Method for Predicting Mechanical Properties of Tire on Flat Pavement Based on Drum Test Rig Test Data

A technology of test data and drum test, applied in the direction of automobile tire testing, etc., can solve the problems of lateral force, unaligning torque, difficult conversion, complicated relationship, etc., and achieve the effect of accurate tire finite element model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

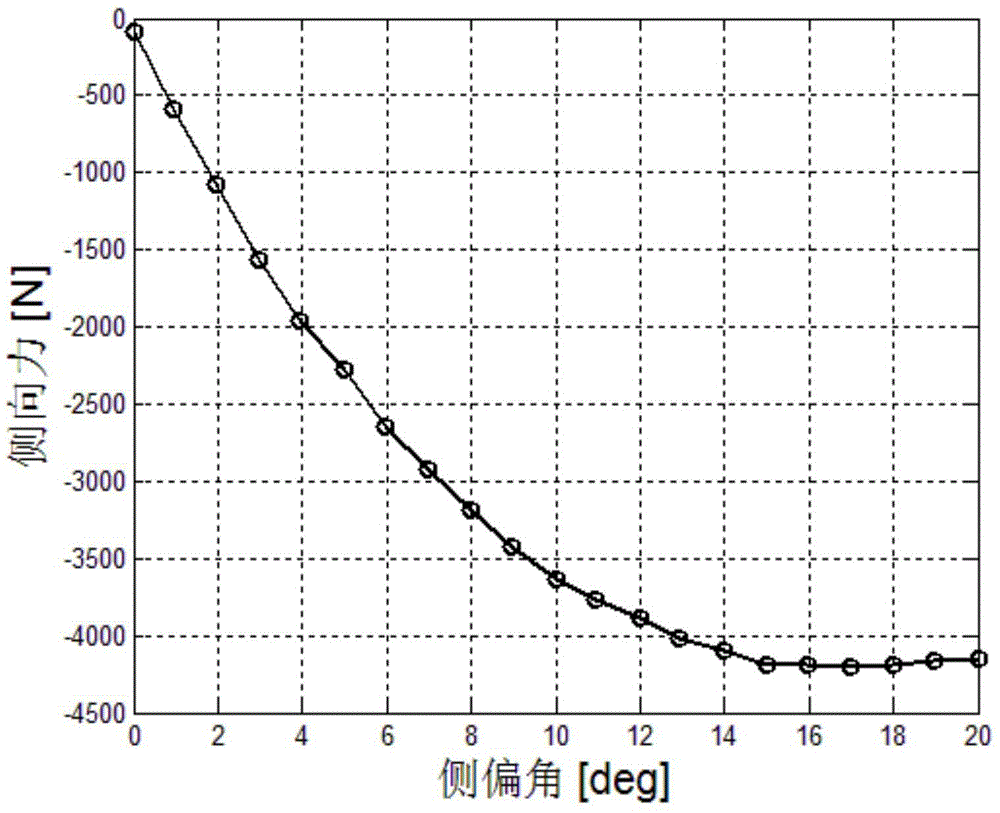

[0039] Predict the mechanical properties of a radial tire on a flat road surface under the conditions of load 6000N, tire pressure 760KPa, road surface friction coefficient u=0.85, rolling speed 0.15m / s, and side slipping.

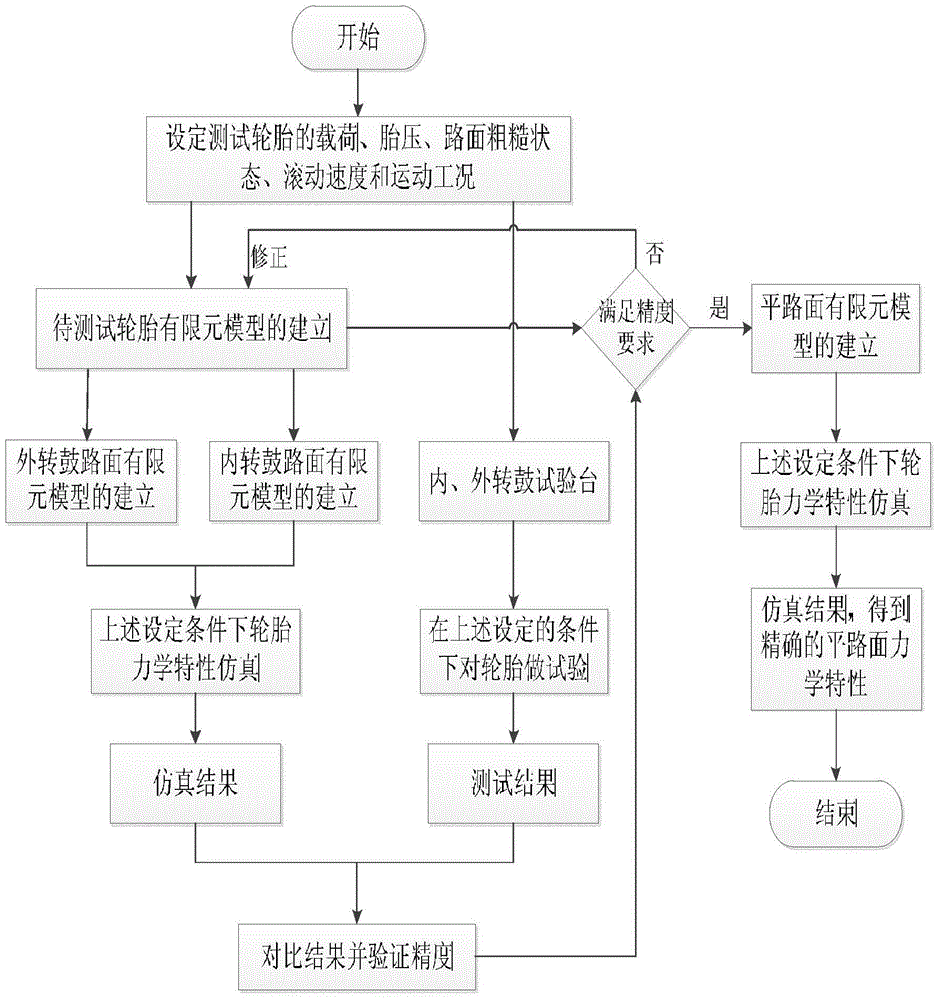

[0040] figure 1 It is an implementation flow chart of the prediction method of the present invention. The implementation process of the method for predicting the tire flat road mechanical properties based on the drum test bench test data provided by the present invention will be specifically described below with a tire example.

[0041] Step 1: Set the test tire load to be 6000N, tire pressure to 760KPa, road surface friction coefficient to 0.85, rolling speed to 0.15m / s, and the motion condition to be the sideways condition when the mechanical properties of the flat road surface to be predicted are set. The tests and simulations in the following steps are all implemented under this set condition;

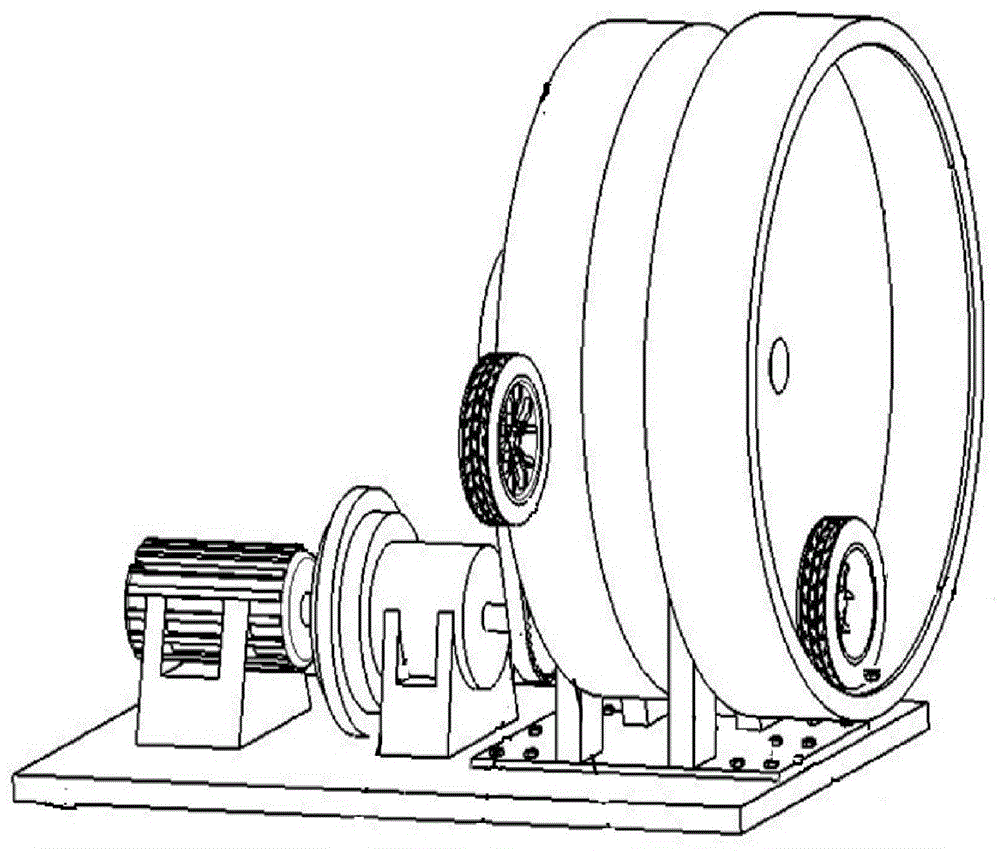

[0042] The second step: using the figure 2 The tire in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com