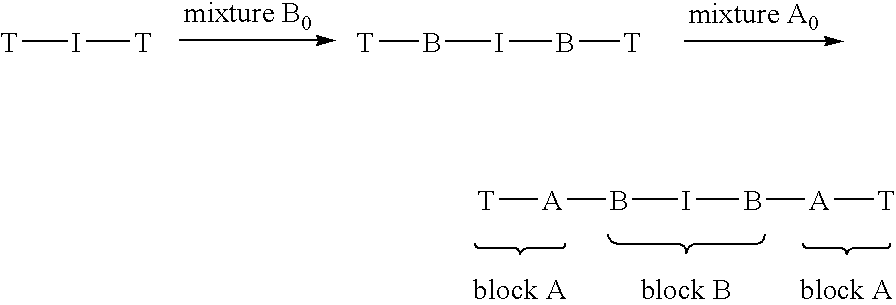

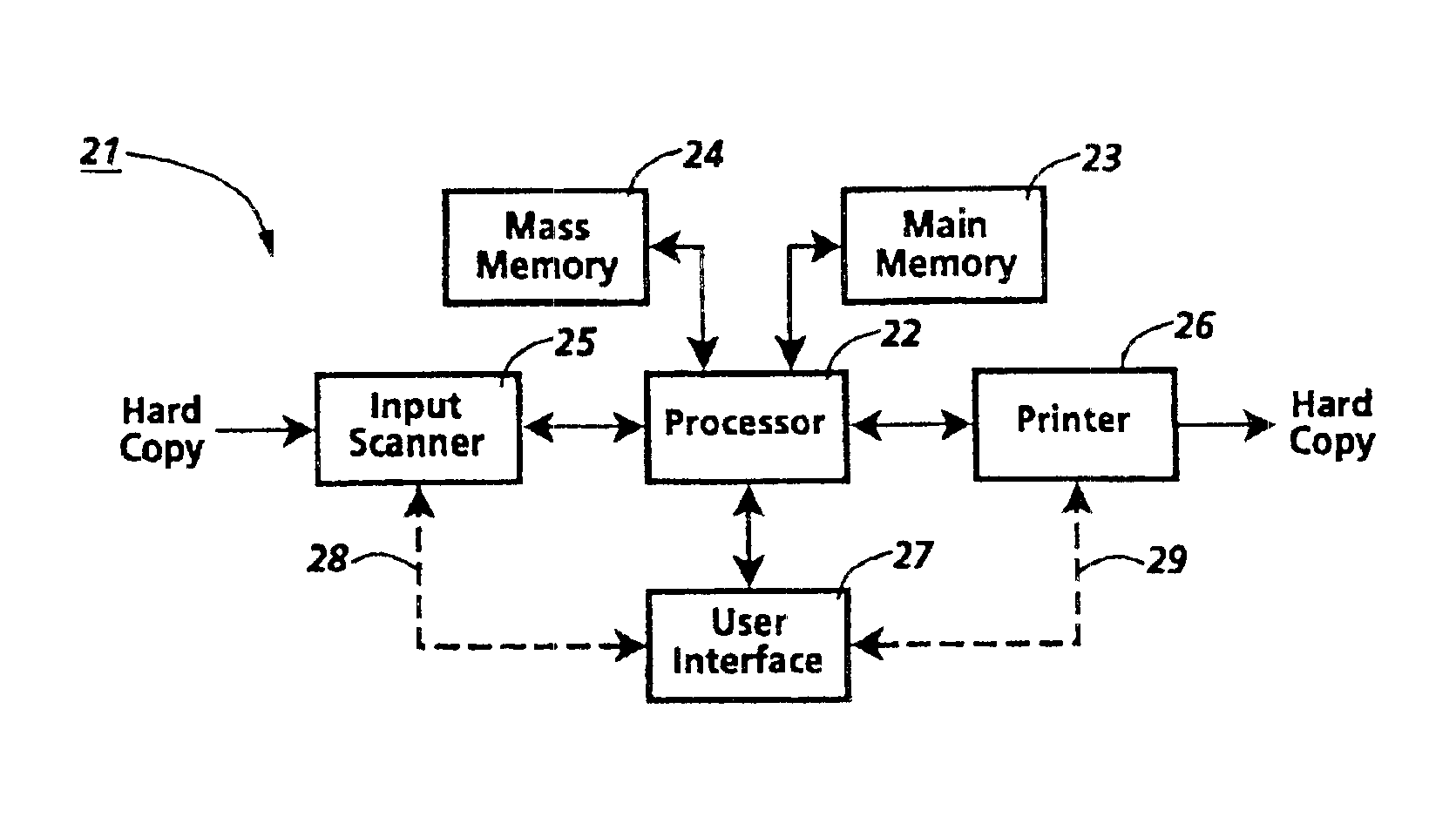

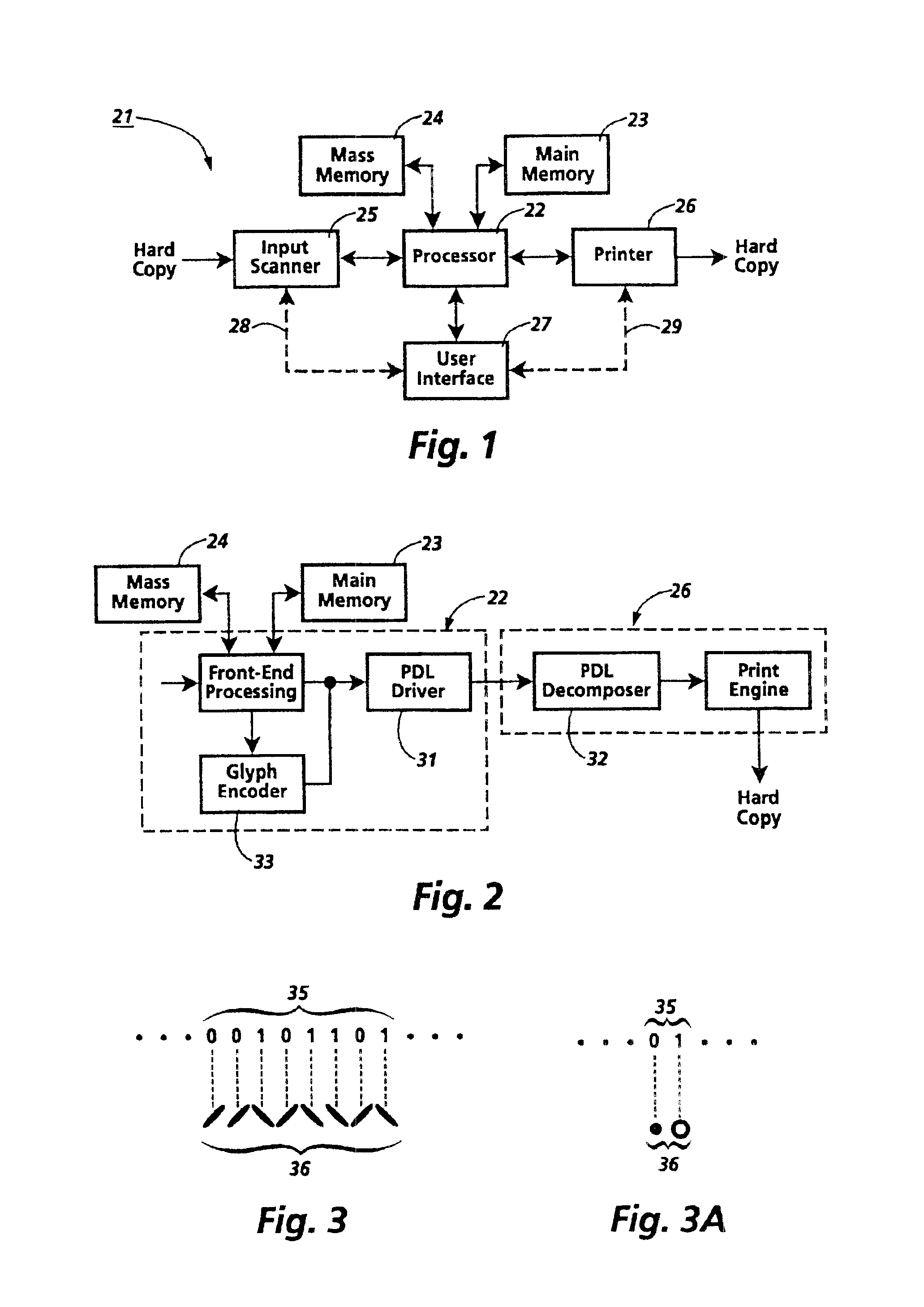

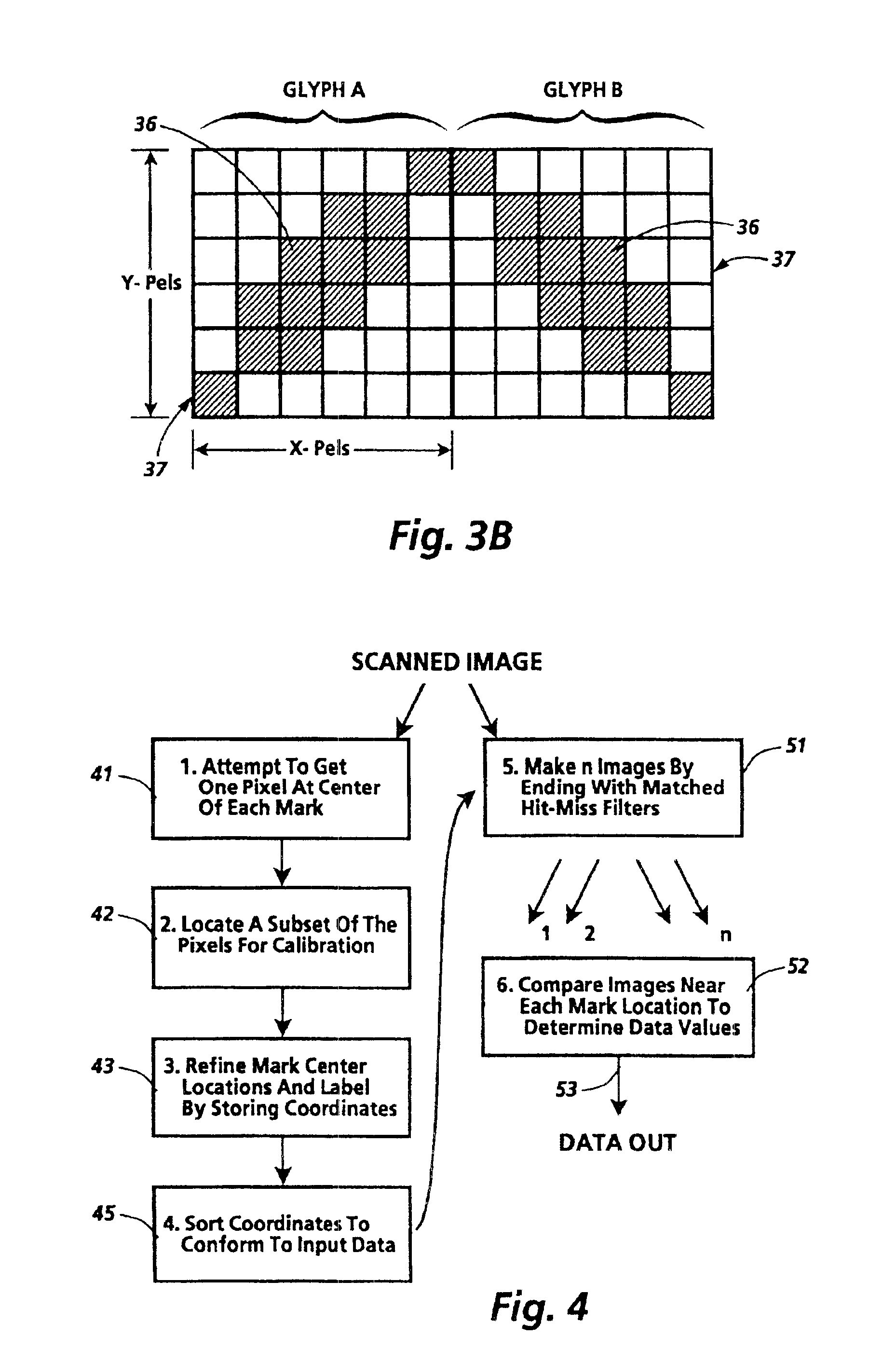

Self-clocking glyph shape codes

InactiveUSRE38758E1Uniform textureSuitable for printingSensing detailsCharacter and pattern recognitionDigital dataElectronic document

Owner:XEROX CORP

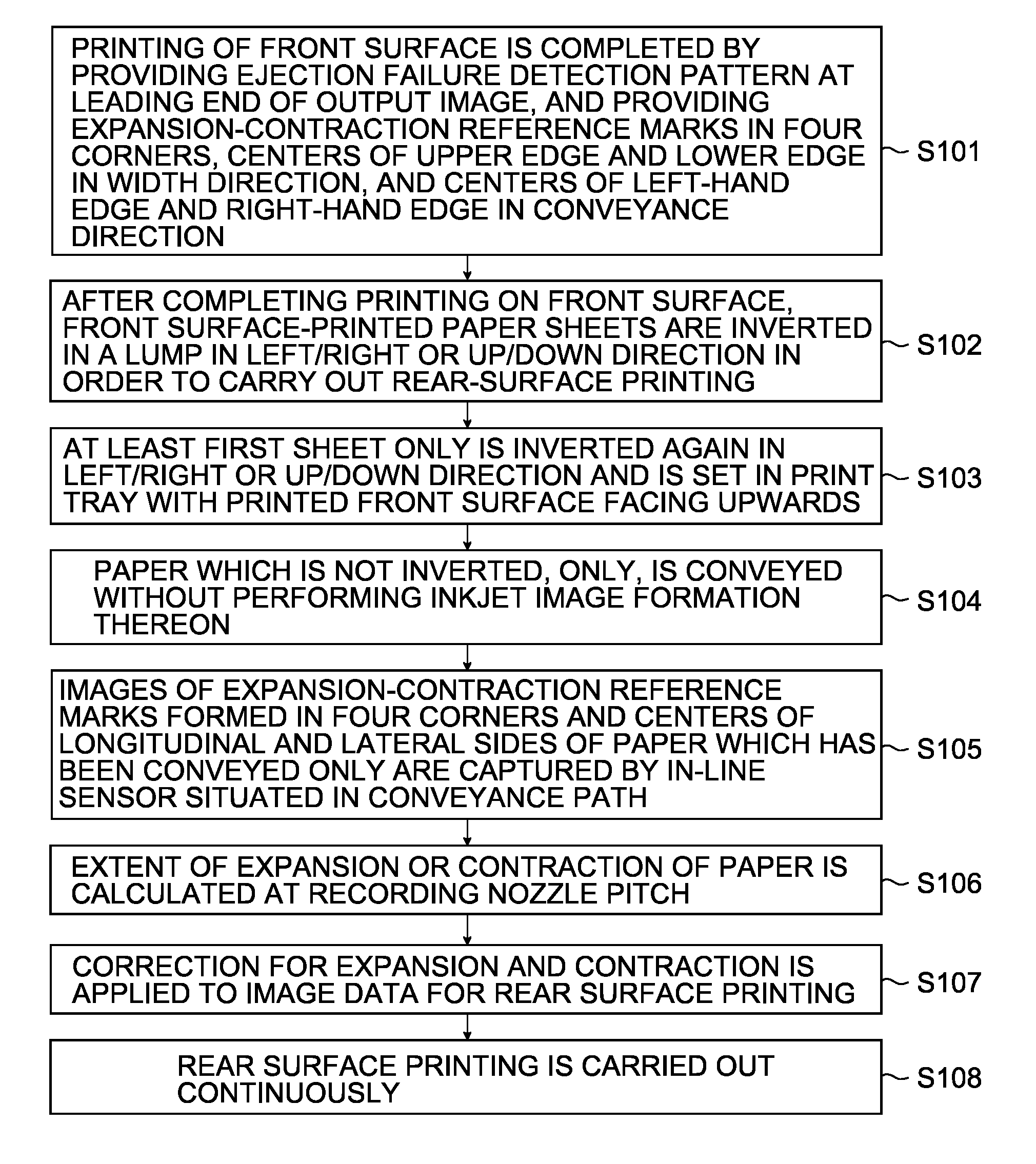

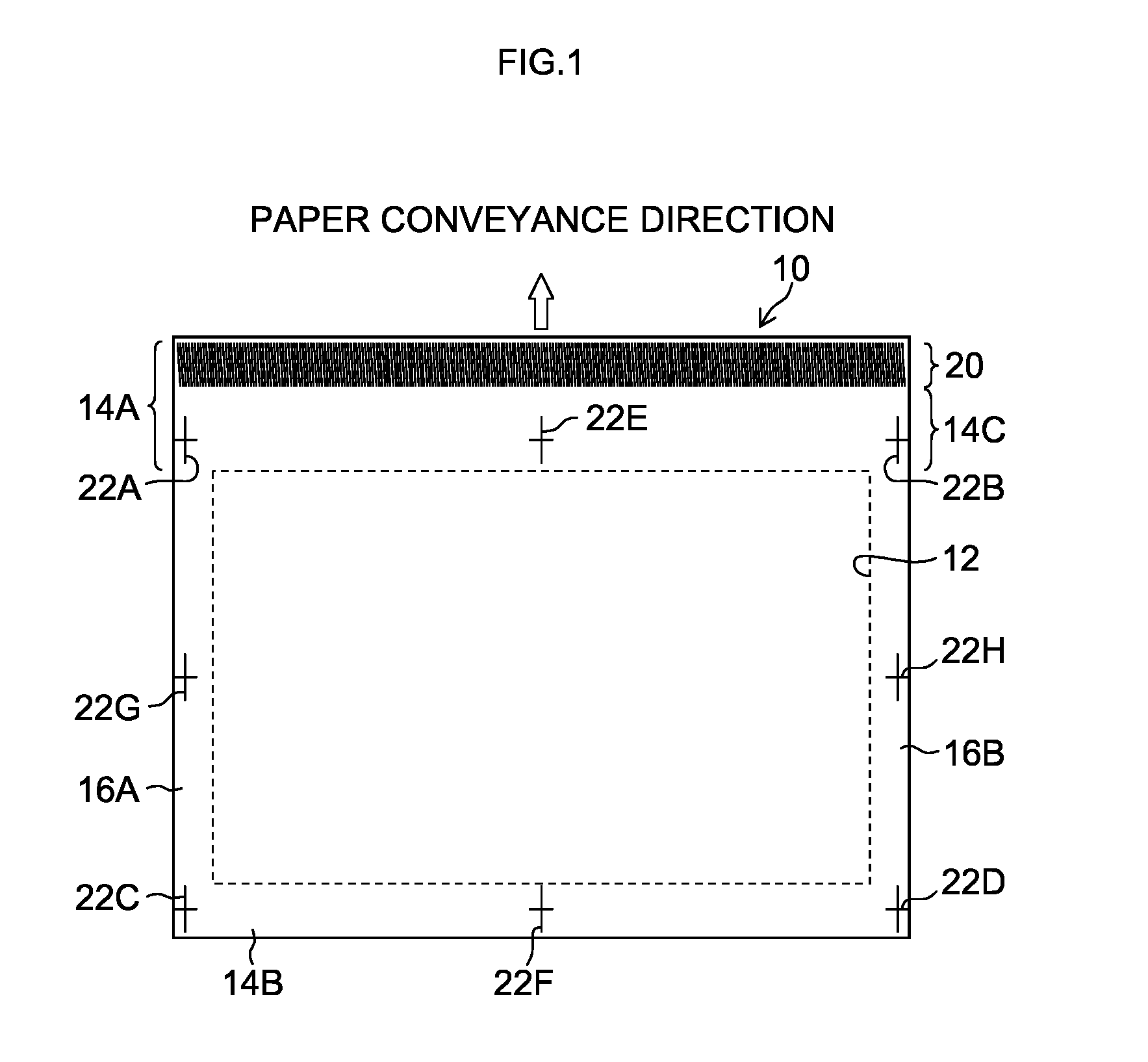

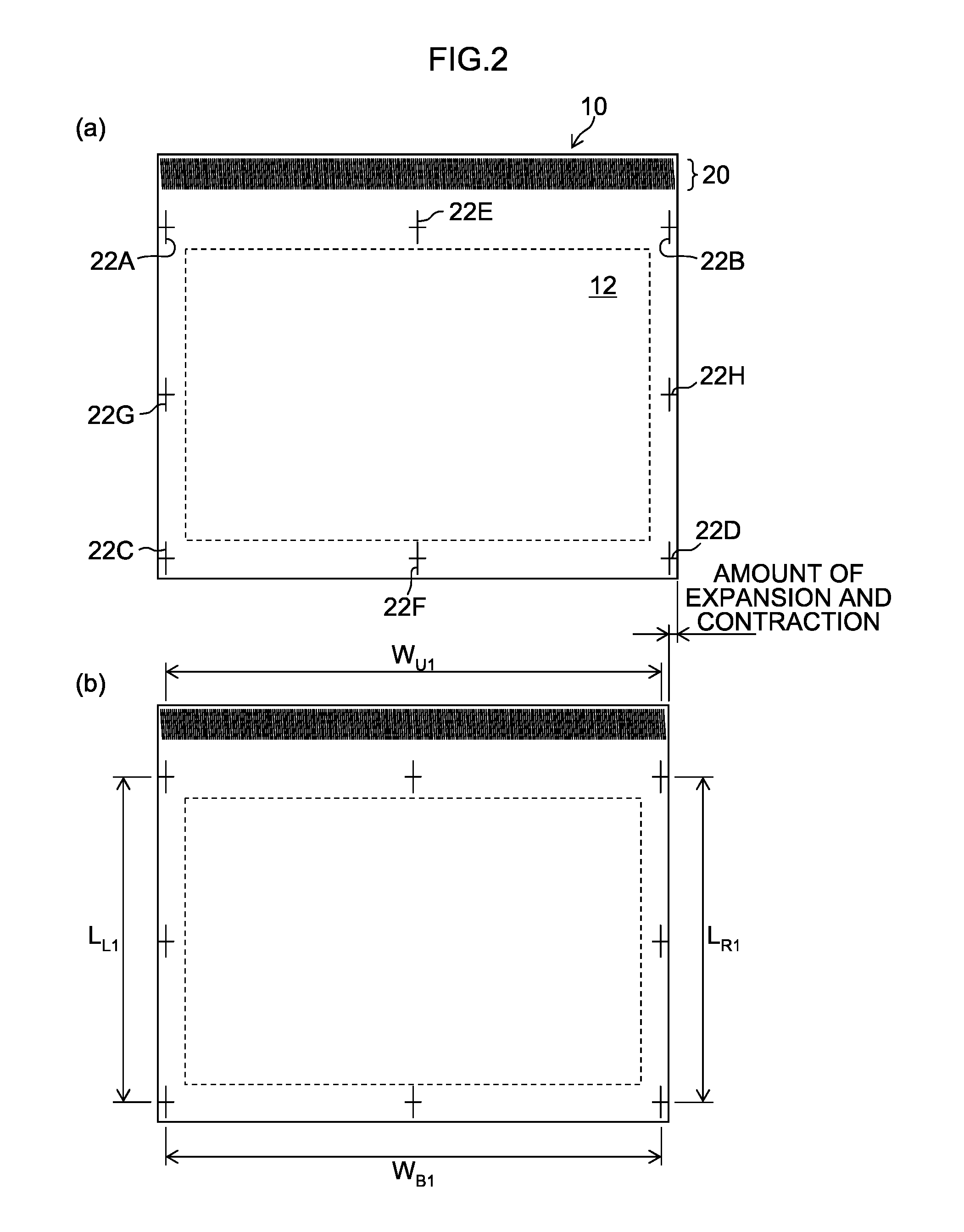

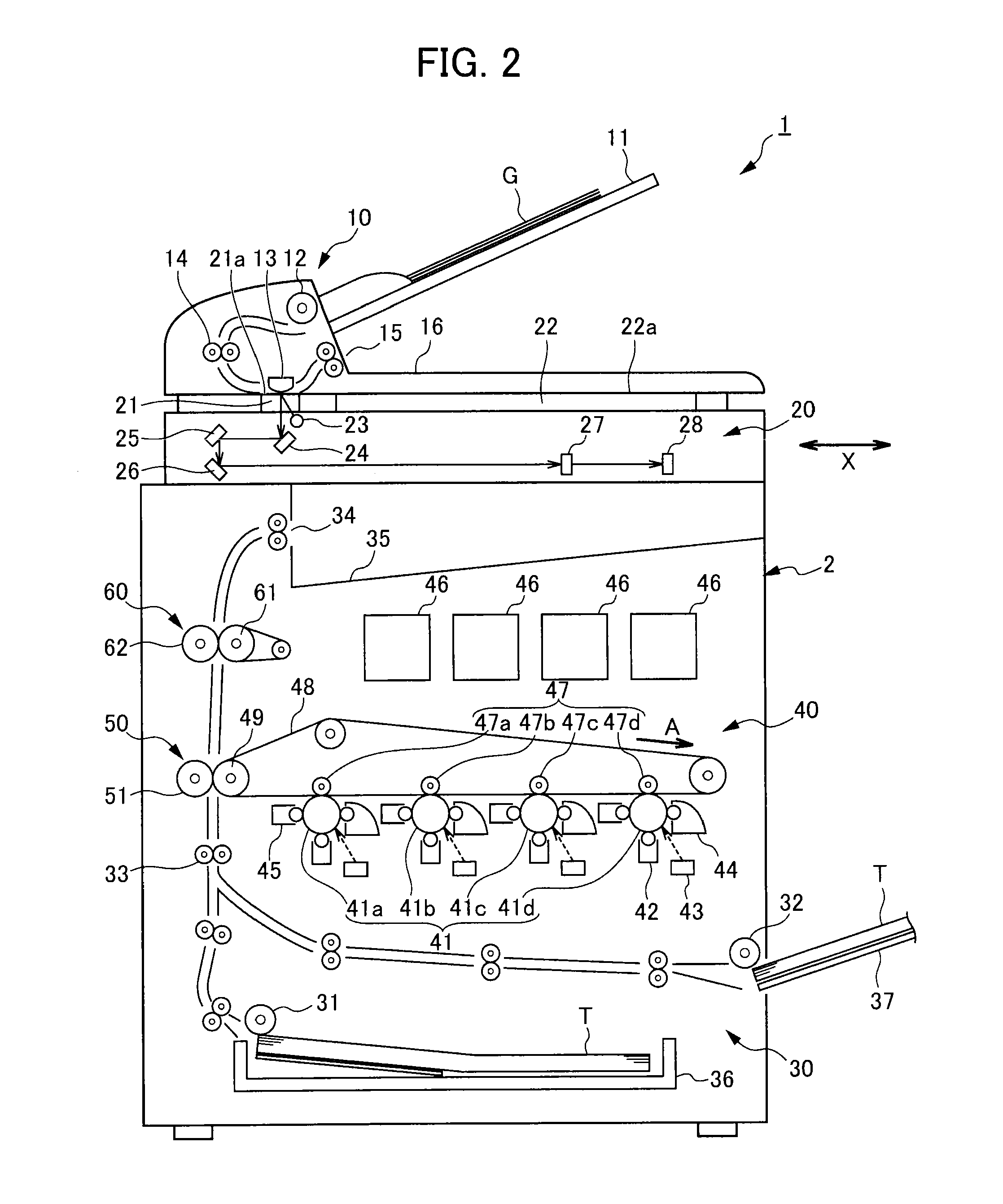

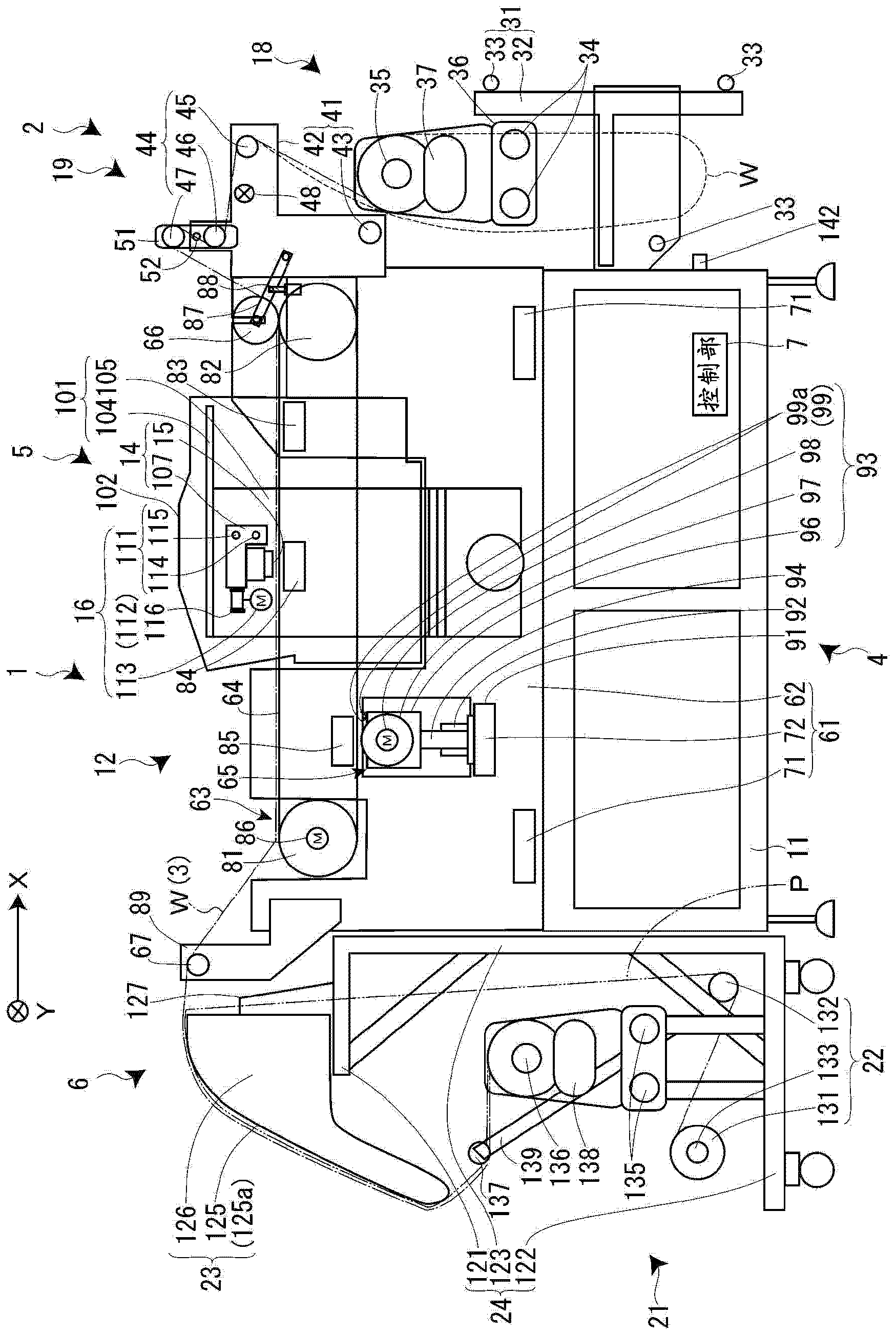

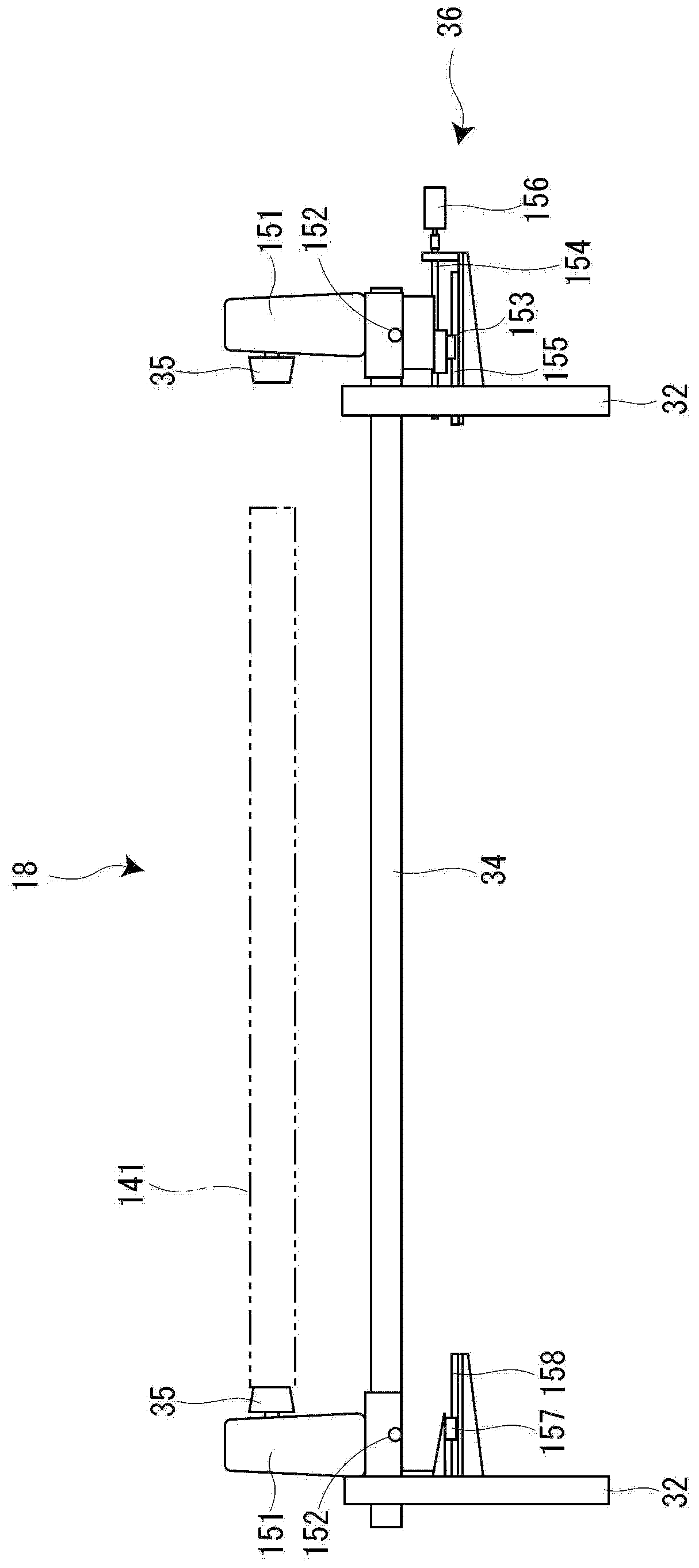

Inkjet printing apparatus and printing method of inkjet printing apparatus

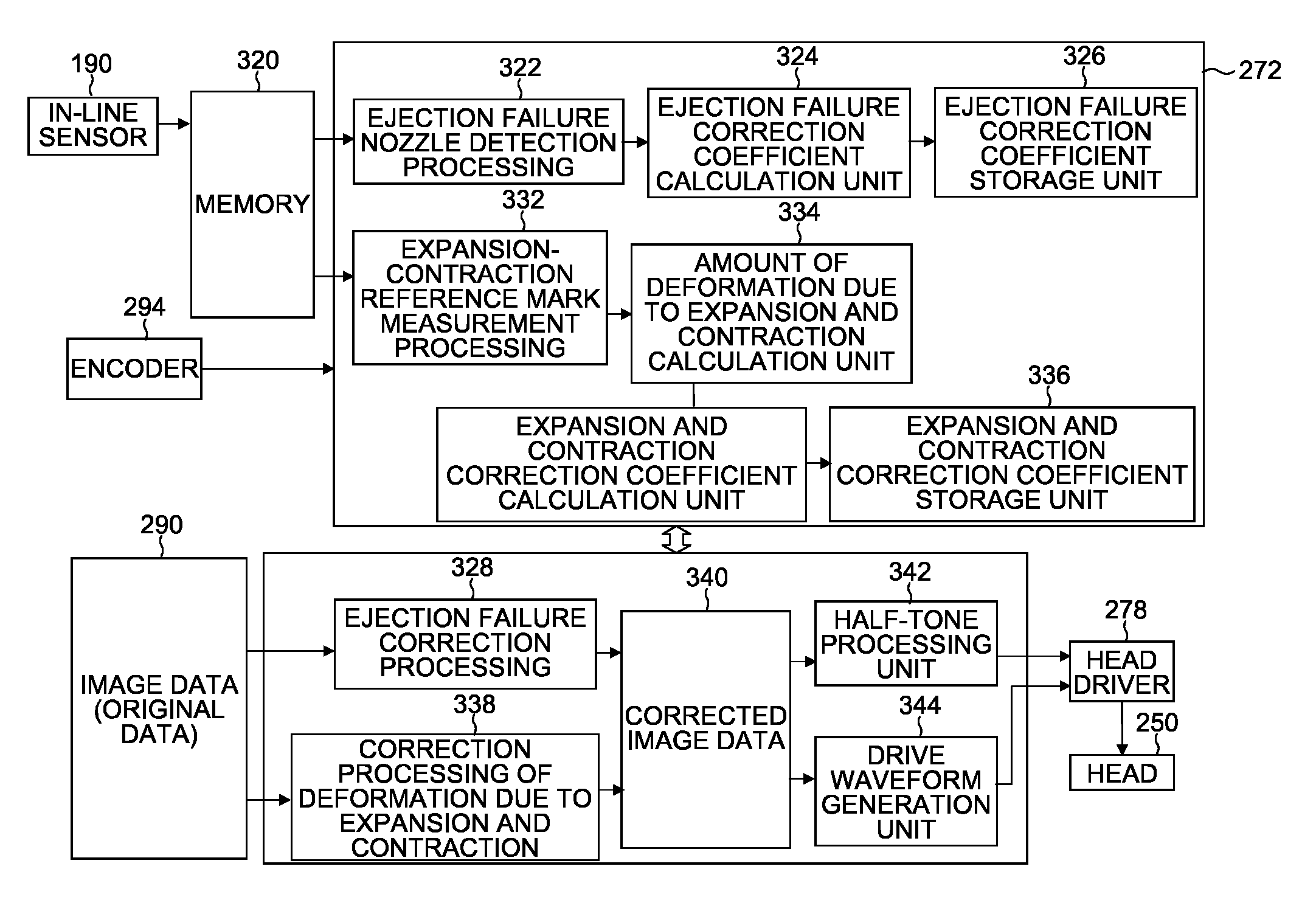

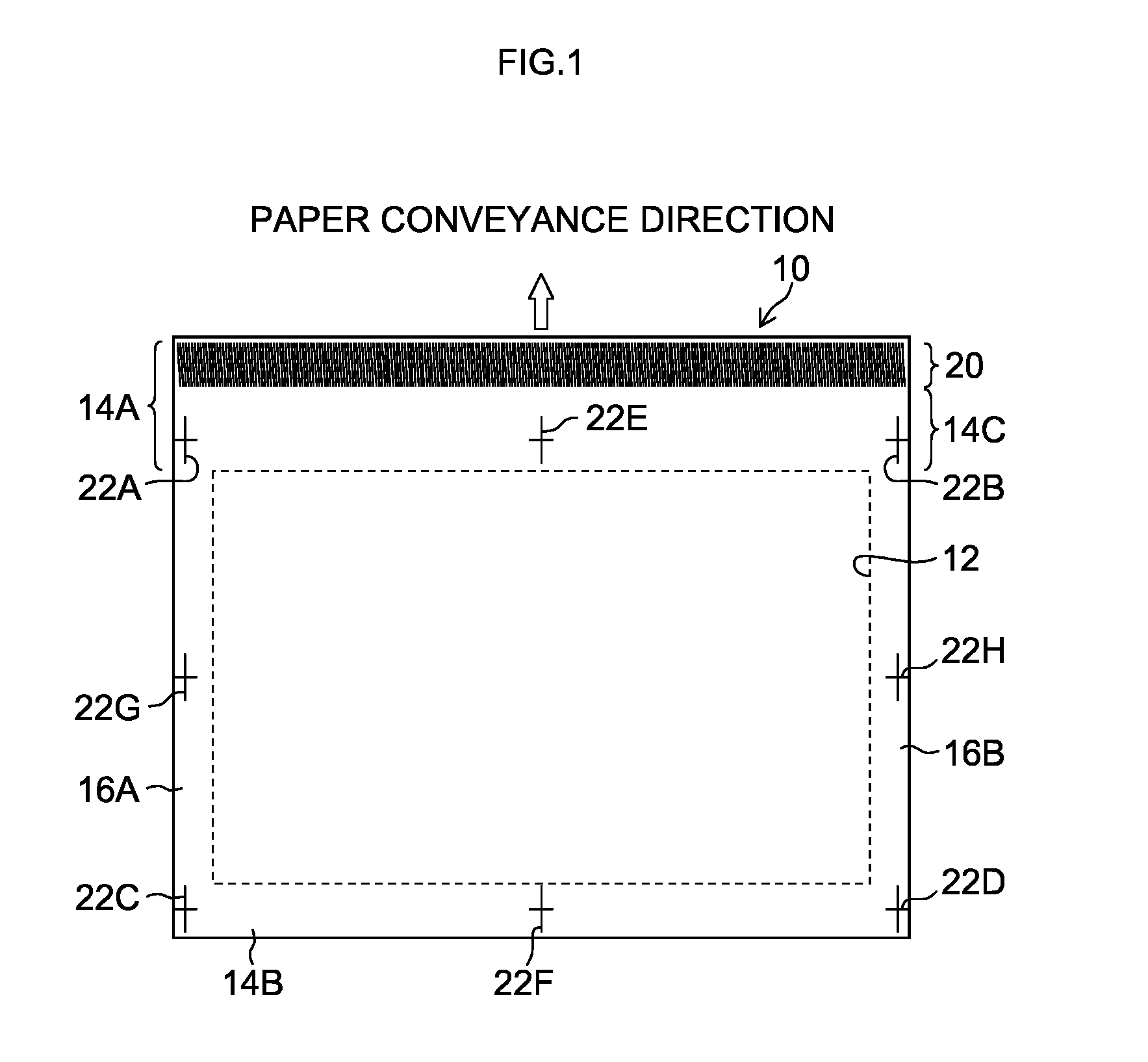

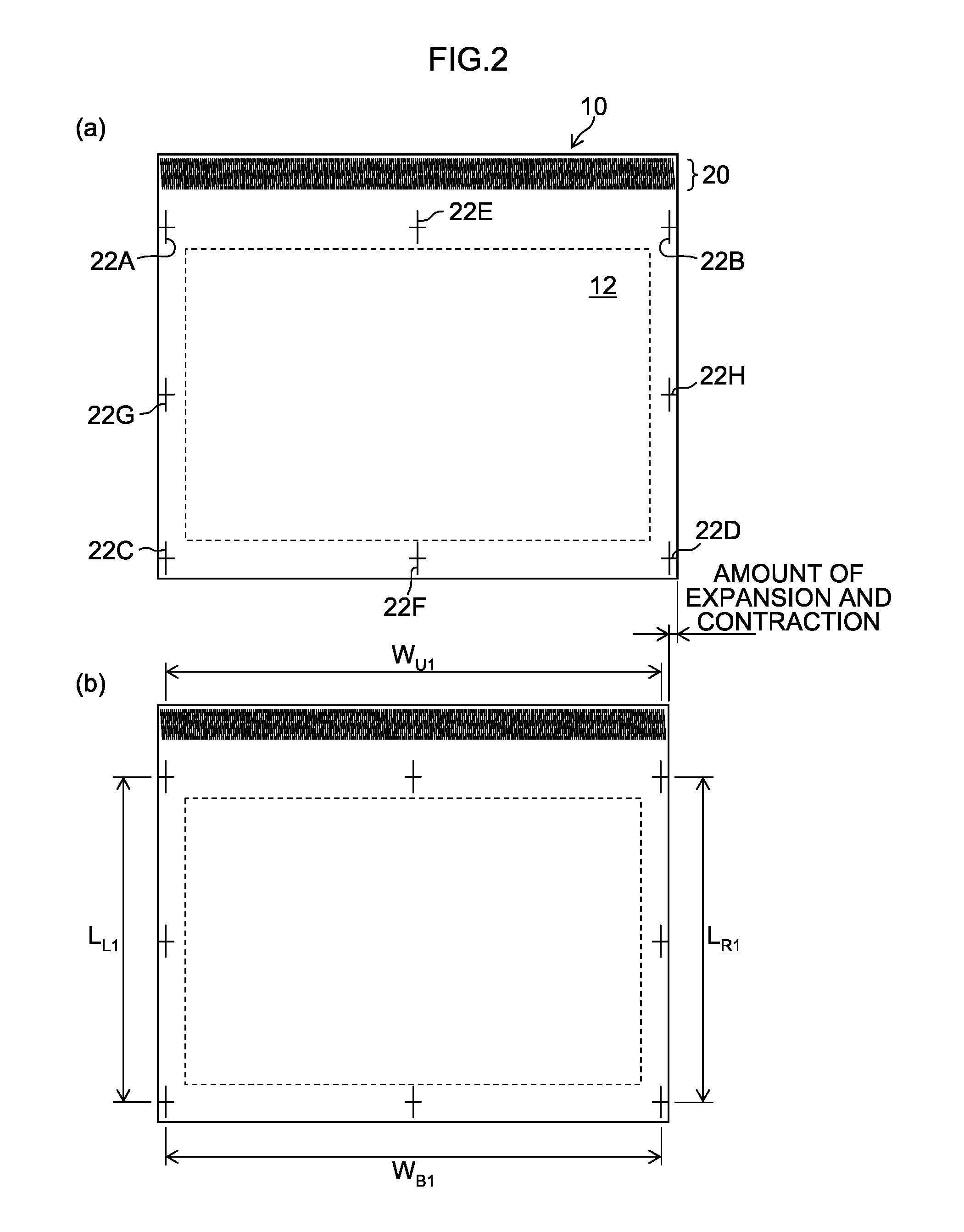

InactiveUS20110316925A1Improve position deviationExceeding resolution of imagingTypewritersOther printing apparatusMeasurement deviceImage formation

An inkjet printing apparatus includes: an inkjet head having nozzles which eject ink; a first conveyance device which moves at least one of an image formation medium and the inkjet head during image formation by the inkjet head; a second conveyance device which conveys the image formation medium along a conveyance path after the image formation by the inkjet head; an imaging device; a test pattern printing control device which controls ejection of the inkjet head; an ejection failure nozzle detection processing device; an expansion-contraction reference mark printing control device; an expansion-contraction deformation amount measurement device; an image deformation processing device which applies image deformation processing corresponding to the amount of deformation due to expansion and contraction, to image data to be printed on the second surface,; and a print control device which carries out the printing on the second surface on a basis of the image data which has been corrected through the image deformation processing.

Owner:FUJIFILM CORP

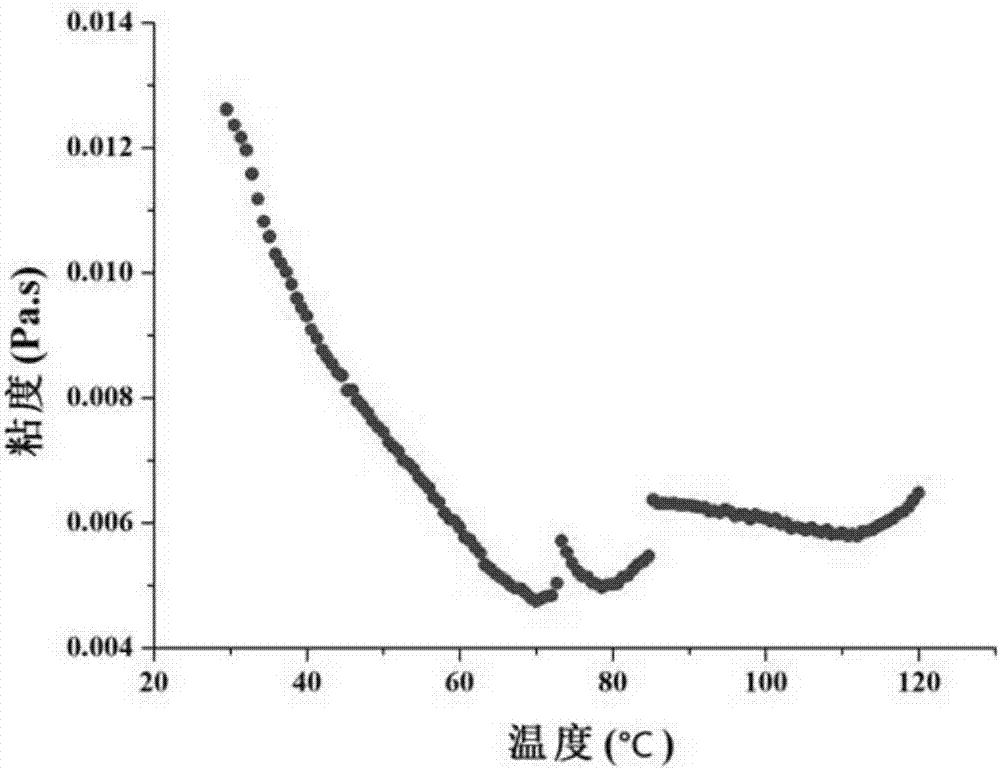

Ink for inkjet printing and preparation method as well as zirconia film printed by ink for inkjet printing

ActiveCN107151483AImprove flatnessImprove surface topographyInksPrintingPolymer scienceCoffee ring effect

The invention discloses an ink for inkjet printing and a preparation method as well as a zirconia film printed by the ink for the inkjet printing. The preparation method for the ink for the inkjet printing comprises the steps: (1) dissolving zirconium oxychloride in a mixed solvent to obtain a mixed solution, wherein the mixed solvent is prepared from ethylene glycol monomethyl ether and ethylene glycol in a volume ratio of (0.5 to 2) to (2 to 1)1; (2) adding PVP to the mixed solution obtained in the step (1), dissolving and standing to aging, and obtaining the ink for the inkjet printing. According to the ink for inkjet printing and the preparation method as well as the zirconia film printed by the ink for the inkjet printing, the polymer PVP is introduced in the process of preparing the ink for the inkjet printing, the viscosity and the dispersion of the solution are adjusted by due to the existence of the polymer, the system is more likely to generate gelatinization, and the flow of the liquid phase is restricted and the coffee-ring effect is weakened, so that the flatness of the surface of the zirconia film printed by the ink is improved.

Owner:SOUTH CHINA UNIV OF TECH

Multilayer acrylic film with improved optical and mechanical properties

InactiveUS20050233124A1Good scratch resistanceHigh transparencyGroup 5/15 element organic compoundsSynthetic resin layered productsMethyl methacrylateEmulsion

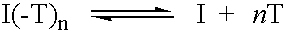

Multilayer acrylic film comprising: a layer (A) made from a thermoplastic acrylic composition comprising from 75 to 95% of a metliacrylic (co)polymer containing mostly methyl methacrylate units and from 5 to 25% of an impact modifier a layer (B) made from either a composition comprising a methacrylic (co)polymer and an impact modifying compound, or a composition prepared by sequential polymerization in aqueous emulsion of acrylate-based monomer systems, or a composition comprising, a block copolymer, and a layer (C) made from a thermoplastic acrylic composition comprising from 75 to 95% of a methacrylic (co)polymer containing mostly methyl methacrylate units and from 5 to 25% of an impact modifier. Use of the film for coating a substrate (thermoplastic resin, thermosetting resin, etc.).

Owner:ARKEMA FRANCE SA

Watersoluble silk screen printing ink and method of producing the same

The invention discloses water-based silk screen ink and a preparation method thereof. The water-based silk screen ink comprises 70 to 75 percent of water-based polyurethane latex, 15 to 20 percent of pigment, 0.8 to 1.5 percent of antifoaming agent, 1.0 to 1.5 percent of dispersant, 0.5 to 1.0 percent of wetting agent, and 1.0 percent of thickening agent. The antifoaming agent is a mixture of polysiloxane or non-silicone amide and hydrocarbon, the dispersant is polyacrylic acid ammonium salt or polyacrylic acid sodium salt, the wetting agent is nonionic surfactant, the thickening agent is alkali-swelling acrylic ester copolymer, and the pigment is pearlied gold or silver paste. The preparation method comprises the following steps: A, firstly filtering the water-based polyurethane latex; B, adding the pigment, the antifoaming agent, the dispersant, the wetting agent and the thickening agent into the filtered water-based polyurethane latex; and C, fully stirring the mixture to obtain the ink. The water-based silk screen ink has the advantages of high temperature resistance, high adhesive strength and high card peeling strength, and is particularly suitable for printing card products.

Owner:天津渤海化学股份有限公司

Acrylic acid coating film and its manufacturing method

ActiveCN1686712AGood low temperature heat sealabilityHigh heat sealing strengthLayered productsEmulsionSoftened water

An acrylic acid coated film is composed of a substrate layer, a coated acrylic paint layer and a sandwich layer between the first two layers. Its preparing process includes such steps as preparing acrylic paint from acrylic emulsion, softened water, smoothing agent and detackifier, coating it on the substrate and baking.

Owner:HAINAN SHINER IND

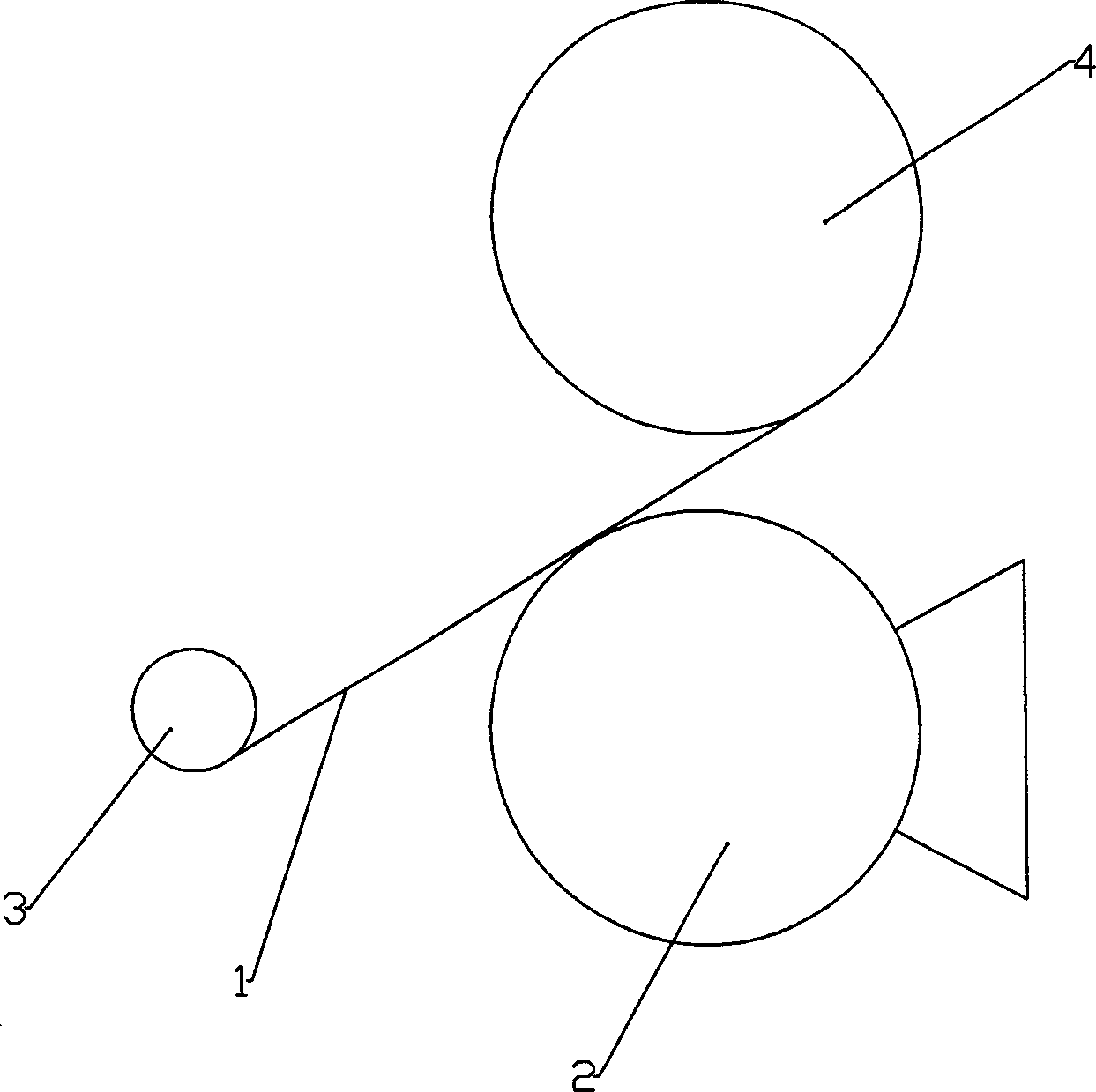

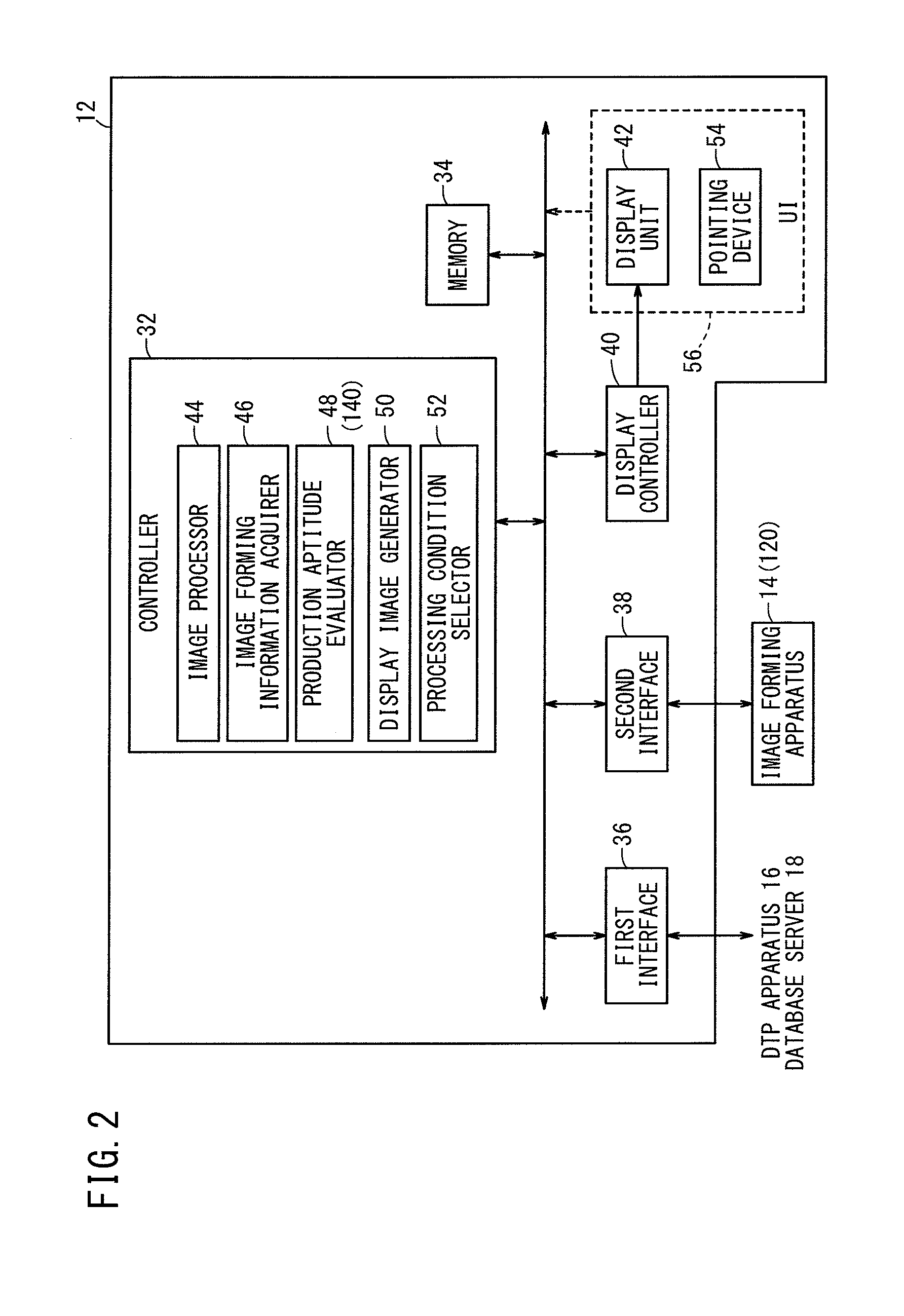

Processing condition selecting apparatus, processing condition selecting method, and storage medium

InactiveUS20120257256A1Easy to masterSuitable for printingVisual presentation using printersInput/output processes for data processingComputer graphics (images)Image formation

A processing condition selecting apparatus, a processing condition selecting method, and a storage medium storing a program therein serve to evaluate the production aptitude of a print under a signal processing condition, based on image forming information with respect to the print and prescribed evaluation criteria, to thereby generate a display image visually representing the production aptitude of the print that has been evaluated.

Owner:FUJIFILM CORP

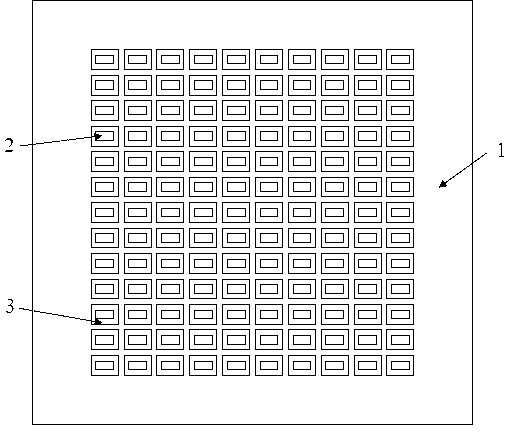

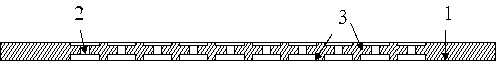

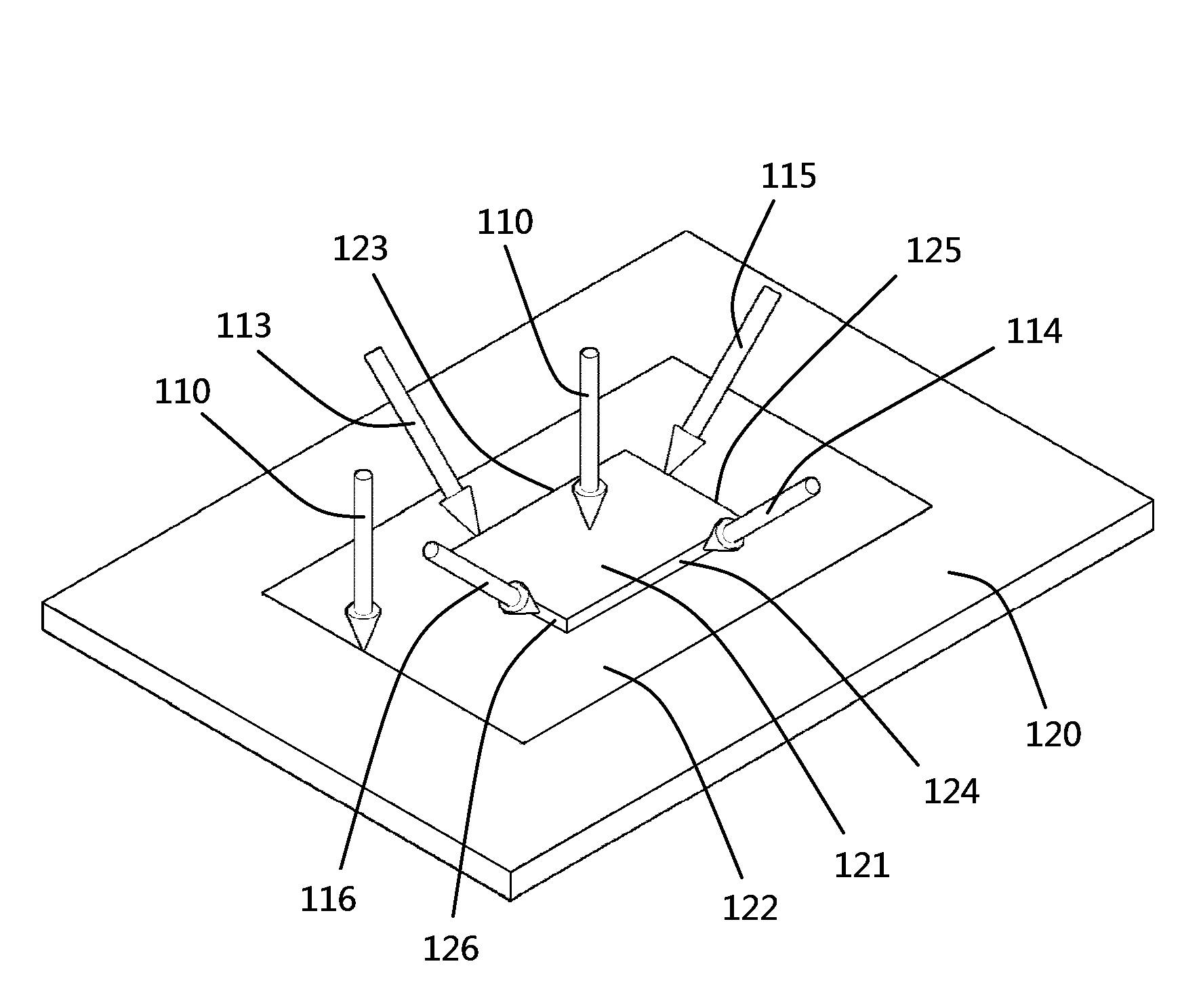

Printing method of side face of ceramic substrate and printing device

ActiveCN102837516ASuitable for printingImprove alignment accuracyScreen printersOther printing apparatusElectrical conductorMetallurgy

The invention belongs to the technical field of a ceramic package. The invention relates to a printing method of a side face of a ceramic substrate and a printing device. A frock clamp with high position precision in the printing device is provided; the ceramic substrate is placed in the clamp; a conductor pulp is printed on the side face of the ceramic substrate, so that terminal electrodes on the side face of the ceramic substrate are connected to each other. By adopting the method, the productivity is largely improved from one substrate printed every time to more than one hundred of substrates printed every time; so that the speed of side printing a low temperature co-fired ceramic (LTCC) substrate is largely improved, and the method plays an important role in the post-printing technique production of the LTCC substrate.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Single-component waterborne glass ink and preparation method thereof

InactiveCN104194488AImprove high temperature resistanceGood weather resistanceInksWater basedGas phase

The invention provides single-component waterborne glass ink. The single-component waterborne glass ink comprises the following main raw materials in parts by weight: 25-55% of water-soluble acrylic resin, 1-15% of waterborne inorganic nano-silicate resin, 10-35% of waterborne amino resin, 0.3-1% of dispersant, 0.1-1.5% of waterborne organosilicone defoaming agent, 0.1-1% of leveling agent, 0.1-1% of fumed silica, 0-2% of silane coupling agent, 0.5-1.8% of polyethylene wax, 4-30% of water-based pigment and 3-15% of deionized water. Accordingly, the invention also provides a preparation method of the single-component waterborne glass ink. By adopting the preparation method disclosed by the invention, the hardness, high-temperature resistance, solvent resistance, weather resistance and boiling resistance of the glass ink can be greatly improved so as to meet the requirements of the ink for the glass panel of a mobile phone.

Owner:南昌来捷尔新材料技术有限公司

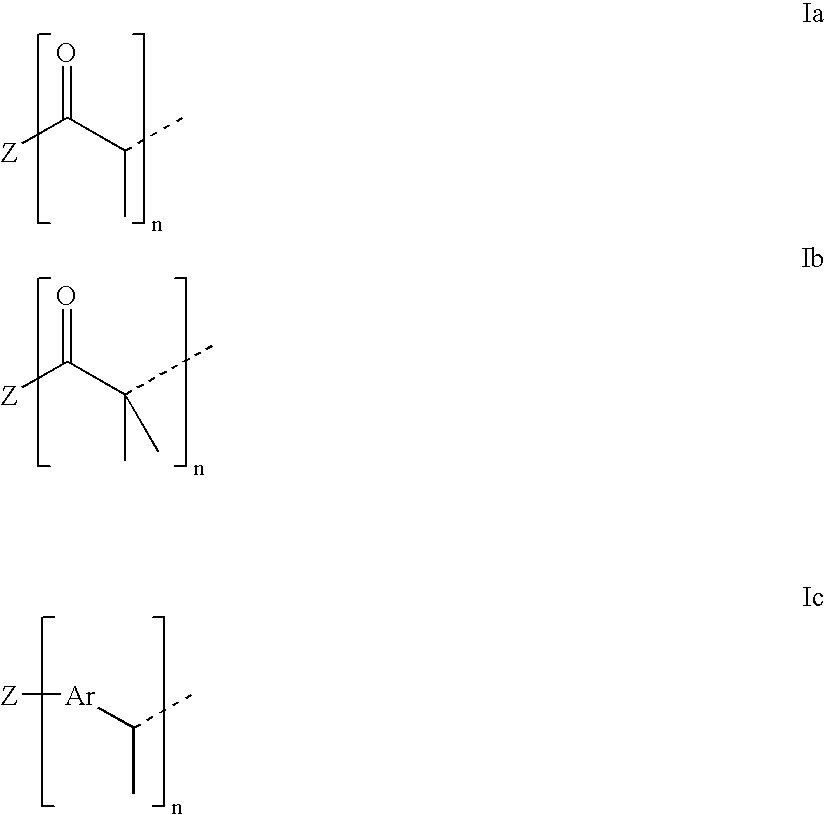

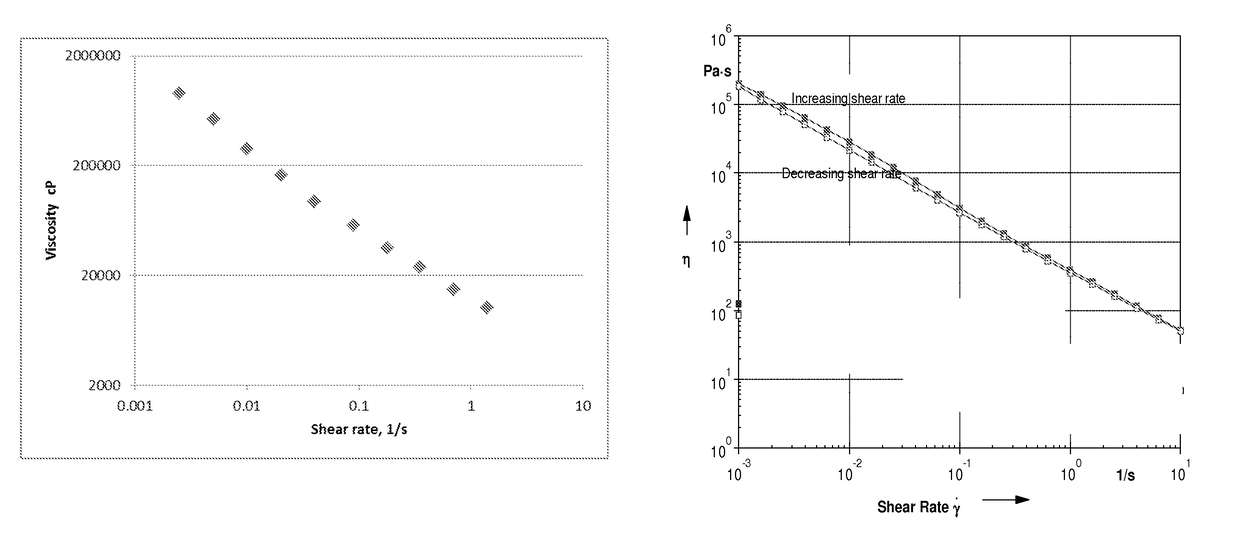

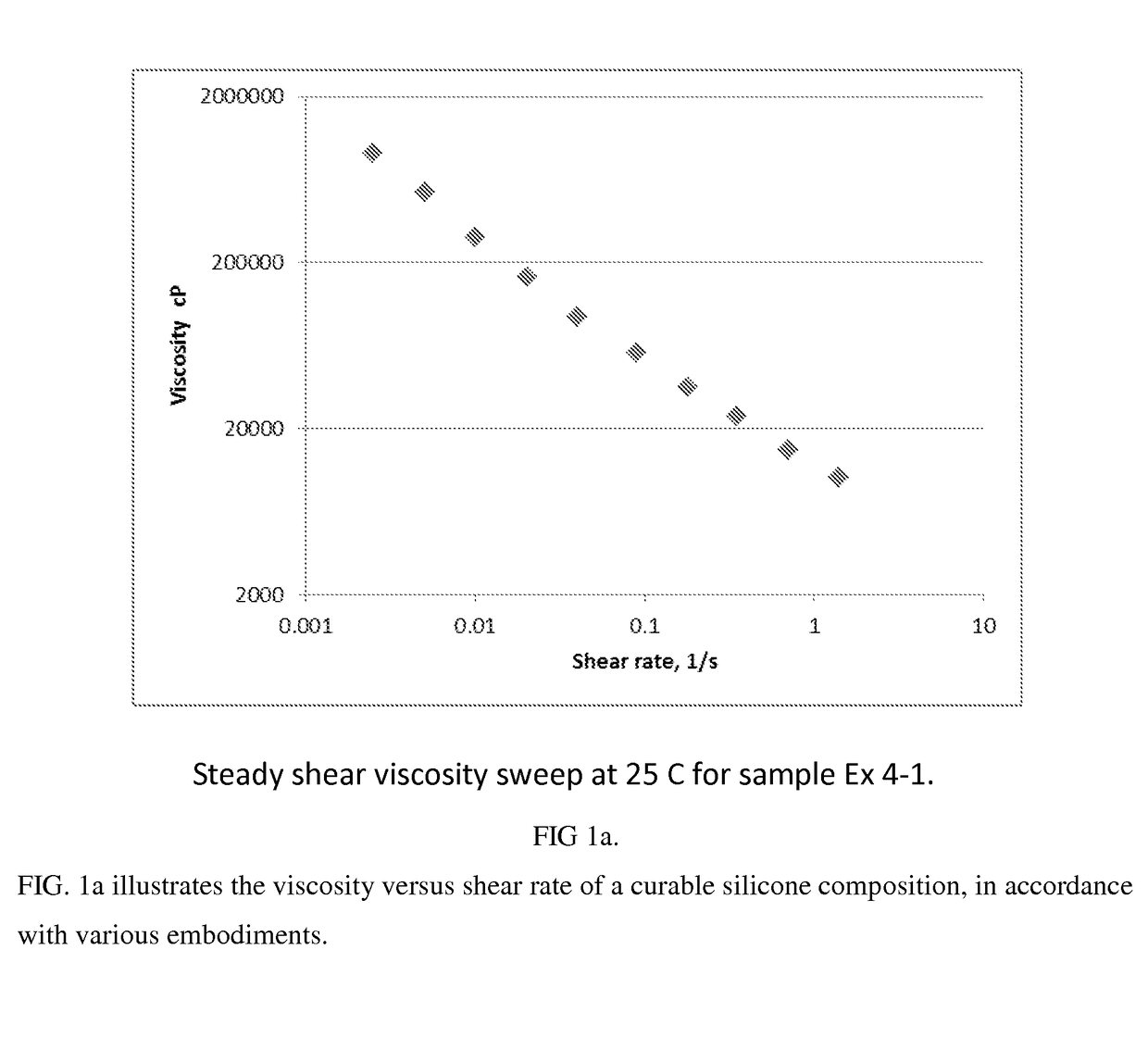

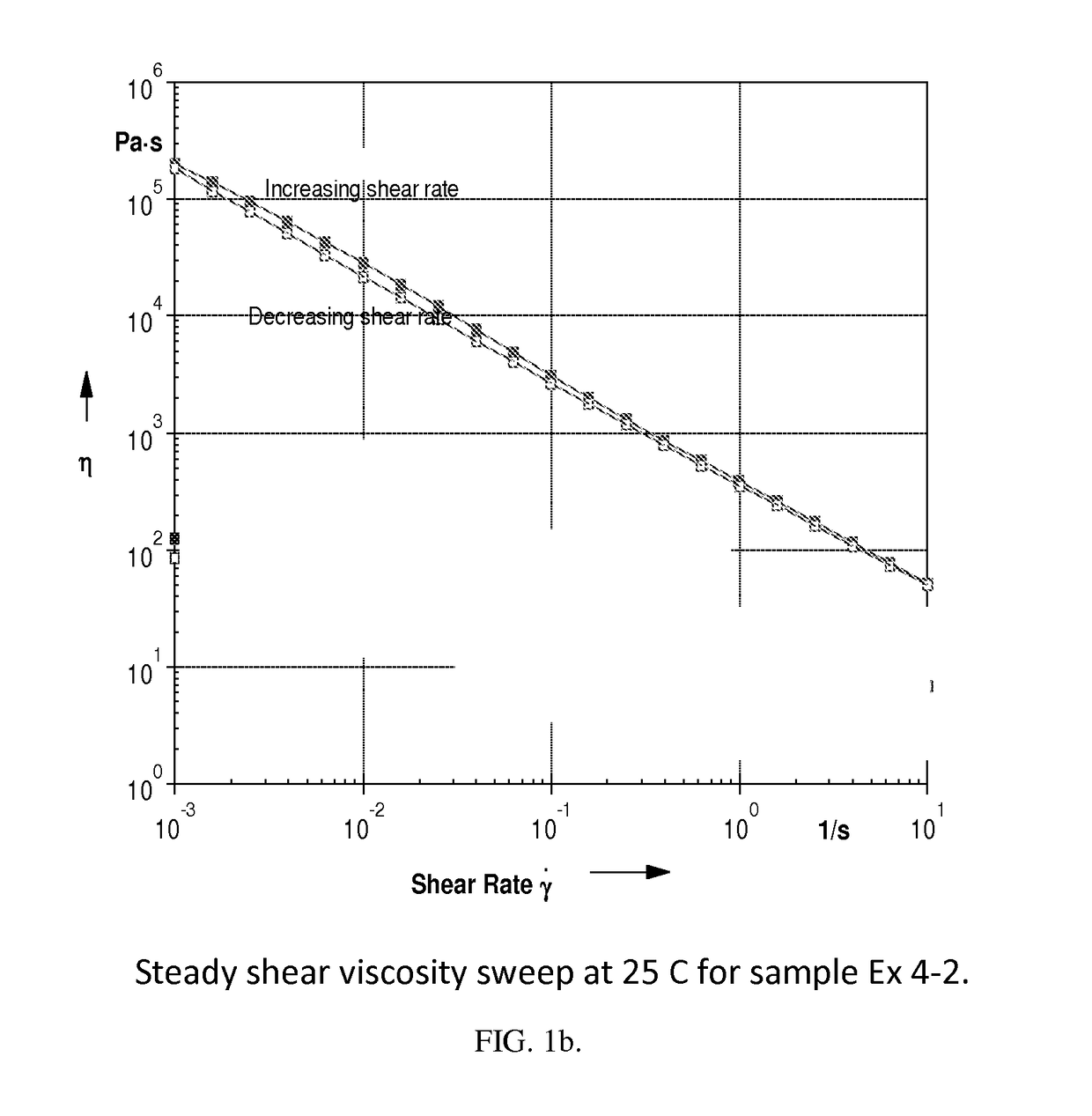

UV-curable silicone composition, cured products thereof, and methods of using the same

ActiveUS9732239B2Good shear thinning propertySuitable for printingInksCoatingsUV curingCarbon–carbon bond

Various embodiments disclosed related to UV-curable silicone composition, cured products thereof, and methods of using the same. Various embodiments provide a shear-thinning UV-curable silicone composition. The composition can include (A) a mercapto-functional polyorganosiloxane having the unit formula [(CH3)3SiO1 / 2]x[(CH3)2SiO]y[R(CH3)SiO]z wherein x is about 0.01 to about 0.1, y is about 0 to about 0.94, z is about 0.05 to about 0.99, and at each occurrence R is independently a mercapto(C1-30)hydrocarbyl group. The composition can include (B) at least one of (B1) a polyorganosiloxane comprising at least two aliphatic unsaturated carbon-carbon bonds, and (B2) an organic molecule comprising at least two aliphatic unsaturated carbon-carbon bonds; the composition can include (C) a filler. The composition can also include (D) a photoinitiator.

Owner:DOW SILICONES CORP

Inkjet printing apparatus and printing method of inkjet printing apparatus

InactiveUS8585174B2Improve position deviationExceeding resolution of imagingTypewritersOther printing apparatusMeasurement deviceImage formation

An inkjet printing apparatus includes: an inkjet head having nozzles which eject ink; a first conveyance device which moves at least one of an image formation medium and the inkjet head during image formation by the inkjet head; a second conveyance device which conveys the image formation medium along a conveyance path after the image formation by the inkjet head; an imaging device; a test pattern printing control device which controls ejection of the inkjet head; an ejection failure nozzle detection processing device; an expansion-contraction reference mark printing control device; an expansion-contraction deformation amount measurement device; an image deformation processing device which applies image deformation processing corresponding to the amount of deformation due to expansion and contraction, to image data to be printed on the second surface; and a print control device which carries out the printing on the second surface on a basis of the image data which has been corrected through the image deformation processing.

Owner:FUJIFILM CORP

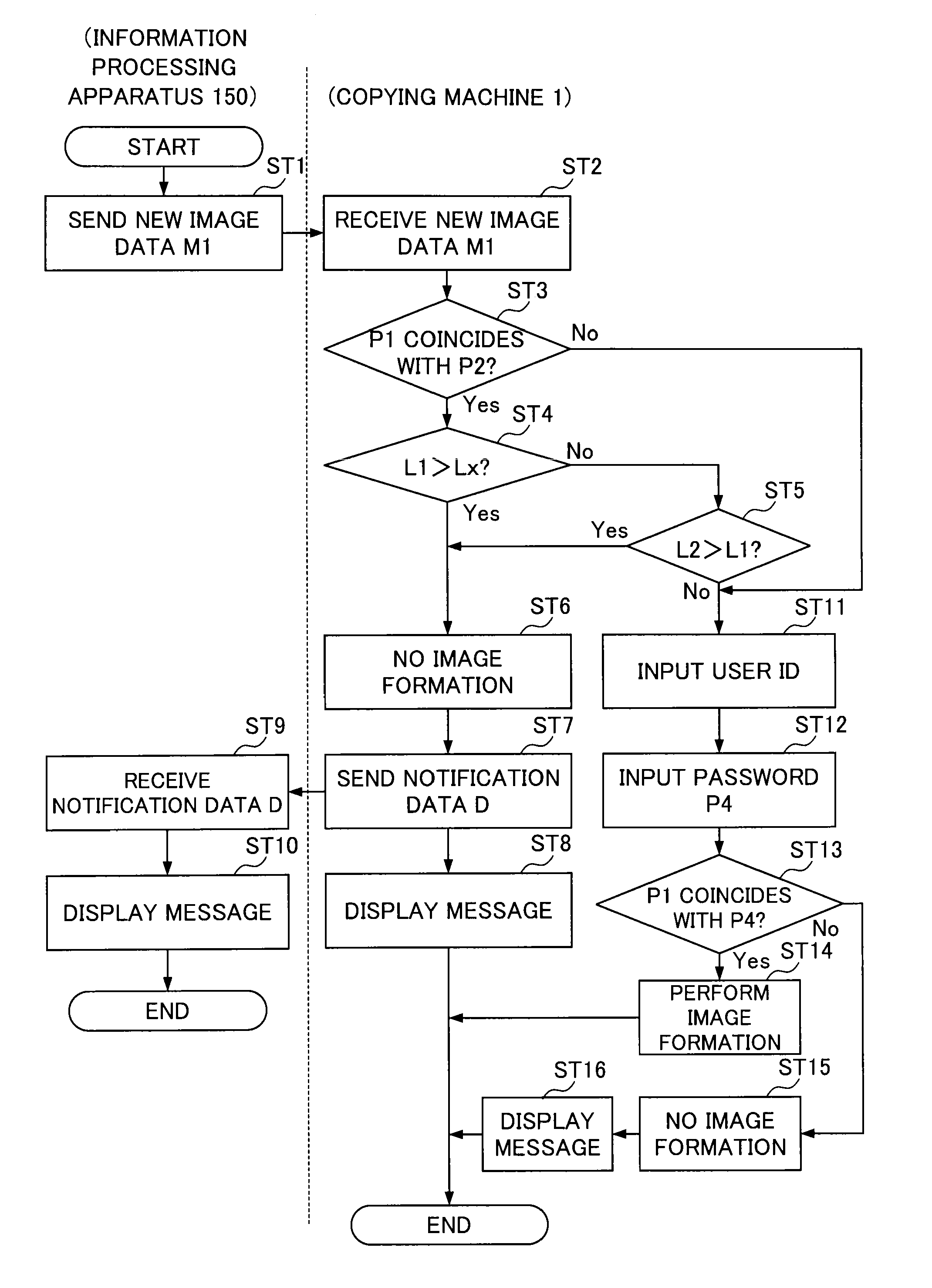

Image forming apparatus

InactiveUS20110211215A1Suitable for printingDigital data processing detailsVisual presentation using printersComputer hardwarePassword

When new image data is received by a communication I / F portion, a determination portion determines whether or not a password set to image data stored in the storage portion coincides with a password set to new image data received by the reception portion. A second image forming control portion does not execute image formation based on the new image data with a first image forming control portion when the determination portion determines that a password set to image data stored in the storage portion coincides with a password set to new image data received by the communication I / F portion.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Filling master batch capable of increasing strength and toughness of plastic product and preparation method of filling master batch

The invention belongs to the technical field of preparing a plastic product, and particularly relates to filling master batch capable of increasing strength and toughness of the plastic product and a preparation method of the filling master batch. The filling master batch is prepared by inorganic powder, a dispersing agent, a lubricating agent, a coupling agent, a heat stabilizer and carrier resin, and the inorganic powder is a mixture which is compounded by talcum powder and mica powder, of which the average grain diameters are 6-8 mum, in 1 : 1 mass ratio by passing through a 1800-2000 mesh screen. The filling master batch provided by the invention is mainly used for replacing part of synthetic resin in raw materials of an existing plastic product. Compared with the prior art, according to the filling master batch provided by the invention, the cost is low, and the production cost can be reduced to a large extent after part of the synthetic resin is replaced; and meanwhile, the filling master batch provided by the invention has the advantages of increasing the production efficiency, improving the product mechanical performance, increasing the heat-resisting temperature of the plastic product and the like, the plastic product, particularly a thin film product, which is prepared by adding the filling master batch is suitable for printing and is suitable for food and medical packaging industry.

Owner:河南惠强新能源材料科技股份有限公司

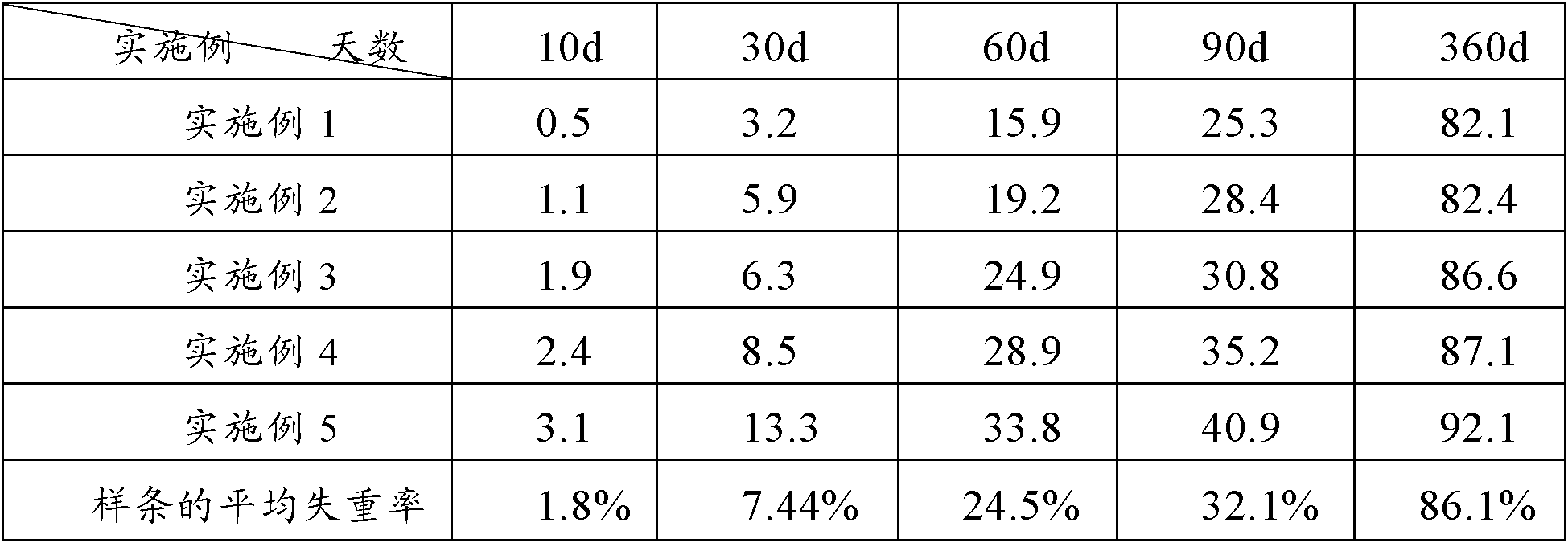

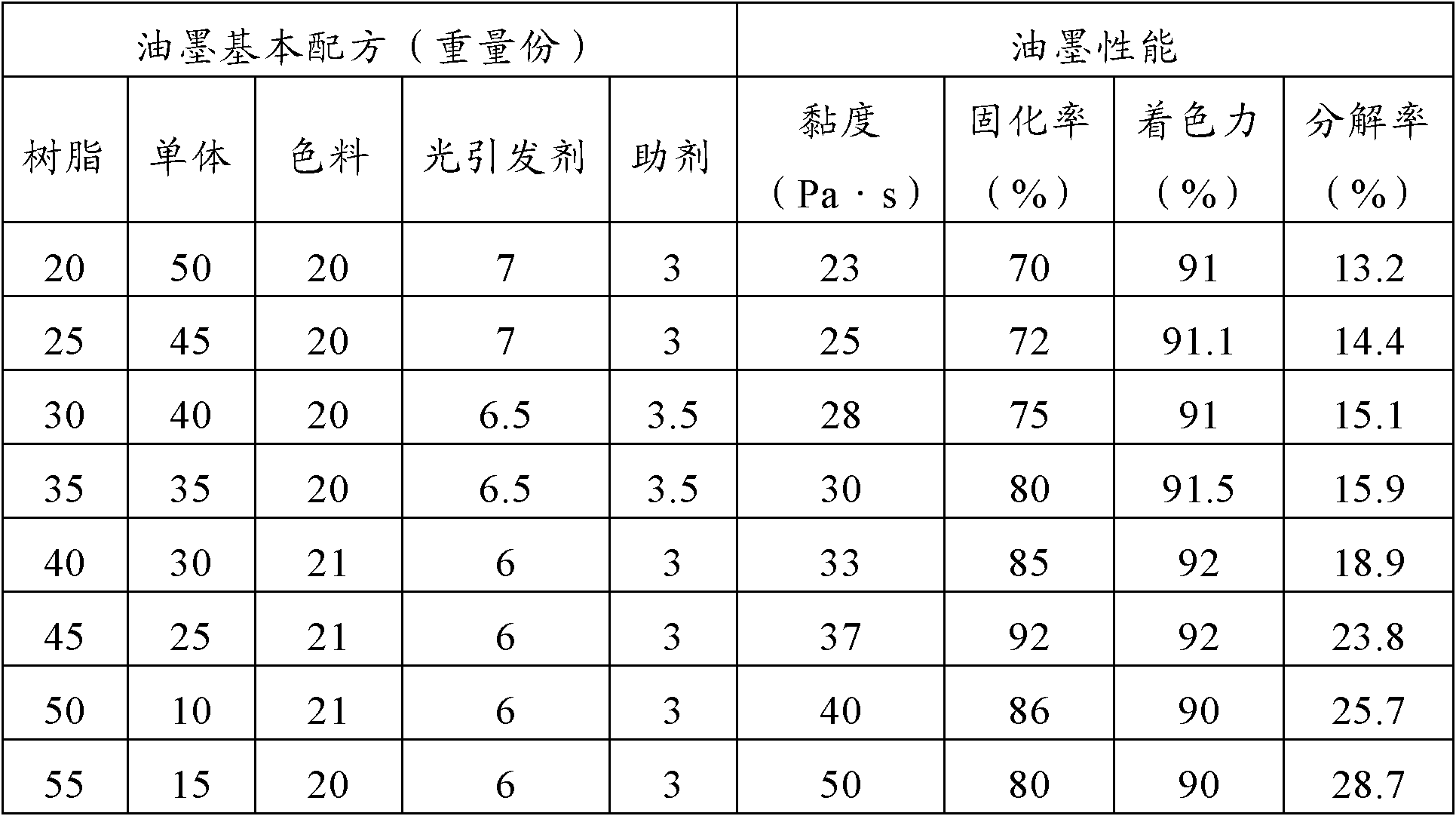

Dissoluble light-cured resin and dissoluble ultraviolet (UV) printing ink and preparing method thereof

ActiveCN102558580AShort decomposition periodWide range of printing materialsInksPolyurea/polyurethane coatingsPrepolymerChemistry

The invention relates to biodegradable light-cured resin and ultraviolet (UV) printing ink containing the light-cured resin. The dissoluble light-cured resin contains the following components by weight: 30-180 parts of polyhydroxyalkanoate (PHA), 20-190 parts of prepolymer, 1-10 parts of curing agents, 0.1-5 parts of polymerization inhibitors and 0.5-10 parts of catalysts. The UV printing ink contains the following components by weight: 25-70 parts of dissoluble light-cured resin, 10-50 parts of monomers, 15-40 parts of pigment, 1-10 parts of photo-initiation, 0.1-5 parts of polymerization inhibitors, 1-10 parts of flatting agents, 1-10 parts of antifoaming agents and 1-10 parts of wetting dispersant reagents. The UV printing ink can be decomposed by biology under the premise of ensuring printing ink printability and printing quality, and can be widely used in packing materials having high requirements for toxicity, such as food, drugs, health care products, books and periodicals and labels.

Owner:中国印刷科学技术研究所

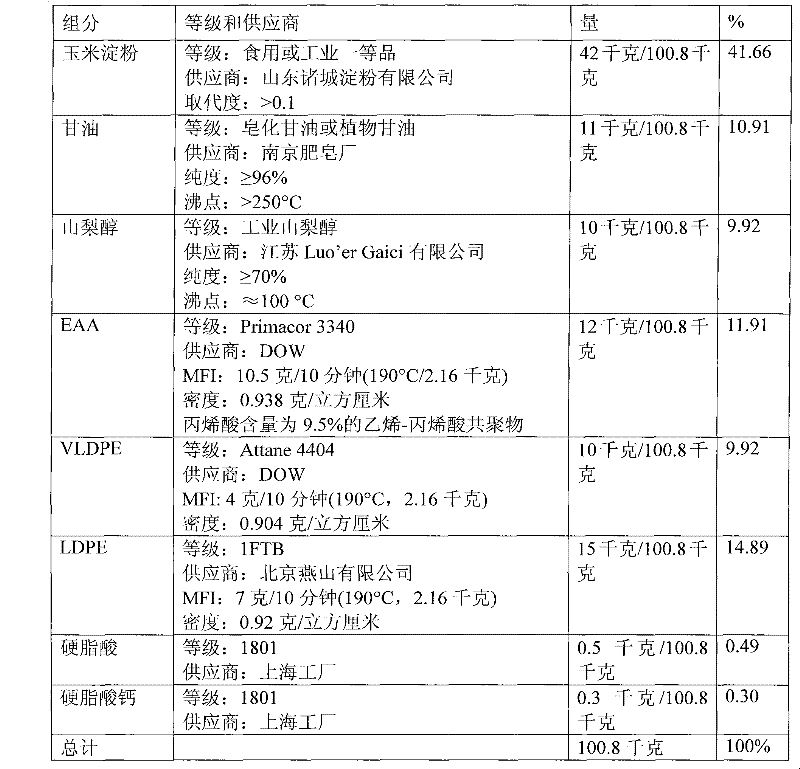

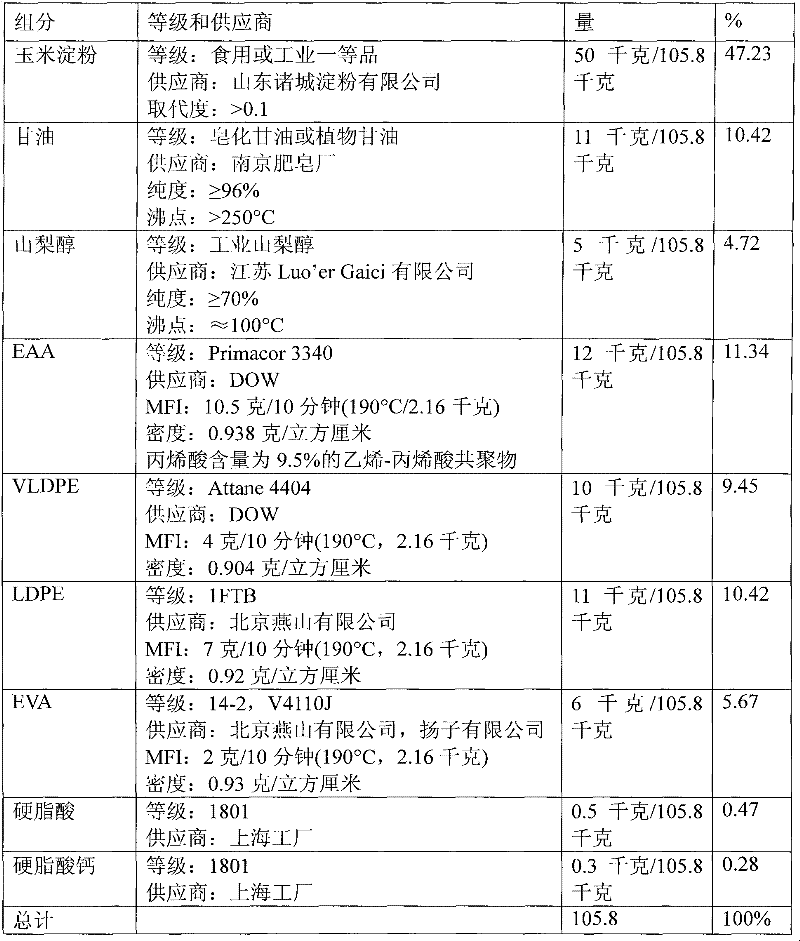

Completely degradable paper-like material with starch as basic material and its preparation

InactiveUS20050258567A1Improve heat resistanceImprove impact resistanceNon-fibrous pulp additionNatural cellulose pulp/paperChemistryStarch

Owner:WANG HUIQUN

Anti-yellowing high-temperature resistant wallpaper printing ink

Owner:LETONG CHEM CO LTD

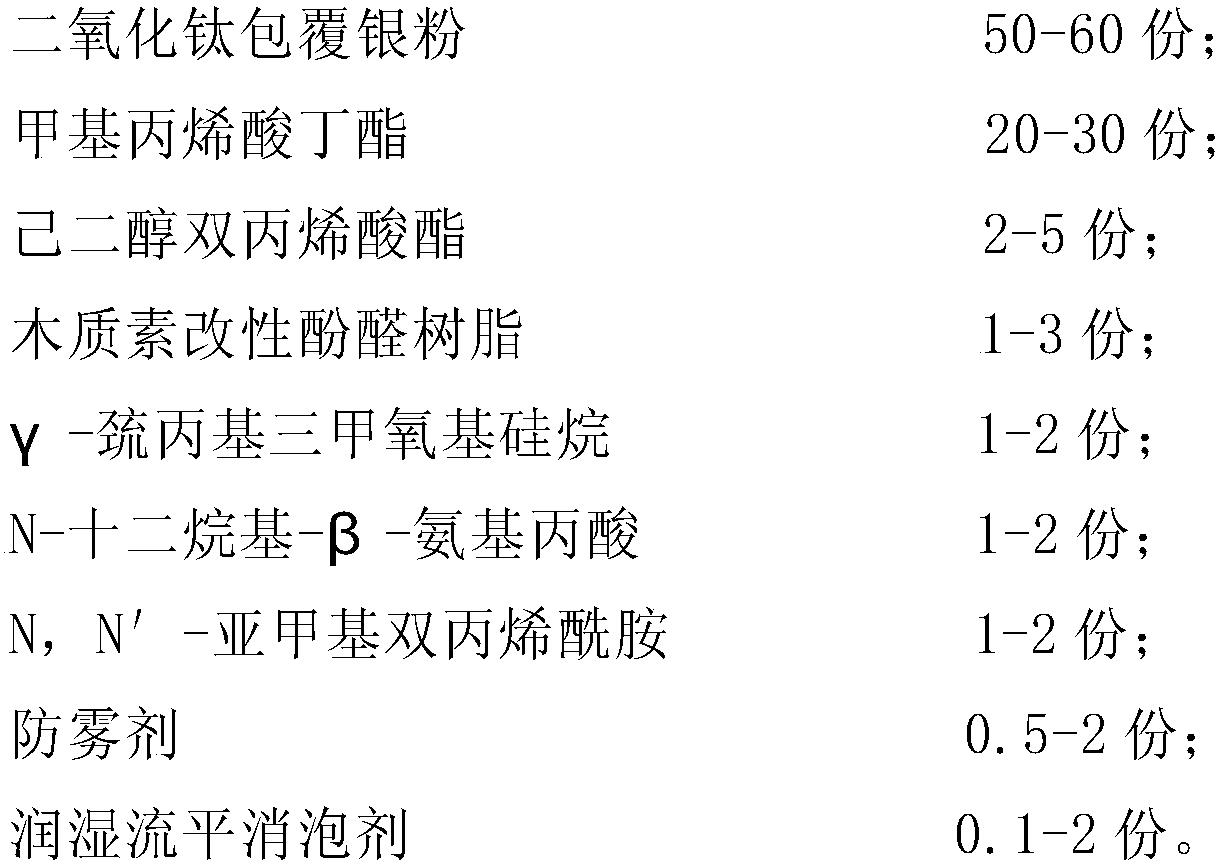

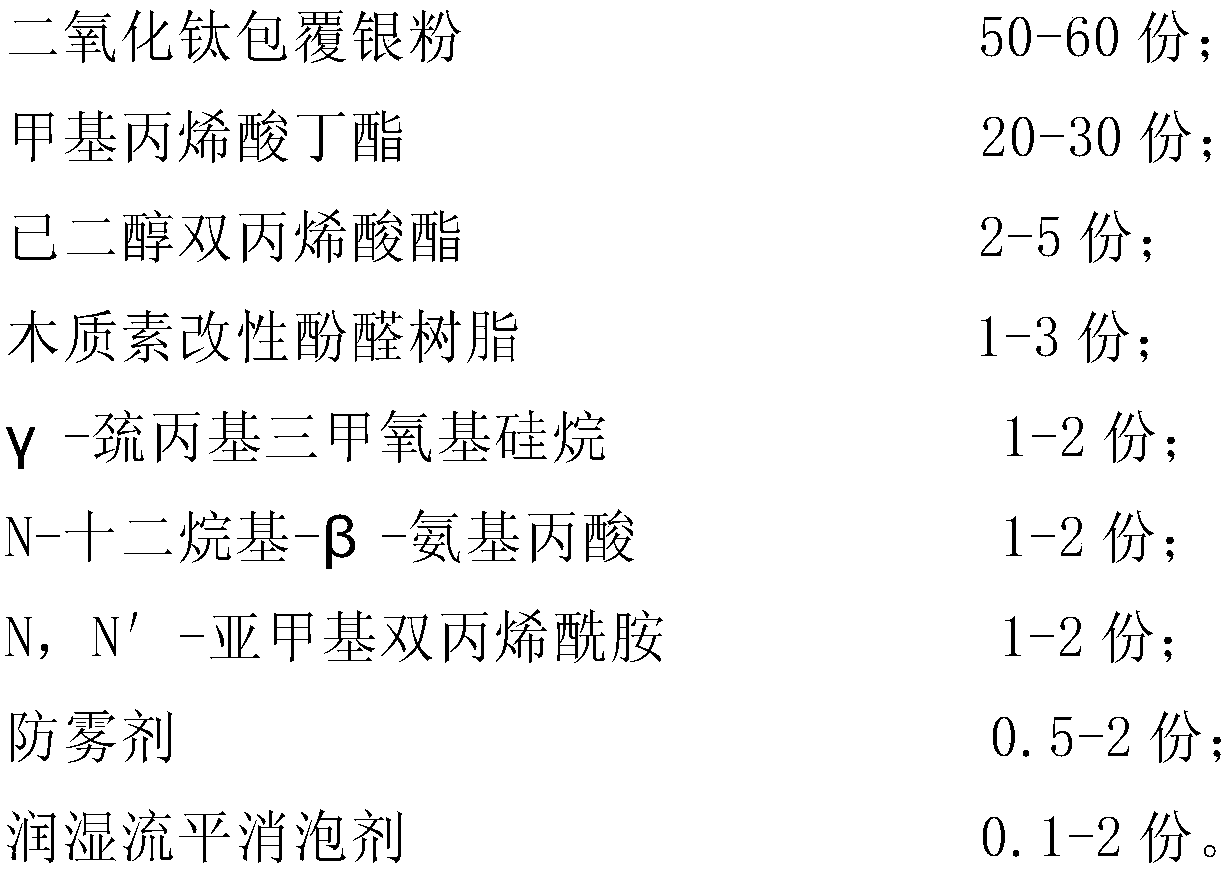

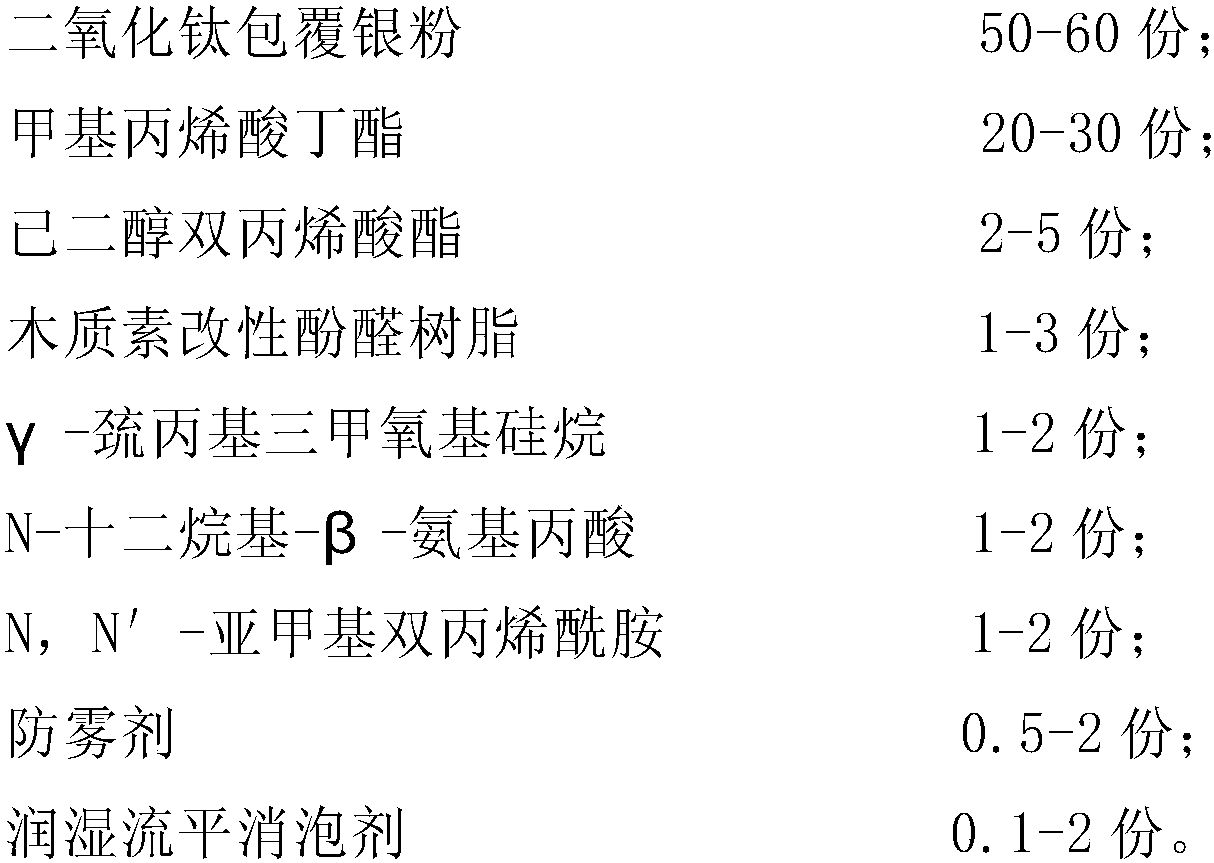

Silver-coating printing process for paperboard of cigarette case

The invention relates to a silver-coating printing process for a paperboard of a cigarette case. The silver-coating printing process comprises the following steps: (1) a laser engraving gravure printing plate is adopted; (2) silver ink for gravure printing is prepared; (3) the silver ink is transferred to the surface of the white paperboard by adopting gravure printing; (4) DNA anti-counterfeitingink is overprinted onto the white paperboard coated with a silver base by adopting gravure printing; (5) color ink is overprinted onto the white paperboard coated with the DNA anti-counterfeiting inkby adopting gravure printing; and (6) UV curable varnish is printed on the white paperboard by adopting gravure printing. The silver ink prepared in the silver-coating printing process provided by the invention is good in silver powder leveling property, strong in adhesive force, high in glossiness, and suitable for the large-area silver paste solution printing operation of a gravure printing machine; through DNA anti-counterfeiting ink printing, the anti-counterfeiting effect of the cigarette case is improved; and accordingly, the cigarette case has a unique anti-counterfeiting identity forauthentication as well as the characteristics of being easy to identify and difficult to copy.

Owner:苏州福羊自控科技有限公司

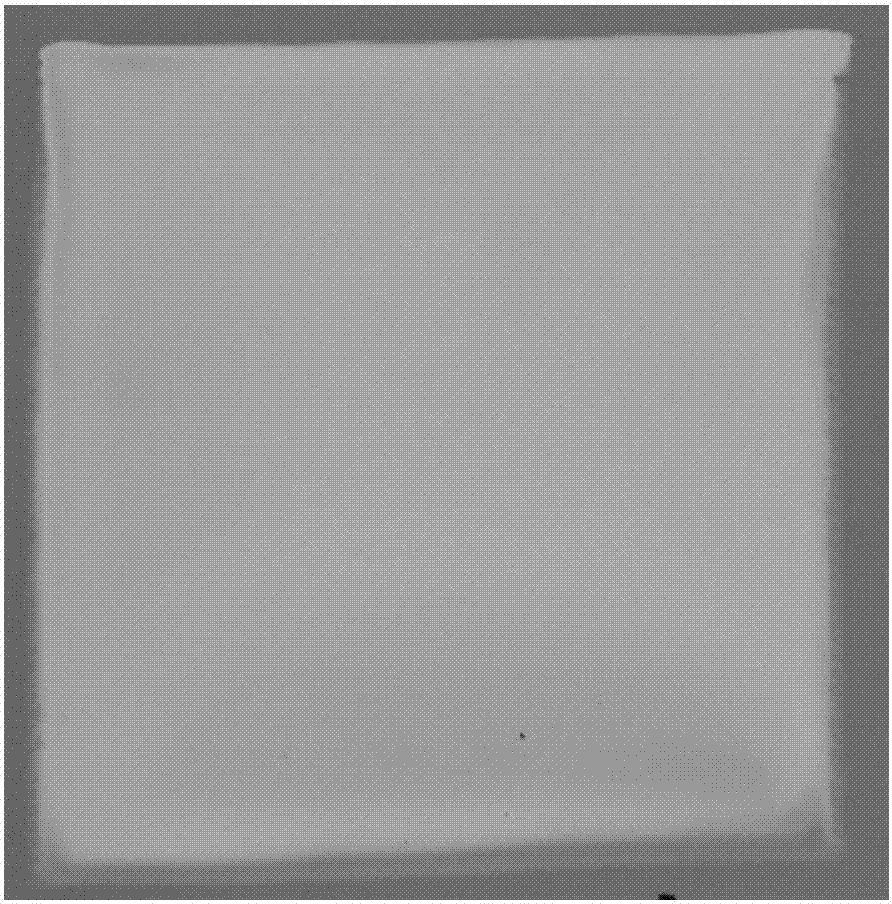

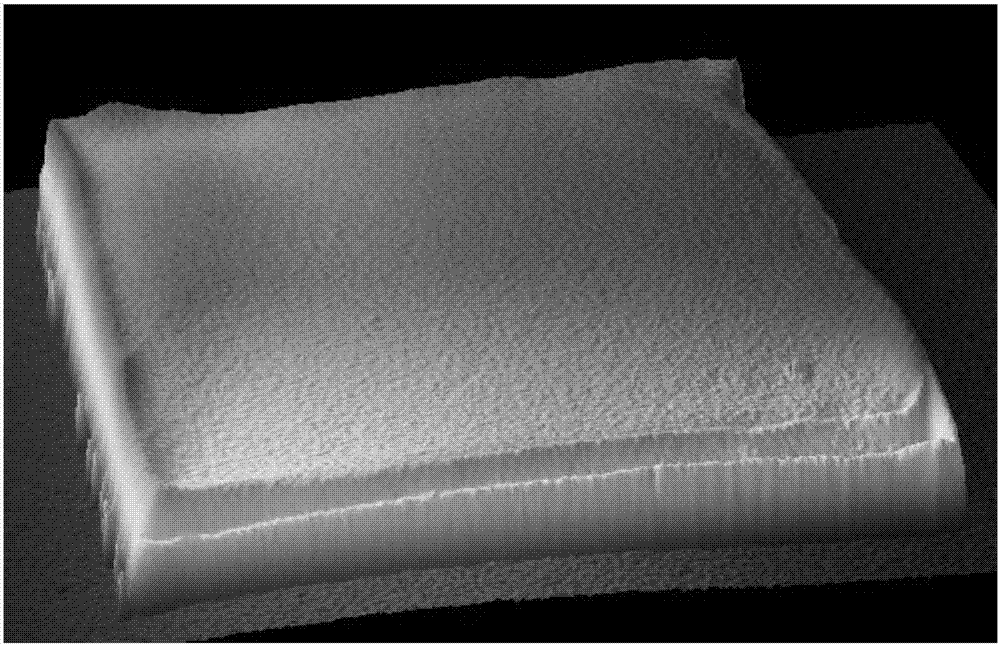

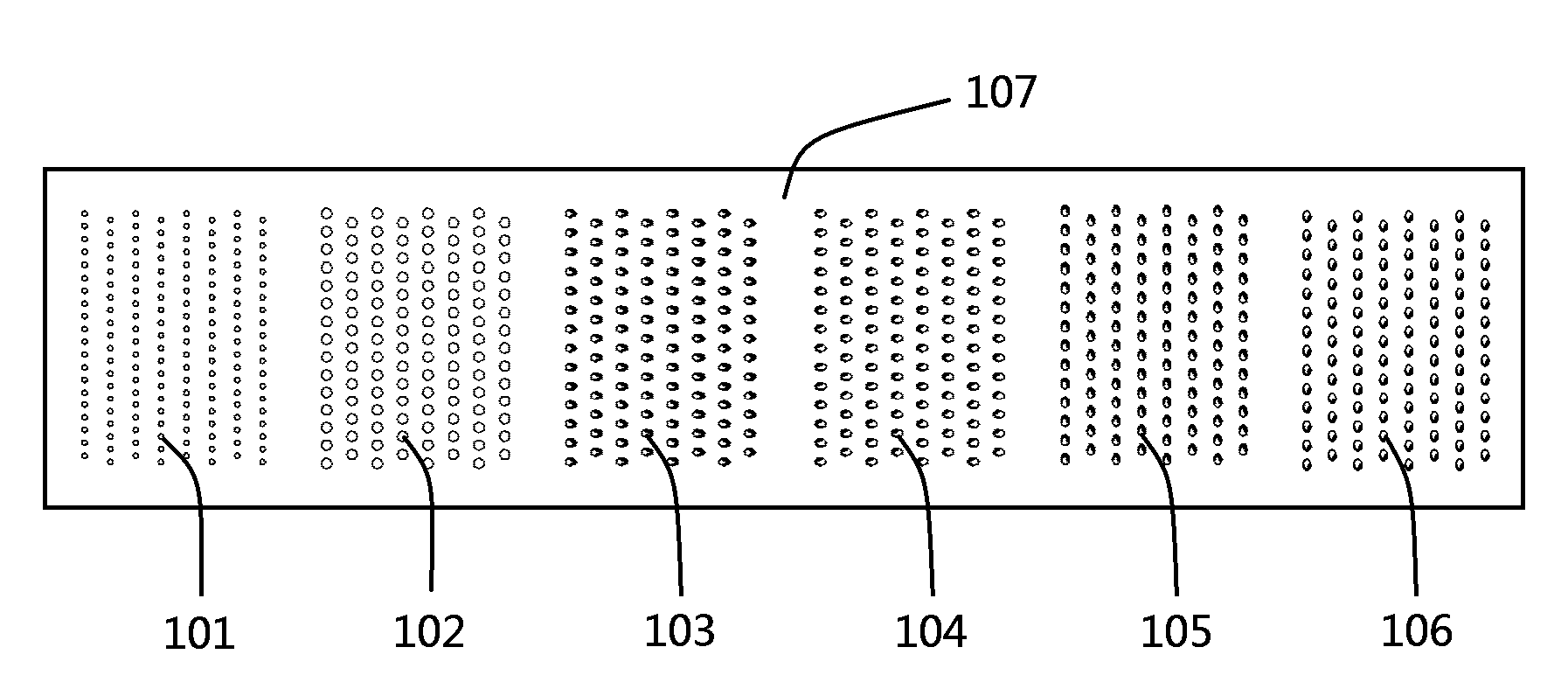

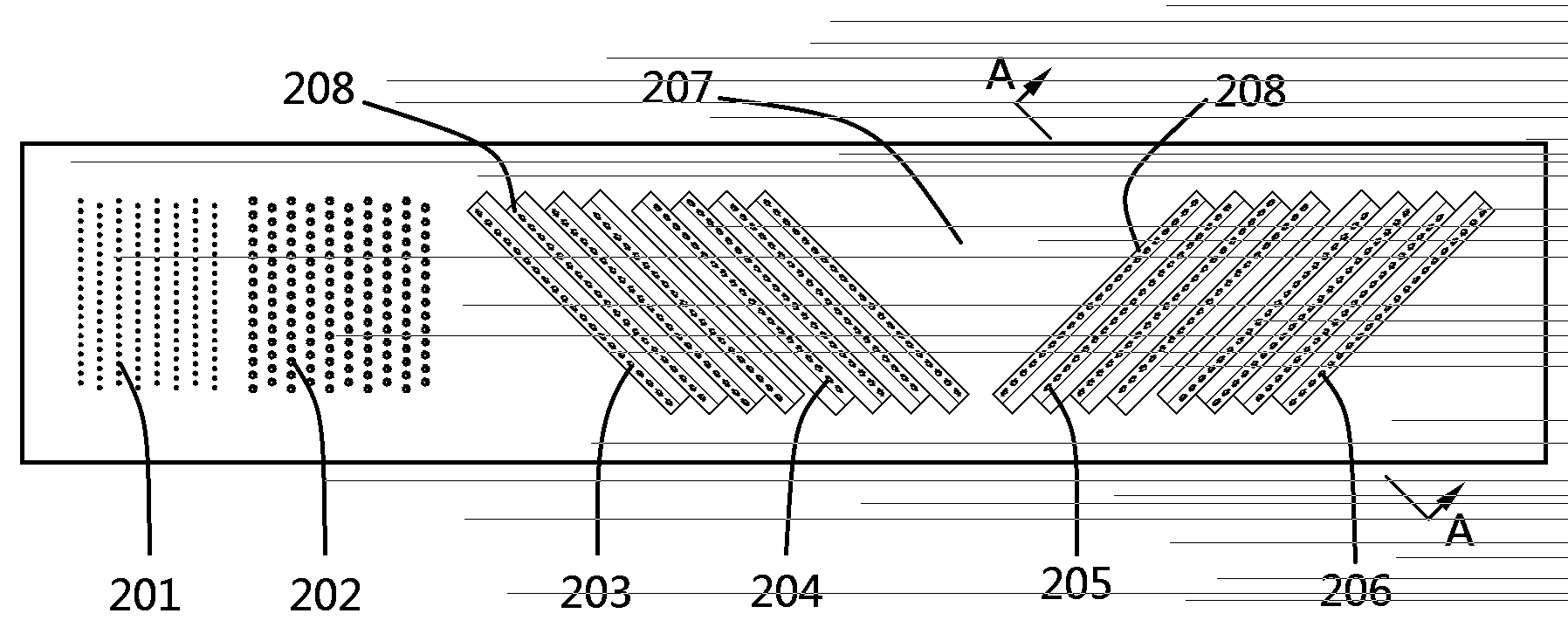

Inkjet printing head

The invention discloses an inkjet printing head. When an inkjet printing head is used to print a covering film, the printing of a fine covering film edge, a sufficient thickness and a convex three-dimensional surface is needed. An existing nozzle has a single vertical spraying direction, the same spraying amount of spraying holes and the limited spraying adjustment range of the spraying holes, and multiple requirements in printing the covering film can not be satisfied at the same time. The invention provides the following solution that an inkjet printing head comprises spraying holes with different spraying amounts and different ink drop spraying directions, different spraying holes are in cooperated working, a small ink drop is used for printing a smooth edge, a large ink drop is used for printing the thickness, and an ink drop which is sprayed in an inclined way is used for printing a side face.

Owner:晏石英

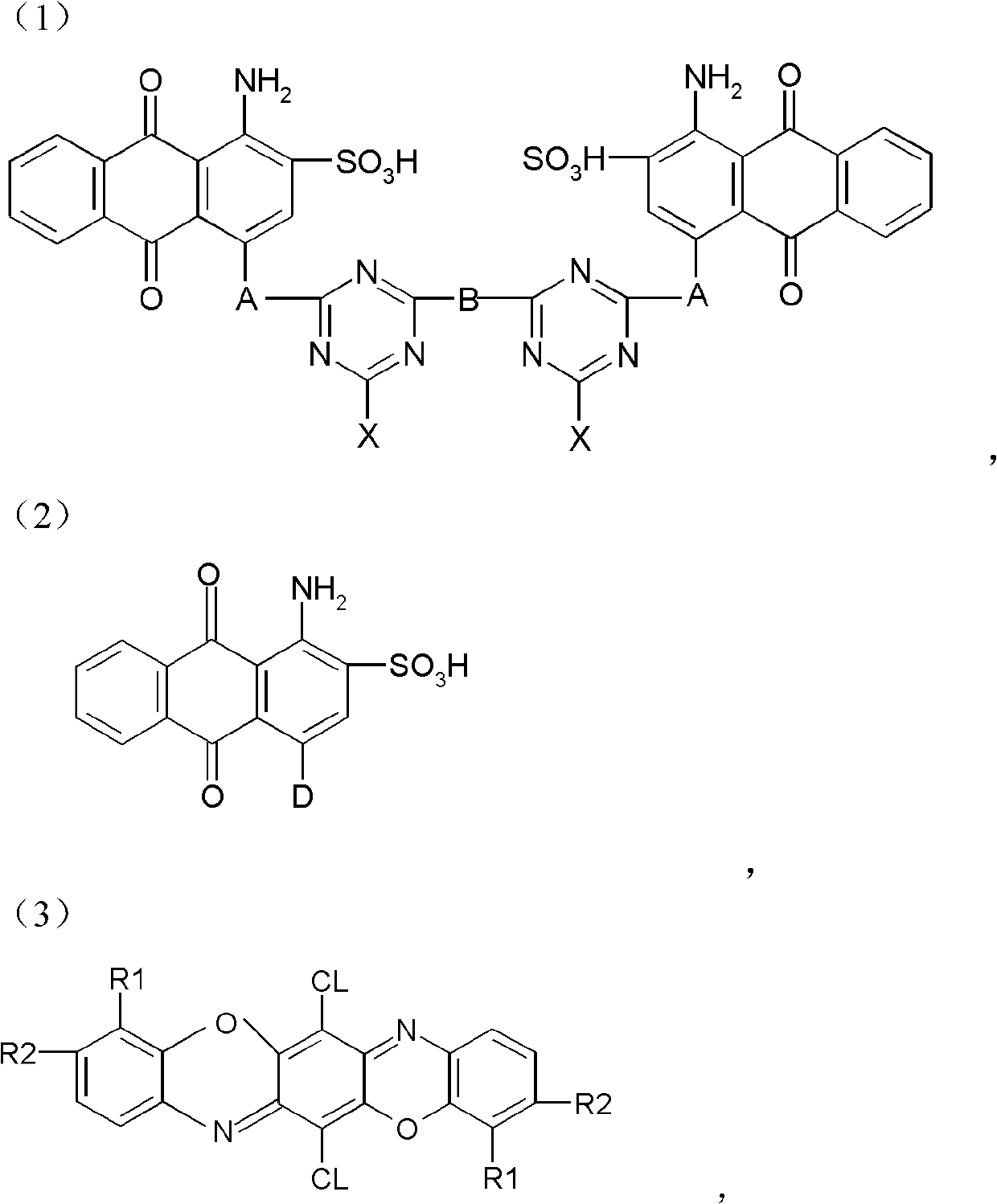

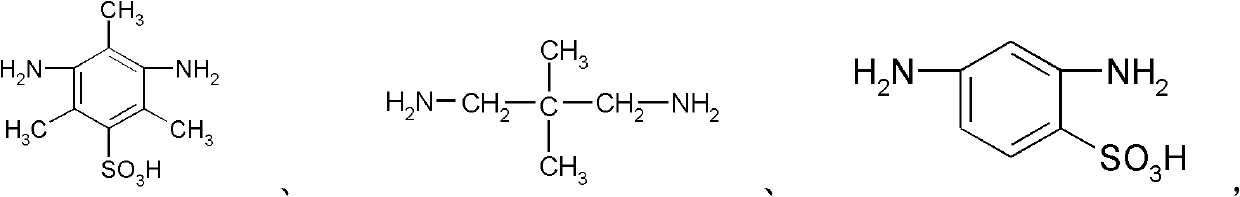

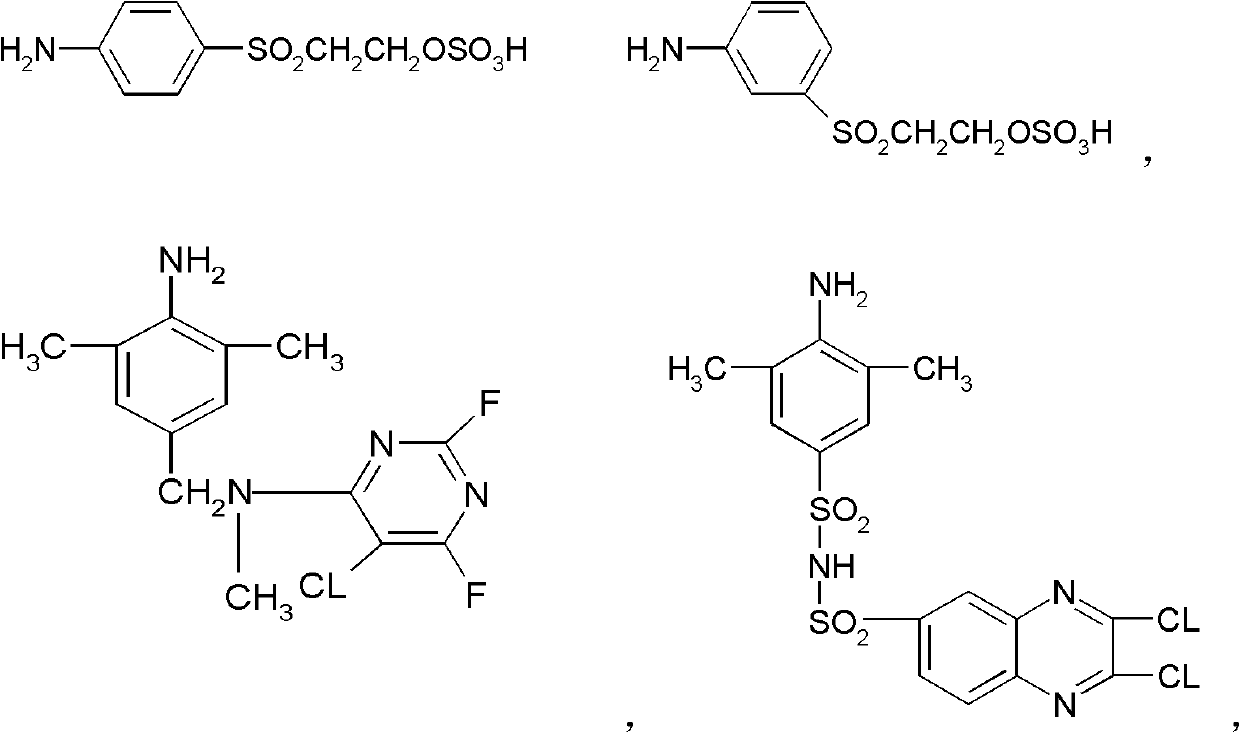

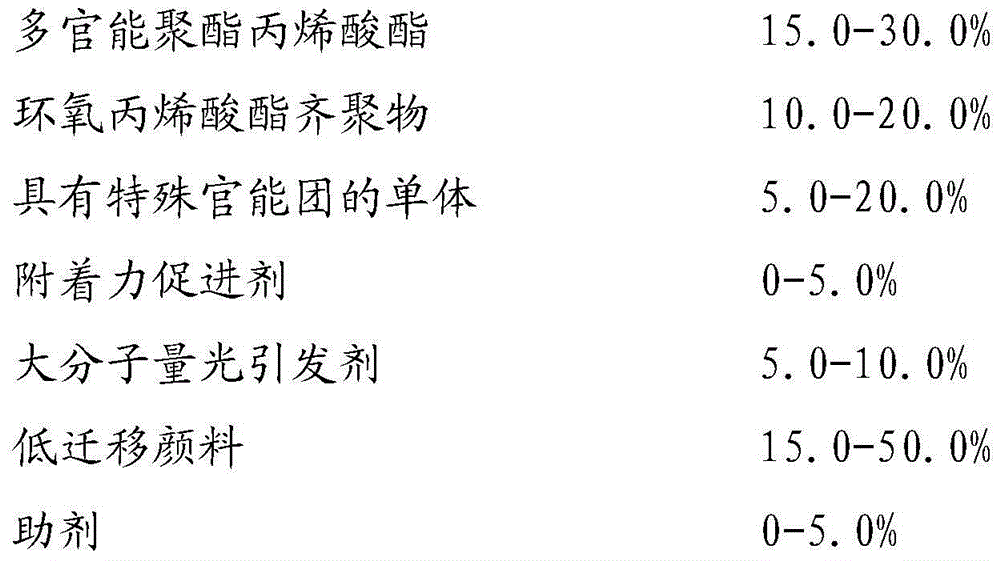

Blue active dye mixture and preparation and application thereof

The invention discloses a blue active dye mixture, which is characterized by comprising a mixture of dyes shown as general formulas (1), (2) and (3), wherein the weight part ratio of the dyes shown as the general formulas (1), (2) and (3) in the mixture is 80:(12-10):(10-8). The dye mixture can be applied to dyeing and printing hydroxyl-containing or nitrogen-containing fiber or a hydroxyl-containing or nitrogen-containing fiber material for ink jet printing, has high dye uptake, high leveling property, high lifting power, high water washing resistance, high light resistance and high comprehensive firm properties such as light ray resistance and dampness resistance.

Owner:HUBEI COLOR ROOT TECH CO LTD

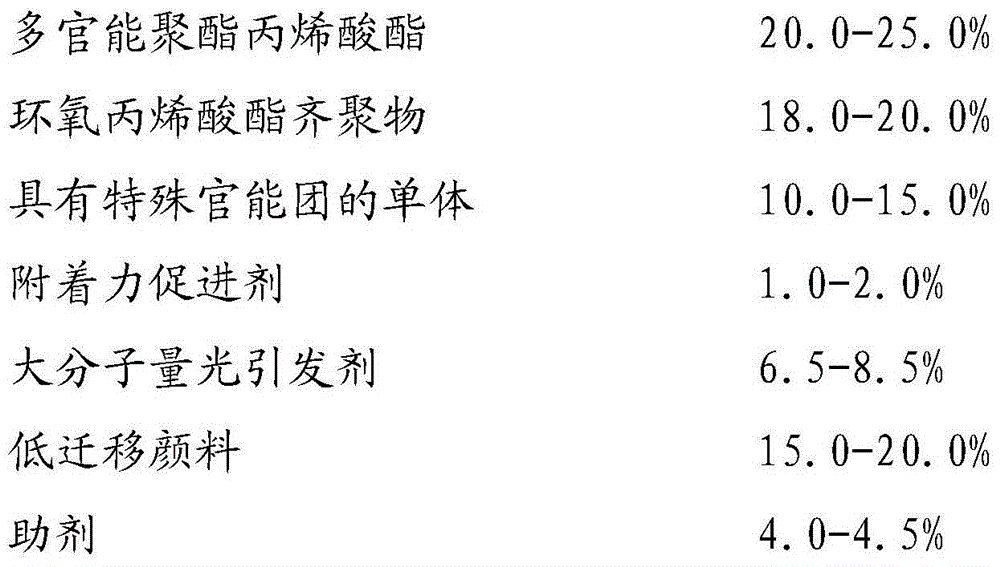

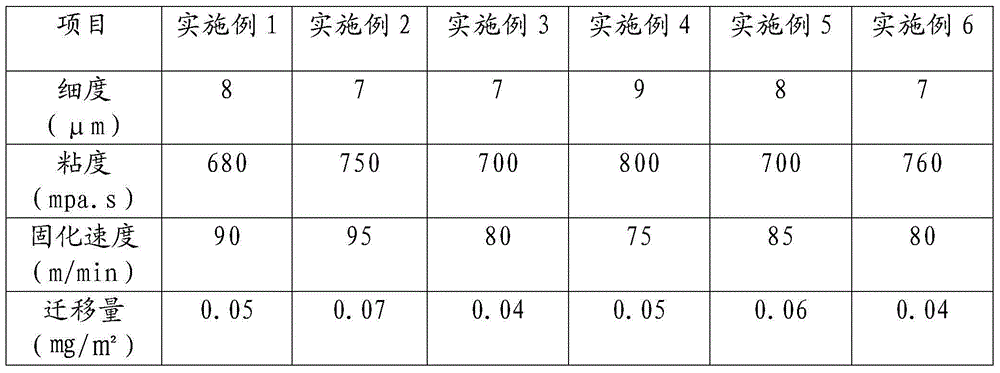

Low-migration UV flexible printing ink and preparation method thereof

The invention belongs to the technical field of ink preparation, and in particular relates to low-migration UV flexible printing ink and a preparation method thereof. The low-migration UV flexible printing ink consists of the following raw materials in percentage by weight: 15.0-30.0% of multifunctional polyesteracrylate, 10.0-20.0% of epoxy acrylate oligomer, 5.0-20.0% of a monomer with a special functional group, 0-5.0% of an adhesion promoter, 5.0-10.0% of a molecular weight photoinitiator, 15.0-50.0% of low-migration pigment and 0-5.0% of additives. The low-migration UV flexible printing ink provided by the invention is simple in preparation method, relatively small in fineness, moderate in viscosity, rapid in curing velocity, low in migration capacity, applicable to high-speed machine printing, and high in security.

Owner:山东力美喷墨科技有限公司 +1

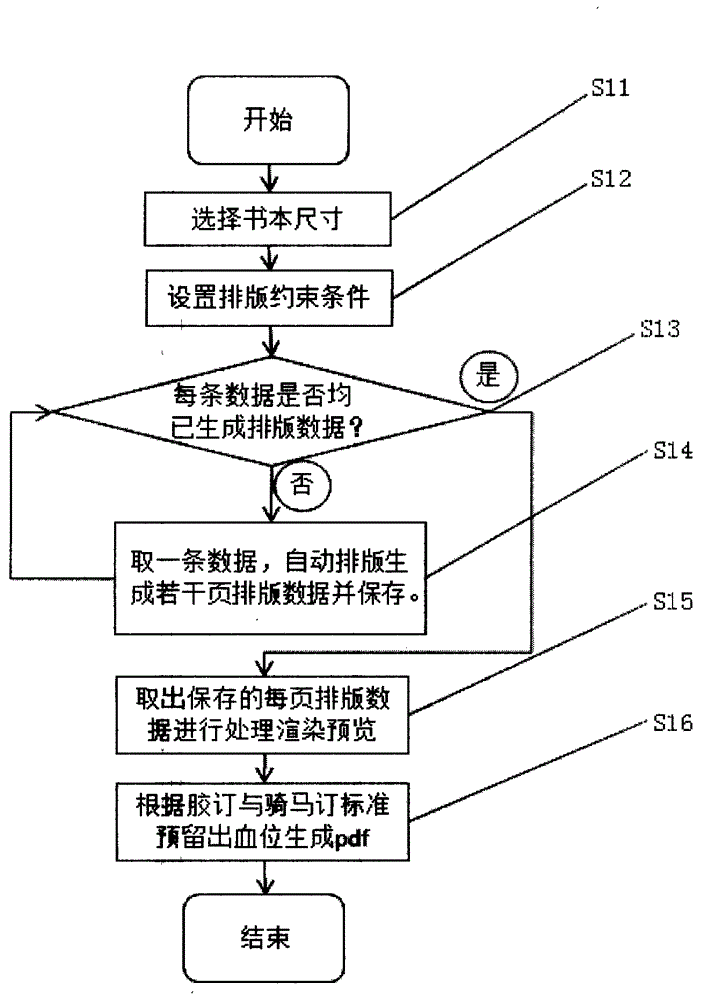

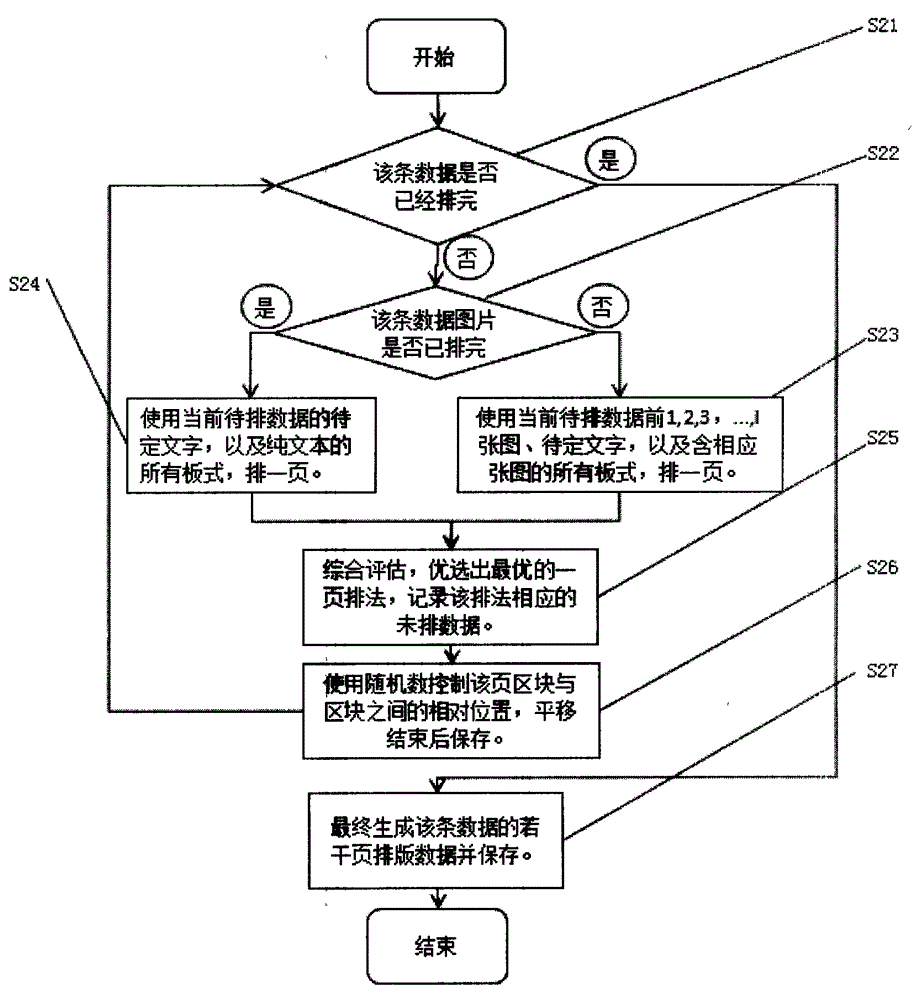

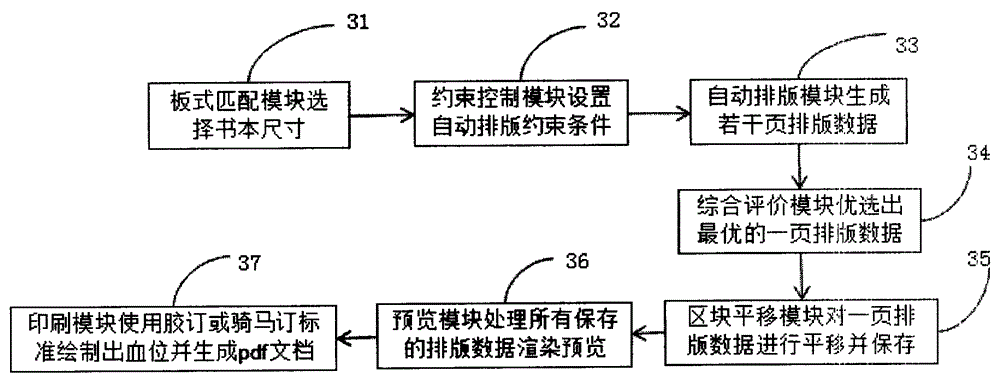

Automatic typesetting-based one-key book publishing method

ActiveCN104021113AGuaranteed independenceSuitable for printingNatural language data processingSpecial data processing applicationsRankingTheoretical computer science

Owner:ANHUI HUARUI DIGITAL TECH

Compositions comprising thermoplastic starch

Owner:TRISTANO PTY LTD

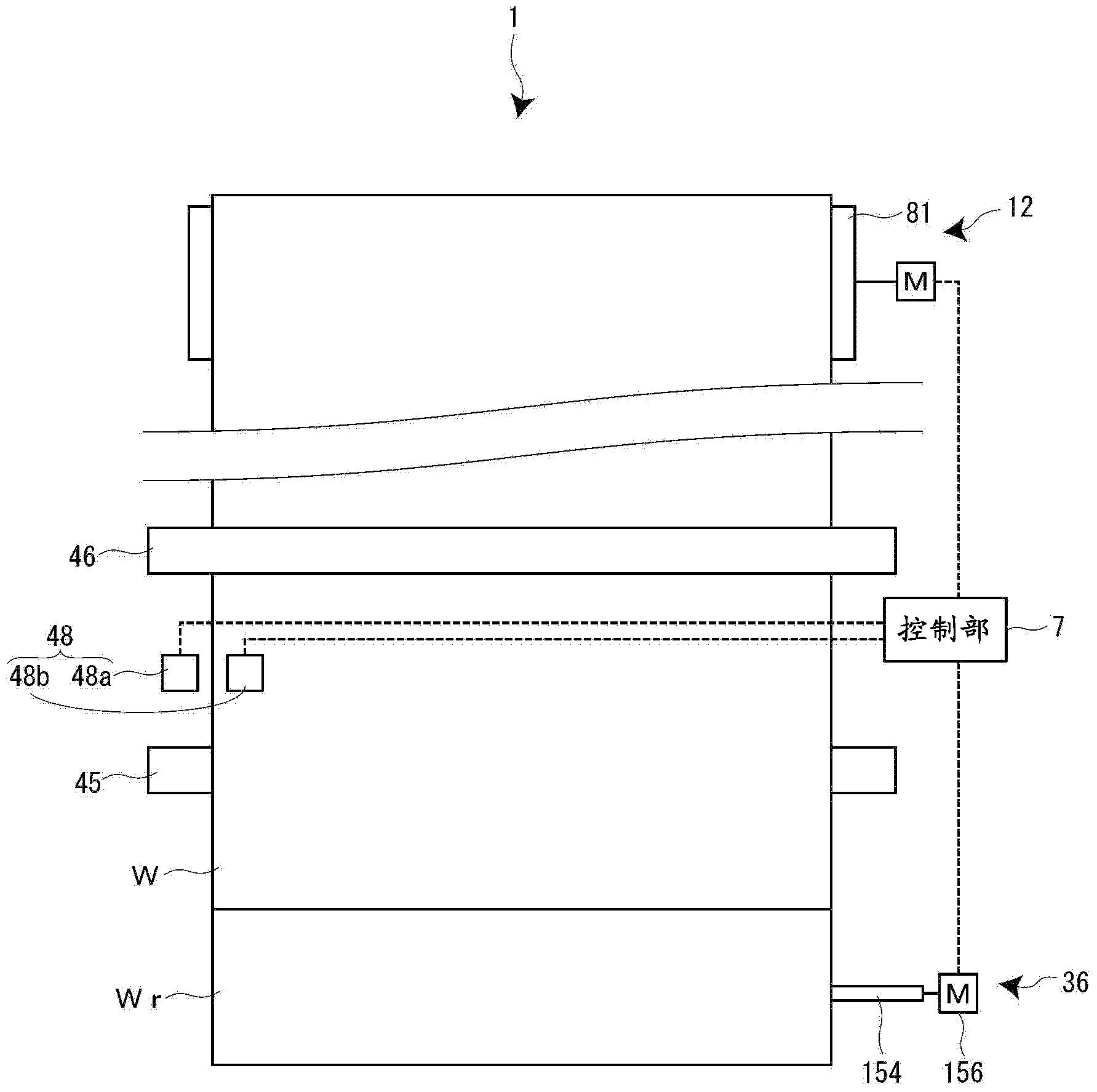

Medium feed device, method for controlling medium feed device, and recording device

ActiveCN103660629AReliable CorrectionSuitable for printingFunction indicatorsOther printing apparatusWrinkle skinRecording media

The advantage of the invention is to provide a medium feed device and the like for intermittently feeding a recording medium (3) in which meandering can be securely corrected without the occurrence of wrinkles in the recording medium (3). The medium feed device has a meandering detection sensor (48)which detects position displacement of a recording medium in a width direction, and a control section (7) which controls driving of a width movement unit based on detection results by the meandering detection sensor (48). The control section stops driving of the width movement unit when stopping feeding of the intermittent feeding.

Owner:SEIKO EPSON CORP

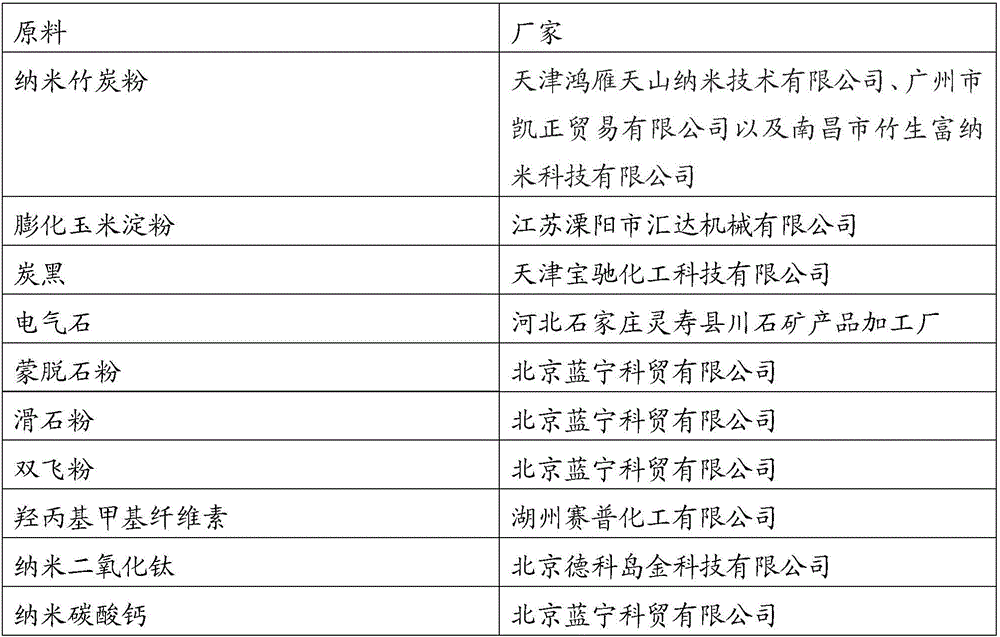

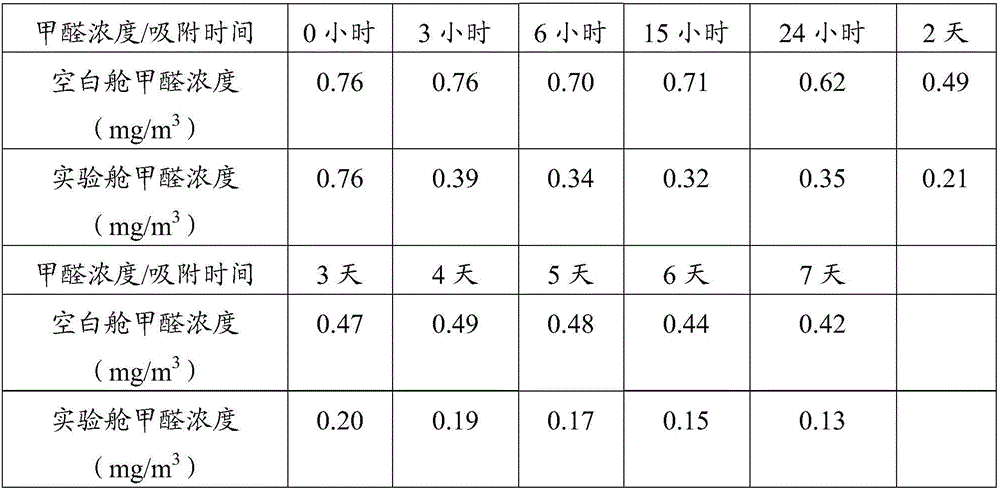

Multifunctional nanometer bamboo charcoal environment-friendly printing ink, a preparing method thereof and applications of the printing ink

Multifunctional nanometer bamboo charcoal environment-friendly printing ink, a preparing method thereof and applications of the printing ink are disclosed. The printing ink includes nanometer bamboo charcoal powder, carbon black, puffed corn starch, tourmaline powder, talcum powder, ground calcium carbonate, montmorillonite powder, nanometer calcium carbonate, nanometer titanium dioxide, hydroxypropyl methyl cellulose and purified water. The printing ink has a high negative ion generating amount and a high far-infrared emissivity, can rapidly improve quality of air around a reader, and can absorb harmful gas, such as volatile organic compounds, and odor generated by other printing ink materials and other products. The wavelength of emitted infrared ray can change microcirculation of readers, protect eyesight, boost immunity, enhance memory and make a reader happy. In addition, the printing ink has automatically sterilizing, mildew-proof, moisture-proof and pest-proof functions and the like, and is particularly suitable for child books, food package printing and archive record printing.

Owner:胡钧 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com