Inkjet printing head

An inkjet print head and inkjet technology, applied in printing and other directions, can solve the problem of not being able to meet the requirements of printing cover film at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

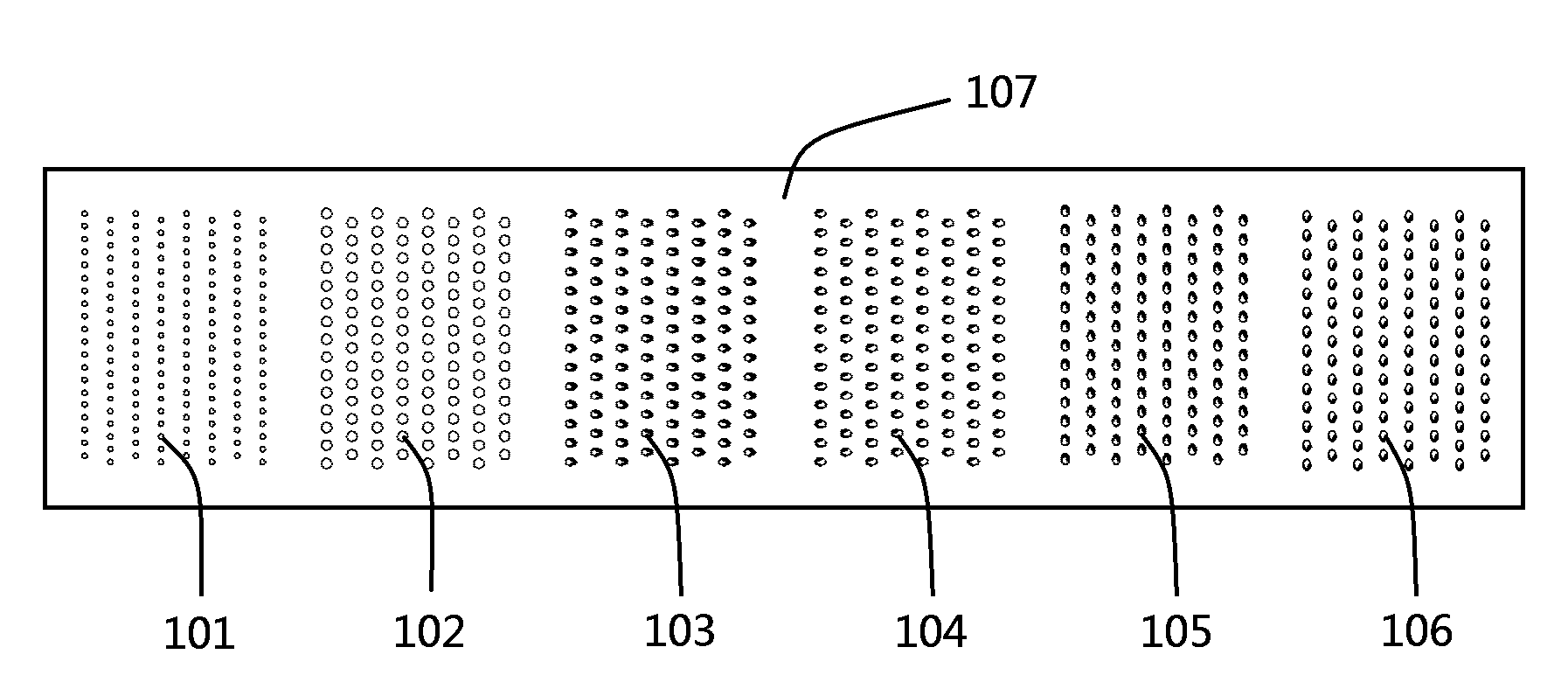

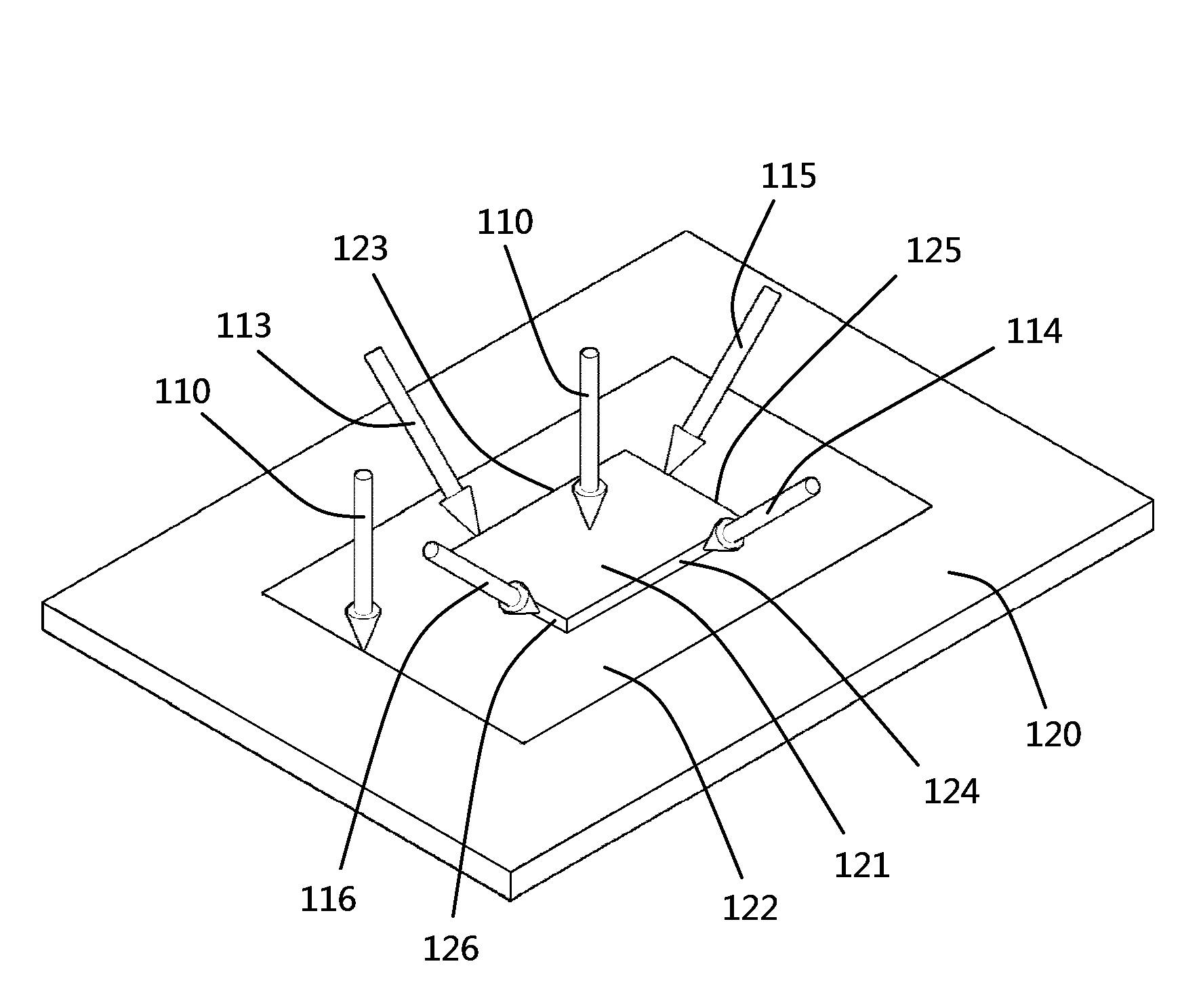

[0023] Embodiment one: see appendix figure 1 And attached figure 2 , On the printing head plane 107 of the inkjet print head, there are fine ink ejection holes 101, thickness ink ejection holes 102, right ink ejection holes 103, left ink ejection holes 104, rear ink ejection holes 105 and front ink ejection holes 106.

[0024] The fine ink ejection hole 101 and the thickness ink ejection hole 102 are vertical ink ejection holes, and the ink drop ejection direction is perpendicular to the printing surface 120; the right ink ejection hole 103, the left ink ejection hole 104, the rear ink ejection hole 105 and the front ink ejection hole 106 is an inclined ink ejection hole, and the ejection direction of the ink drop forms an angle of 45 degrees with the printing surface 120 .

[0025] Because the ink droplets ejected from the fine inkjet hole 101 are thinner than the ink droplets ejected from the thick inkjet hole 102, the fine inkjet hole 101 is used to print the edge positio...

Embodiment 2

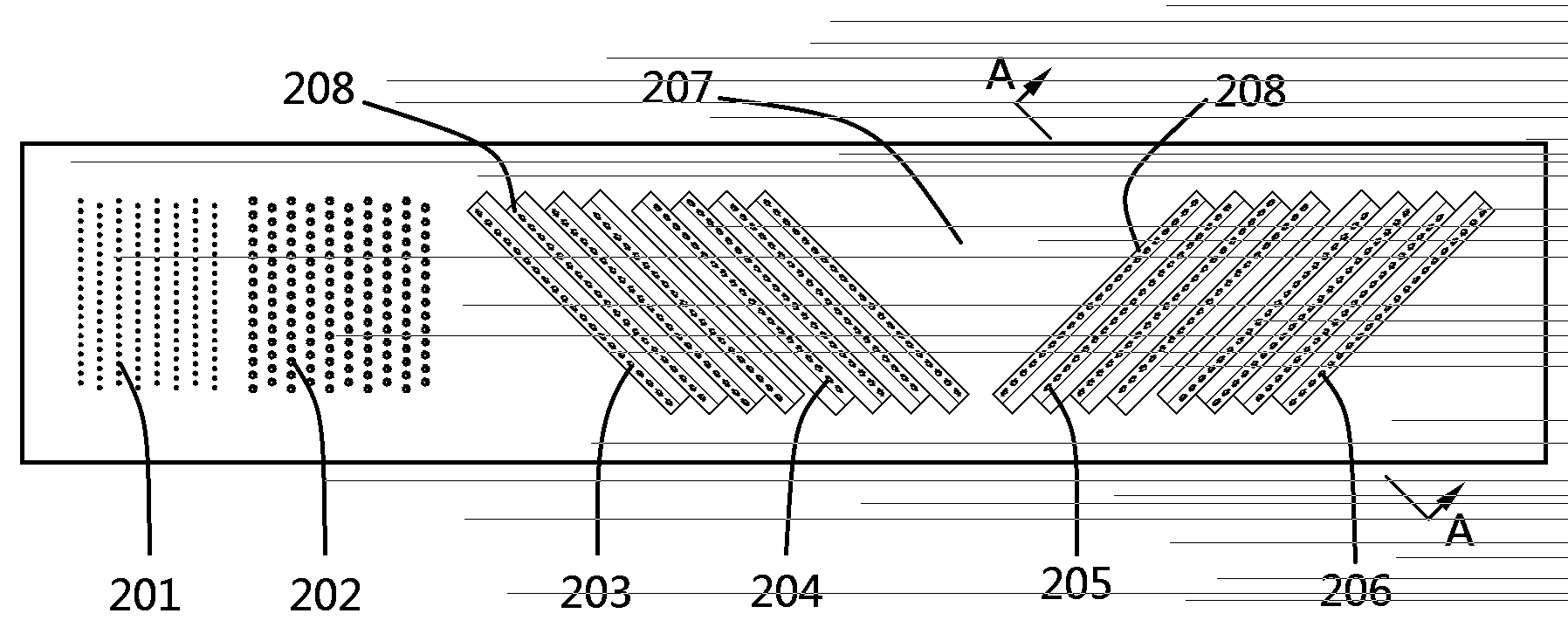

[0033] Embodiment two: see attached image 3 to attach Figure 5 , the printing head plane 207 of the inkjet printhead is distributed with fine inkjet holes 201, thickness inkjet holes 202, and the opening surface 208 is distributed with right rear inkjet holes 203, left front inkjet holes 204, right front inkjet holes 205 and The left rear ink jet hole 206.

[0034] The fine ink ejection hole 201 and the thickness ink ejection hole 202 are vertical ink ejection holes, and the ink drop ejection direction is perpendicular to the printing surface 220; The ink hole 206 is an inclined ink ejection hole, and the ink drop ejection direction forms an angle of 45 degrees with the printing surface 220; the triangular groove on the print head plane 207 provides an opening surface 208 perpendicular to the ink drop ejection direction for the inclined ink ejection hole, Therefore, it is ensured that the openings of the inclined ink ejection holes are circular and axisymmetric along the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com