Medium feed device, method for controlling medium feed device, and recording device

A medium conveying and control method technology, which can be used in printing devices, transportation and packaging, thin material handling, etc., and can solve problems such as wrinkling of recording media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

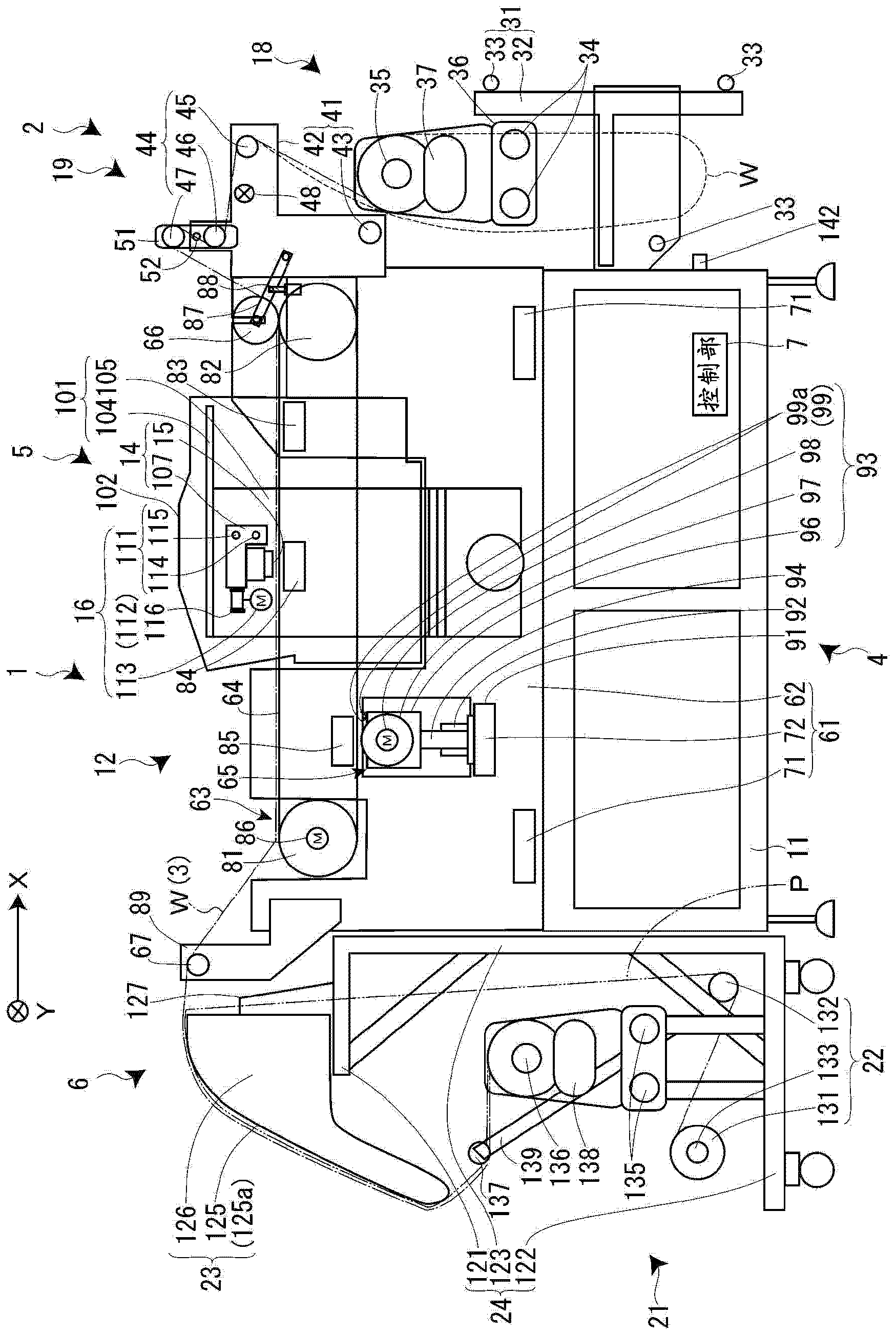

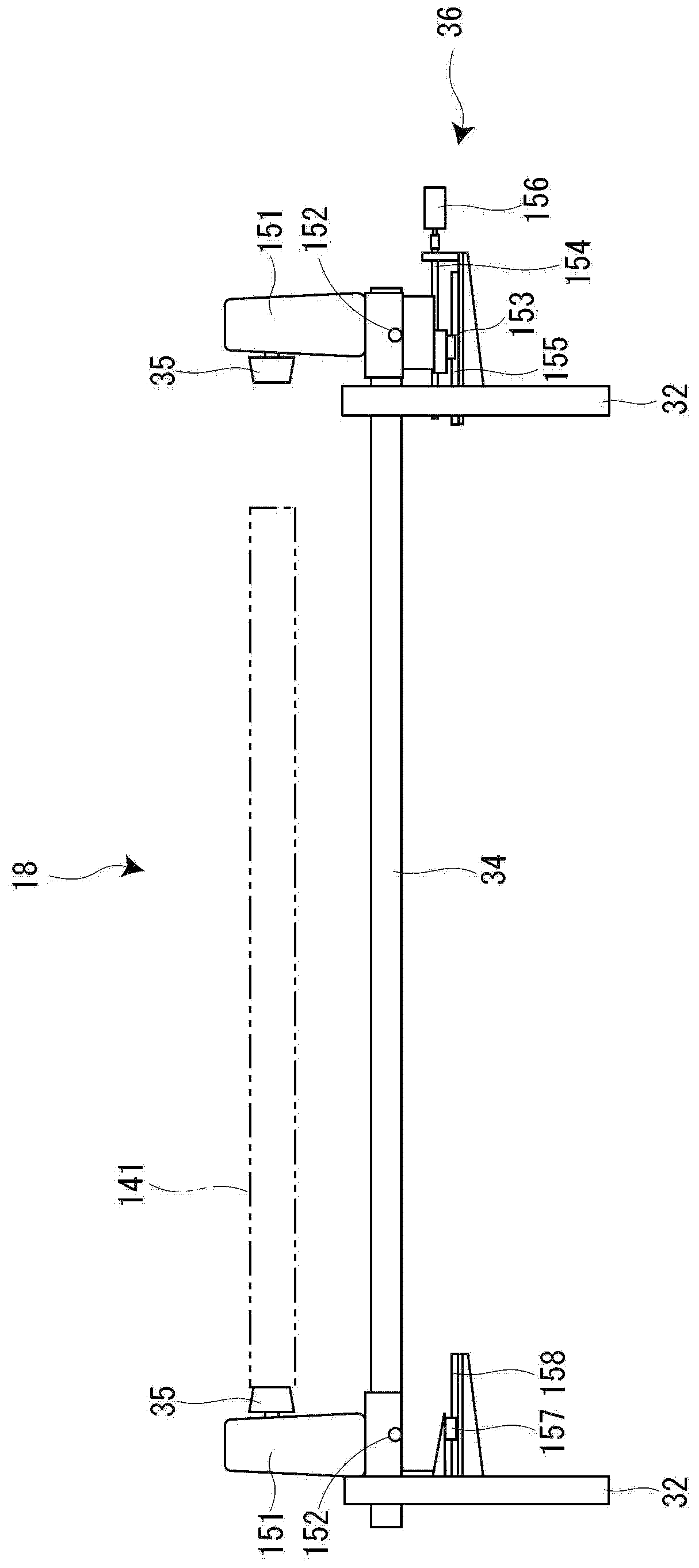

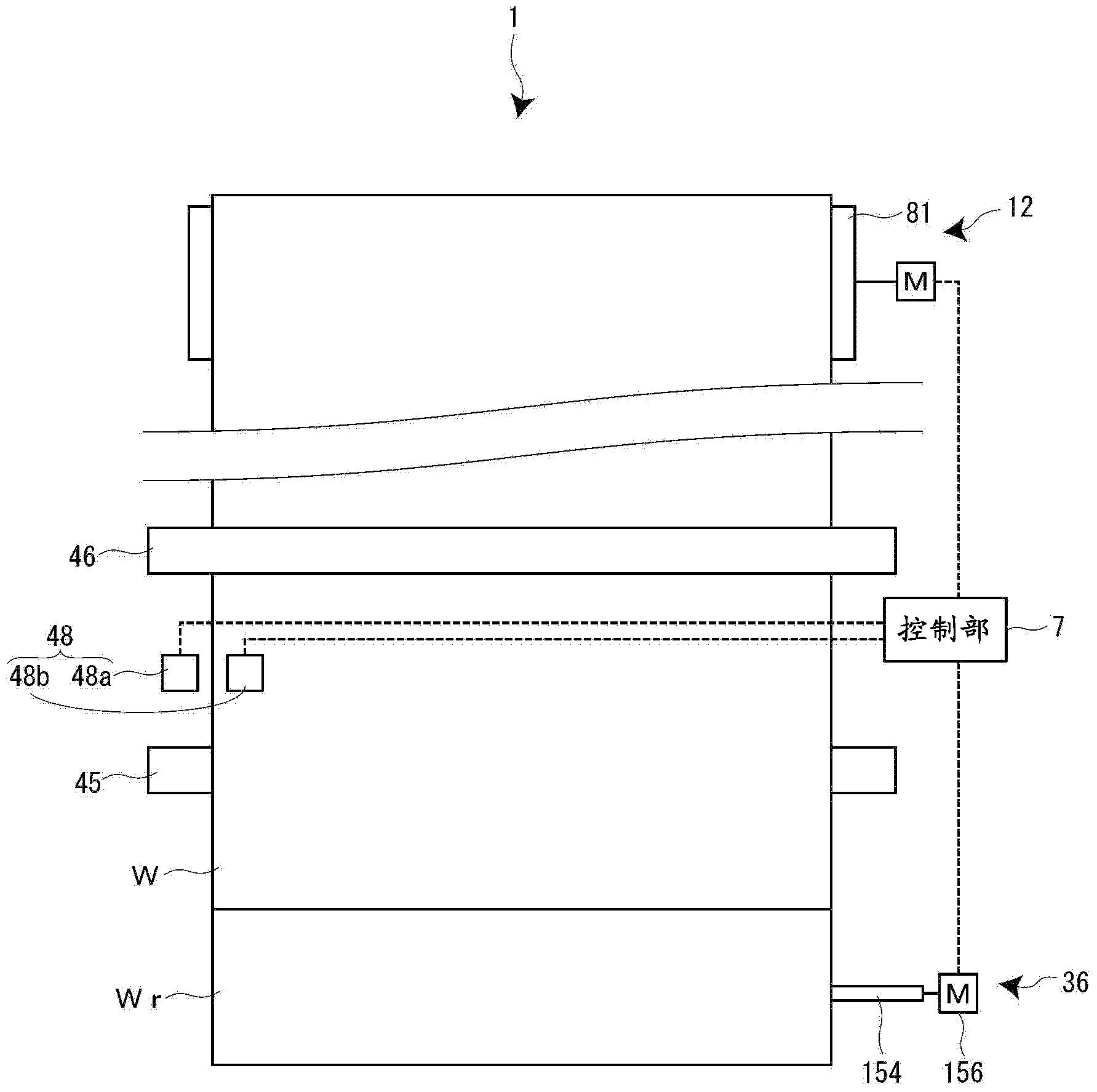

[0024] Hereinafter, an ink jet recording apparatus 1 according to an embodiment of the present invention will be described with reference to the drawings. The ink jet recording apparatus 1 uses a special dye ink to ink-jet print characters and patterns (printing) on a fabric that feeds and receives a material in a so-called reel to reel format. In the following description, the forward and reverse conveyance direction of the recording medium W as a fabric is defined as the X-axis direction, the direction orthogonal to the X-axis direction is defined as the Y-axis direction, and the X-axis direction and The direction of the Y-axis direction is defined as the Z-axis direction.

[0025] figure 1 It is a cross-sectional configuration diagram of the ink jet recording apparatus 1 . As shown in the figure, the inkjet recording apparatus 1 includes a discharge unit 2 that discharges and conveys a recording medium W wound in a roll shape, and an apparatus main body 4 that conveys t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com