Patents

Literature

32results about How to "Reliable Correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser projector

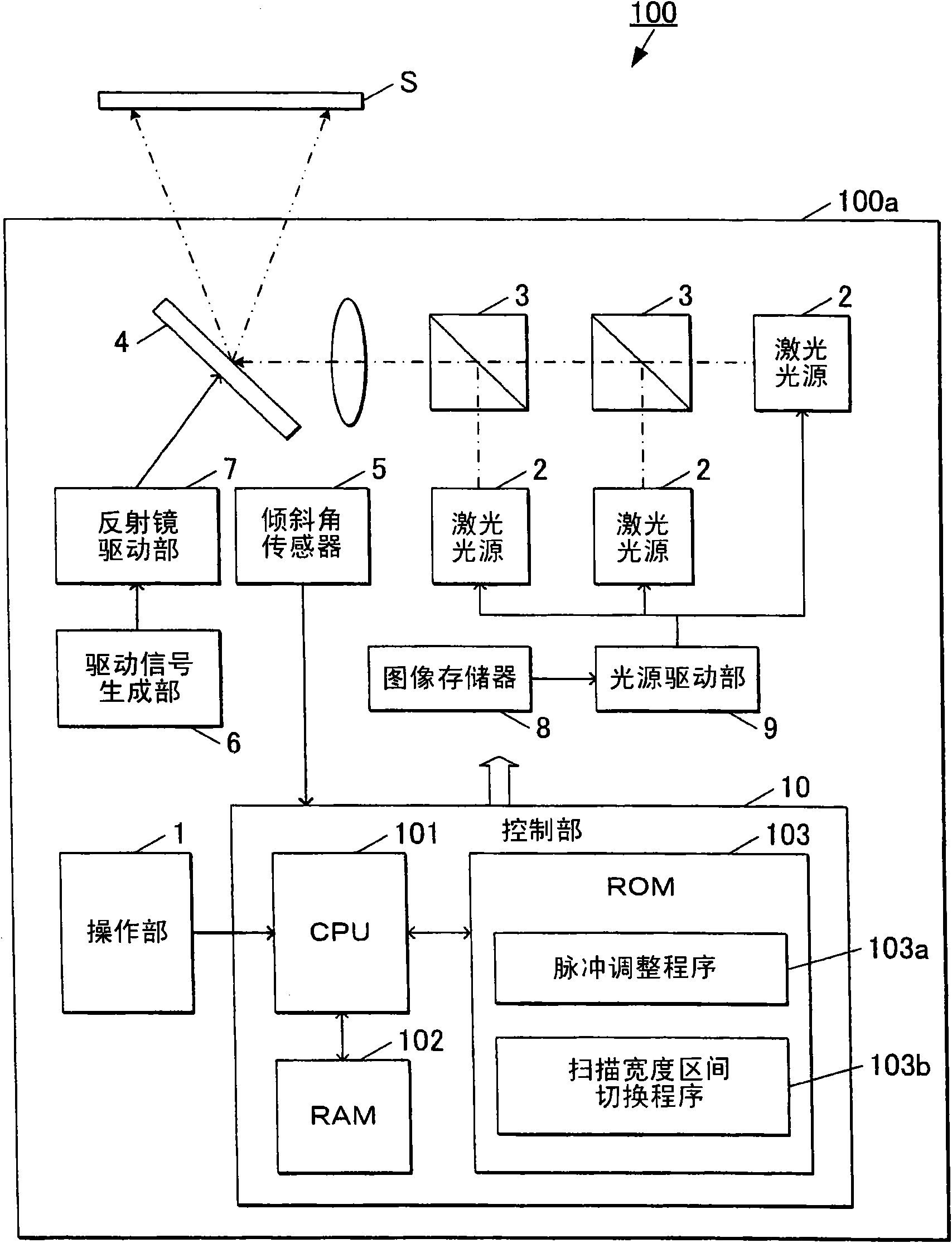

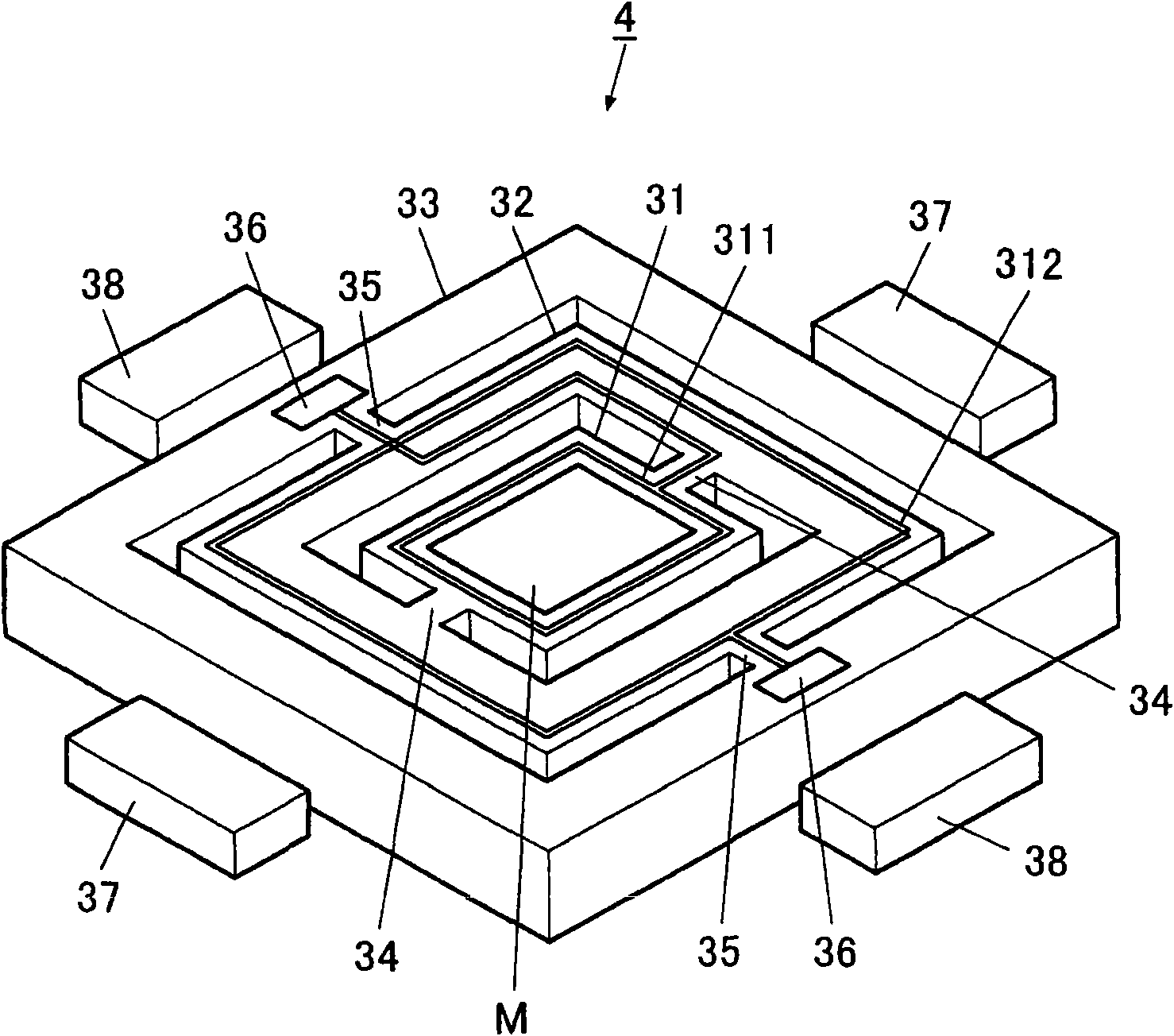

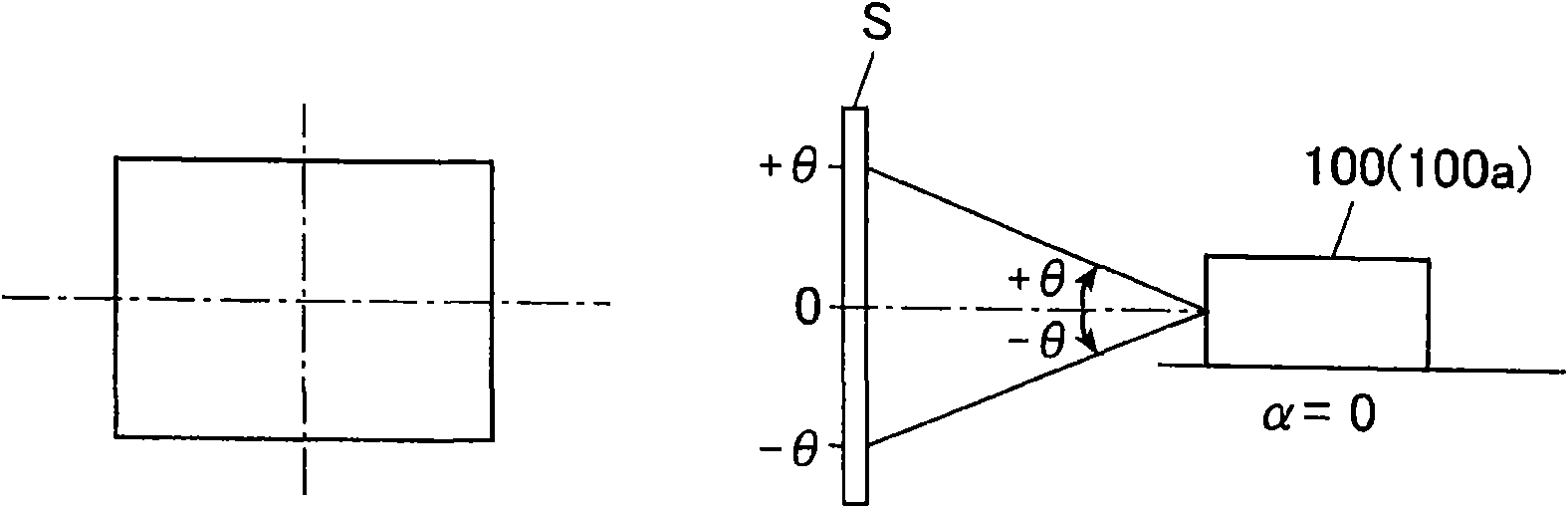

InactiveCN101876778AReliable CorrectionProjectorsColor television detailsProjection screenProjection image

The invention provides a laser projector capable of more reliably correcting the projection image. The laser projector (100) adjusts the left-right swing width of an electromagnetic drive type scan mirror (4) from the first swing width to the second swing width in a projection interval (a) for forming the image on a projection screen (S), thus the projection image on the projection screen (S) is corrected into a rectangle. Especially after moving to a later-state interval (b2) before the projection interval (a) for projecting the image on the projection screen (S), the left-right swing width of the electromagnetic drive type scan mirror (4) is kept be the first swing width corresponding with the width at the initial end of the projection interval (a), the left-right swing width of the electromagnetic drive type scan mirror (4) is easily adjusted from the first swing width to the second swing width to project the corrected image, thus image is more reliably corrected and projected.

Owner:FUNAI ELECTRIC CO LTD

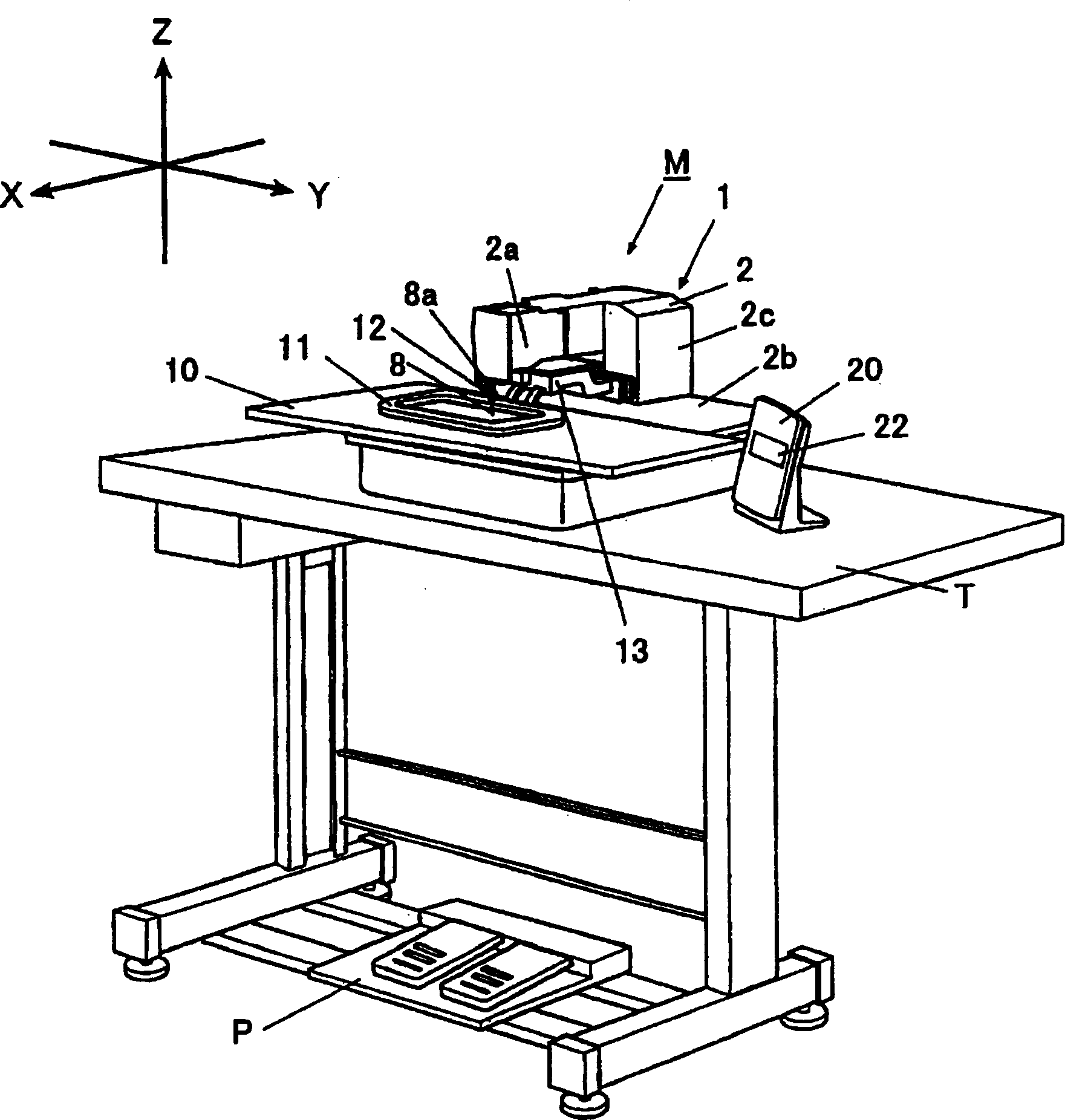

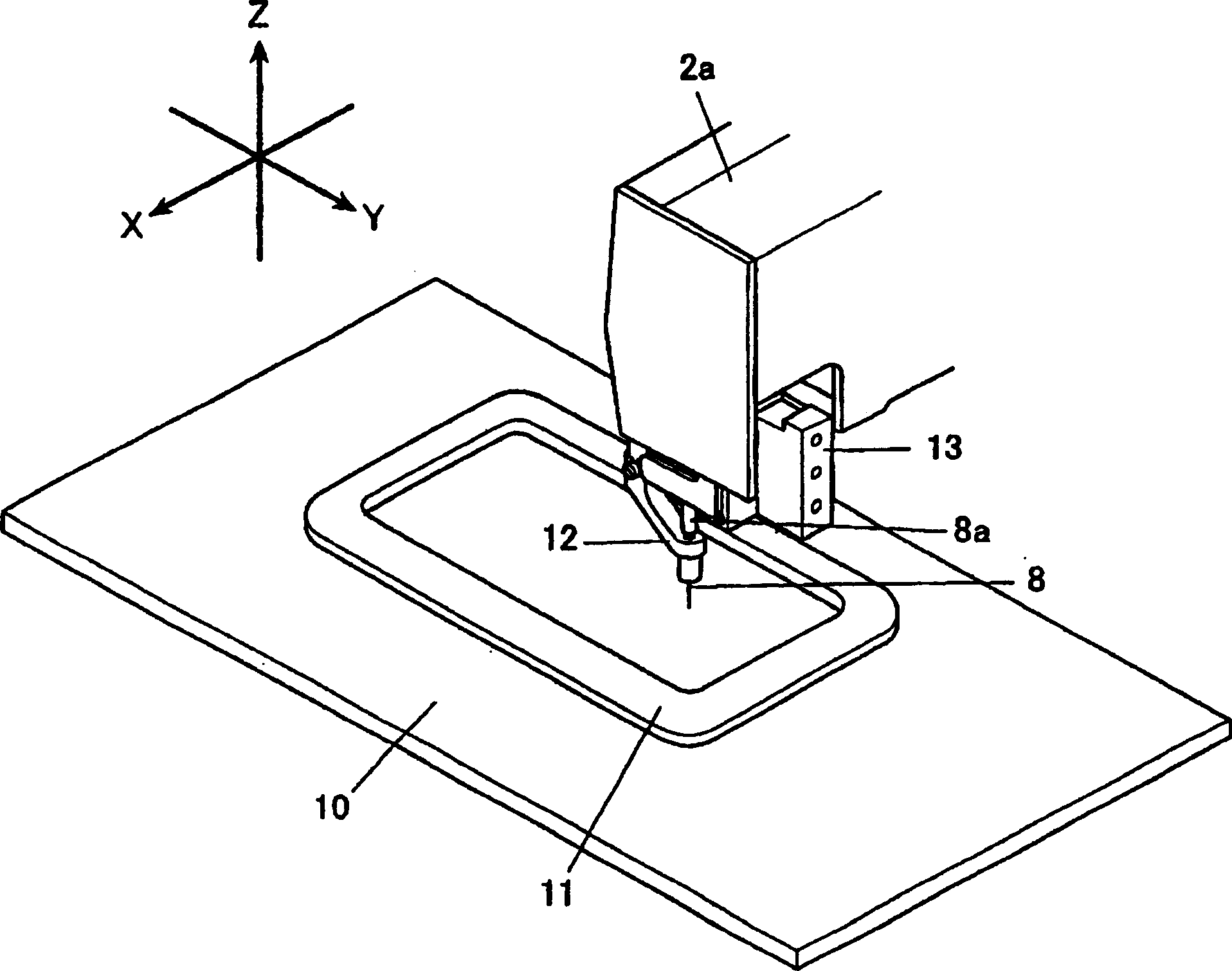

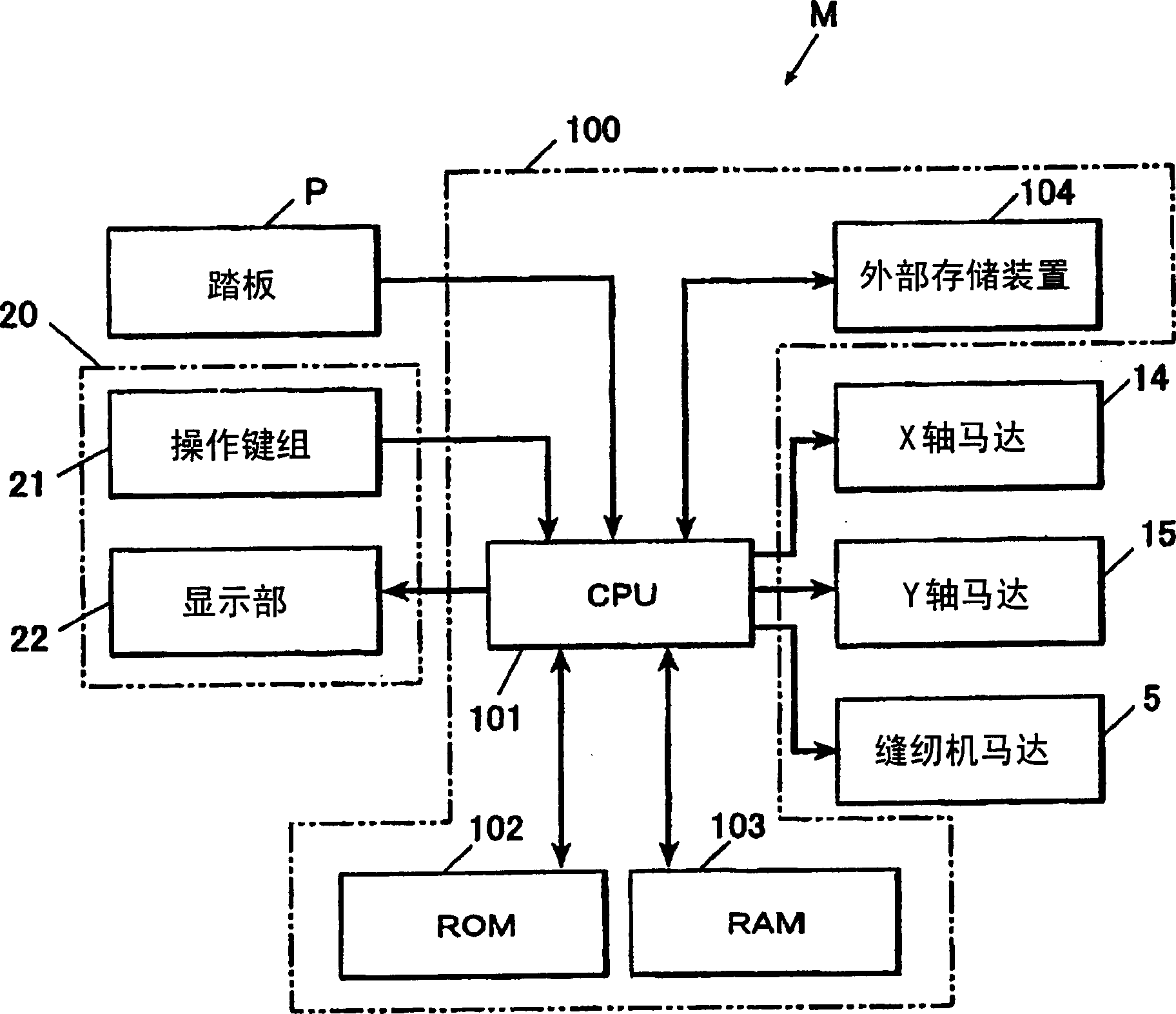

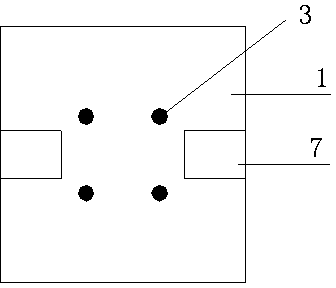

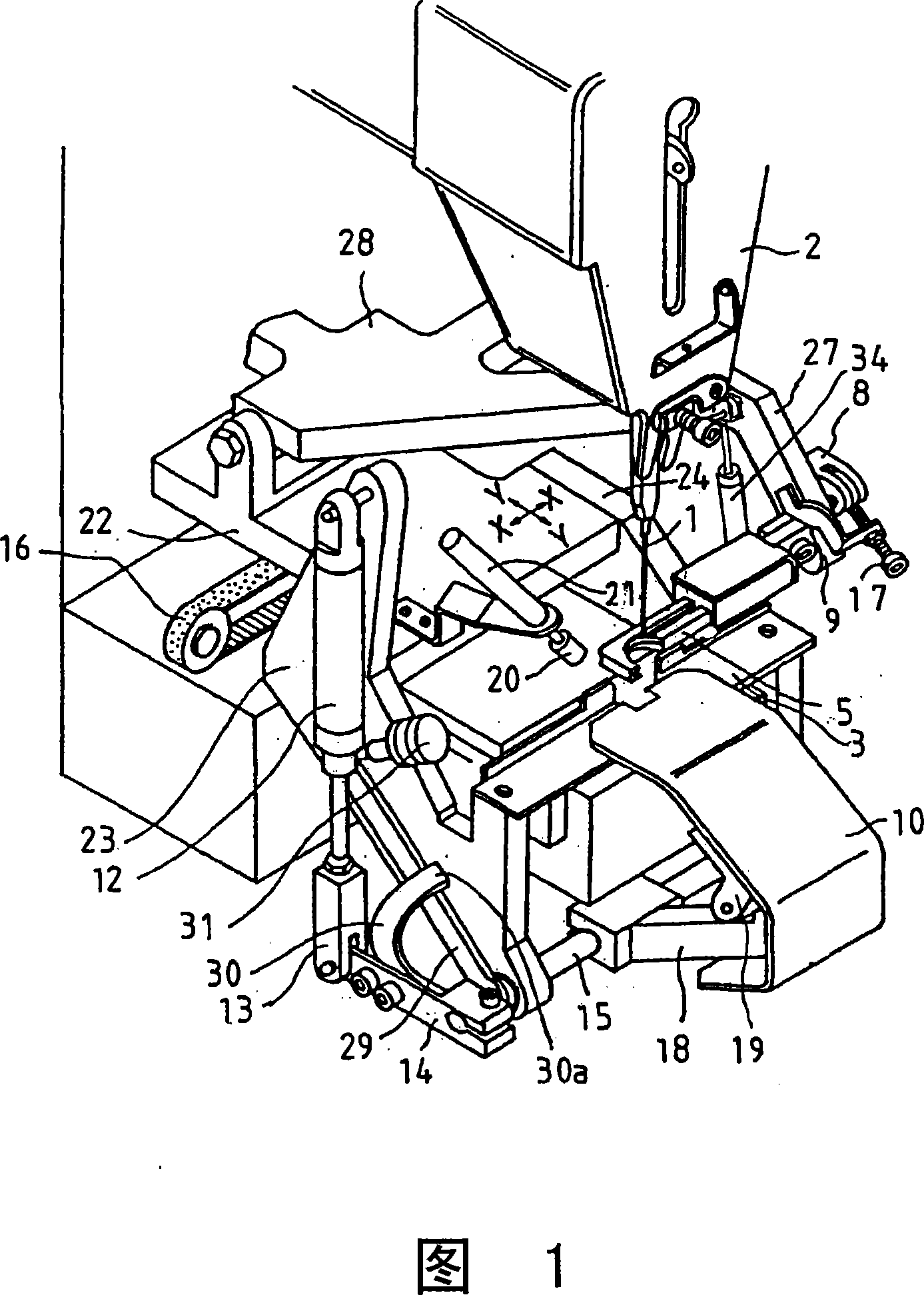

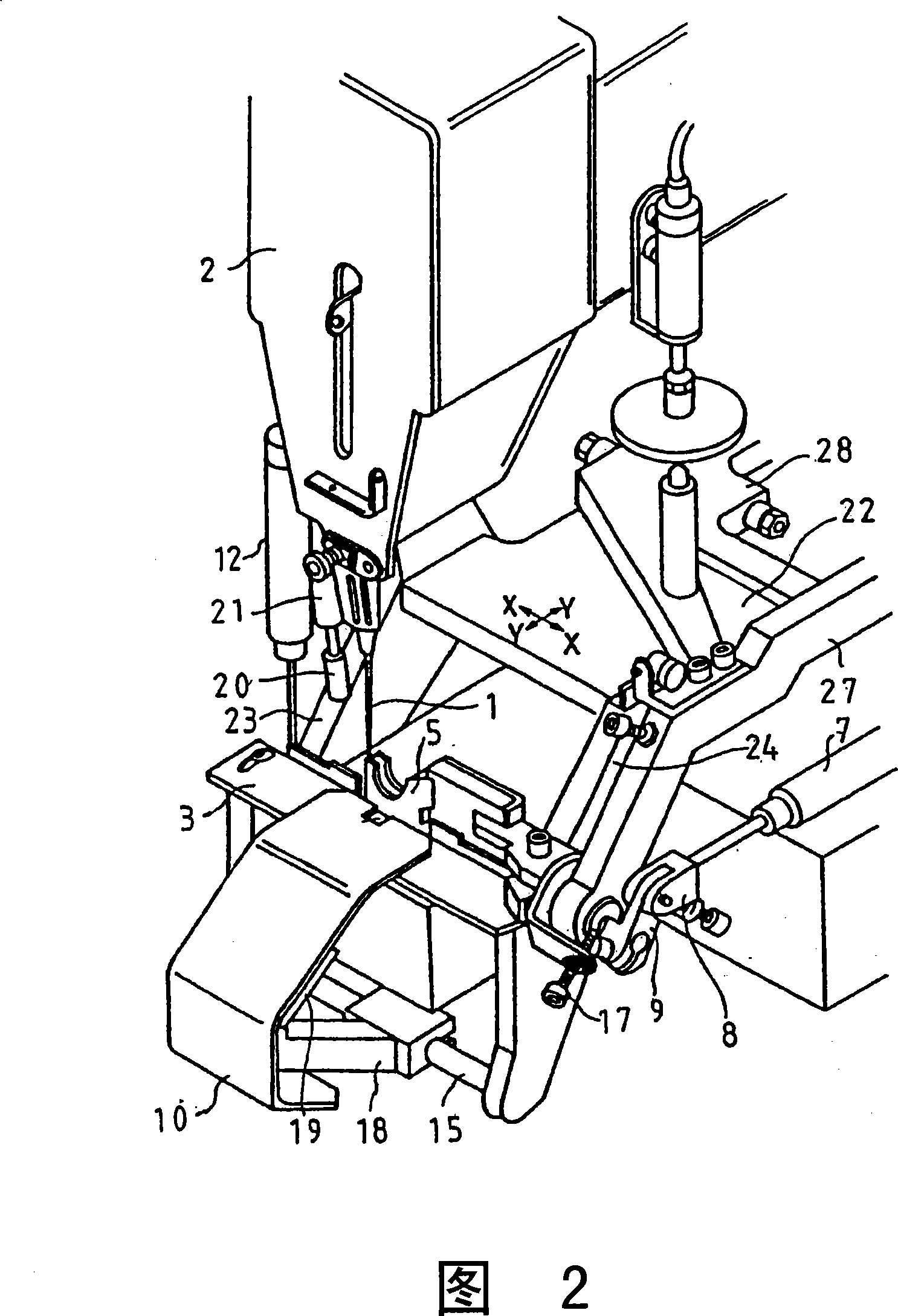

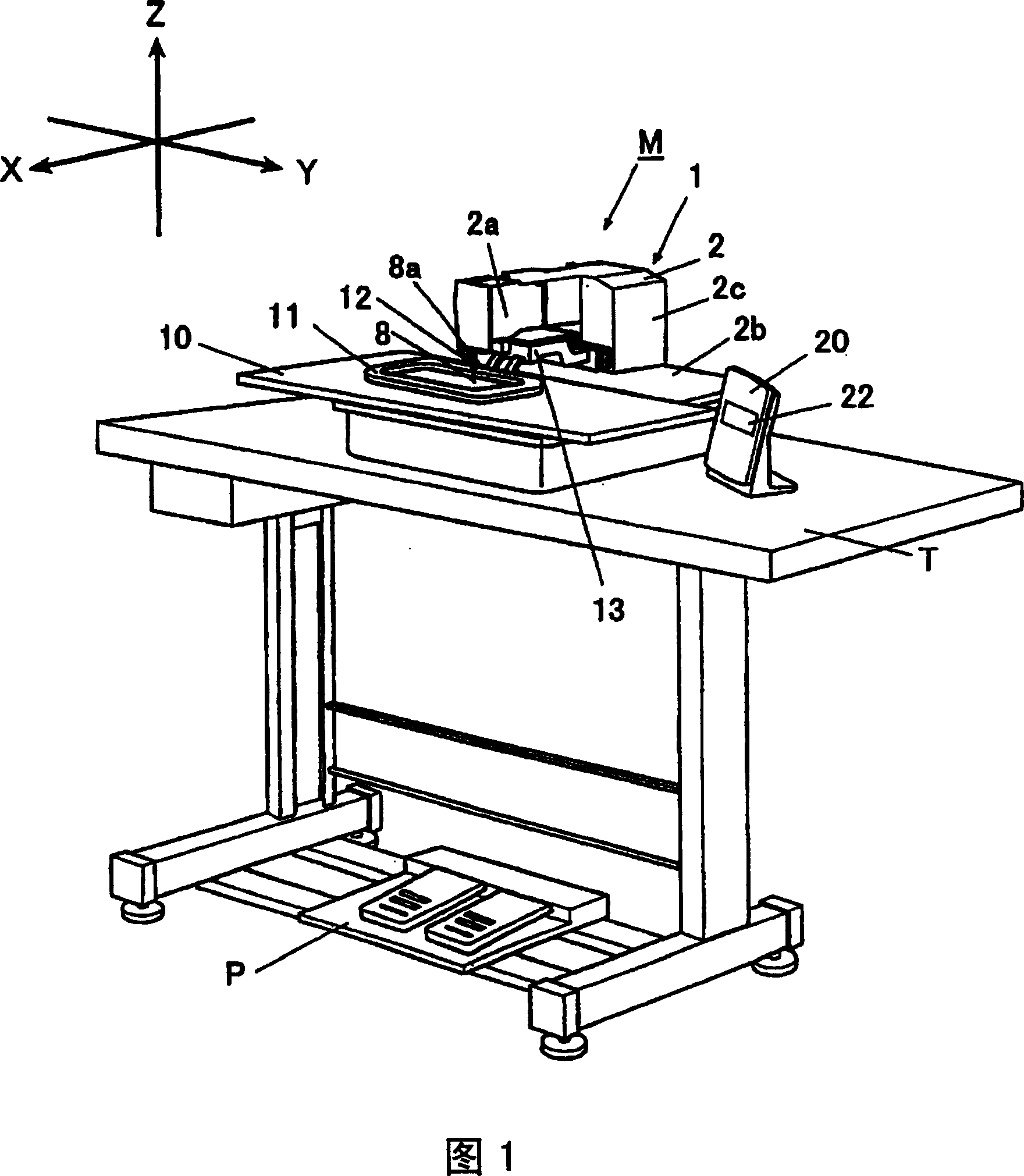

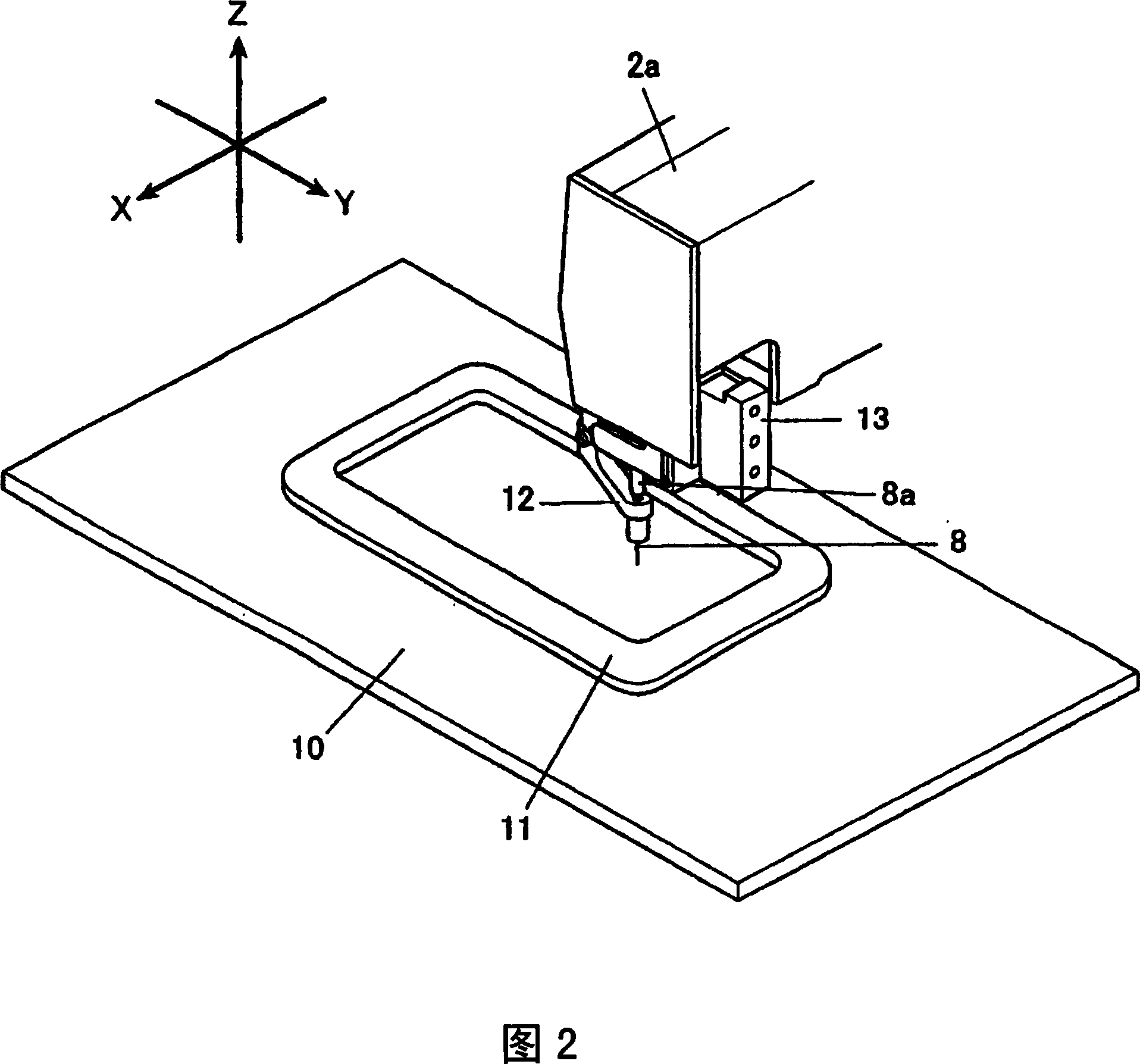

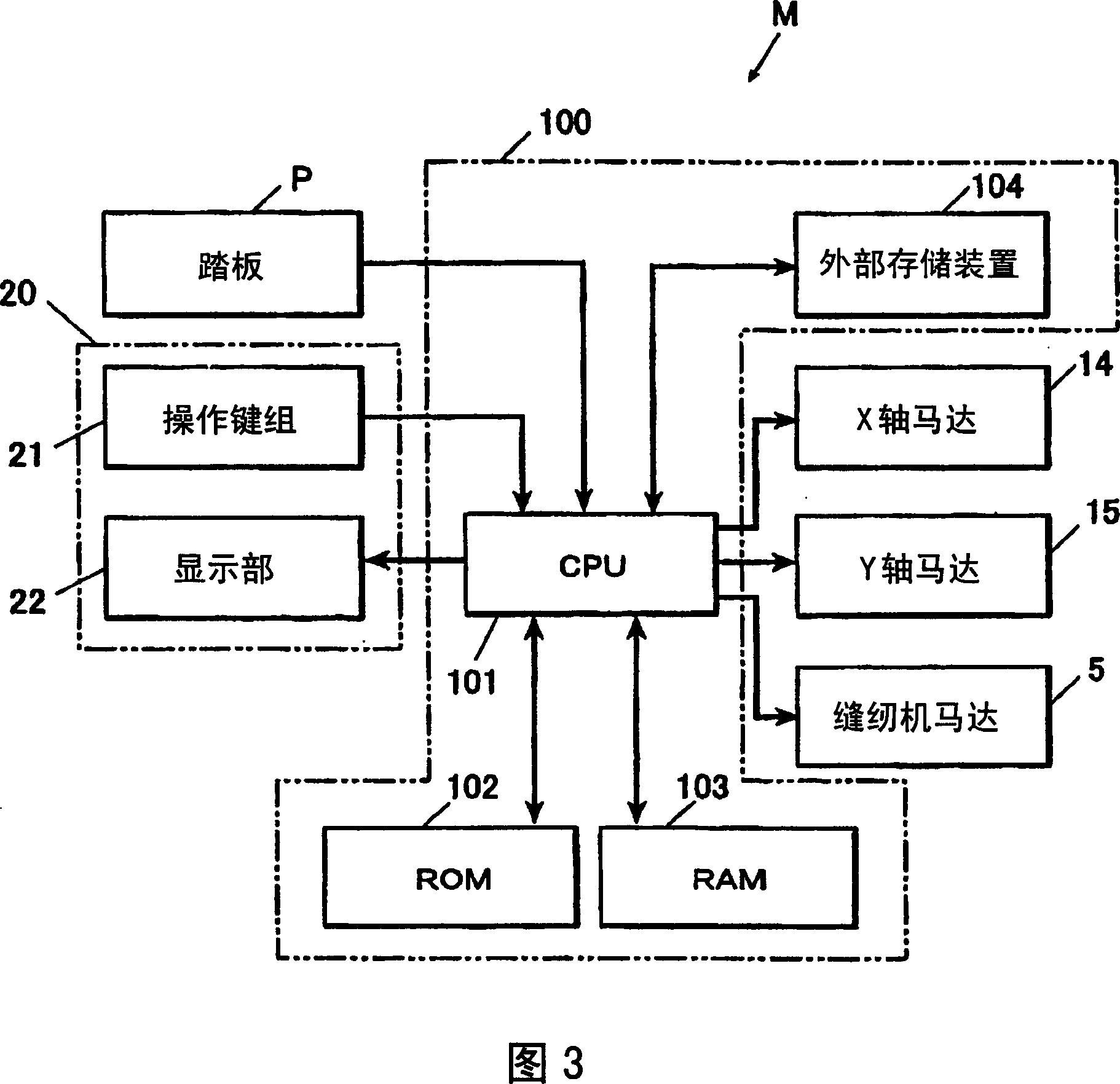

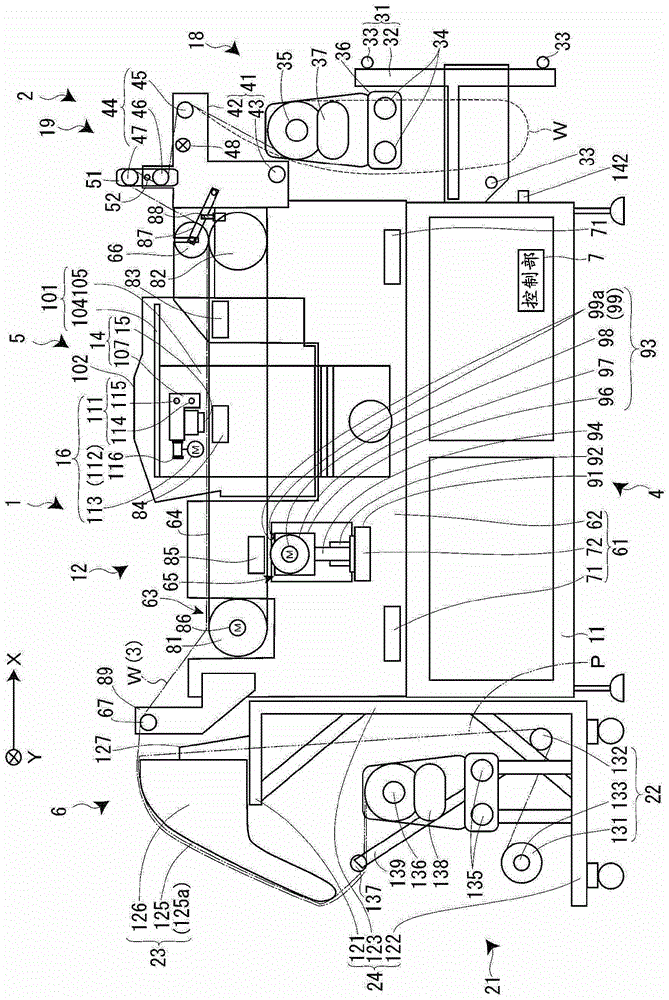

Sewing machine

ActiveCN1807737AEasy to judge and displayReliable inputProgramme-controlled sewing machinesOther angling devicesEngineeringData entry

Disclosed is a sewing machine, characterized in that when the area facing the inner side of the sewing machine(M), which is provided with a retainer frame(11) is kept on the sewing target object, the needle(8) of the sewing machine drops, forming stitches; the coordinate data corresponding to the positions of the stitches are inputted into the sewing machine(M) and then judgment of whether the coordinate data is contained in the prearranged coordinate data corresponding to the sewable area is carried out and then the judgment result is displayed in a displayer in different modes with respect to whether the coordinate data is contained in the prearranged coordinate data or not. Therefore, the sewing machine of the invention is easy to tell the data regarding the sewing of the sewing machine and to tell whether the data are effective for sewing.

Owner:JUKI CORP

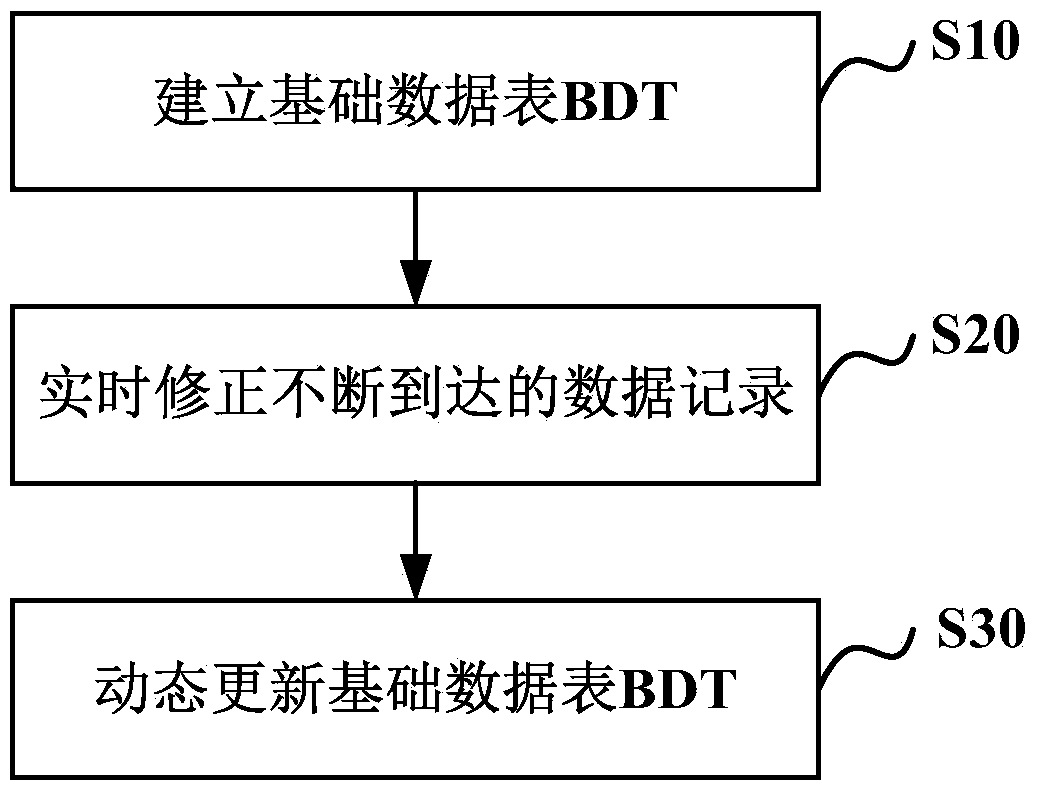

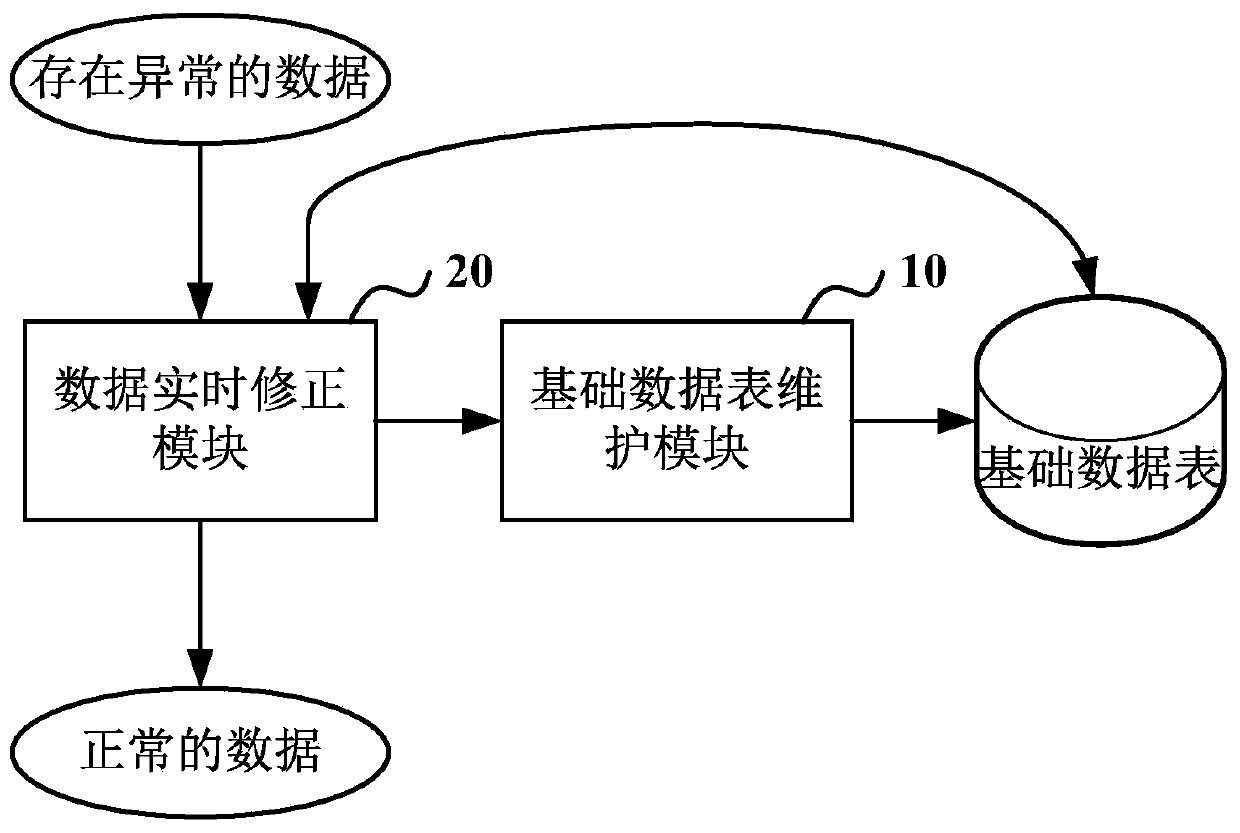

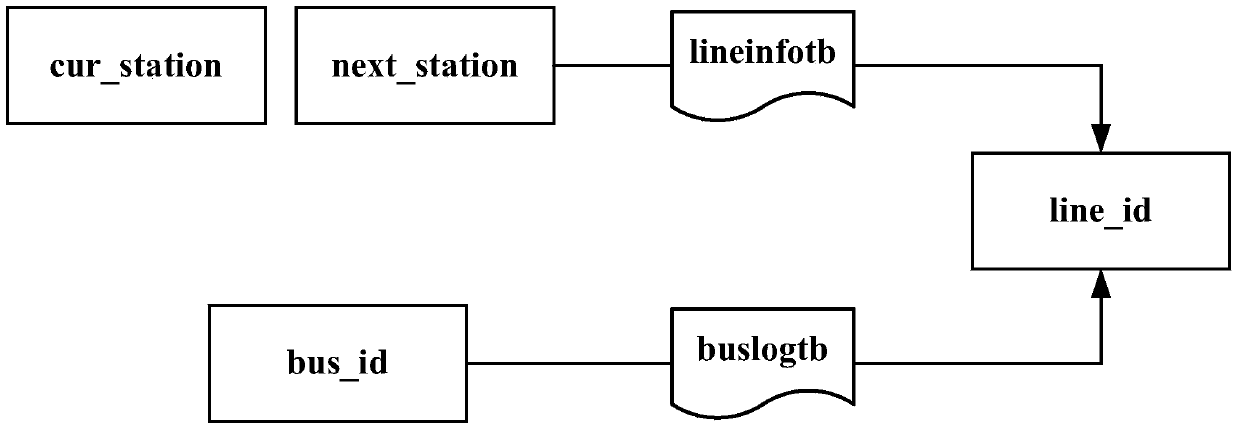

Bus real-time geographic information data cleaning method and system

InactiveCN103699680AReal-time correctionEasy to cleanMultiprogramming arrangementsGeographical information databasesReal-time dataInformation data

The invention relates to the technical field of intelligent buses and provides a bus real-time geographic information data cleaning method and system. The method includes: under an initial state, building a basic data table according to real-time data; correcting data records arriving continuously in real time according to the basic data table; dynamically updating the basic data table; wherein the basic data table saves the historical information of various data records in real-time data. By the method, reliable and real-time cleaning of the real-time bus geographic information data is achieved, and foundation is laid on bus data real-time calculation.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +2

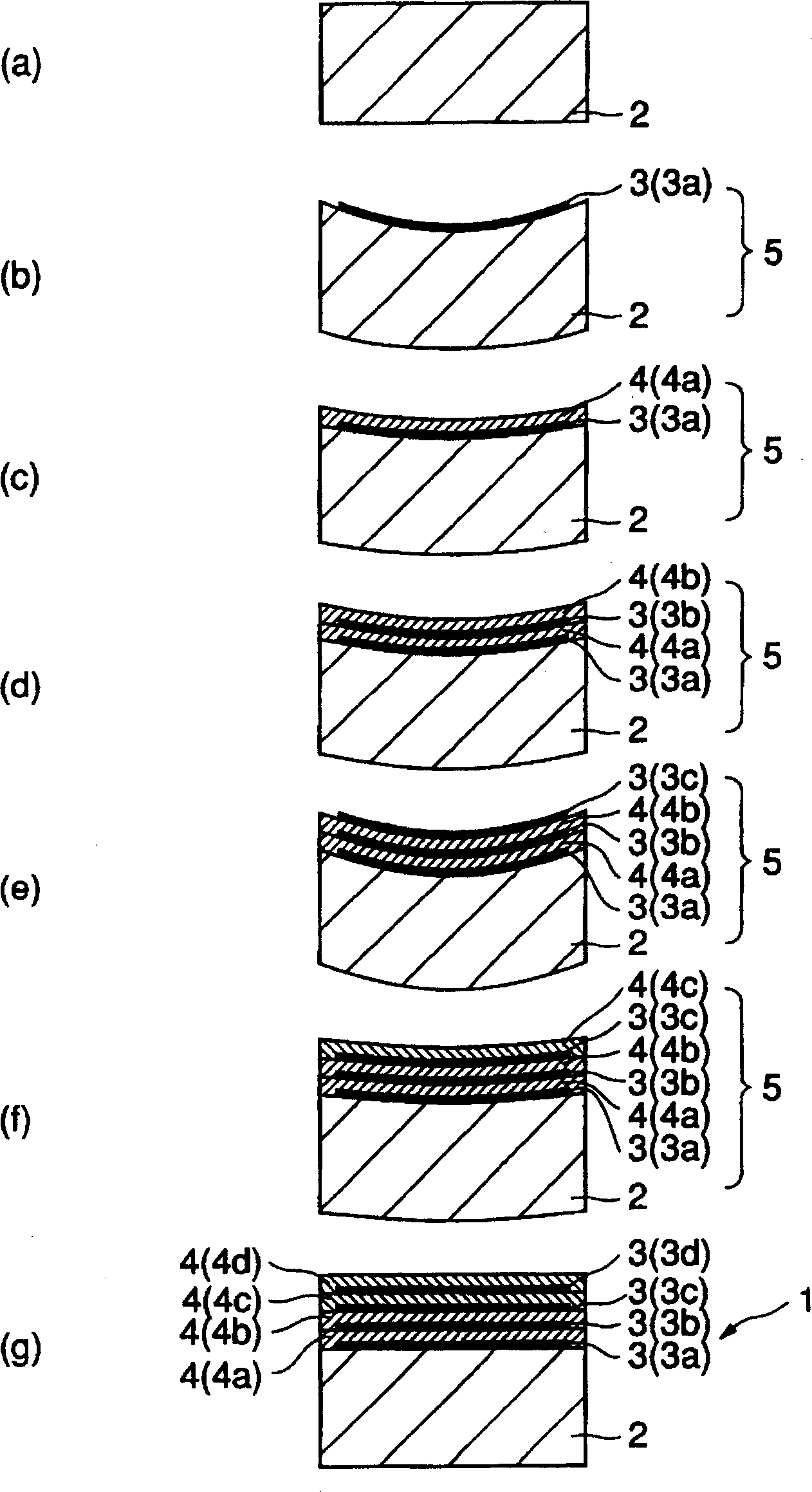

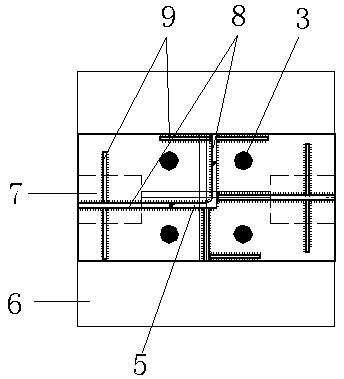

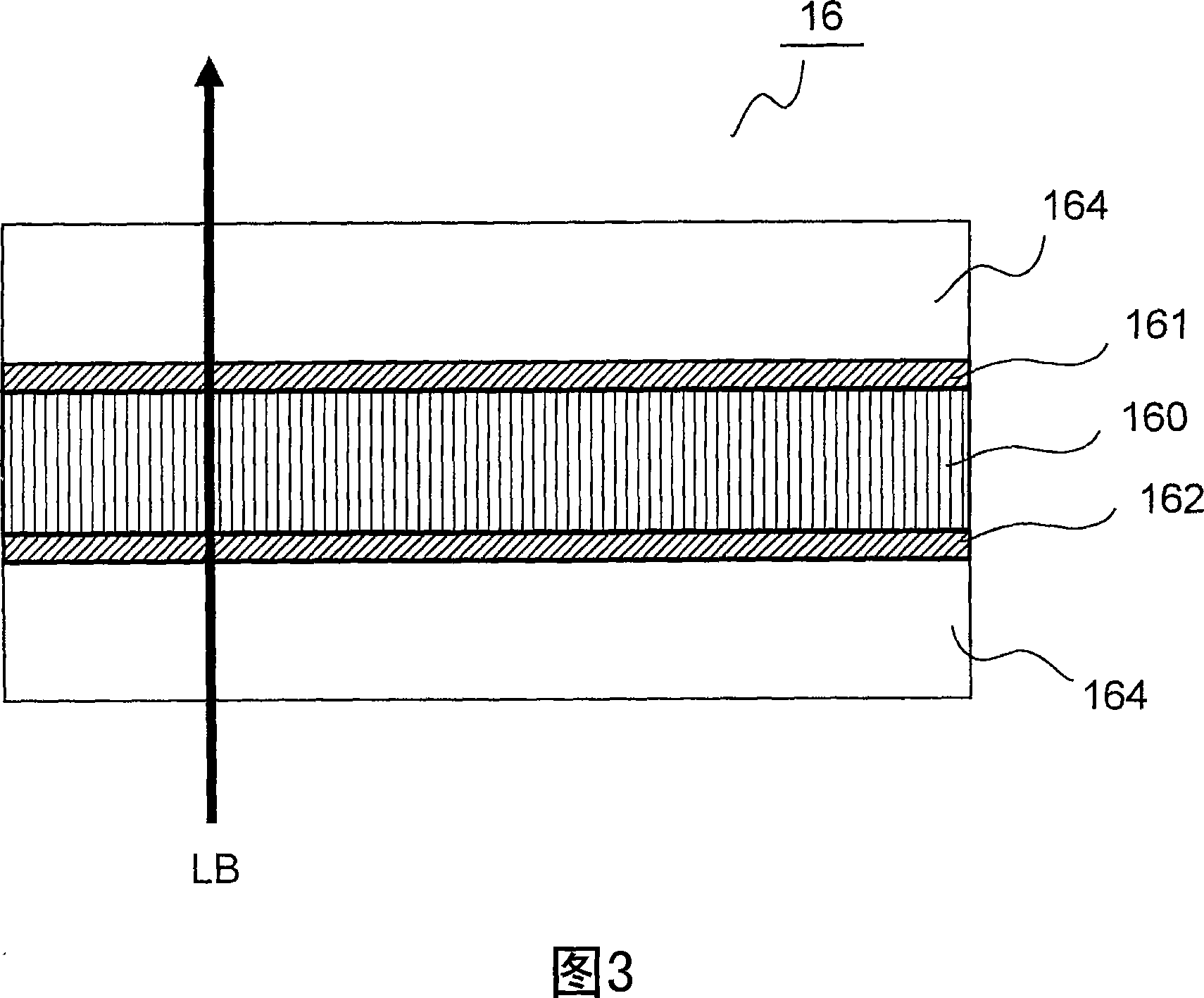

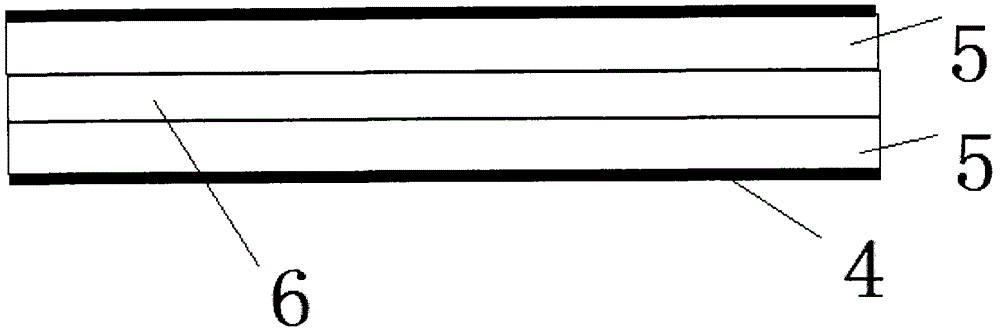

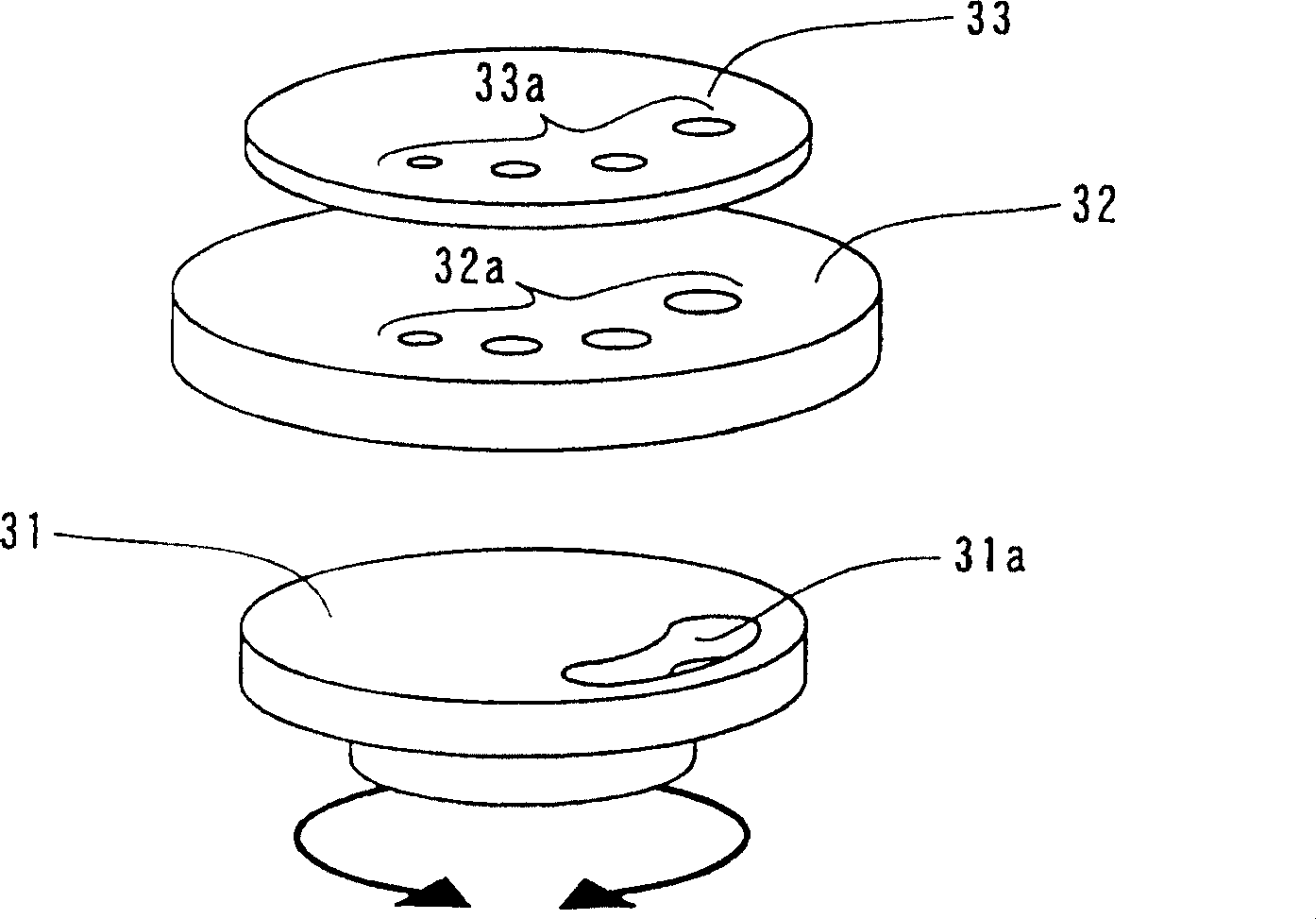

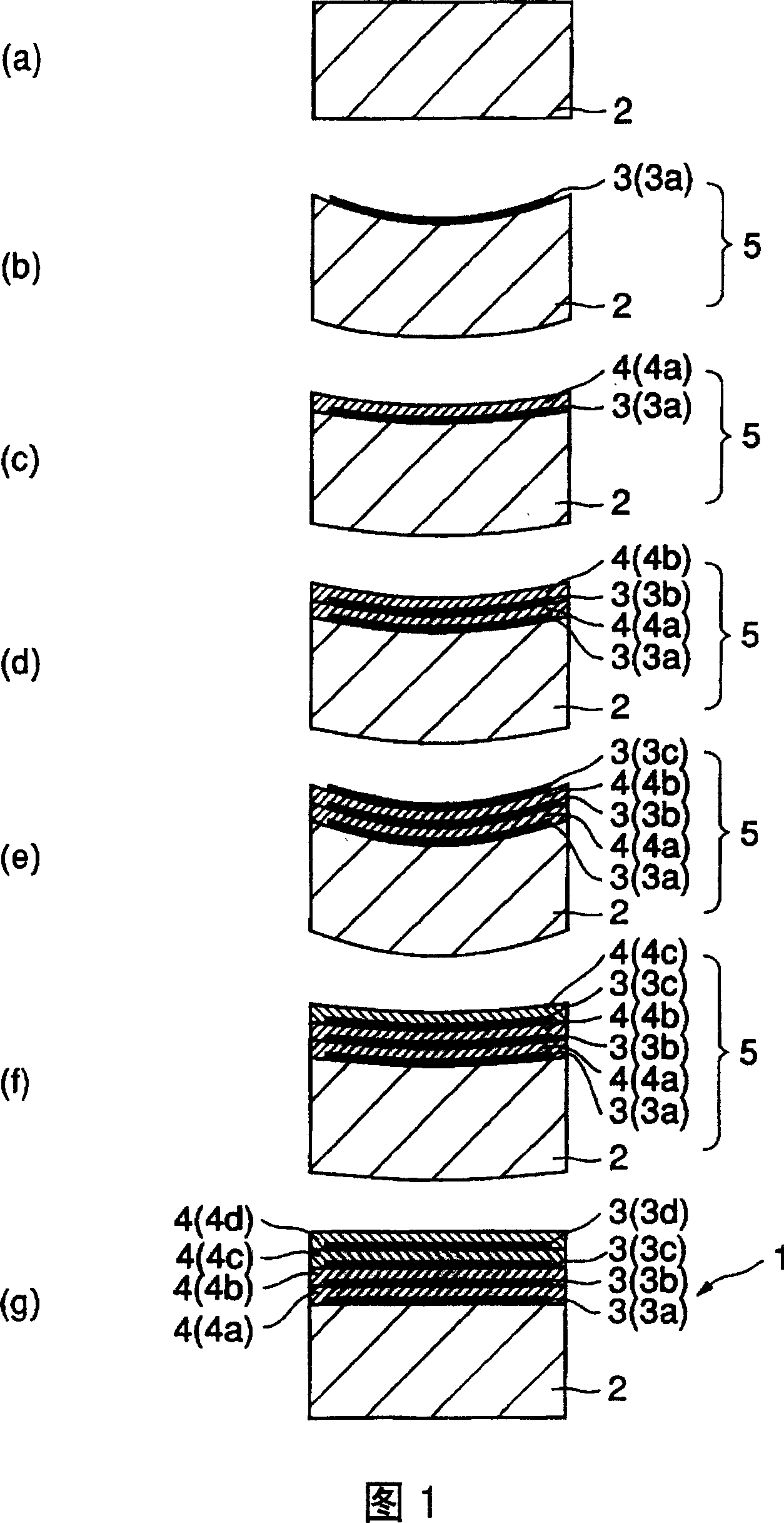

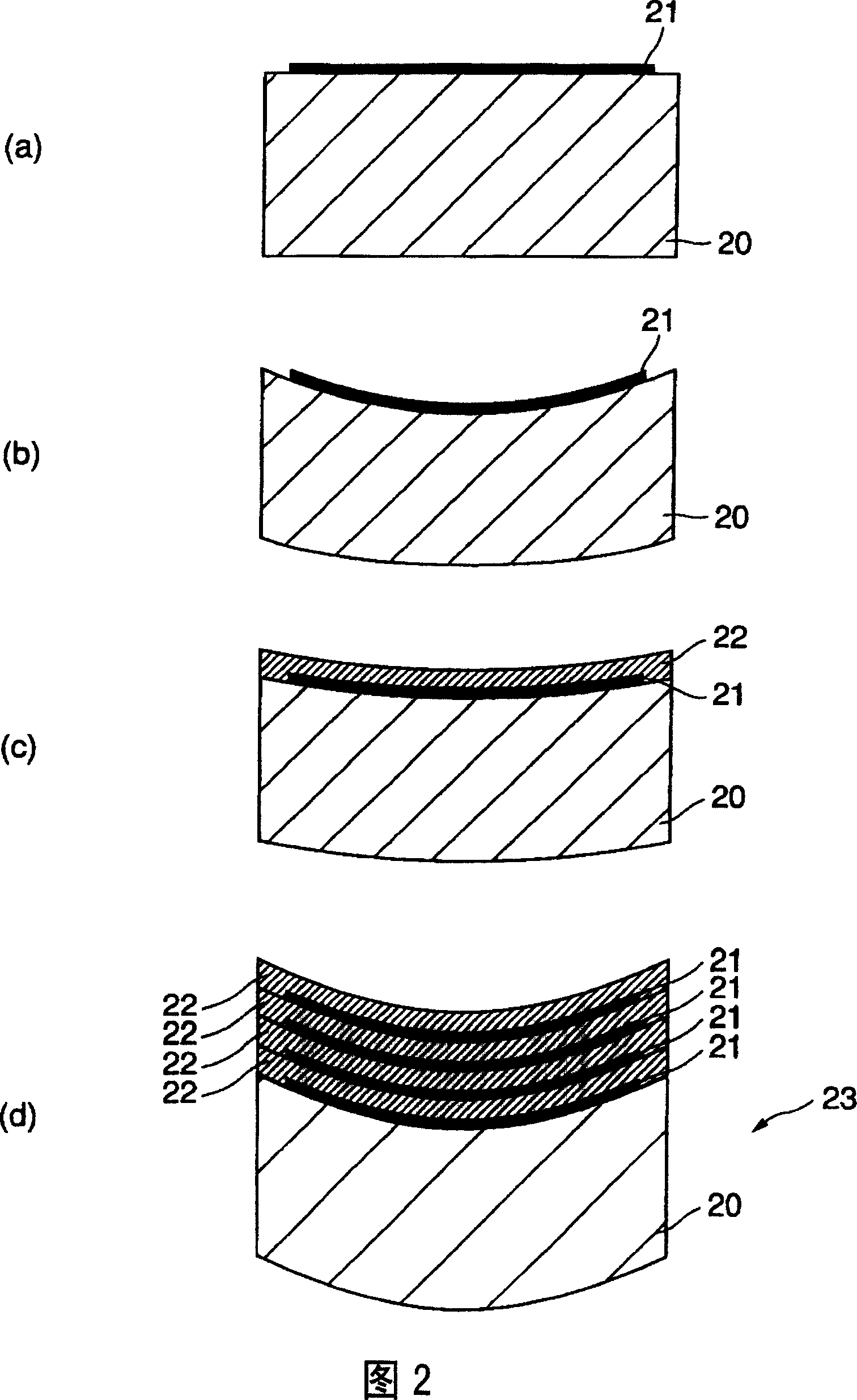

Multi-layer structure unit and its manufacturing method

ActiveCN1498059AReliable CorrectionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

The purpose of the present invention is to correct the warpage of multilayer composite 5 in the process of alternatively forming conductor pattern 3 and insulation layer 4 on the insulation body substrate 2. In the process of alternatively forming conductor pattern 3 and insulation layer 4 on the insulation body substrate 2, the constituting material of the insulation layer is modified to be the other insulation material which can correct the warpage of the multilayer composite 5 according to the predetermined schedule, or in the forming step to constitute the multilayer composite 5 by the insulation substrate 2, conductor pattern 3 and insulation layer 4. Thus, the insulation layer 4 is formed, and thereby the warpage of the multilayer composite 5 can be corrected with high accuracy.

Owner:MURATA MFG CO LTD

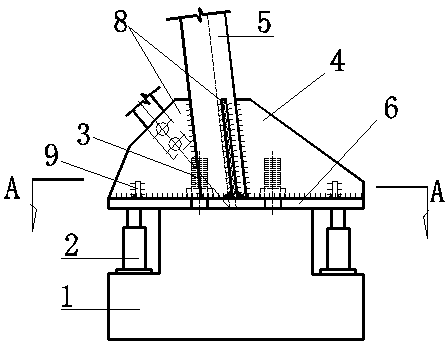

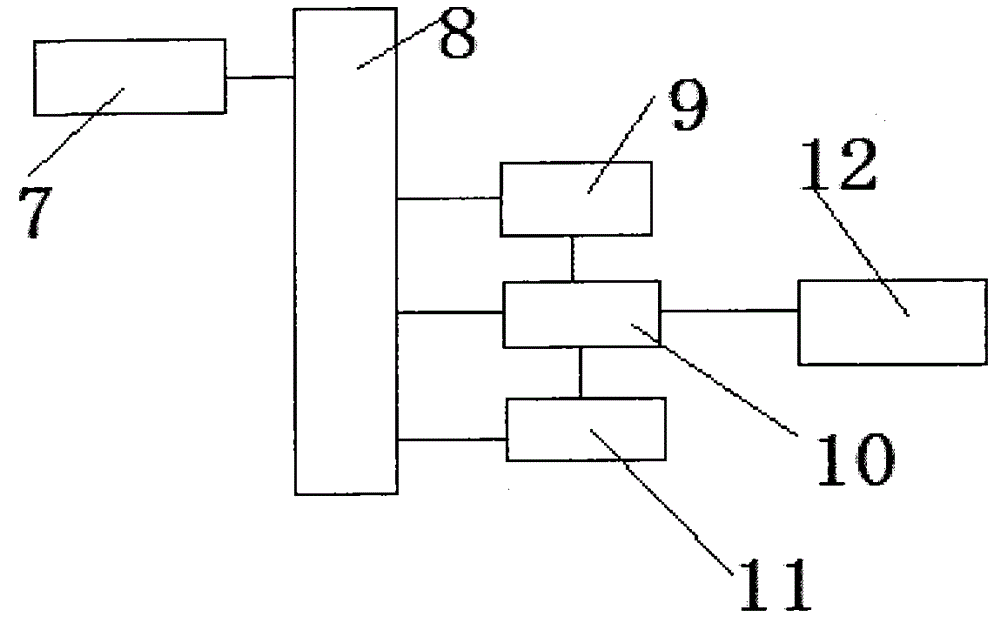

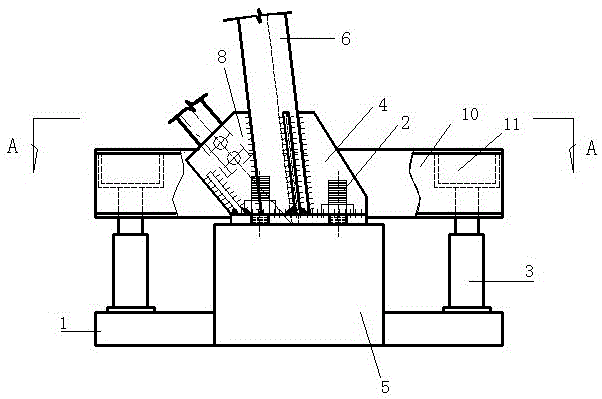

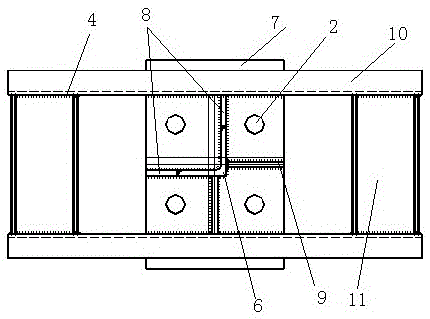

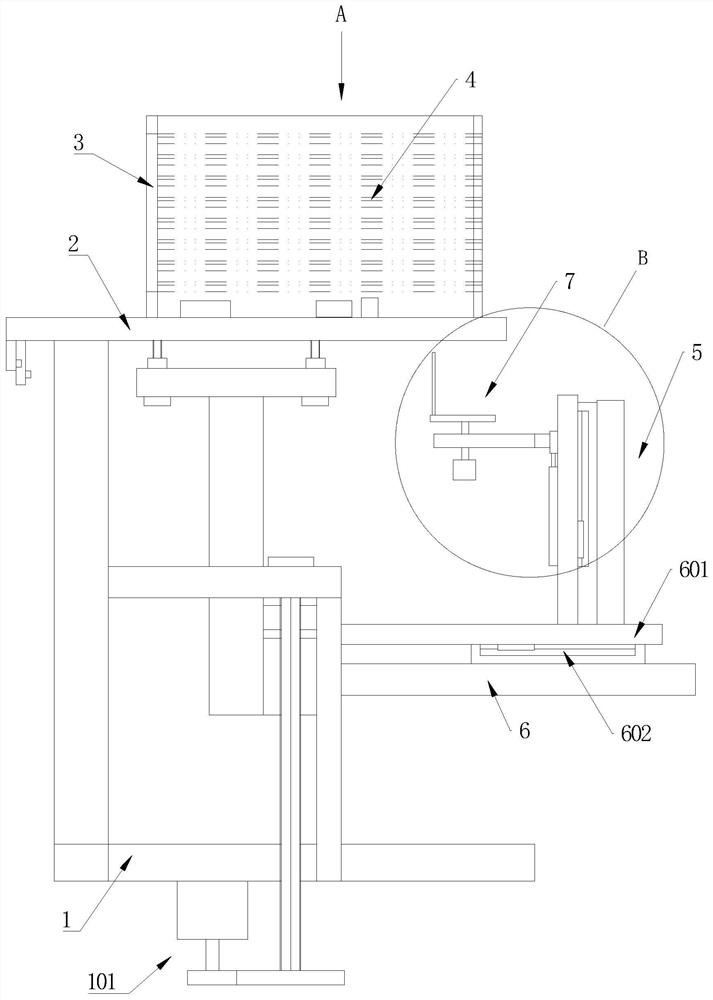

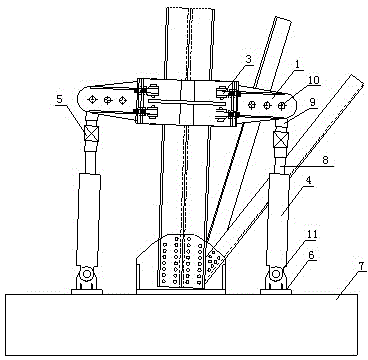

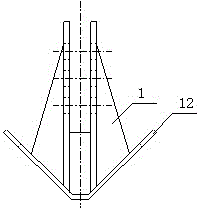

Jacking device for deviation rectification of steel pylon in mining area of coal mine

InactiveCN103669432ASafety CorrectionReliable CorrectionFoundation engineeringScrew threadStructural system

The invention discloses a deviation rectification device for a steel pylon, and particularly relates to a jacking device for deviation rectification of the steel pylon in a mining area of a coal mine. The jacking device for deviation rectification of the steel pylon in the mining area of the coal mine comprises an independent long-column concrete foundation (1), foundation bolts (3) and a pylon leg plate (4) capable of being jacked, wherein the pylon leg plate capable of being jacked (4) comprises a base plate (6) and a steel pylon principle material connecting plate (8) welded to the base plate (6), the steel pylon principle material connecting plate (8) is welded to a steel pylon principle material (5) along the edge, the base plate (6) of the pylon leg plate capable of being jacked (4) is connected with the independent long-column concrete foundation (1) through the foundation bolts (3), loading holes (7) used for installation of jacks (2) are formed in the independent long-column concrete foundation (1), and the length of exposed screw threads of each foundation bolt (3) is no smaller than 150mm. According to the structural system, the jacking device for deviation rectification of the steel pylon in the mining area of the coal mine is simple in structure, when the steel pylon inclines, the foundation bolts (3) are loosened, the jacks can be used for directly jacking the pylon leg plate capable of being jacked, and deviation rectification can be carried out.

Owner:STATE GRID CORP OF CHINA +2

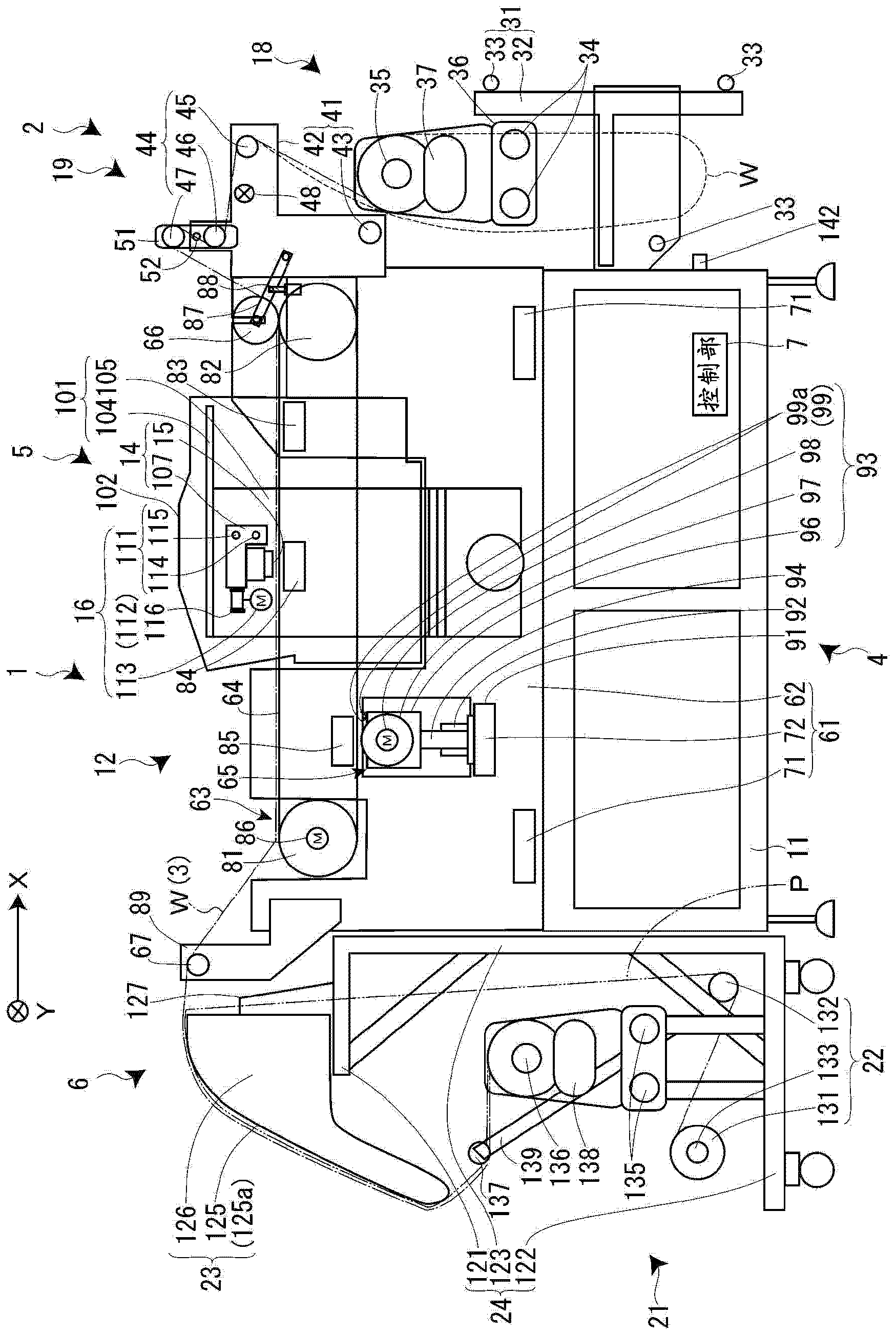

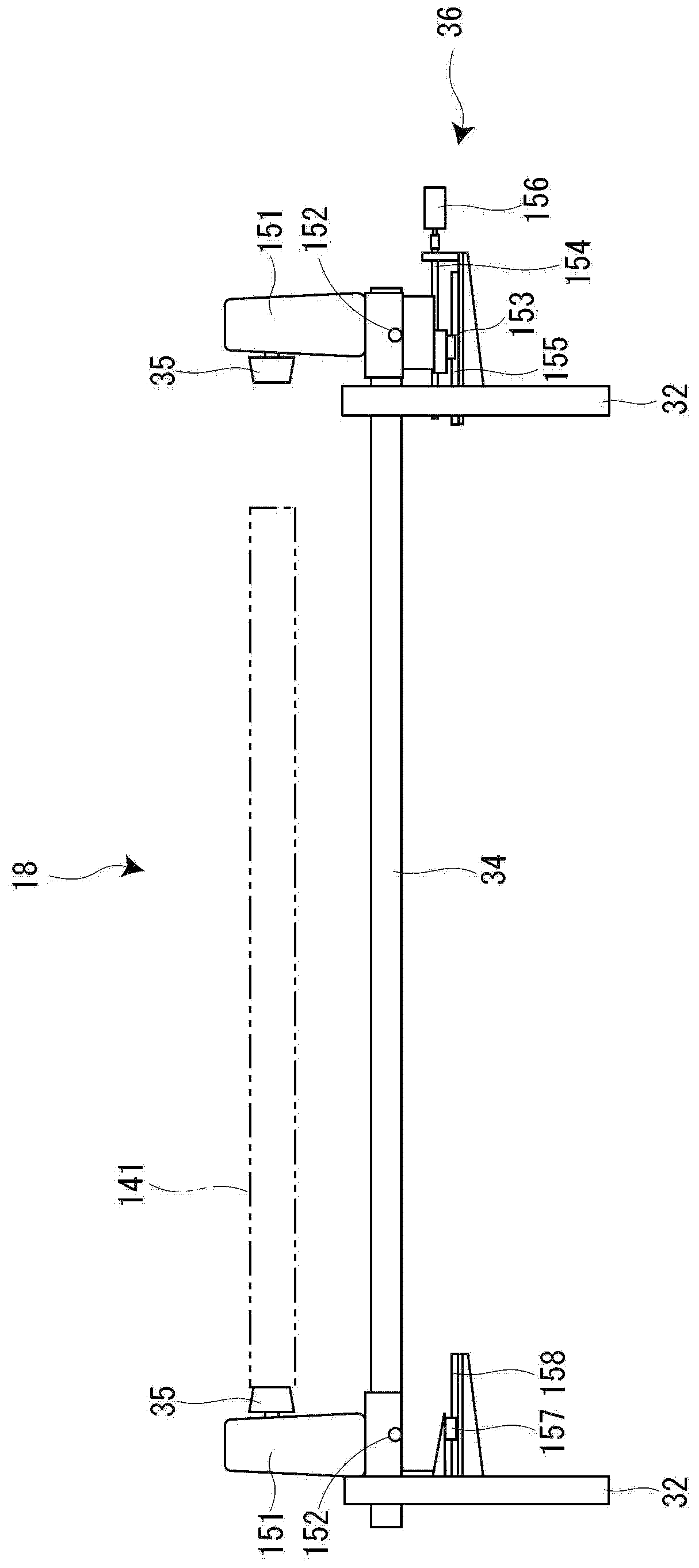

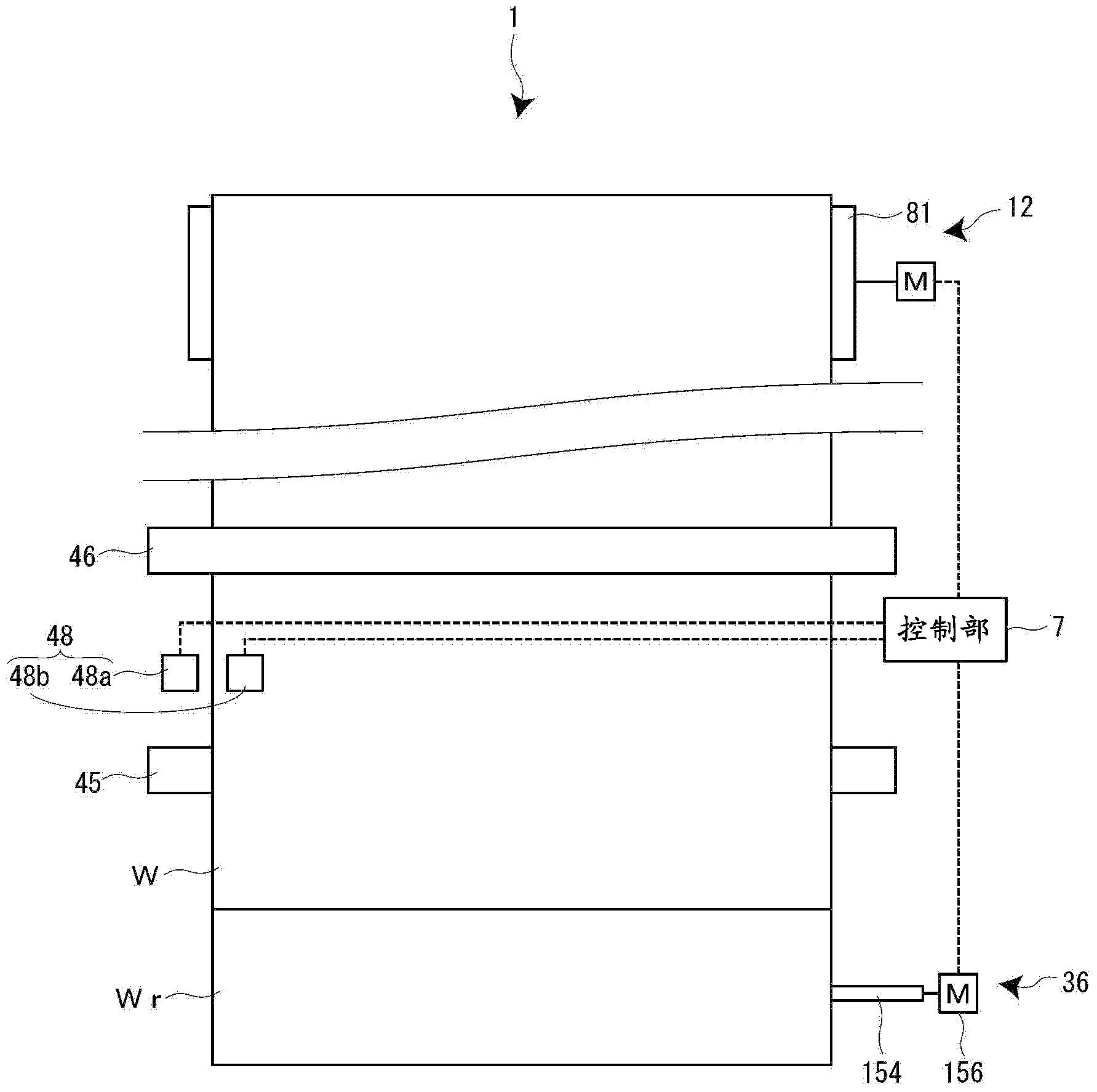

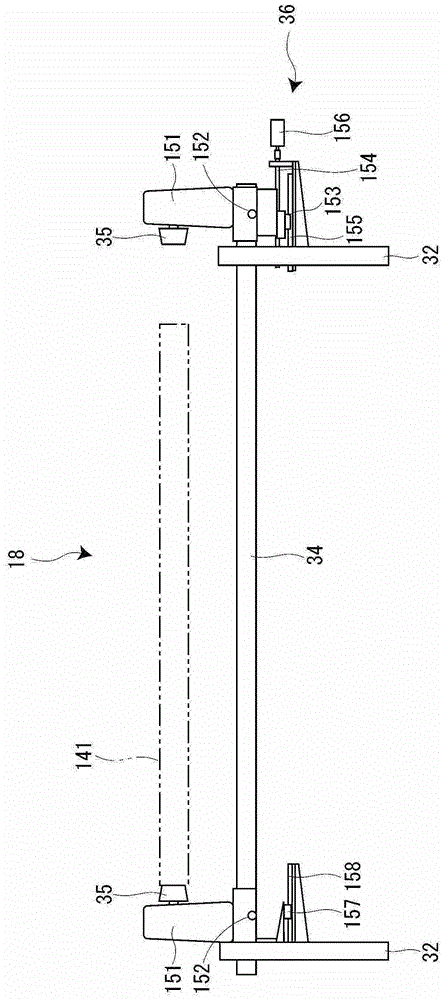

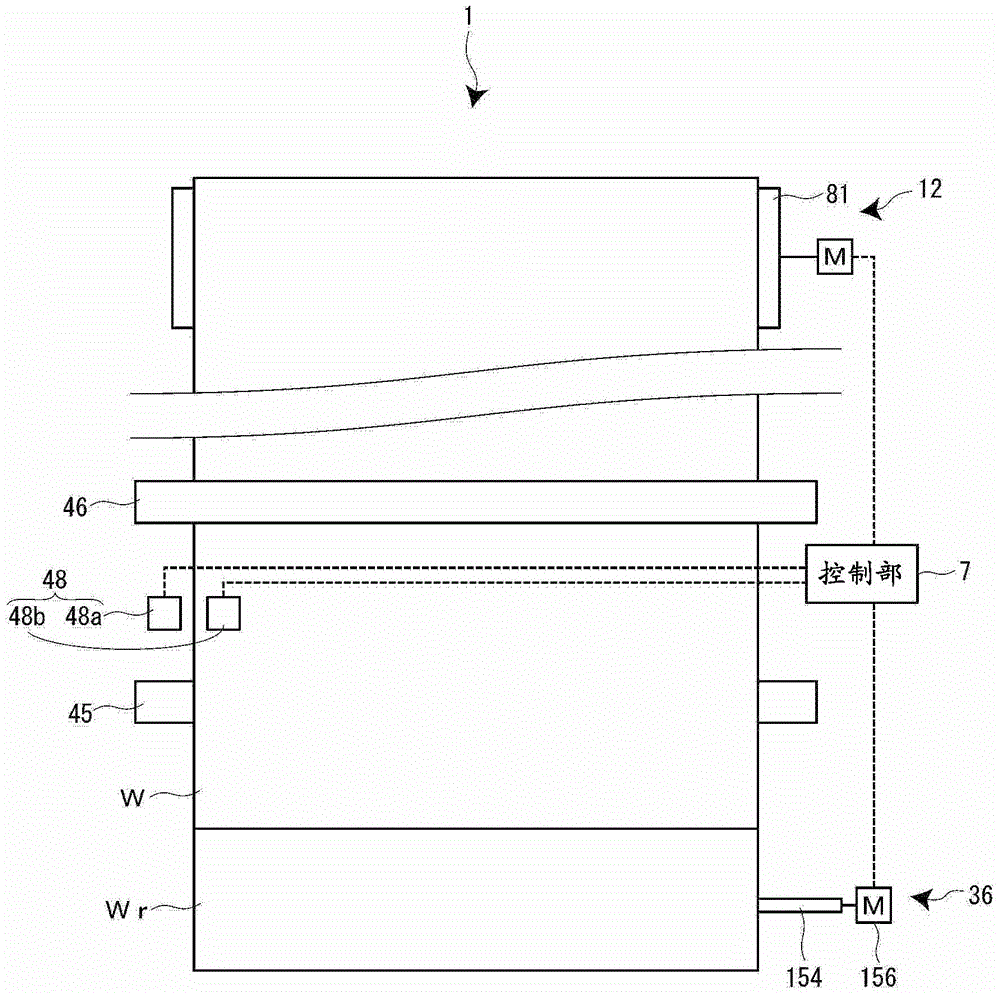

Medium feed device, method for controlling medium feed device, and recording device

ActiveCN103660629AReliable CorrectionSuitable for printingFunction indicatorsOther printing apparatusWrinkle skinRecording media

The advantage of the invention is to provide a medium feed device and the like for intermittently feeding a recording medium (3) in which meandering can be securely corrected without the occurrence of wrinkles in the recording medium (3). The medium feed device has a meandering detection sensor (48)which detects position displacement of a recording medium in a width direction, and a control section (7) which controls driving of a width movement unit based on detection results by the meandering detection sensor (48). The control section stops driving of the width movement unit when stopping feeding of the intermittent feeding.

Owner:SEIKO EPSON CORP

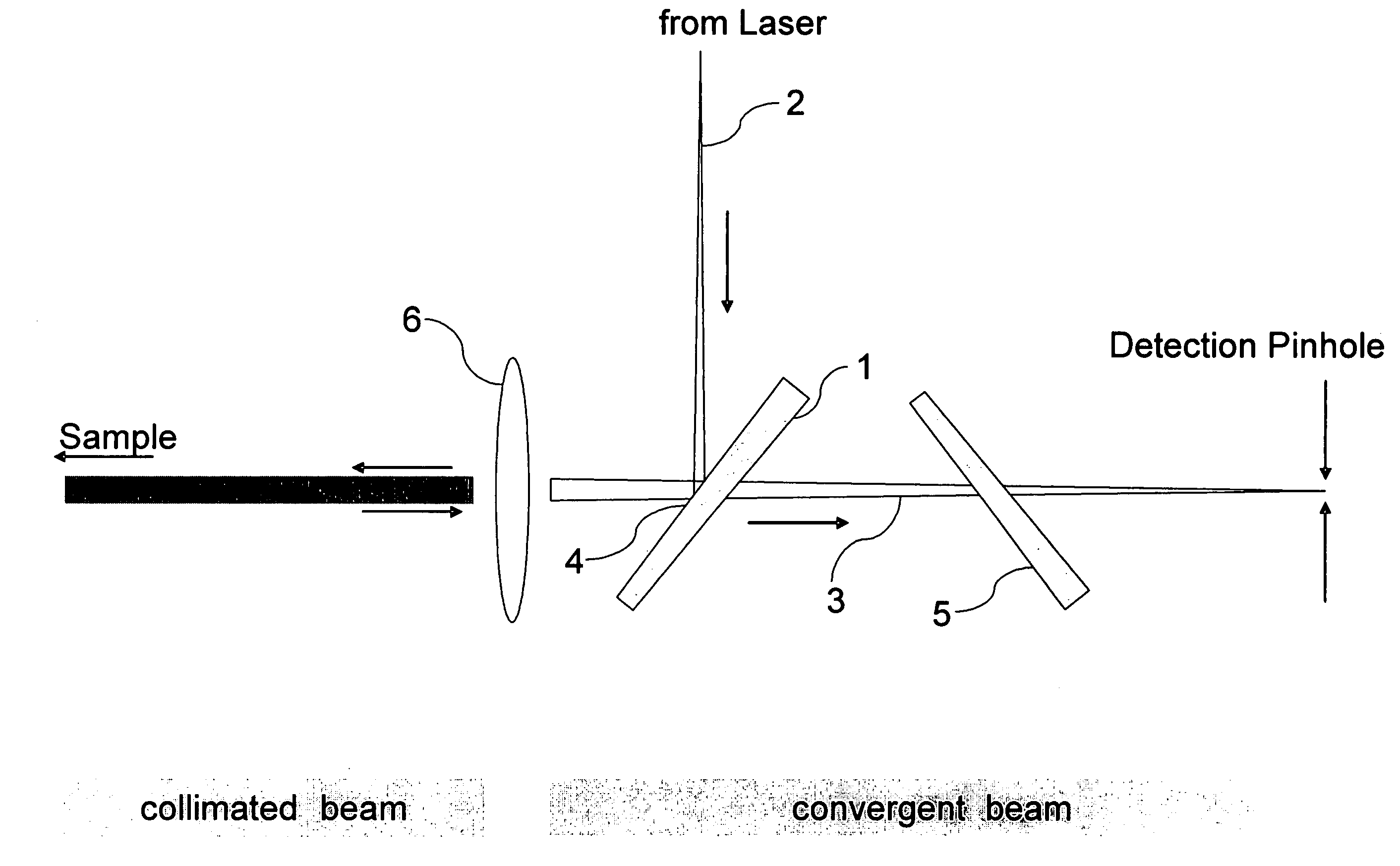

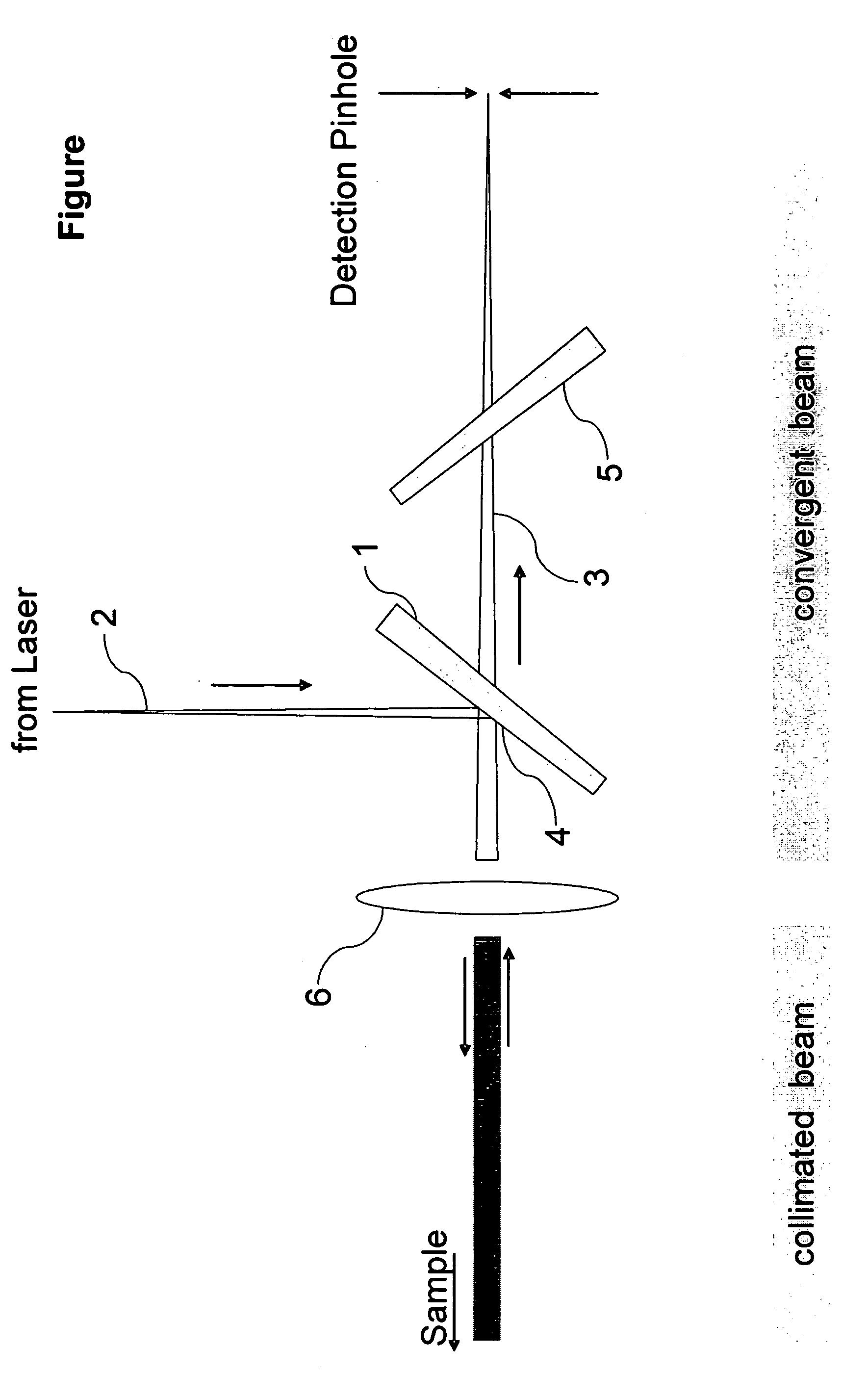

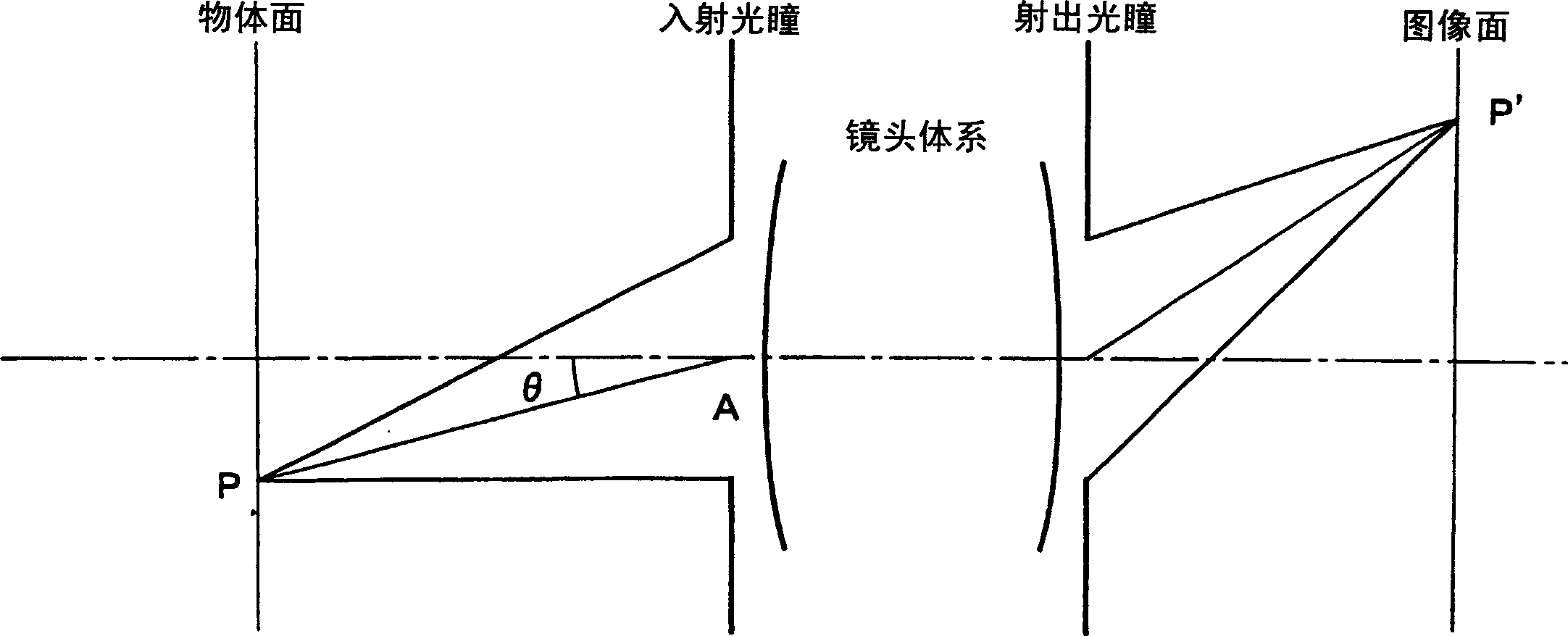

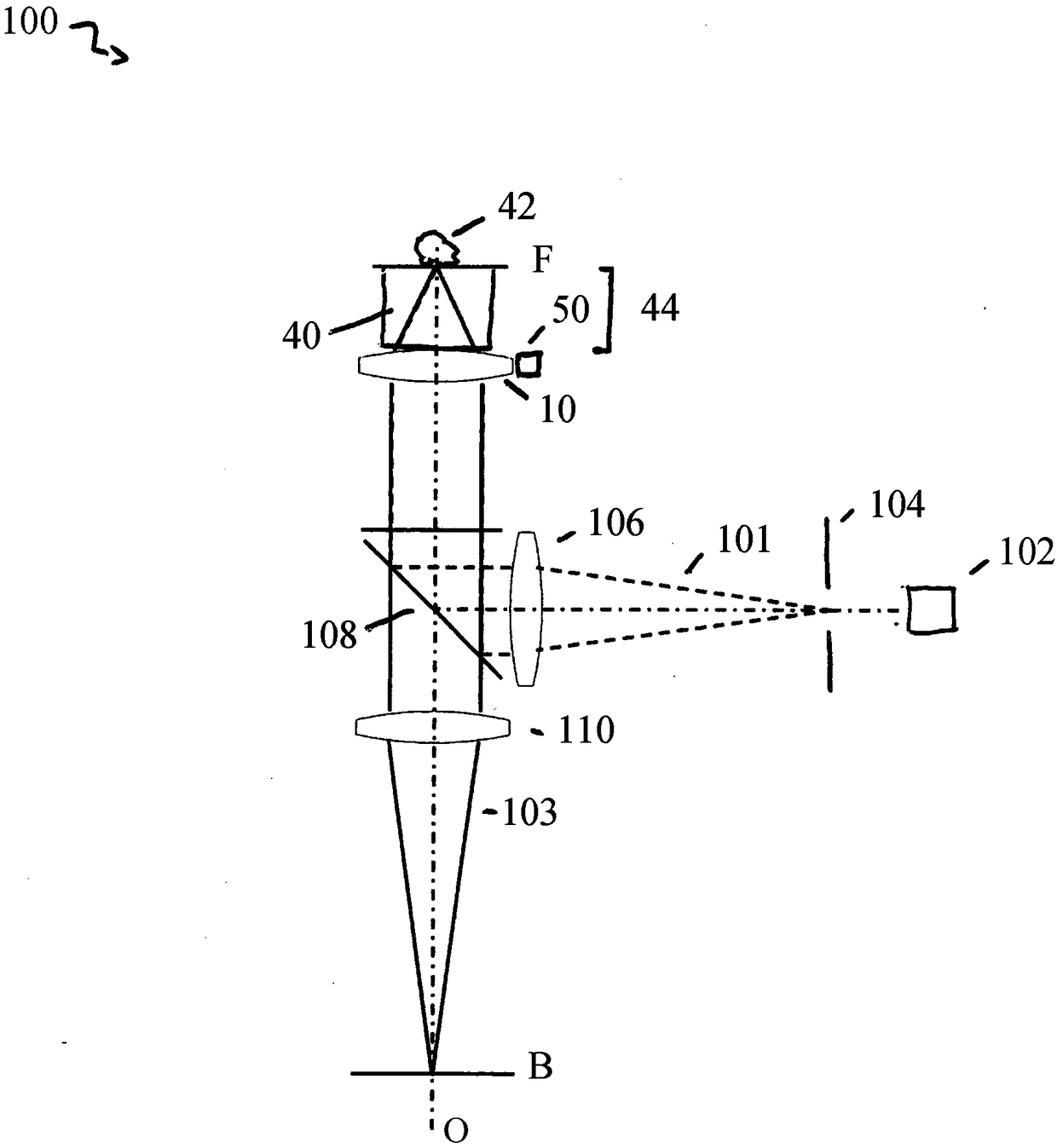

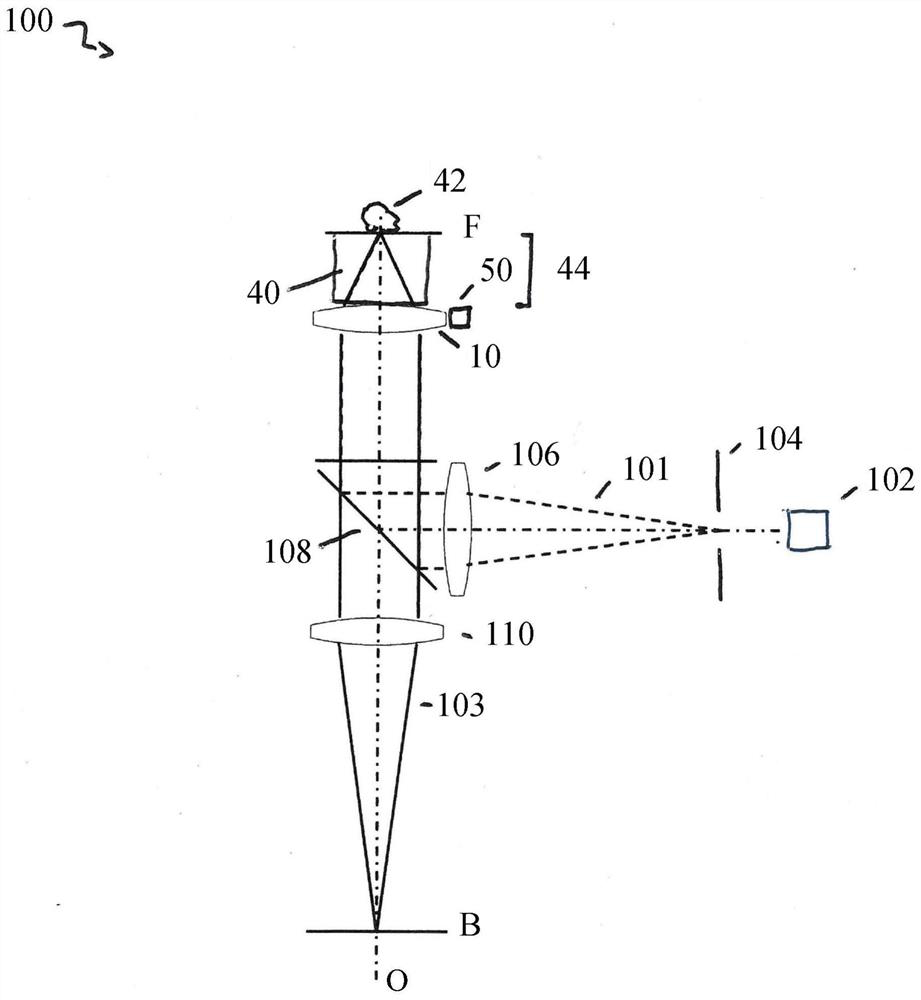

Optical arrangement for microscope and microscope

InactiveUS20060119866A1Reliable CorrectionReliable calibrationUsing optical meansMicroscopesMicroscopeOptoelectronics

An optical arrangement for a microscope, in particular for a scanning microscope, with a beam splitter 1 arranged in a divergent and / or convergent beam path for separating an illumination light 2 that is produced by an illumination source from a detection light 3 that is emitted by a sample being tested, which with regard to reliable correction of imaging errors can be implemented and developed even when using thick beam splitters 1 such that the beam splitter 1 is wedge-shaped and implemented as a beam splitter plate for reflection primarily at a glass-air interface 4. Furthermore, a microscope with such an optical arrangement is disclosed.

Owner:LEICA MICROSYSTEMS CMS GMBH

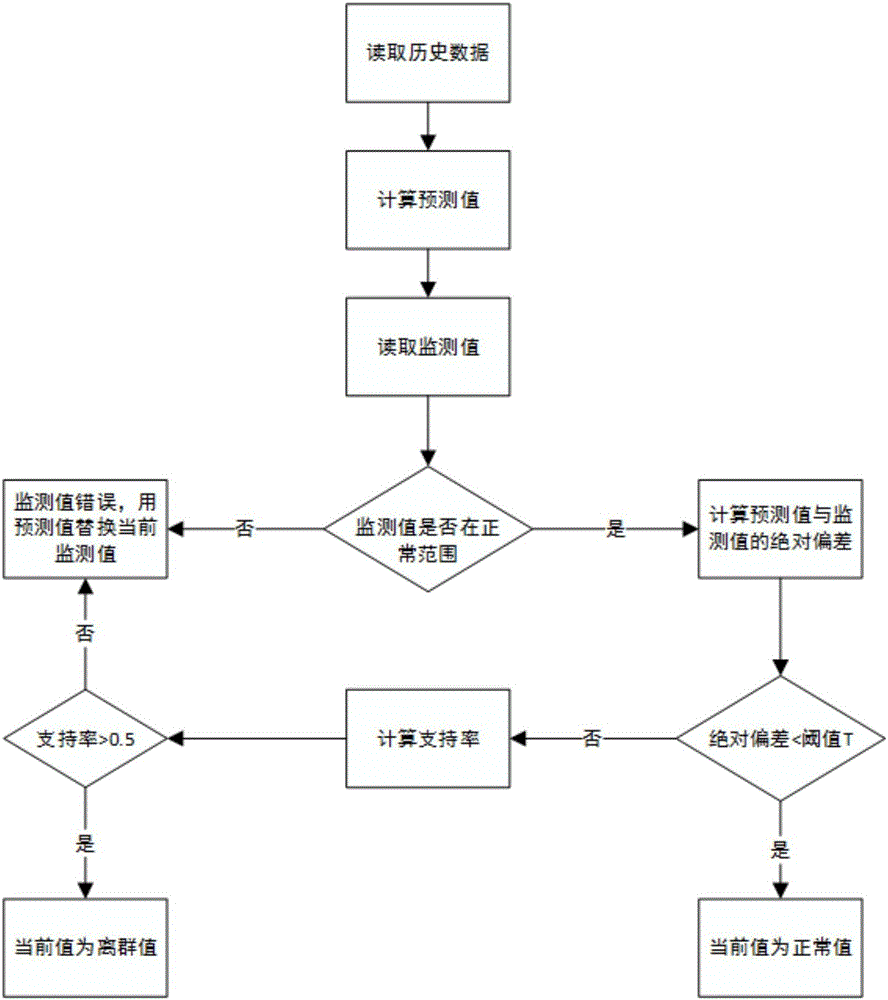

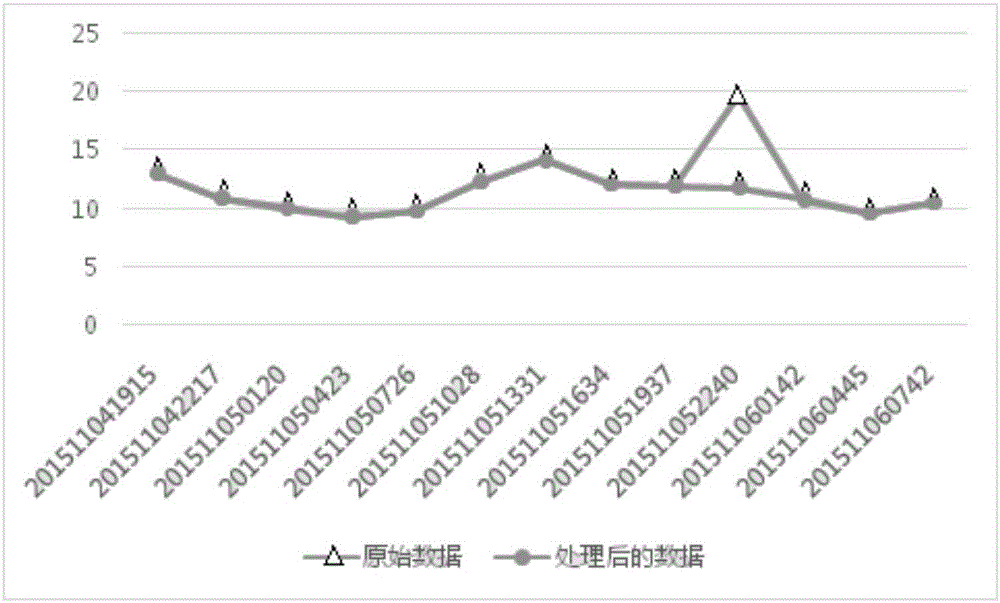

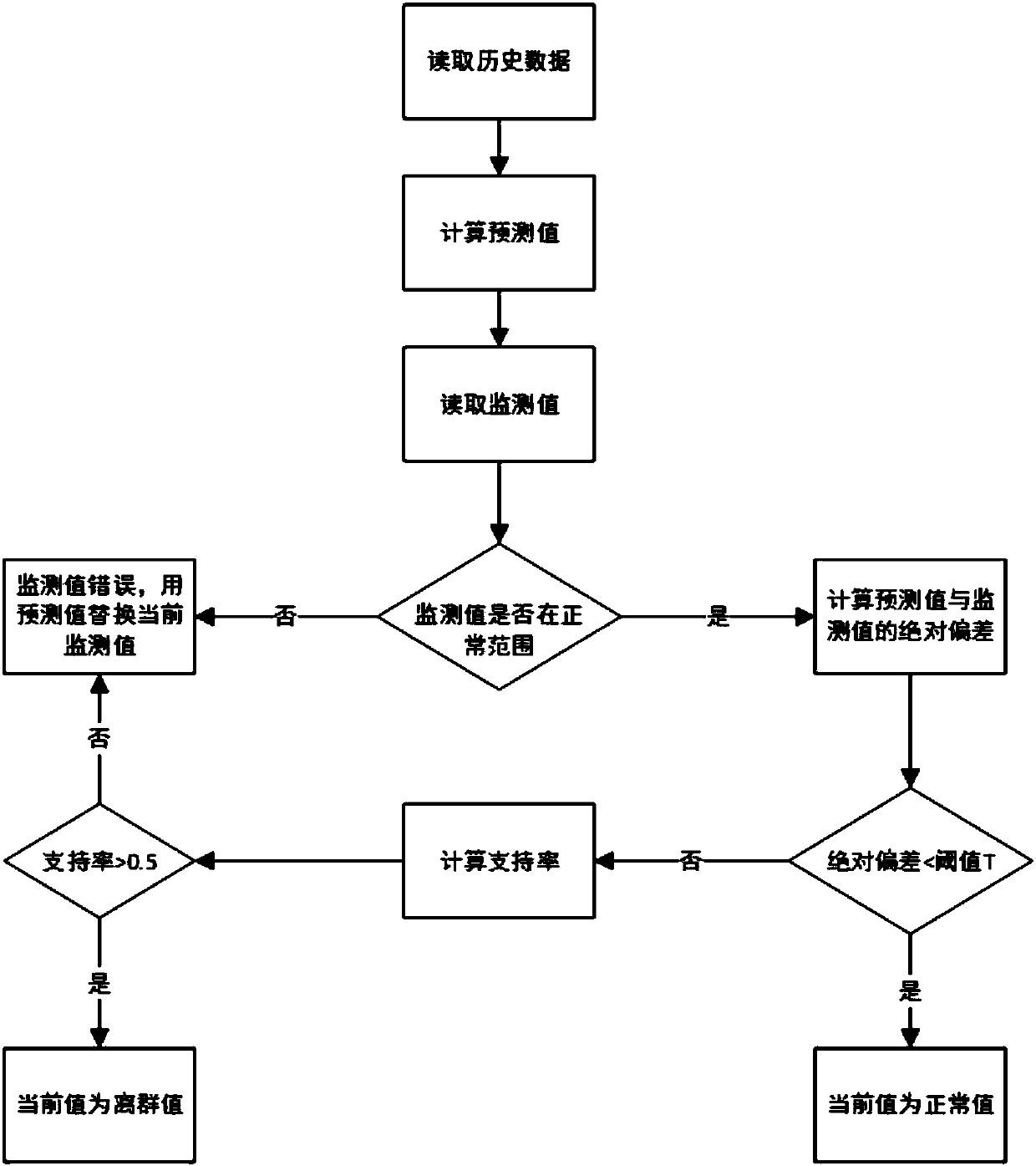

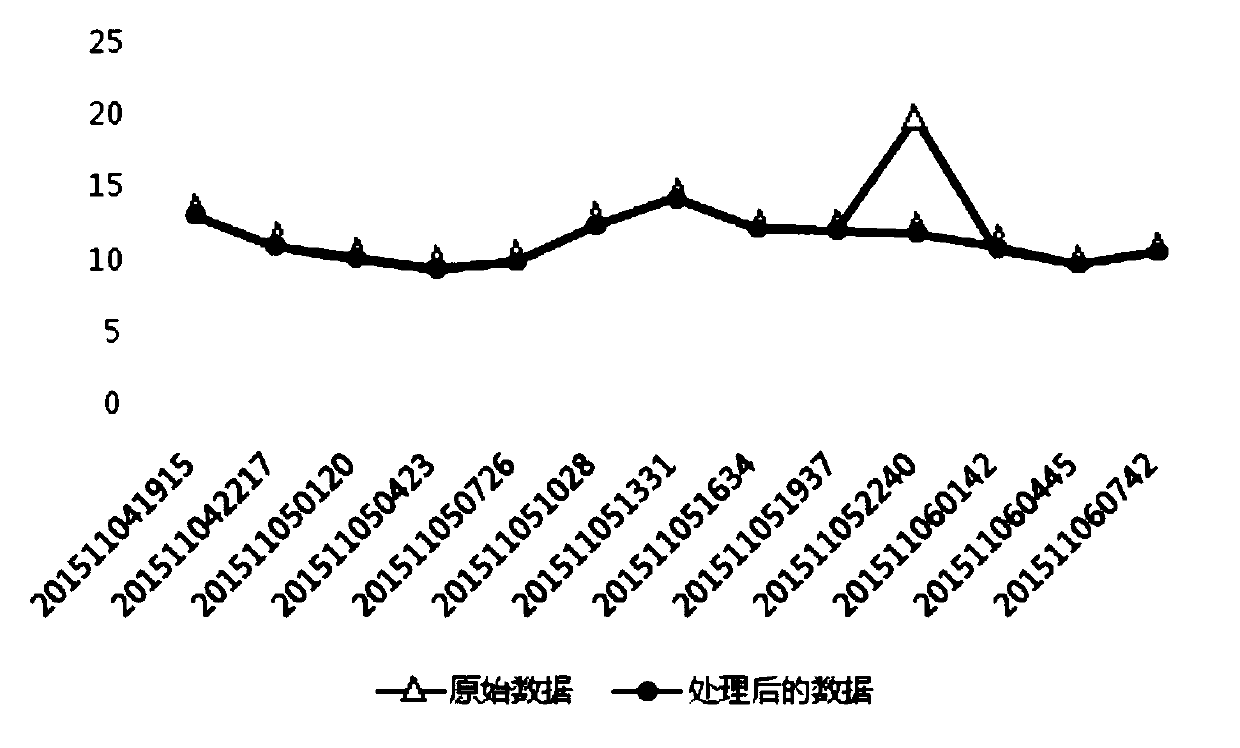

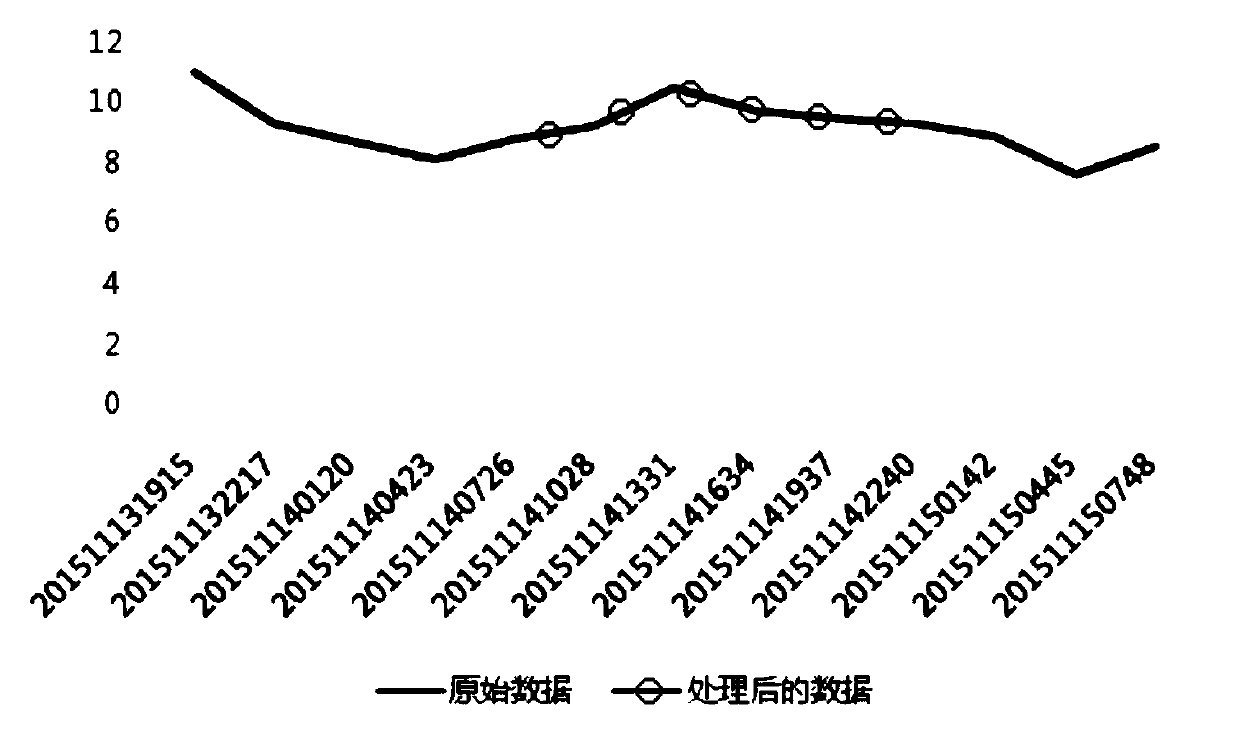

Earthen site monitoring data correcting and fitting method based on spatial and temporal correlation

InactiveCN105787283AAccurate calculationIn line with real monitoring statusForecastingResourcesSite monitoringMissing data

The invention discloses an earthen site monitoring data correcting and fitting method based on spatial and temporal correlation. Spatial and temporal correlation analysis is performed by using predicted values of historical data and current detection data, the correctness of the current data is further judged, noise data are corrected, and missing values are fitted. The method is applied to the field of earthen site protection, realizes intelligent state monitoring of earthen sites, can accurately find and correct noise data and fit missing data trends especially for mass environmental data and earthen site ontology data and provides the scientific basis for risk early-warning and effective management of earthen sites.

Owner:NORTHWEST UNIV

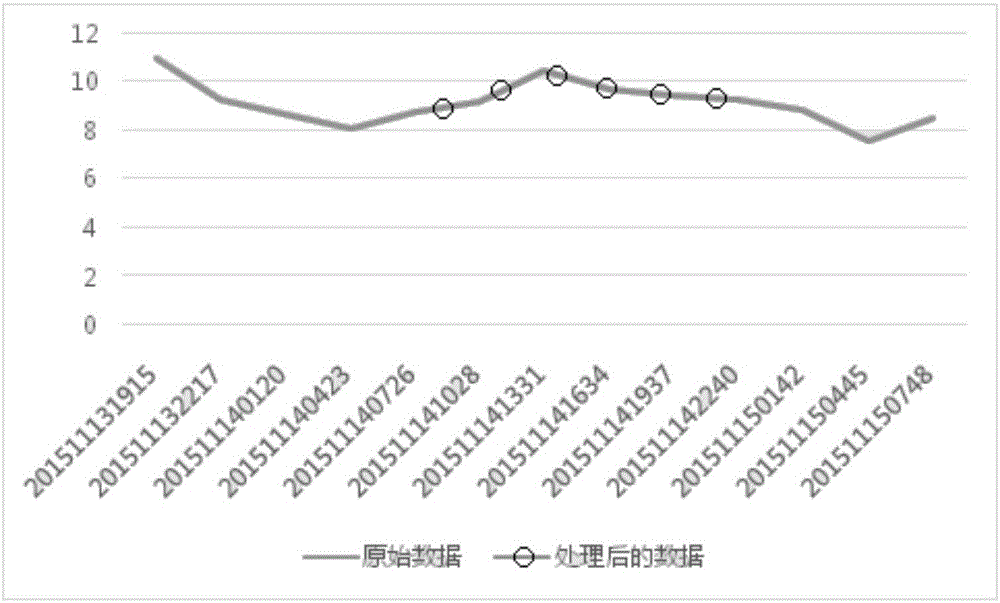

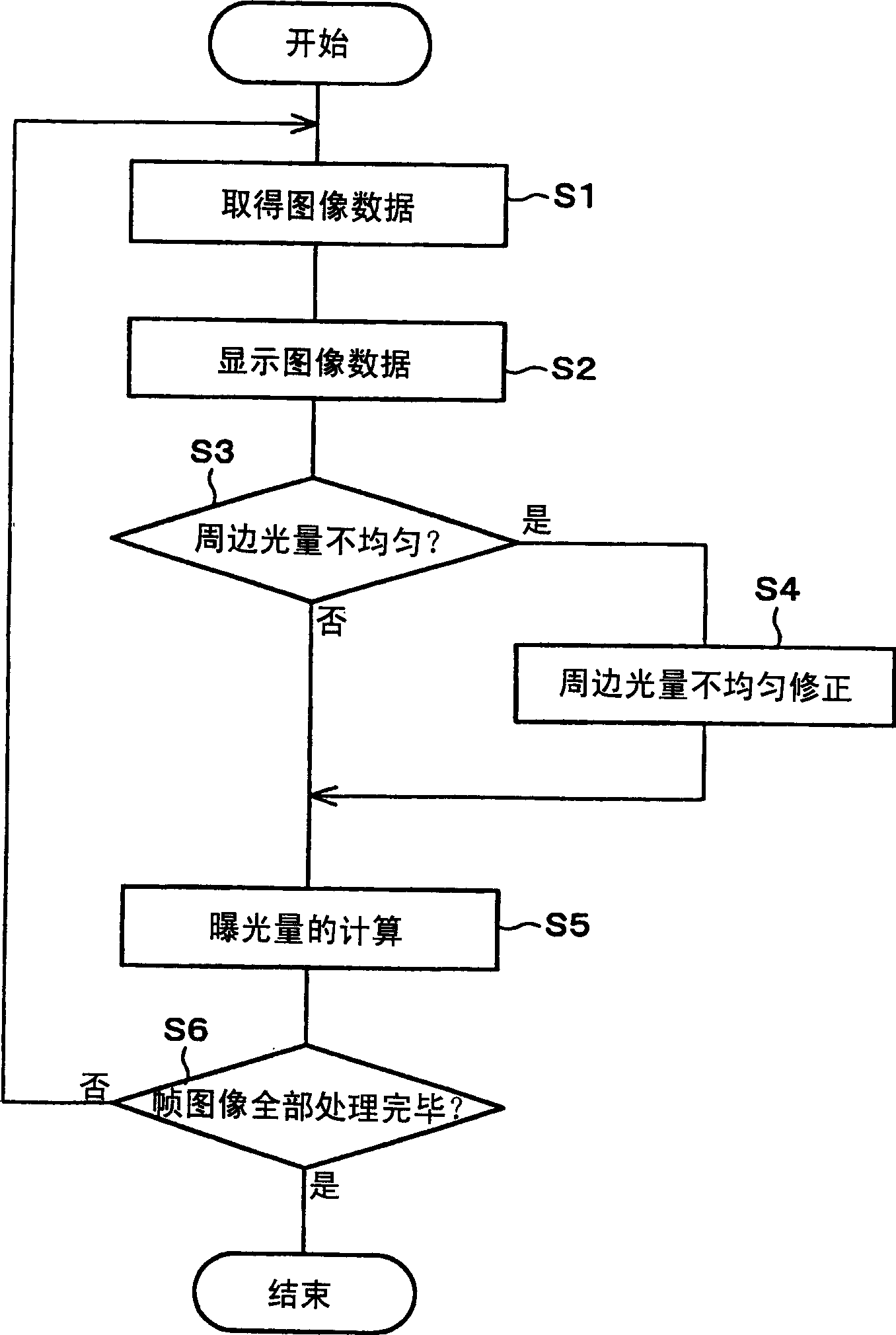

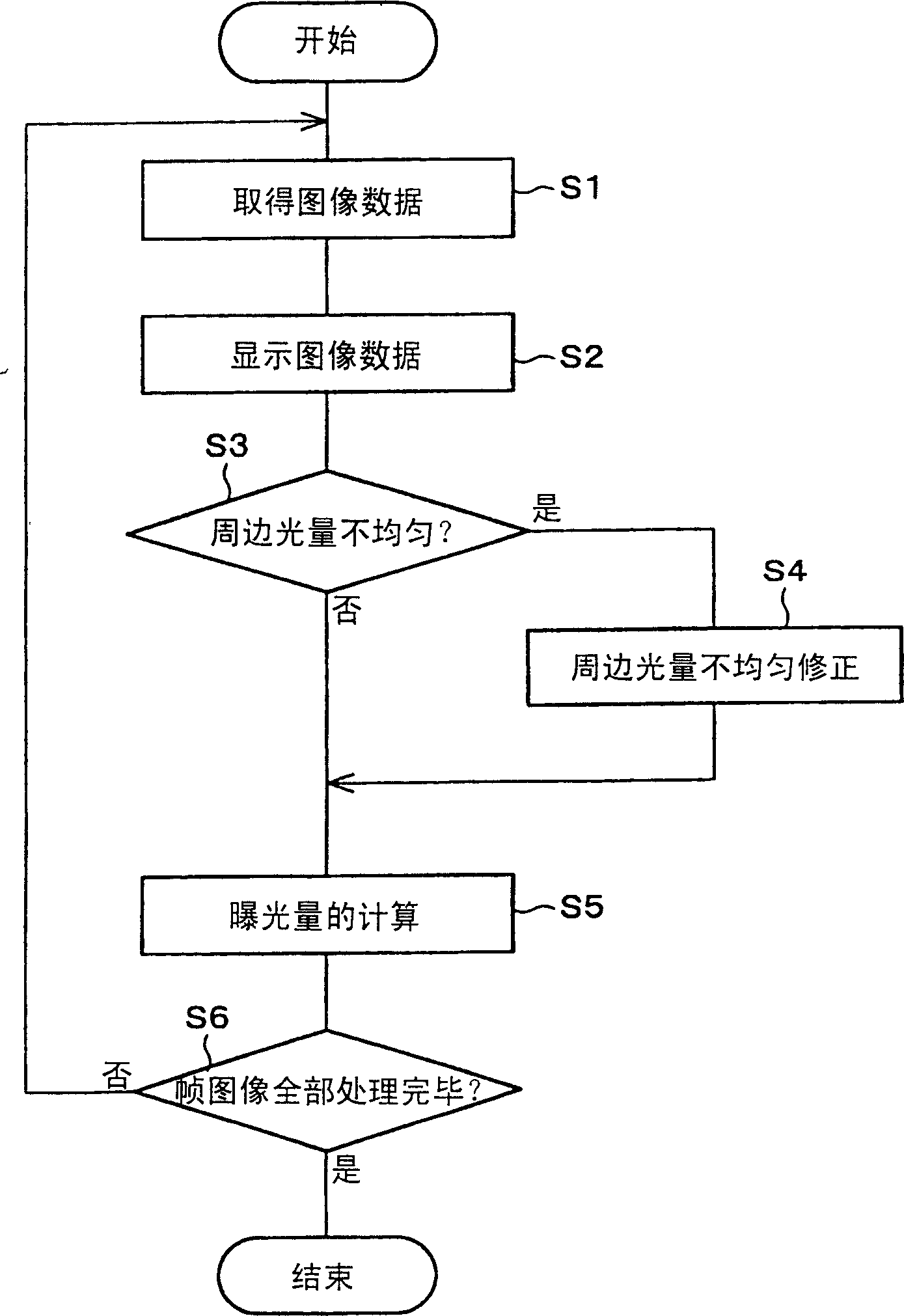

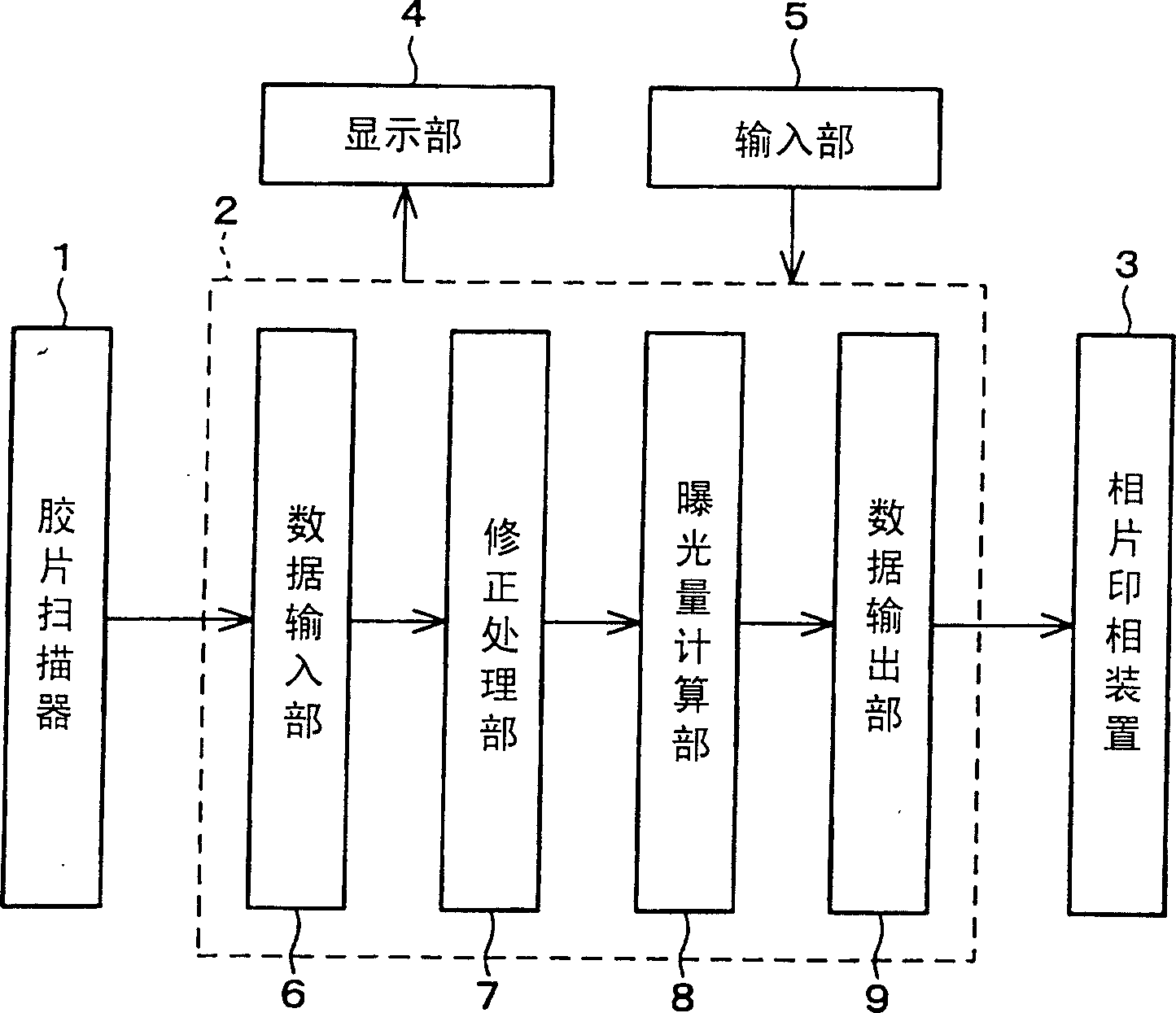

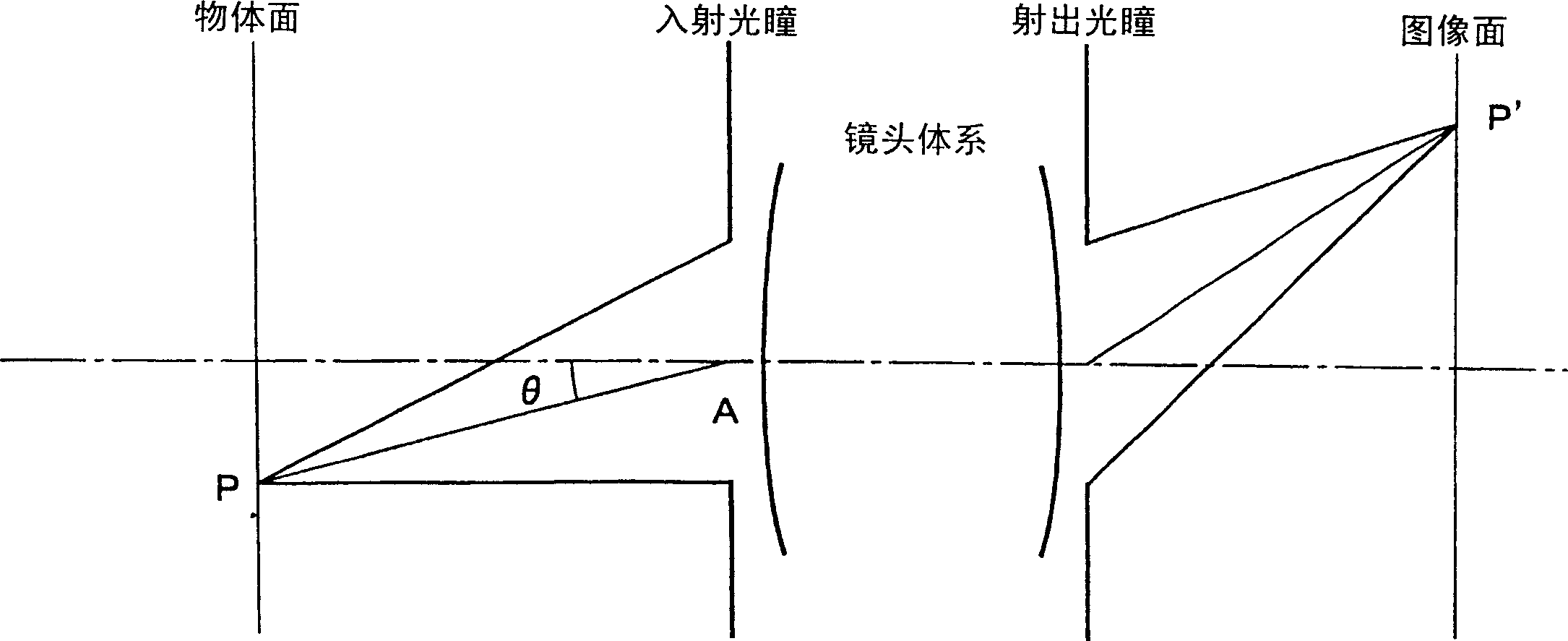

Image processing method, image processing program and recording medium for recording the same program

InactiveCN1469314AReliable CorrectionEffective correctionImage enhancementImage data processing detailsImaging processingEllipse

An image correction processing apparatus for correcting a pixel value of each pixel constituting image data obtained from an original image affected by the peripheral light-off is disclosed. The apparatus includes a pixel coordinate transforming unit (70) for converting a distance between each pixel of a group of pixels which have an equal amount of peripheral light amount reduction and which are located on a common contour line of an oval about a predetermined reference pixel located at the center thereof and said predetermined reference pixel into a radius of a true circle having a diameter corresponding to the major axis of the oval; a cos<4> calculating unit (71) for obtaining, for each pixel, an angle value thereof in proportion to the radius obtained by the conversion and then obtaining a cos<4> value of the angle value; and a correction calculating unit (72) for multiplying an inverse of said cos<4> value obtained for each pixel by a pixel value of this pixel, thereby to obtain a corrected pixel value for the pixel.

Owner:NORITZ CORP

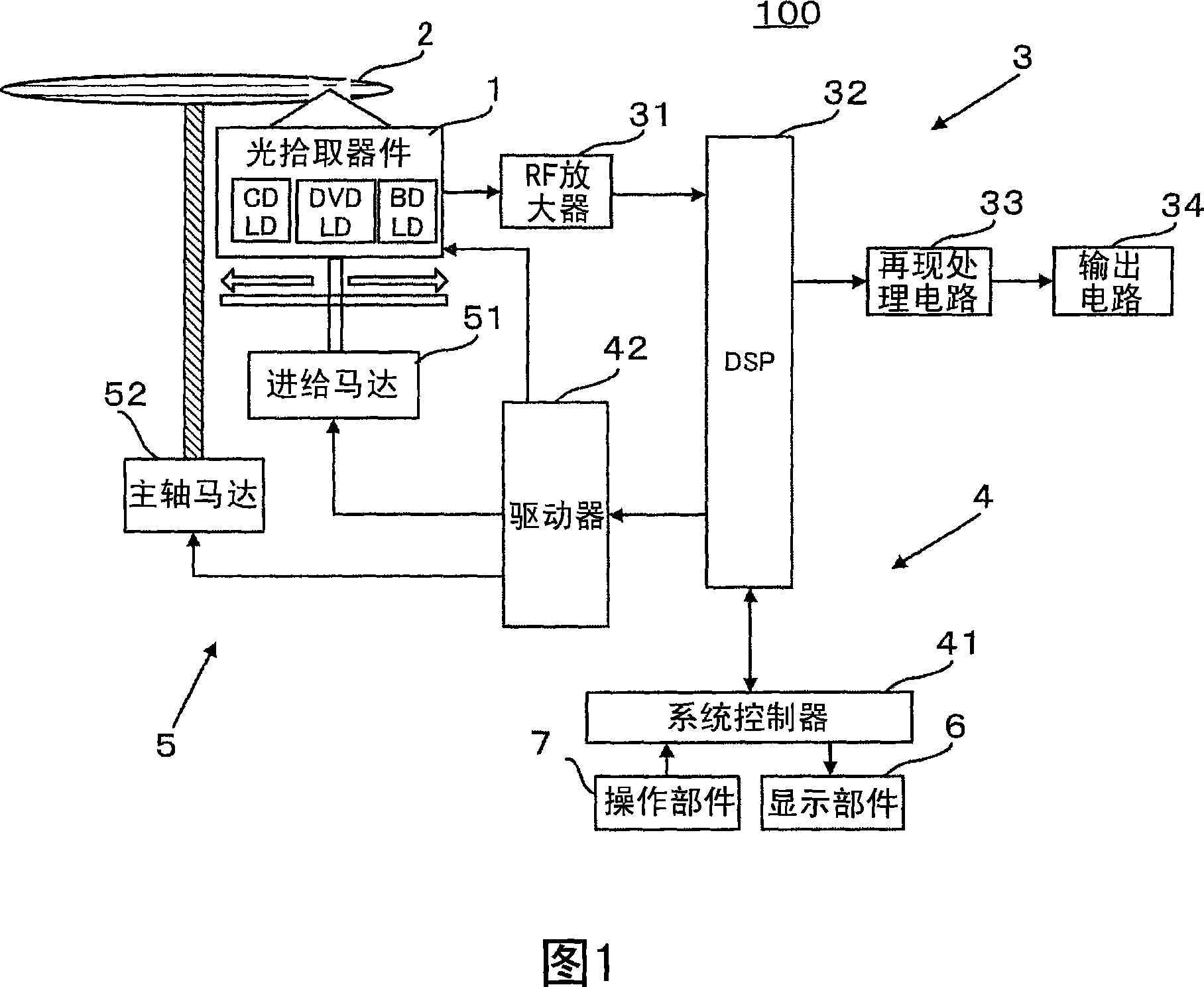

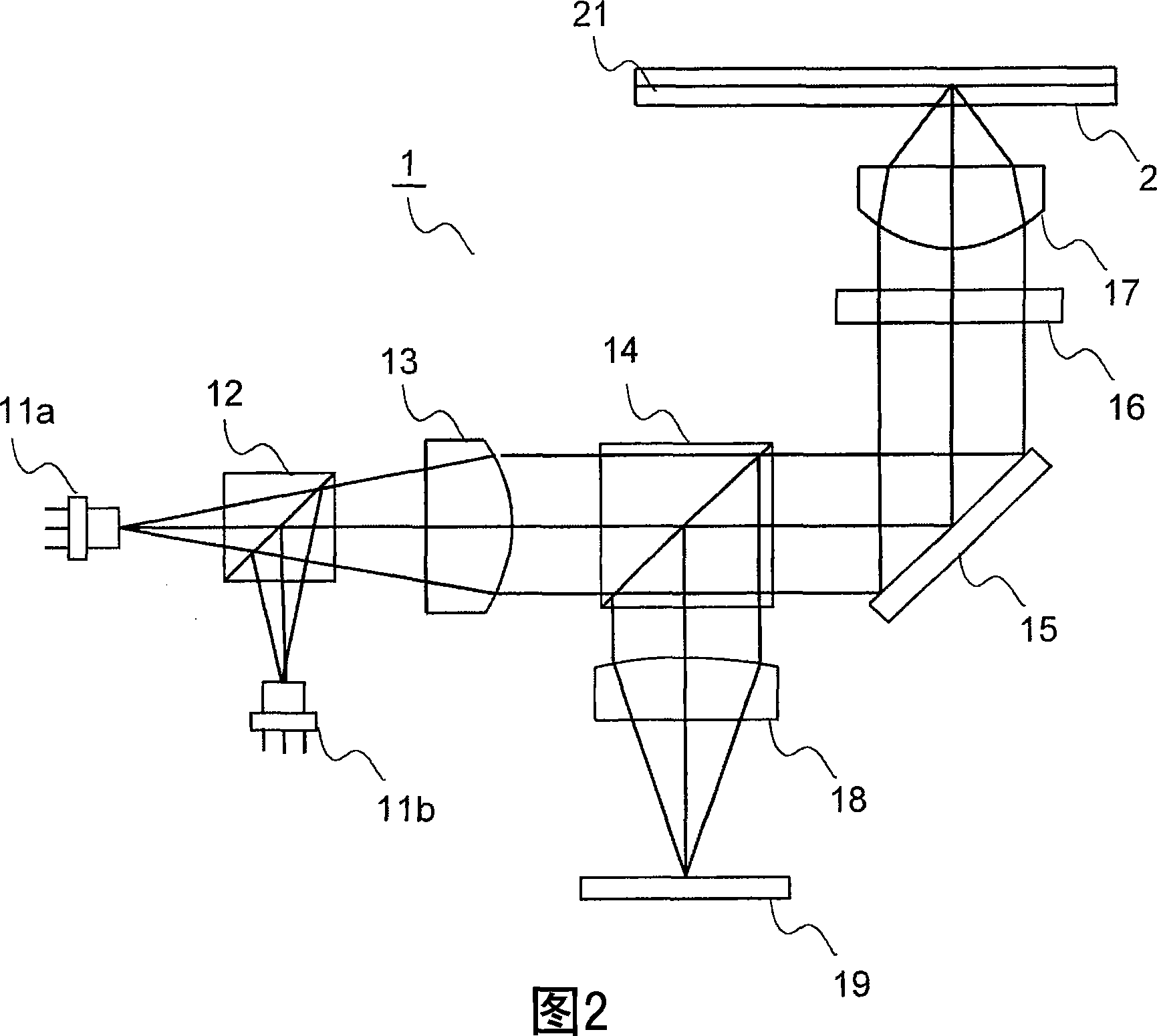

Aberration correcting device, aberration correcting method, optical pickup device, and information reproducing apparatus

InactiveCN101051488AShorten design timeReliable CorrectionOptical beam sourcesRecord information storagePhase correctionOptical pickup

Owner:FUNAI ELECTRIC CO LTD

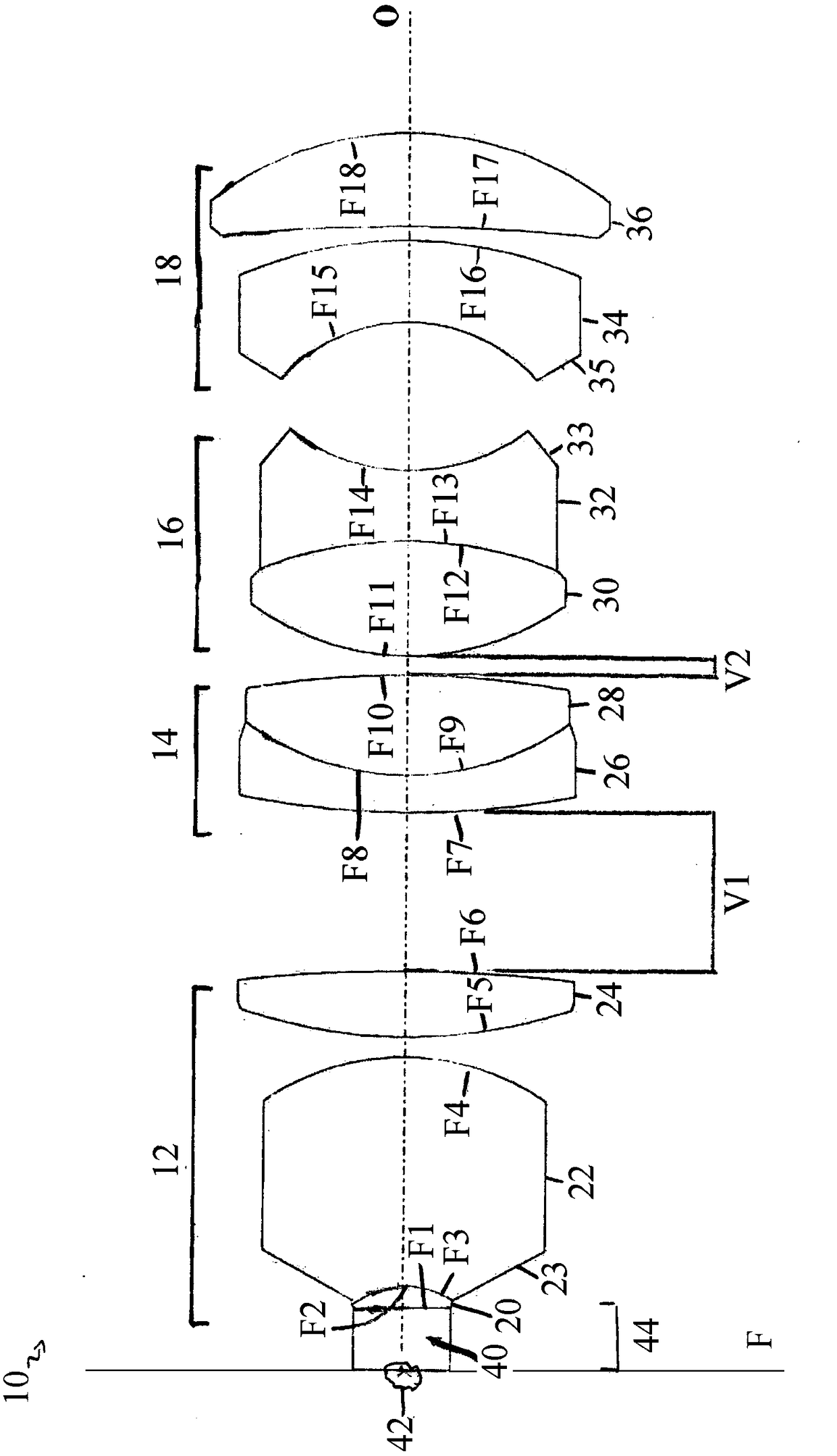

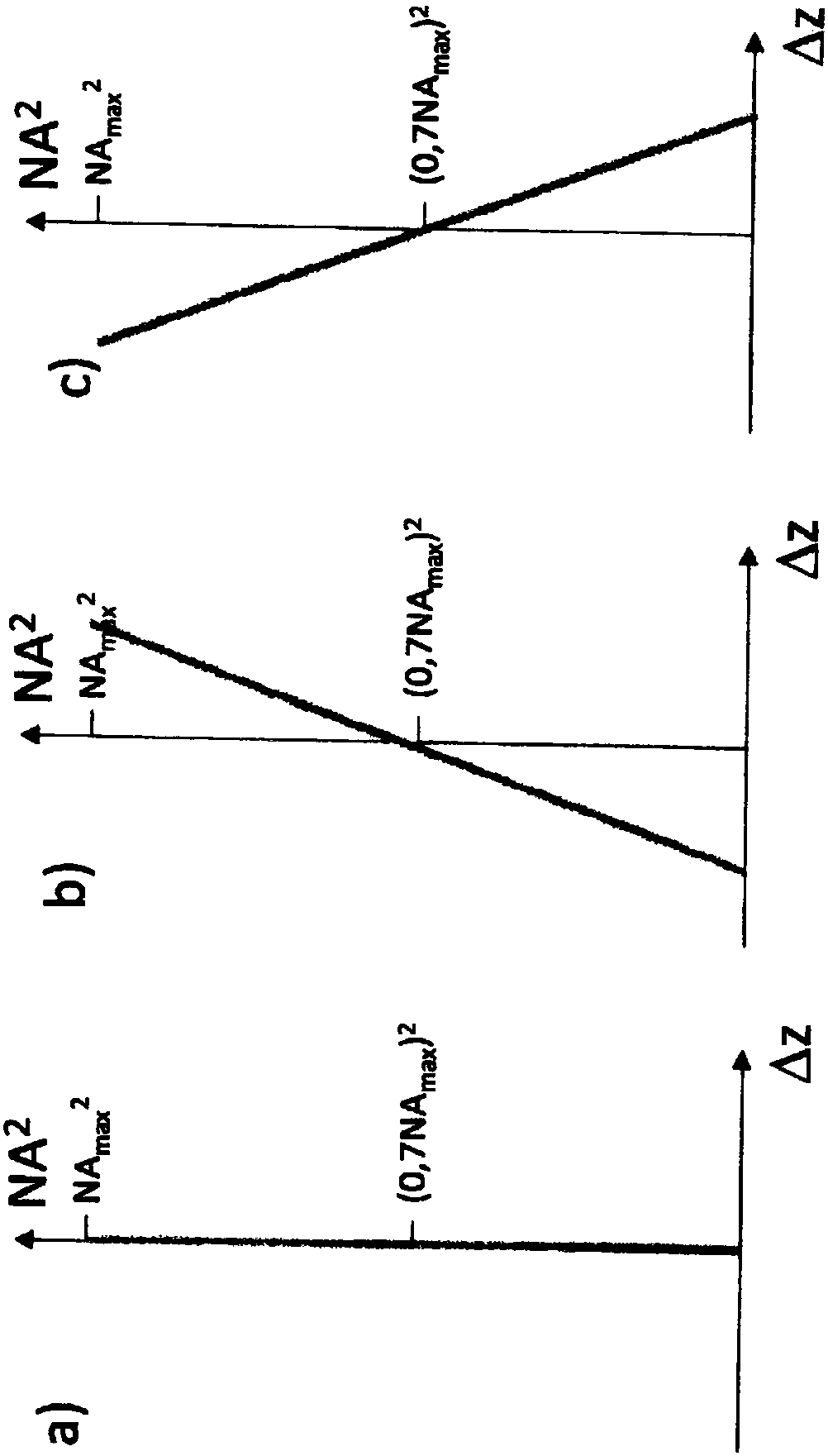

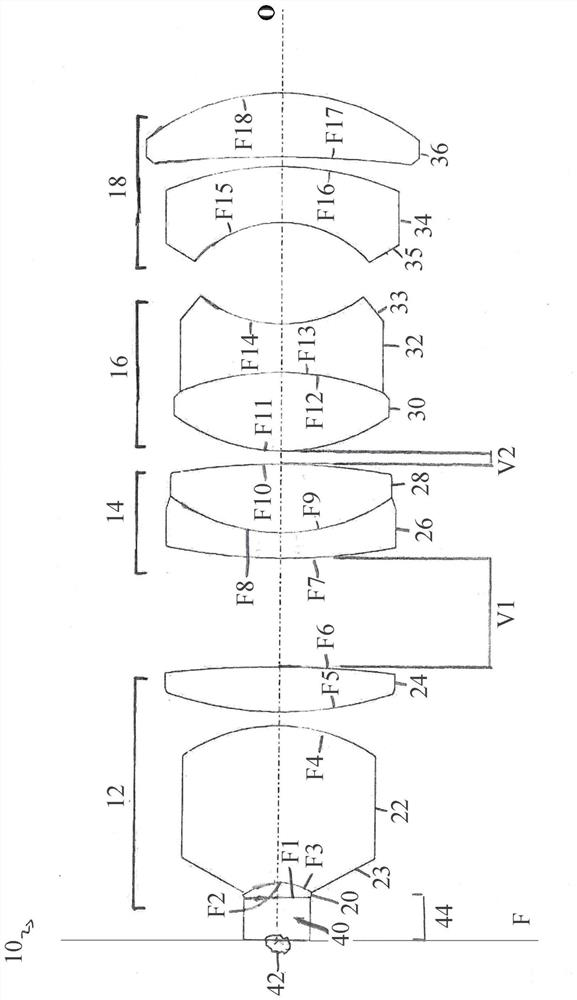

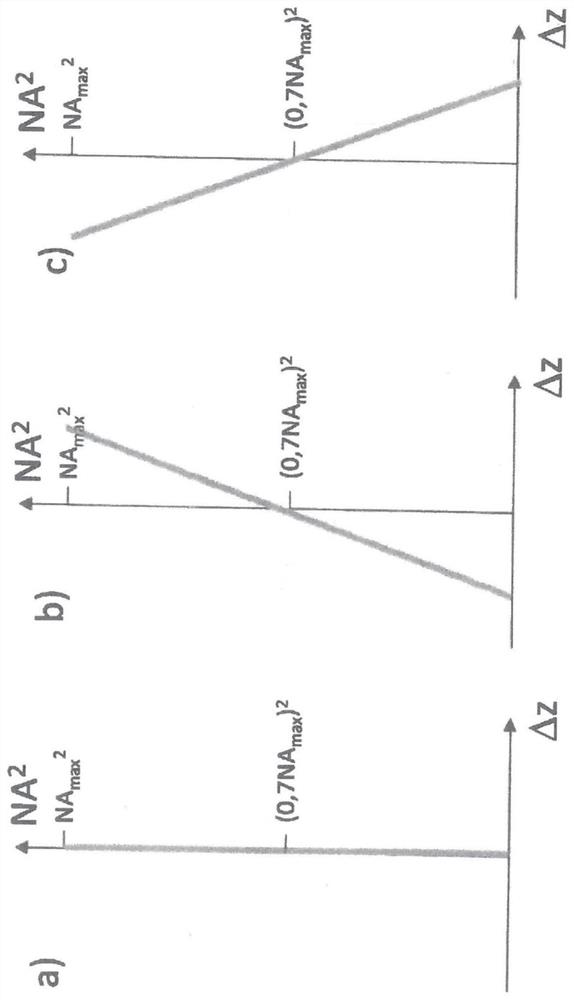

Immersion objective lens for microscope

An immersion objective lens 10 for a microscope 100 includes a first lens group 12 having positive refractive power, a second lens group 14 having positive refractive power, a third lens group 16 having negative refractive power and a fourth lens group having positive refractive power disposed in this sequence from the object side. The second lens group 14 is moveable along an optical axis O so asto achieve a corrective effect with respect to a spherical aberration, such that a sum of a distance V1 between the second lens group 14 and the first lens group 12 and of a distance V2 between the second lens group 14 and the third lens group 16 is constant. The corrective effect of the second lens group 14 is predetermined such that the spherical aberration is minimized for a light incidence that corresponds to a mean numerical aperture that lies between zero and a nominal aperture of the immersion objective lens 10.

Owner:LEICA MICROSYSTEMS CMS GMBH

Paper diaper capable of calculating amount of exercise

InactiveCN104473723AReal-time monitoring of exerciseControl movementDiagnostic recording/measuringAbsorbent padsGyroscopeDigitaria sanguinalis

The invention discloses a paper diaper capable of calculating the amount of exercise, which belongs to the technical field of products for babies. The paper diaper comprises a paper diaper body and a shield; an exercise gauge is arranged inside the bottom of the paper diaper body; the paper diaper body consists of a waterproof layer at the outer part, a hydrophilic non-woven fabric layer at the sub outer part and a water adsorption layer at the inner part. The paper diaper disclosed by the invention can monitor the amount of exercise of a baby in real time, so that parents can control motion of the baby and the baby is kept growing healthily. The exercise gauge disclosed by the invention adopts a gravity acceleration sensor to sense the amount of exercise; a gyroscope is adopted to carry out correction; the paper diaper has the advantages of accuracy, rapidness and reliability; extract of common cephalanoplos herb or extract of digitaria sanguinalis not only can take a bactericidal effect and increase urine adsorption capacity, but also can promote the gravity acceleration sensor to play functions and improve efficiency.

Owner:XIAOLU

A kind of tilt adjustment device of transmission tower in coal mining area

The invention discloses a device for adjusting an inclined steel pylon in a mining area of a coal mine. The device for adjusting the inclined steel pylon in the mining area of the coal mine comprises foundation bolts, a pylon leg plate capable of being jacked, a steel pylon foundation and a base, wherein the pylon leg plate capable of being jacked is connected with the steel pylon foundation through the foundation bolts, the base is arranged on the outer side of the bottom of the steel pylon foundation, the pylon leg plate capable of being jacked comprises a base plate, a steel pylon principle material connecting plate and two bearing U-bars, the steel pylon principle material connecting plate is welded to the base plate, the bearing U-bars are welded to the base plate in a parallel mode, the steel pylon principle material connecting plate is welded along the edge of a steel pylon principle material, a connecting U-bar is perpendicularly welded to one end of one of the bearing U-bars and the end, corresponding to the end of the bearing U-bar, of the other bearing U-bar, and a connecting U-bar is welded to the other end of one of the U-bars and the end, corresponding to the other end of the U-bar, of the other U-bar, the connecting U-bars are arranged above the base, and the length of exposed screw threads of each foundation bolt is no smaller than 150mm. The device for adjusting the inclined steel pylon in the mining area of the coal mine has the advantages that due to the facts that when the steel pylon is installed, the pylon leg plate capable of being jacked is arranged in advance, and the connecting U-bars on the pylon leg plate capable of being jacked are arranged corresponding to the base used for placement of jacks, deviation rectification can be carried out on the inclined steel pylon safely, correctly and reliably, and the frequency of the inclination phenomenon of the steel pylon can be effectively reduced.

Owner:STATE GRID CORP OF CHINA +2

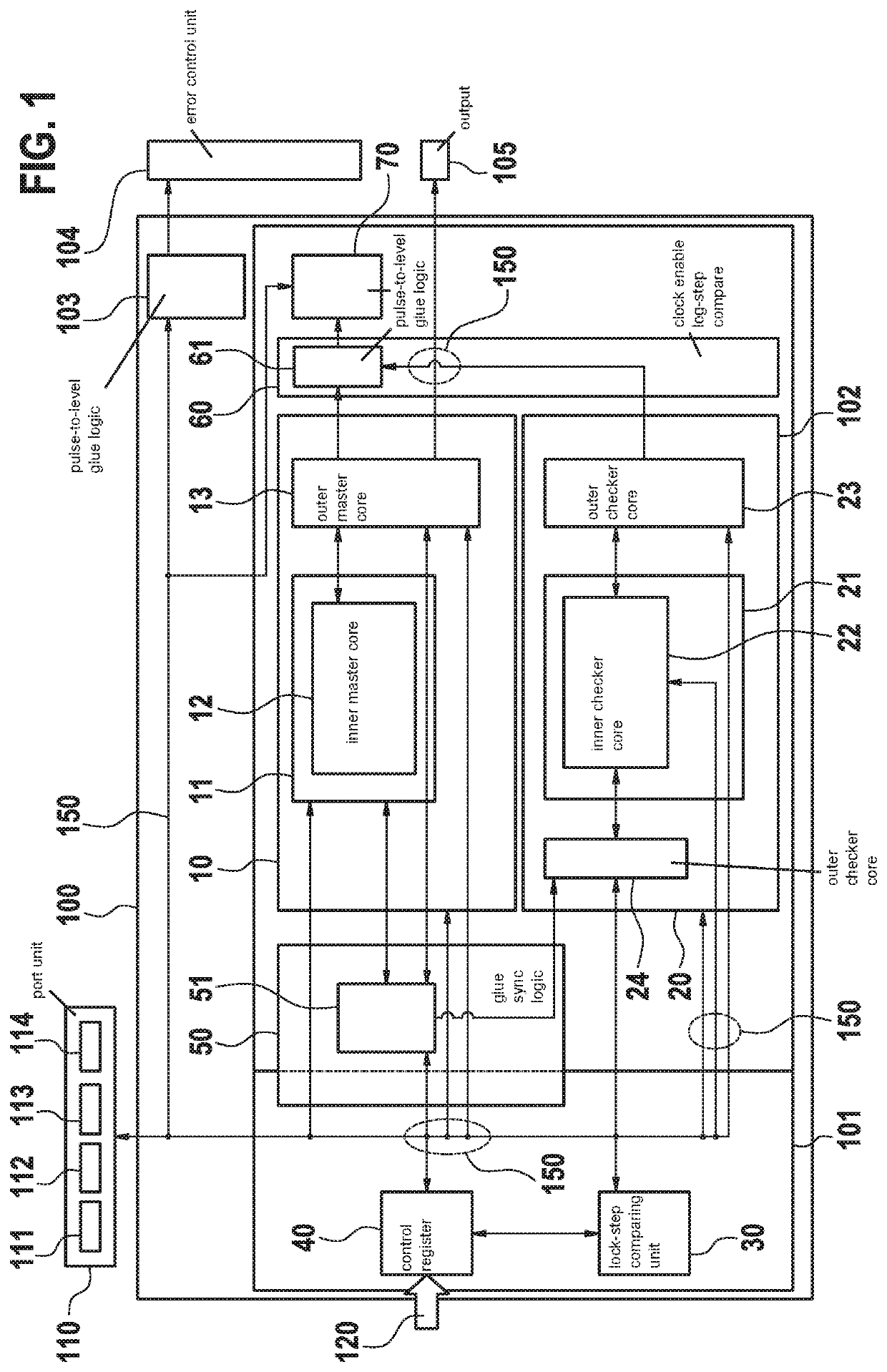

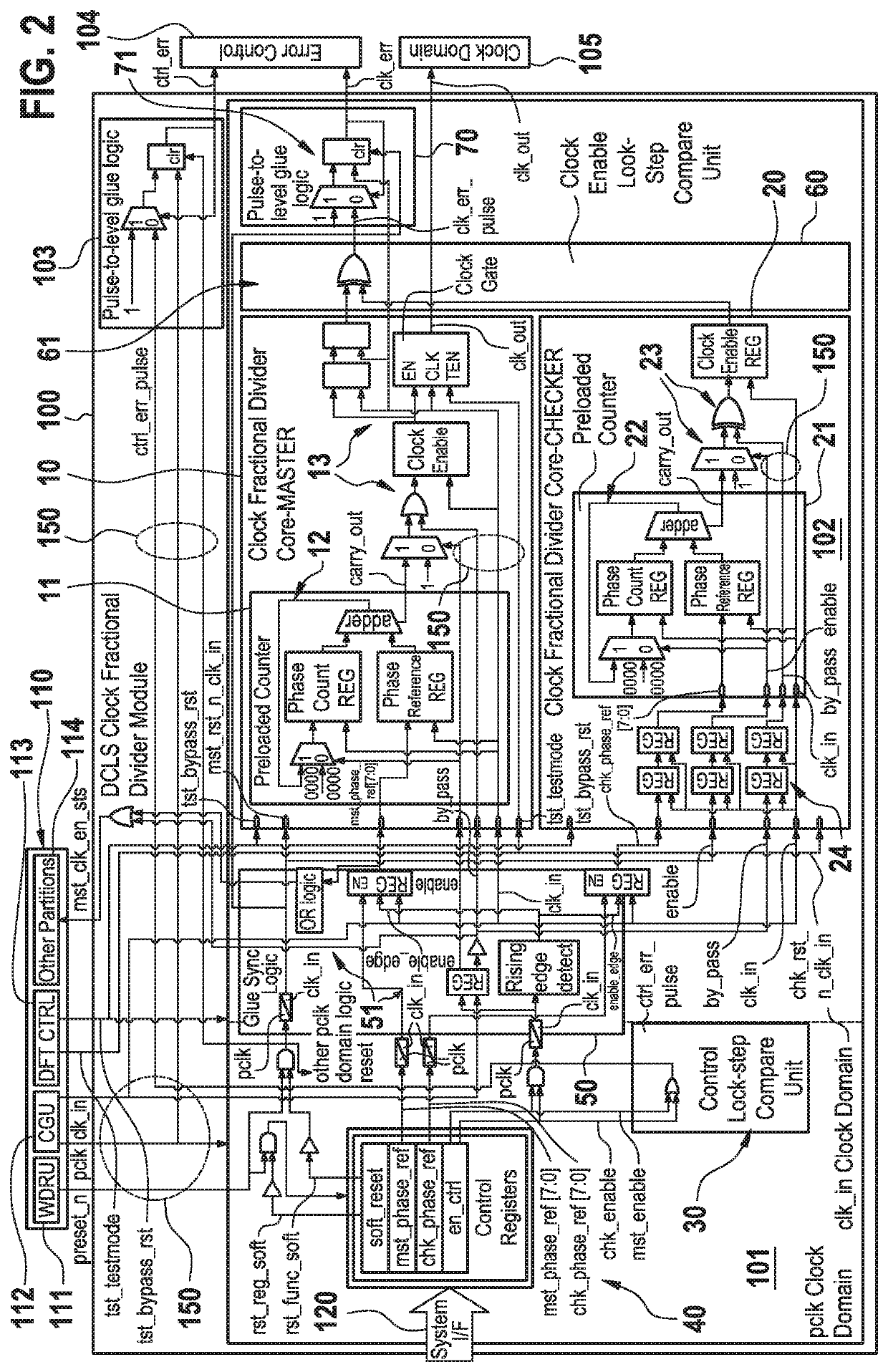

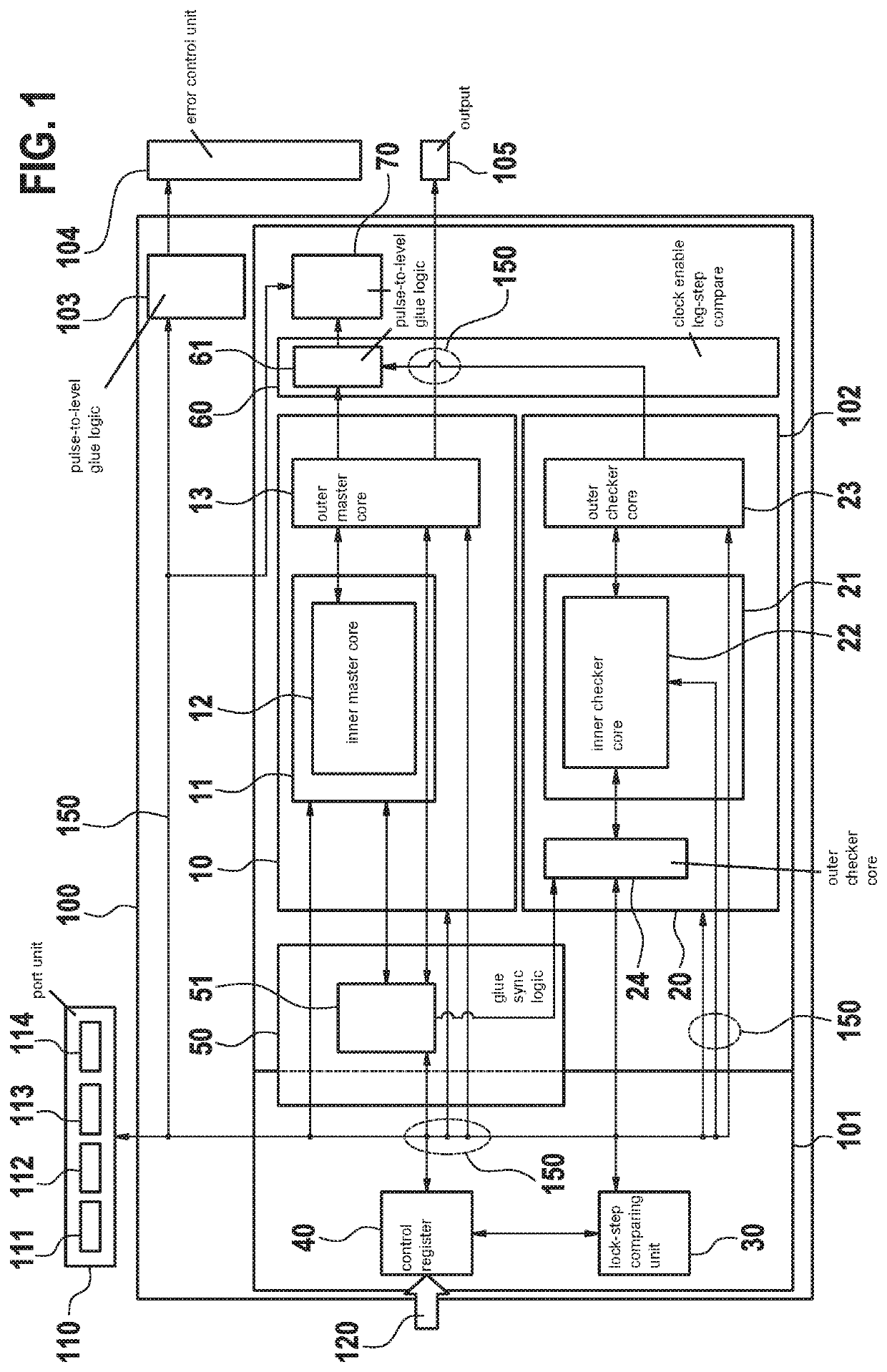

Clock fractional divider module, image and/or video processing module, and apparatus

ActiveUS20200319952A1Reliable detectionReliably recognizingPulse automatic controlFault responseEmbedded systemDual core

A clock fractional divider module which is formed as, comprises or has integrated therein a dual-core lock step unit. The dual-core lock step unit is configured in order to realize a clock fractional division arrangement, mechanism or process accompanied by an error detection, recognition and / or correction arrangement, mechanism or process.

Owner:ROBERT BOSCH GMBH

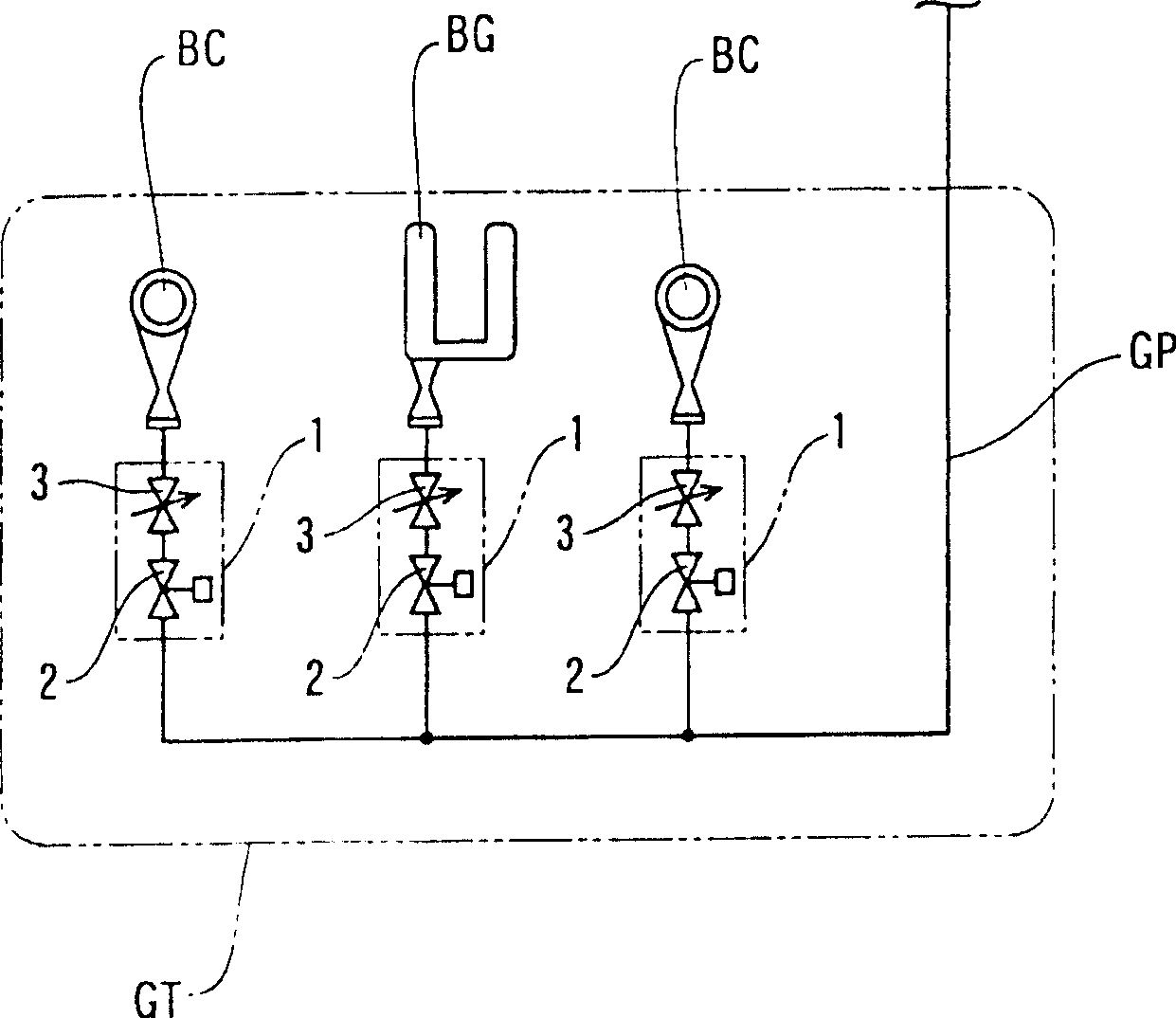

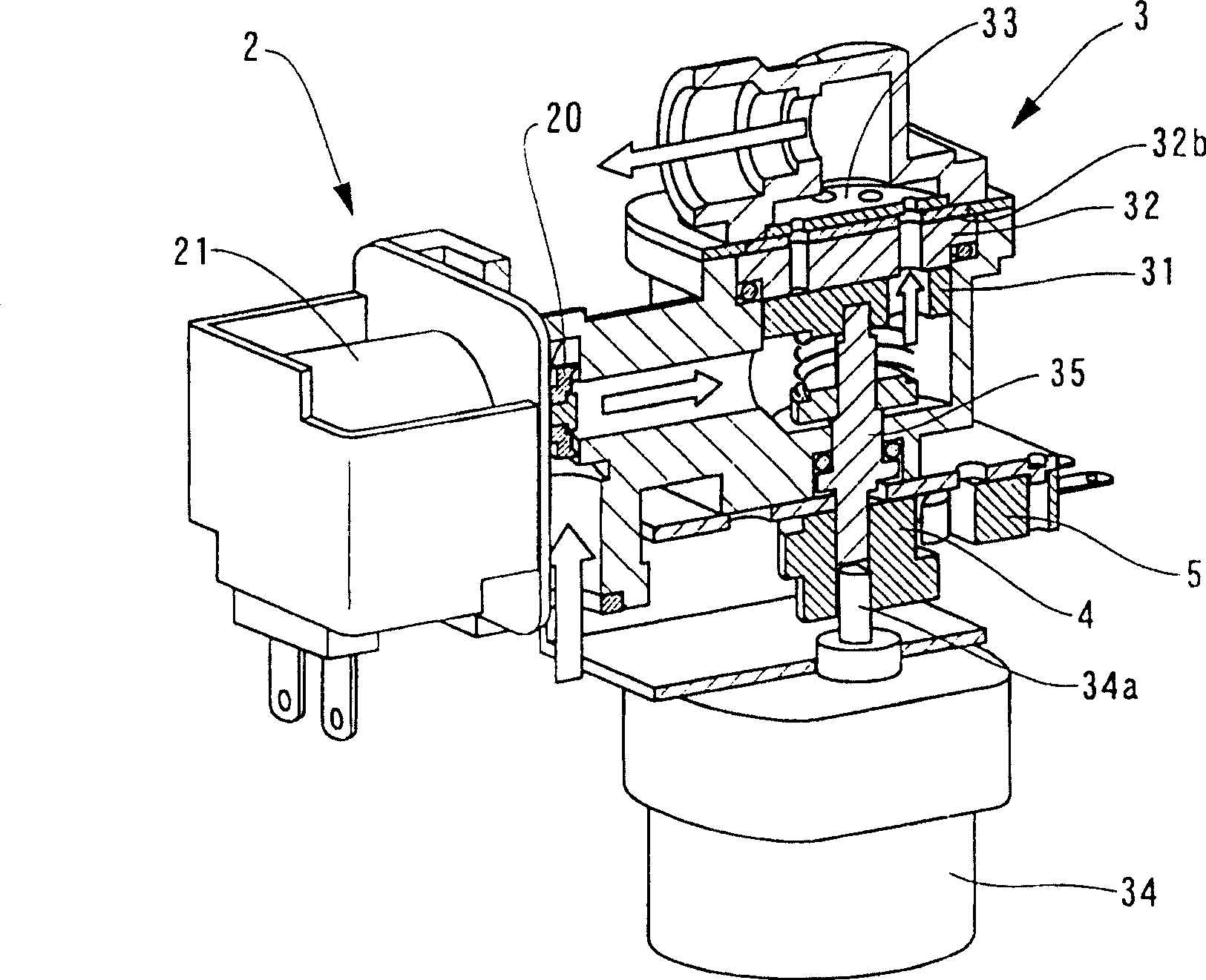

Fire regulating device

InactiveCN100480583CReliable correctionFuel supply regulationGaseous fuel feeder/distributionPulse numberEngineering

When constantly detecting the opening of the flowrate adjusting valve (3) that is driven by a stepping motor (34) with the use of a rotary encoder, etc., the precision of the opening control is increased, but the control device becomes complicated. Therefore, although the opening of the flowrate adjusting valve can be controlled by means of the pulse number supplied to the stepping motor (34), it is necessary to correct positively the pulse deviation due to the step-out. In accordance with this invention, when the micro switch (5) positioned at a position that is adjacent to a completely turn off position and to which the gas amount required for igniting can be supplied is ON, the deviation of the pulse number and the actual opening is corrected.

Owner:RINNAI CORP

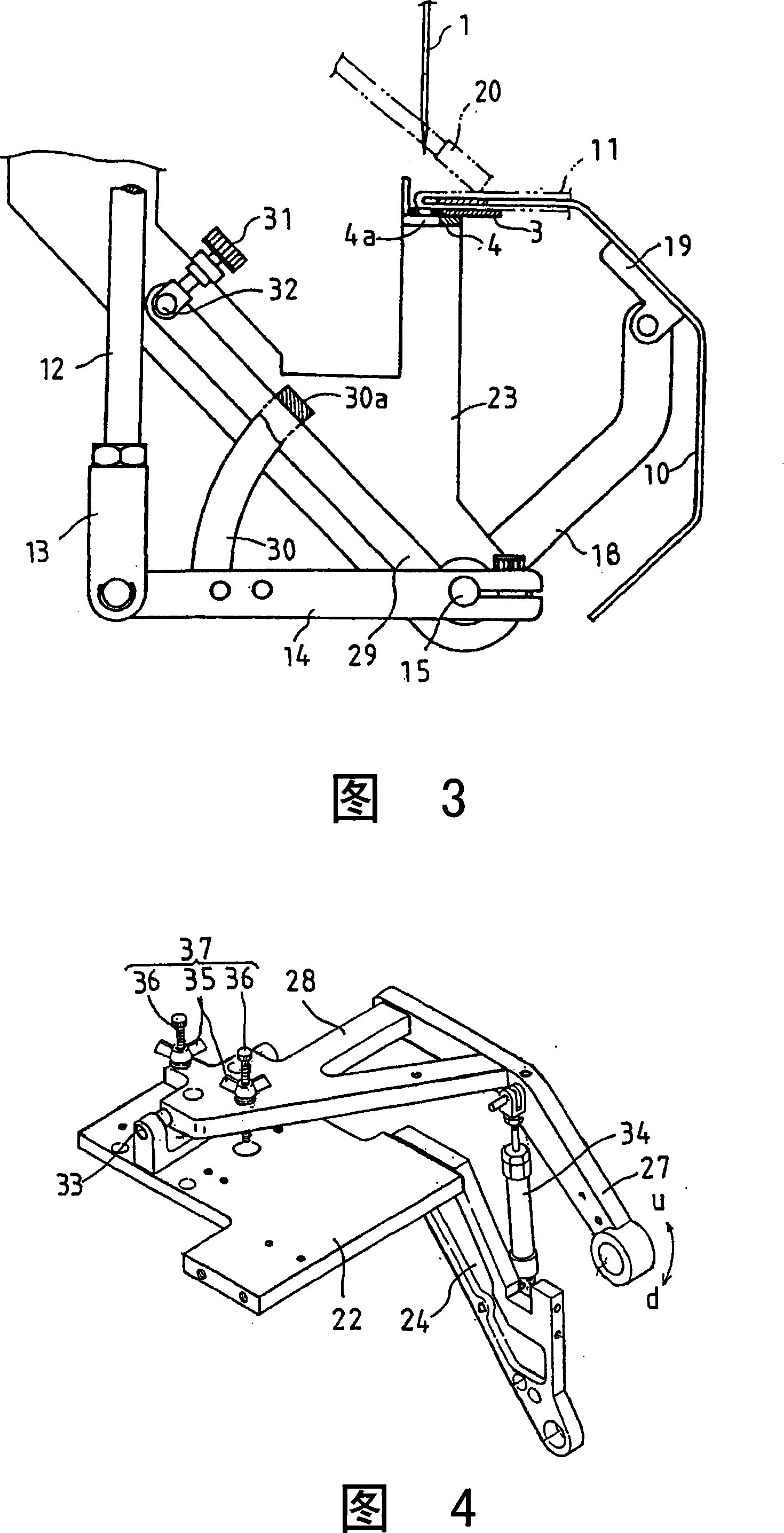

Button sewing method and sewing machine

InactiveCN101135088AGood appearanceGood hand touchSewing-machine control devicesNeedle barsEngineeringSewing machine

A button seam attaching method and a sewing machine thereof are provided. When a button-sewing step is finished, in the stage of before changing to the sinter fused step, a button holder and the button holded on the button holder are moved up and down relative to the cloth, the deflection of the button-sewing thread can be corrected simply and reasonably when switching the button-sewing posture to the sinter fused posture, products with good appearance and touching feel can be acquired.

Owner:YAMATO SEWING MASCH MFG CO LTD

Sewing machine

ActiveCN1807737BEasy to judge and displayReliable inputProgramme-controlled sewing machinesOther angling devicesEngineeringData entry

Disclosed is a sewing machine, characterized in that when the area facing the inner side of the sewing machine(M), which is provided with a retainer frame(11) is kept on the sewing target object, the needle(8) of the sewing machine drops, forming stitches; the coordinate data corresponding to the positions of the stitches are inputted into the sewing machine(M) and then judgment of whether the coordinate data is contained in the prearranged coordinate data corresponding to the sewable area is carried out and then the judgment result is displayed in a displayer in different modes with respect to whether the coordinate data is contained in the prearranged coordinate data or not. Therefore, the sewing machine of the invention is easy to tell the data regarding the sewing of the sewing machine and to tell whether the data are effective for sewing.

Owner:JUKI CORP

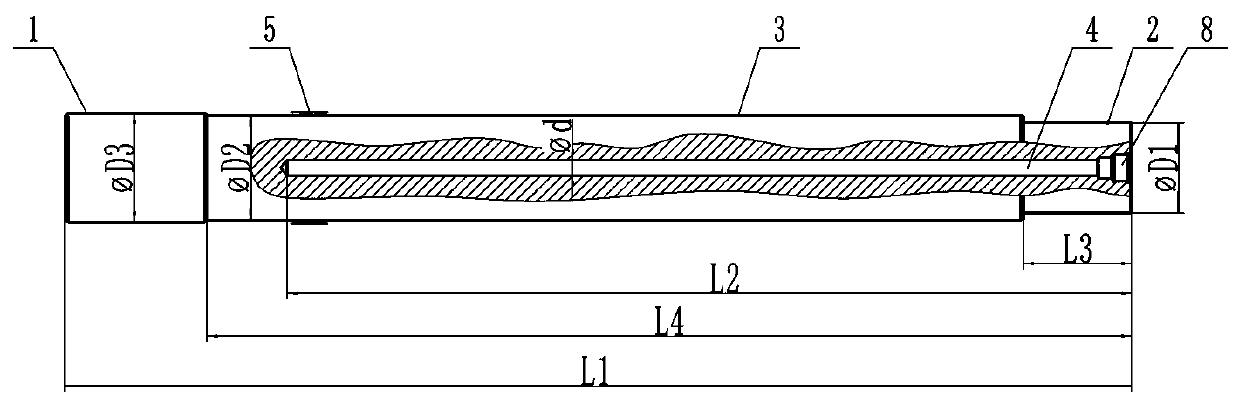

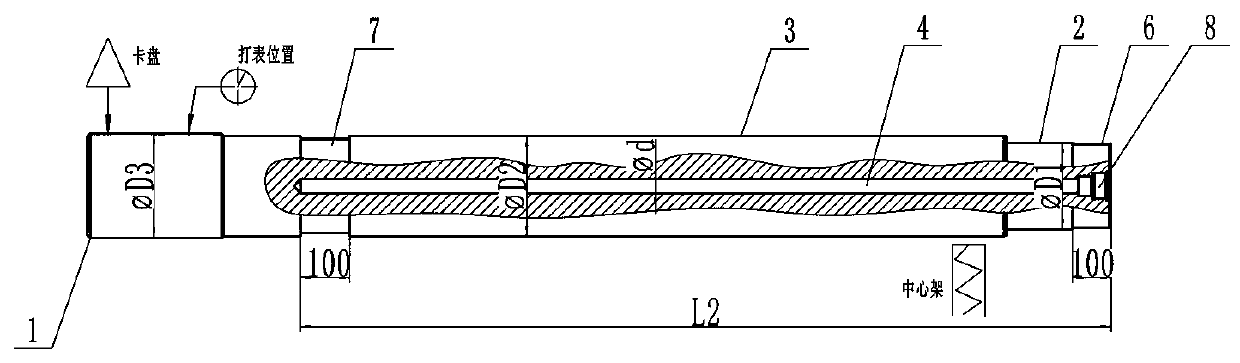

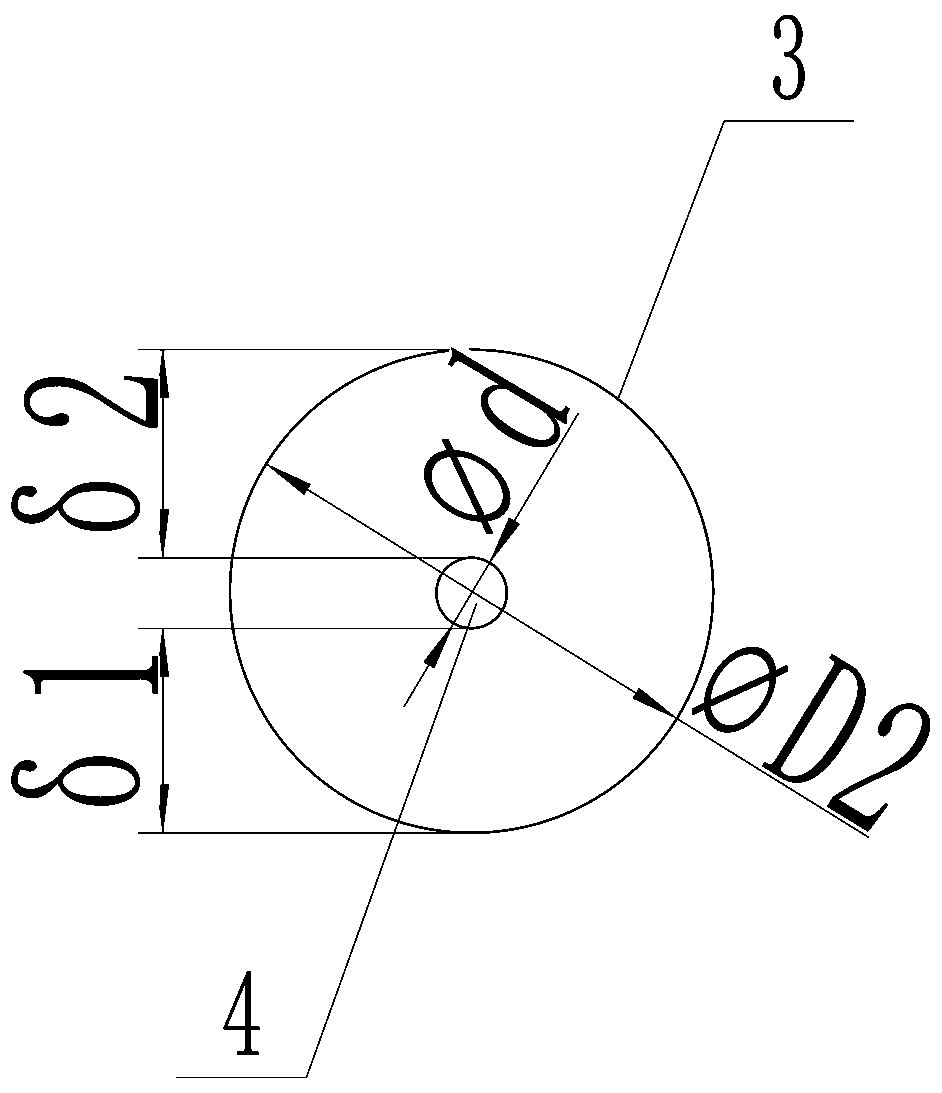

A method for controlling the concentricity between the deep hole and the outer circle of a deep hole piston rod

ActiveCN109531068BImprove coaxialityGuaranteed coaxialityUsing subsonic/sonic/ultrasonic vibration meansMechanical measuring arrangementsRabbetPiston rod

The invention provides a deep hole piston rod deep hole and outer circle coaxiality control method. The method comprise the following steps that (a) the end face of the large-head end of a piston rodand the end face of the hole opening end of the piston rod are flatten through turning, outer circles of the piston rod undergo semi-finish turning, and a blind hole is drilled from the center of thehole opening end; (b) the wall thickness of one circle at the deep part of the blind hole is measured, and the correction size of the outer circle of the large-head end is calculated; (c) the positioncorresponding to the central axis of the blind hole is found on the outer circle of the large-head end by utilizing the correction size, and two reference outer circles are turned on all the outer circles of the piston rod correspondingly; and (d) the two reference outer circles are used as reference, the piston rod is fixed, the end face of the large-head end is flattened through turning, the center hole of the end face of the large-end is corrected, the outer circle at the large-head end is turned to meet the required size through the center hole of the large-head end, the end face of the hole opening end is flatten through turning, a rabbet of the hole opening end is turned, and other outer circles are turned to meet the required sizes through the rabbet of the hole opening end. According to the deep hole piston rod deep hole and outer circle coaxiality control method, the advantages that the design is novel, the product quality is good, the production cost is low, and the production efficiency is high are achieved.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP +1

A correction and fitting method for monitoring data of earthen sites based on temporal-spatial correlation

InactiveCN105787283BAccurate calculationIn line with real monitoring statusForecastingCharacter and pattern recognitionSite monitoringMissing data

The invention discloses a method for correcting and fitting earthen site monitoring data based on spatiotemporal correlation. It uses the prediction value of historical data and current detection data to conduct spatiotemporal correlation analysis, thereby determining the correctness of the current data and correcting the noise data. , missing values are fitted. The invention is used in the field of earthen relics protection to realize intelligent status monitoring of earthen relics. Especially for a large amount of environmental data and earthen relics ontology data, it can accurately realize the discovery and correction of noise data and the fitting of missing data trends, providing a new method for earthen relics. Provide scientific basis for risk early warning and effective management.

Owner:NORTHWEST UNIV

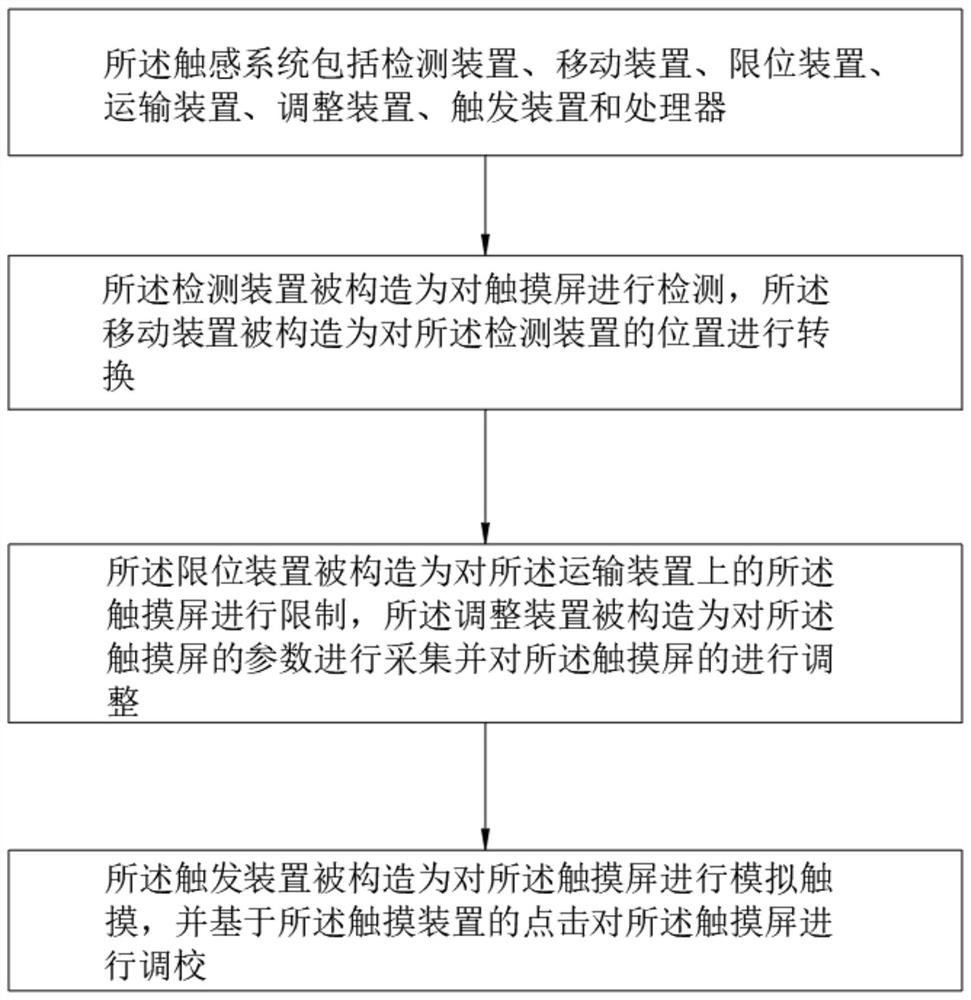

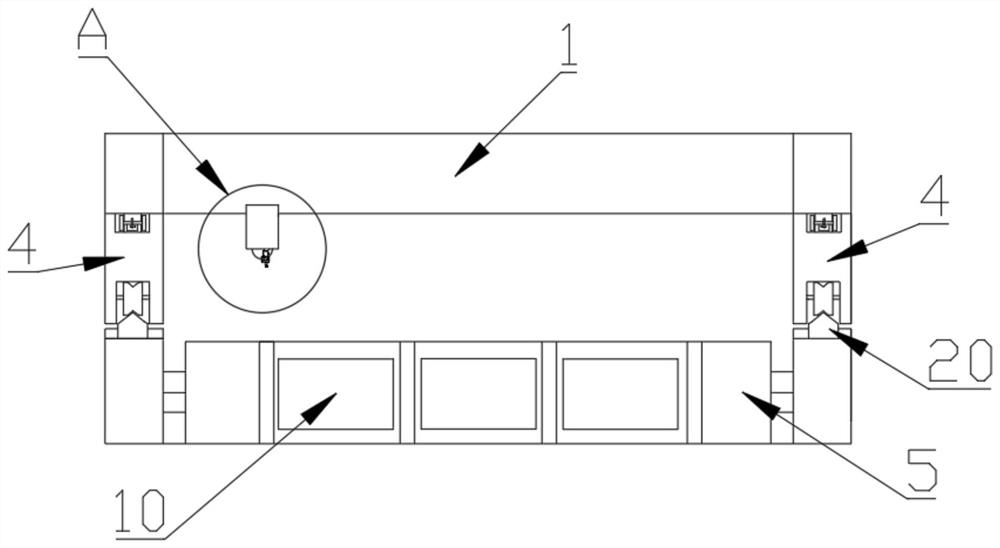

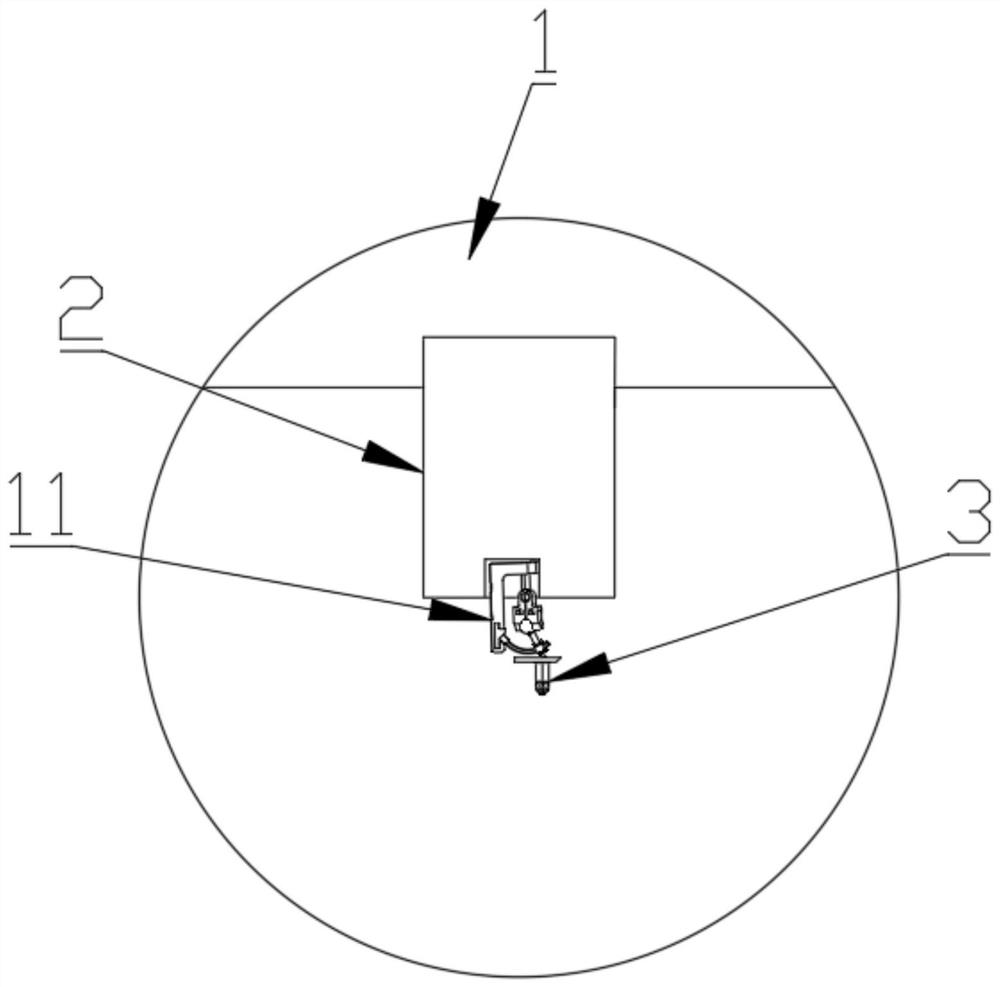

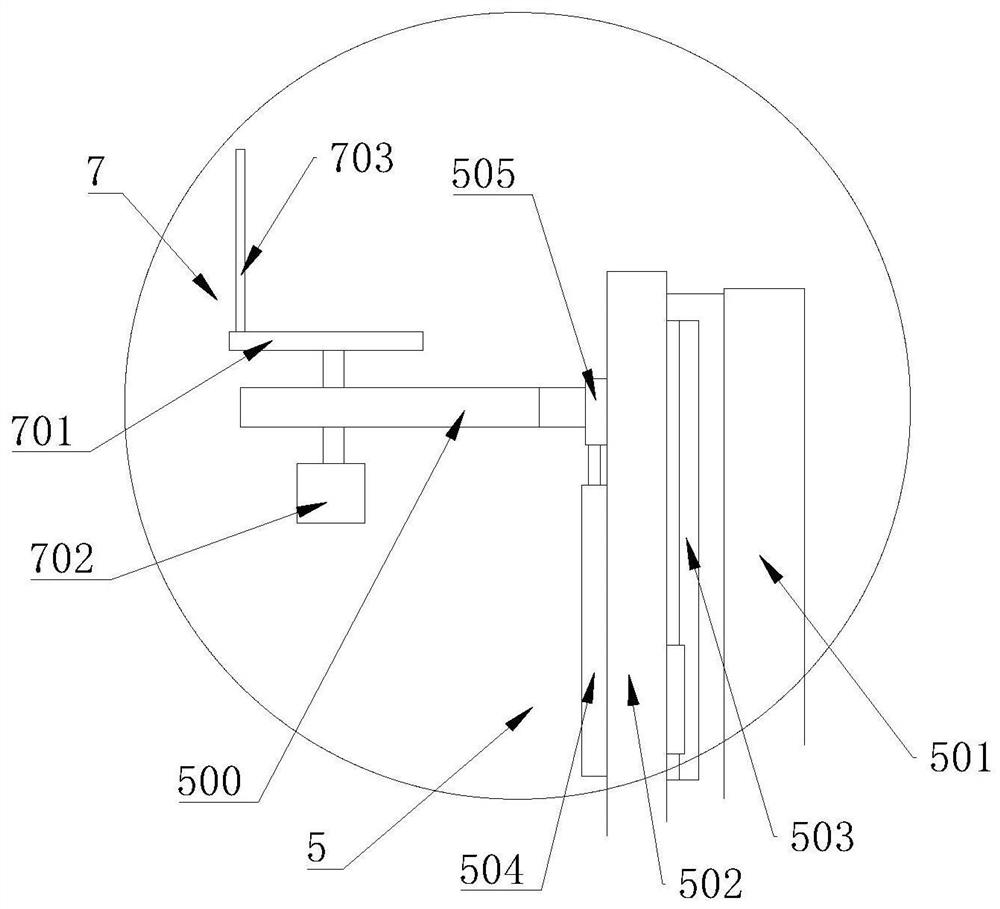

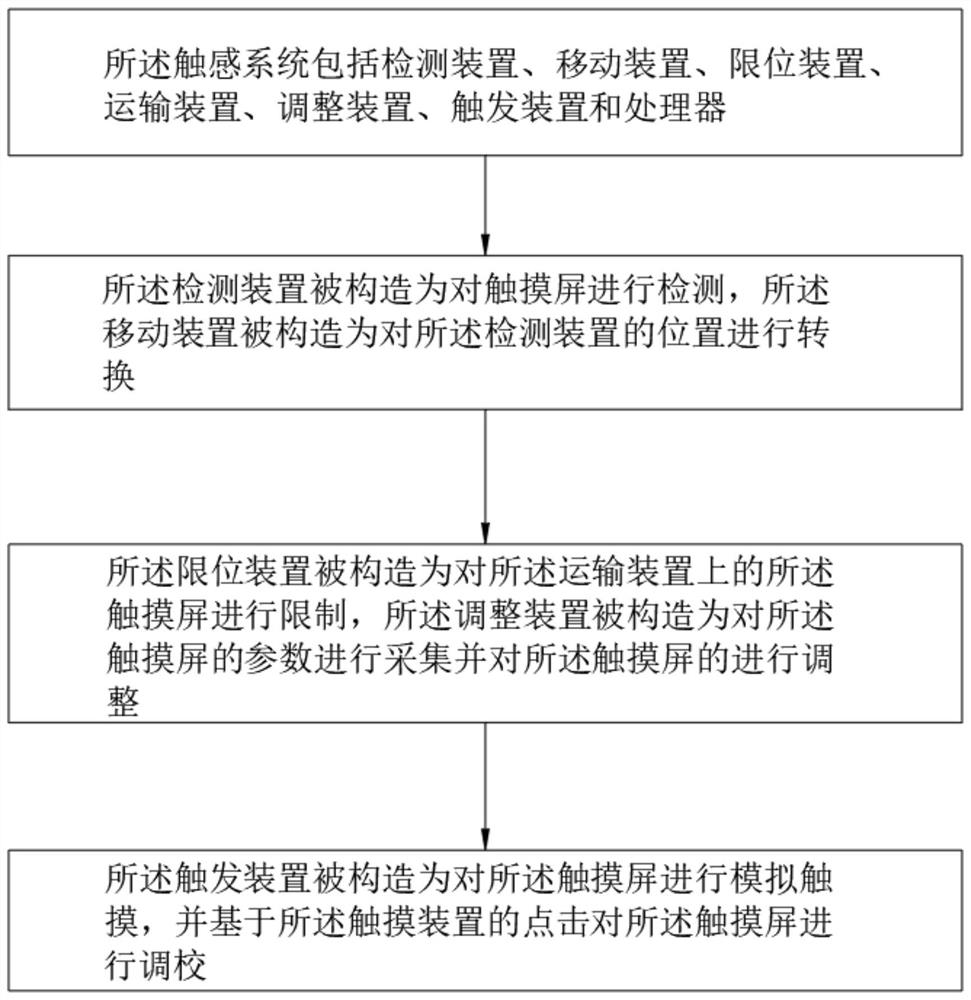

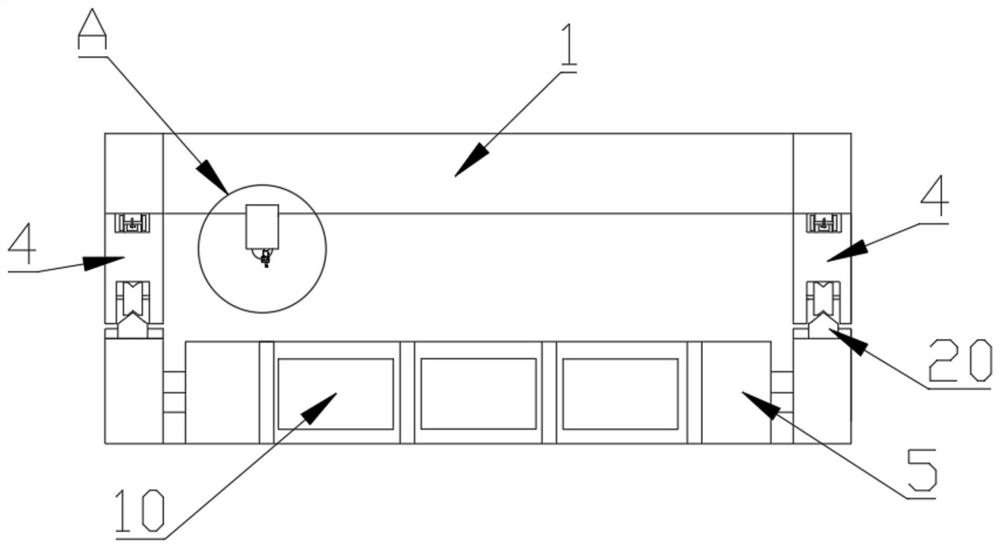

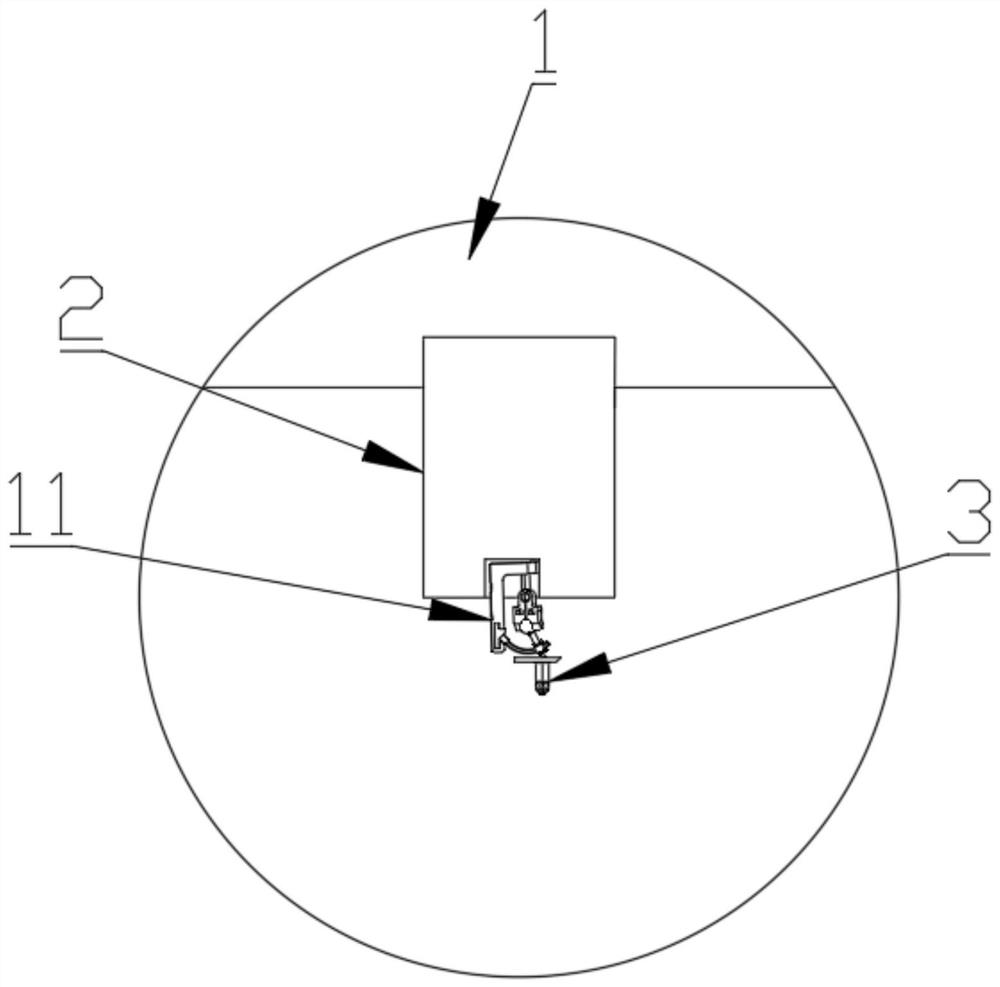

A tactile system for touch screen detection and adjustment

ActiveCN112000246BRealize adjustment operationAccurate detectionInput/output processes for data processingComputer hardwareCapacitive coupling

The invention provides a tactile system for detecting and adjusting a touch screen. The tactile system includes a detection device, a moving device, a limit device, a transportation device, an adjustment device, a trigger device and a processor. The detection device is configured to detect the touch screen, move The device is configured to convert the position of the detection device; the limit device is configured to limit the touch screen on the transport device, and the adjustment device is configured to collect parameters of the touch screen and adjust the touch screen; the trigger device is configured to Simulates a touch on the touch screen. The present invention determines the touch coordinates of the passive touch object close to the sensing array by indicating the capacitive coupling of the trigger signal to multiple electrodes through the passive touch object, ensuring the accuracy of touch screen detection, and at the same time, determining the position of the detected coordinates Adjust the sensitivity to ensure that the touch screen can reliably detect and correct the touch during the detection process.

Owner:深圳市信濠光电科技股份有限公司

Medium conveying device, control method of medium conveying device, and recording device

InactiveCN103660629BReliable CorrectionSuitable for printingFunction indicatorsOther printing apparatusMechanical engineeringRecording media

Owner:SEIKO EPSON CORP

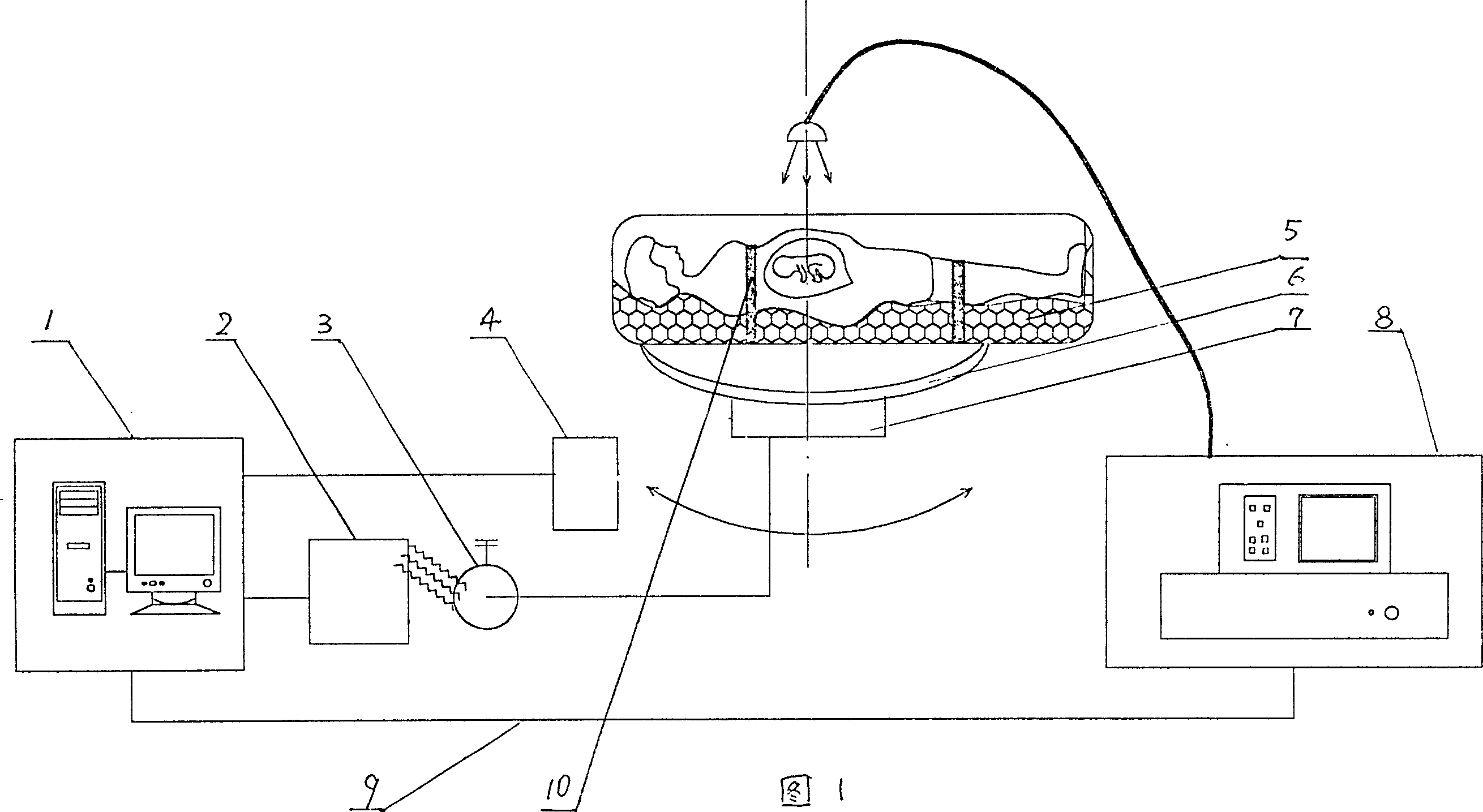

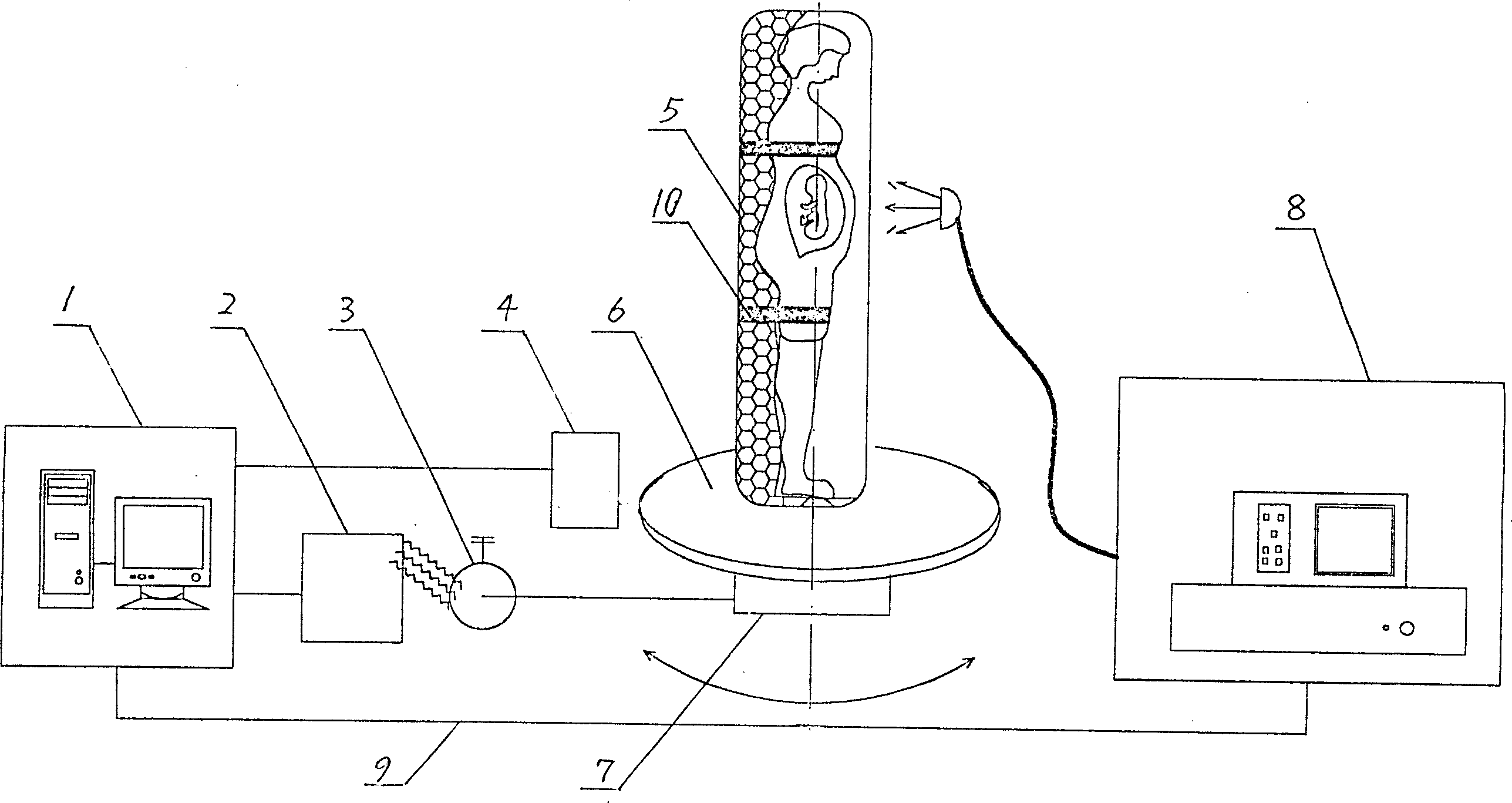

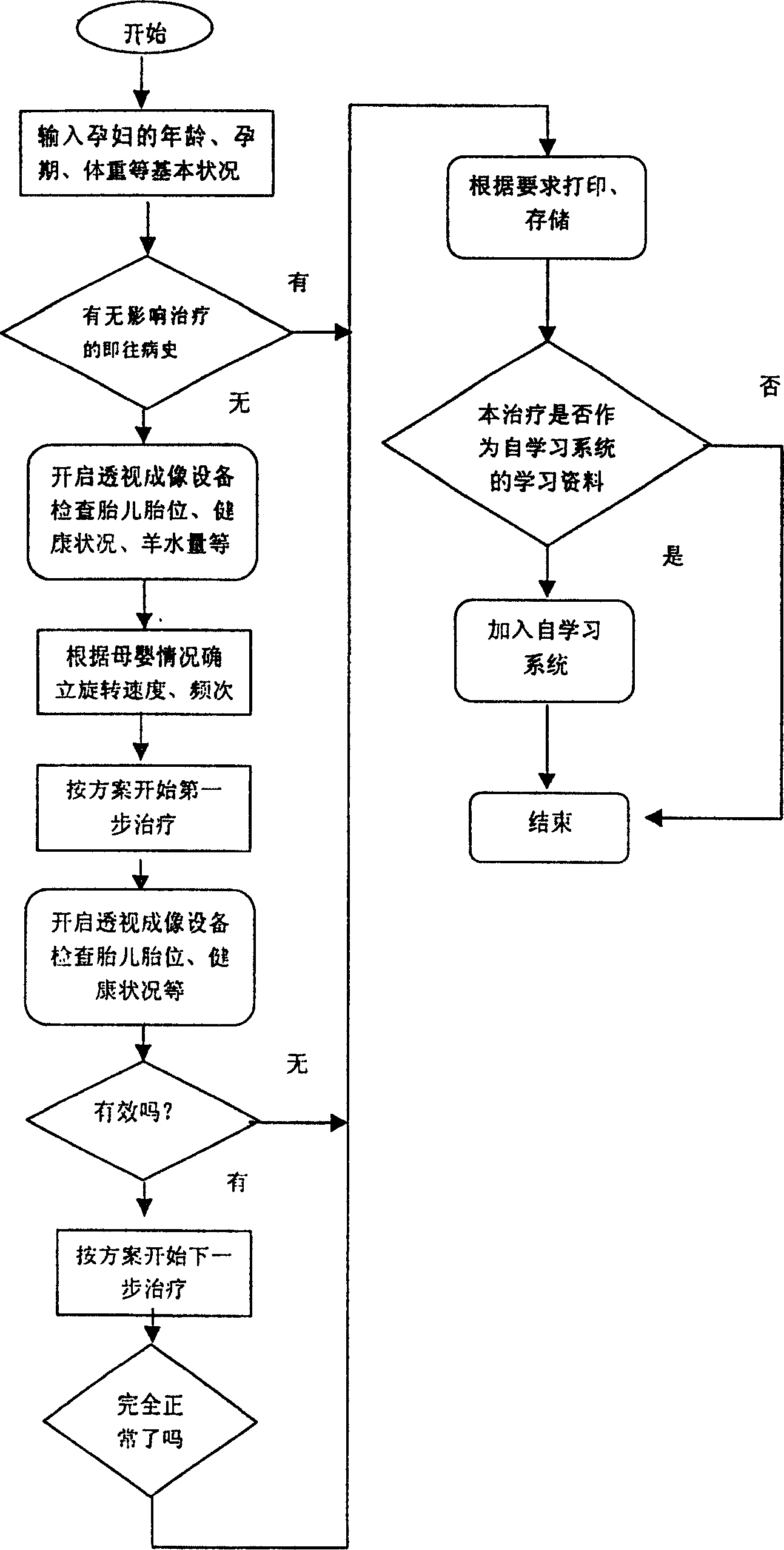

Rotary type fetal position correction therapeutic bed

InactiveCN1229080CRelieve painRelieve stressNursing bedsObstetrical instrumentsCircular discControl system

A rotary fetal position correcting therapeutic bed is composed of a bed body for fixing a gravida on it, a driven mechanism consisting of motor and turntable for arranged said bed body on it, and control system consisting of angular shift sensor and acceleration sensor for said turntable, hardware, software and perspective imaging system for monitoring the position of fetus. When the bed is rotating in different modes, under the action of inertia, the position of fetus in amniotic fluid can be corrected.

Owner:宫恩晴

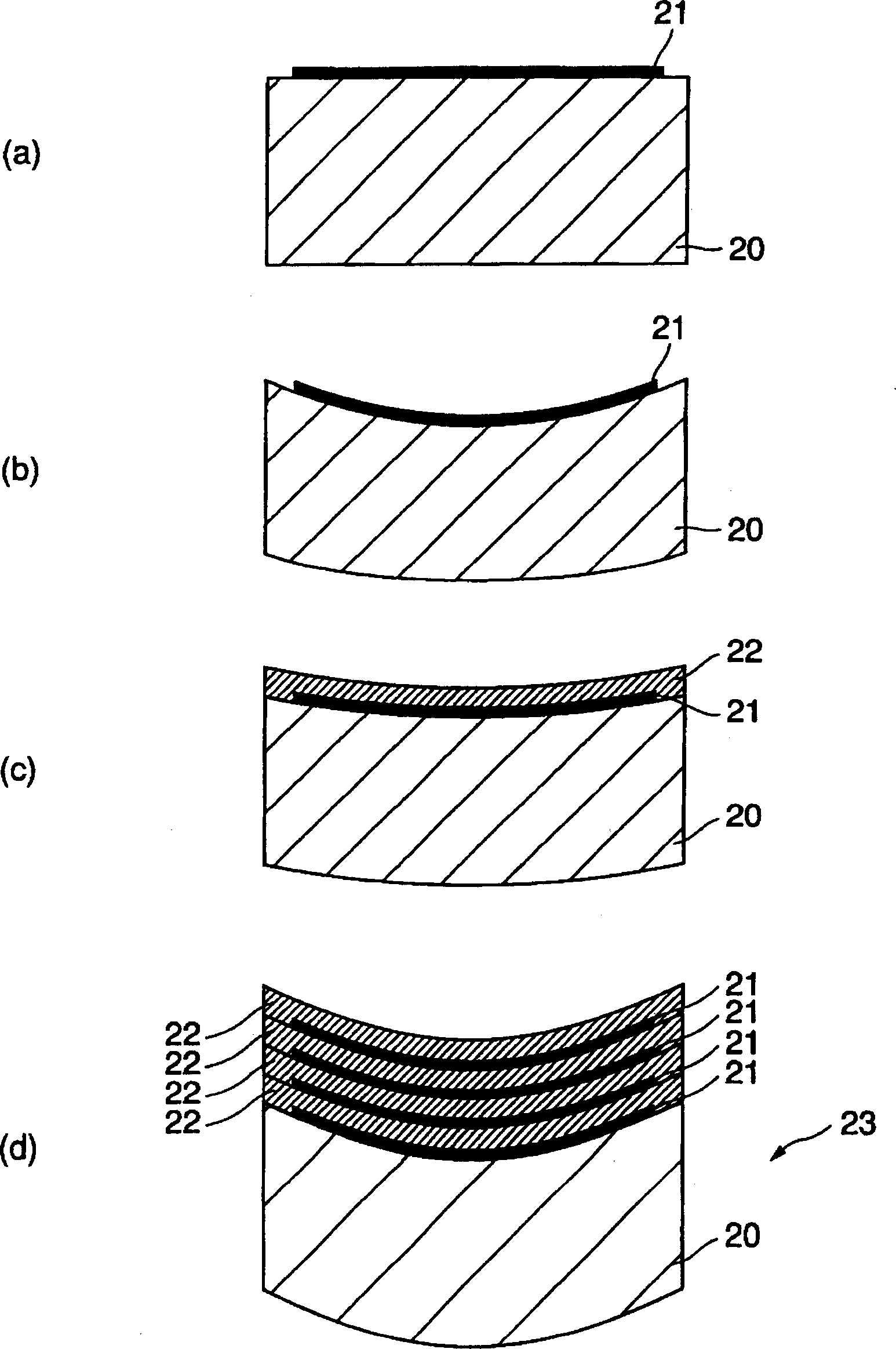

Immersion Objectives for Microscopy

An immersion objective lens (10) for a microscope (100) is introduced, including a first lens group (12) with positive refractive power, a second lens group (14) with positive refractive power, and a third lens group with negative refractive power. (16) and a fourth lens group (18) with positive refractive power. These lens groups are arranged in this order from the object side. In order to achieve a correction effect for spherical aberration, the second lens group (14) can be arranged along the The optical axis (O) moves, so that the distance (V1) between the second lens group (14) and the first lens group (12) is the same as the distance (V1) between the second lens group (14) and the third lens group (14). The sum of the distances (V2) between the lens groups (16) is constant, wherein the corrective effect of the second lens group (14) is predetermined such that the spherical aberration of the light projection corresponds to an average numerical aperture The minimum, average numerical aperture lies between zero and the nominal aperture of the immersion objective (10).

Owner:LEICA MICROSYSTEMS CMS GMBH

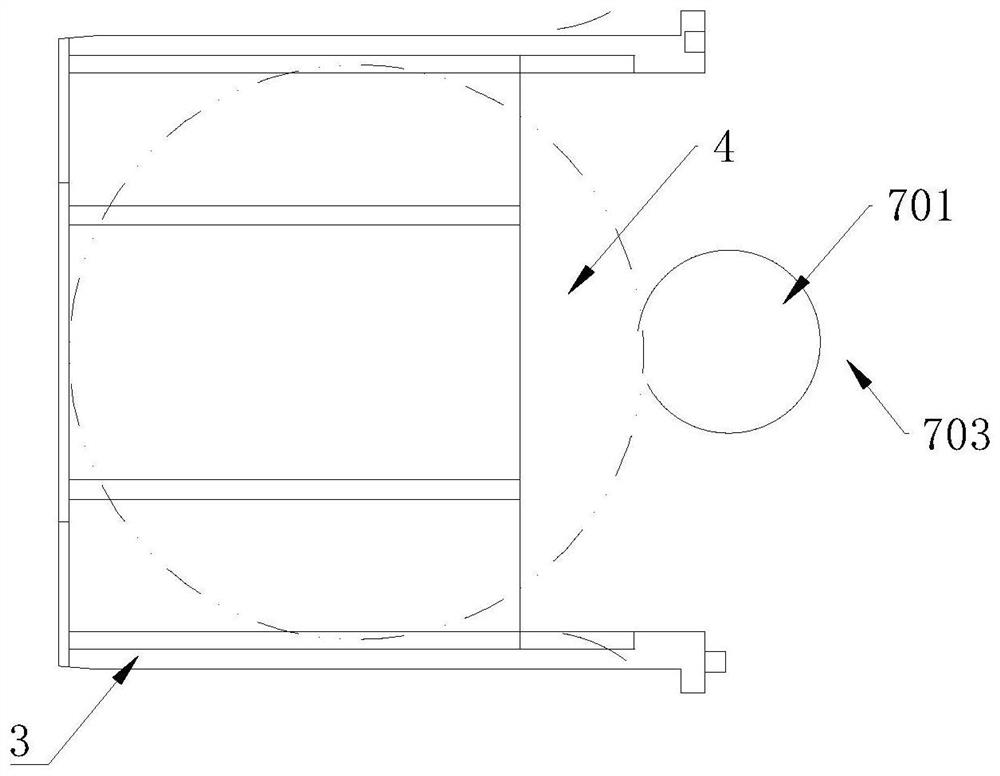

Rotary pre-correction device for silicon wafer

PendingCN111897190AHigh precisionGuaranteed continuityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMachine

The invention discloses a rotary pre-correction device for a silicon wafer. The device comprises a machine frame, a placing platform driven by a lifting driving device is arranged on the machine frame, a silicon wafer containing box is positioned on the placing platform, a horizontal support is arranged on the machine frame, a vertical driving mechanism is arranged on the horizontal support, a supporting base is driven by the vertical driving mechanism, a correcting mechanism is installed on the supporting base in a rotating mode, and the correcting mechanism and the opening end of the siliconwafer containing box are arranged on the same side. The supporting base is driven by the vertical driving mechanism to ascend and get close to the silicon wafer in the silicon wafer containing box; then force is applied to the silicon wafer through the rotating correcting mechanism, and the silicon wafer abuts against the end arm on the silicon wafer containing box, so that before the silicon wafer is transferred to the photoetching machine, the reset correction work of the silicon wafer (the position of the silicon wafer is changed) is completed, the accuracy of transferring the silicon wafer to a photoetching area is improved, and the continuity and the working efficiency of normal working of the photoetching machine are effectively guaranteed.

Owner:江苏晋誉达半导体股份有限公司

Touch system for detecting and adjusting touch screen

ActiveCN112000246ARealize adjustment operationAccurate detectionInput/output processes for data processingComputer hardwareTouch Senses

The invention provides a touch system for detecting and adjusting a touch screen, which comprises a detection device, a moving device, a limiting device, a transportation device, an adjustment device,a triggering device and a processor, and is characterized in that the detection device is configured to detect the touch screen, and the moving device is configured to convert the position of the detection device; the limiting device is constructed to limit the touch screen on the conveying device, and the adjusting device is constructed to collect parameters of the touch screen and adjust the touch screen. The trigger device is configured to perform a simulated touch on the touch screen. According to the invention, the trigger signal is indicated to pass through the passive touch object to be capacitively coupled to the plurality of electrodes, the touch coordinates of the passive touch object close to the sensing array are determined, the detection accuracy of the touch screen is guaranteed, meanwhile, sensitivity adjustment is conducted on the positions of the detected coordinates, and it is guaranteed that the touch screen can reliably correct the touch sense in the detection process.

Owner:深圳市信濠光电科技股份有限公司

Image processing method, image processing program and recording medium for recording the same program

InactiveCN1236402CReliable CorrectionEffective correctionImage enhancementImage data processing detailsImaging processingEllipse

An image correction processing apparatus for correcting a pixel value of each pixel constituting image data obtained from an original image affected by the peripheral light-off is disclosed. The apparatus includes a pixel coordinate transforming unit (70) for converting a distance between each pixel of a group of pixels which have an equal amount of peripheral light amount reduction and which are located on a common contour line of an oval about a predetermined reference pixel located at the center thereof and said predetermined reference pixel into a radius of a true circle having a diameter corresponding to the major axis of the oval; a cos<4> calculating unit (71) for obtaining, for each pixel, an angle value thereof in proportion to the radius obtained by the conversion and then obtaining a cos<4> value of the angle value; and a correction calculating unit (72) for multiplying an inverse of said cos<4> value obtained for each pixel by a pixel value of this pixel, thereby to obtain a corrected pixel value for the pixel.

Owner:NORITZ CORP

Device for correcting inclined iron transmission tower of double combined angle steel main material

The invention discloses a device for correcting an inclined iron transmission tower of double combined angle steel main material, wherein the device is particularly suitable for correcting the inclined iron transmission tower in a coal mine subsidence area. The device comprises an eyelet bolt, an angle steel inner clamp, an auxiliary corner brace, a pressure sensor, a hydraulic supporting column, a base and the like. When differential settlement happens to the iron transmission tower of double combined angle steel main material in the coal mine subsidence area, the device for correcting the inclined iron transmission tower can adjust the iron transmission tower and release the structural additional internal force and deformation which are caused by the differential settlement of a foundation to the iron transmission tower in a mining area, thereby ensuring safety of the iron transmission tower. The device is high in bearing capacity, low in number of tools, flexible in operation, convenient to construct and high in accuracy and reliability and has wide practicability.

Owner:STATE GRID CORP OF CHINA +2

Clock fractional divider module, image and/or video processing module, and apparatus

ActiveUS11138054B2Reliable detectionReliably recognizingPulse automatic controlFault responseDual coreVideo processing

A clock fractional divider module which is formed as, comprises or has integrated therein a dual-core lock step unit. The dual-core lock step unit is configured in order to realize a clock fractional division arrangement, mechanism or process accompanied by an error detection, recognition and / or correction arrangement, mechanism or process.

Owner:ROBERT BOSCH GMBH

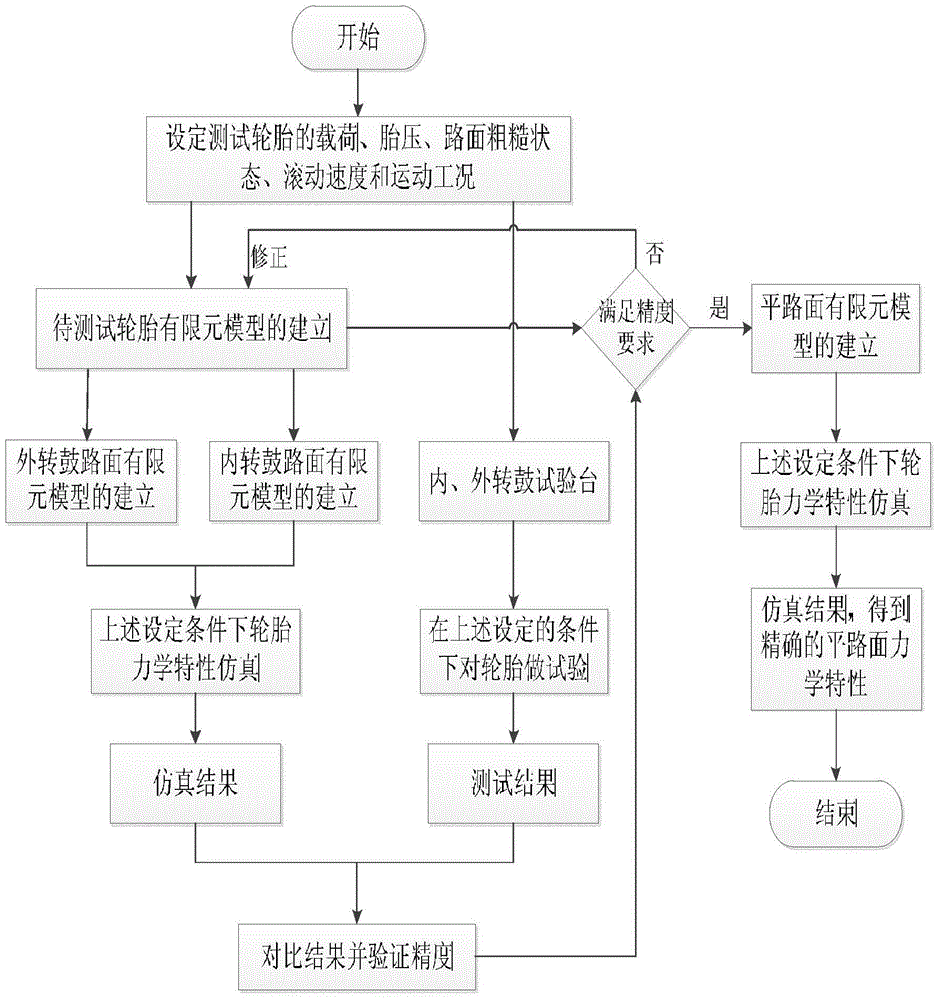

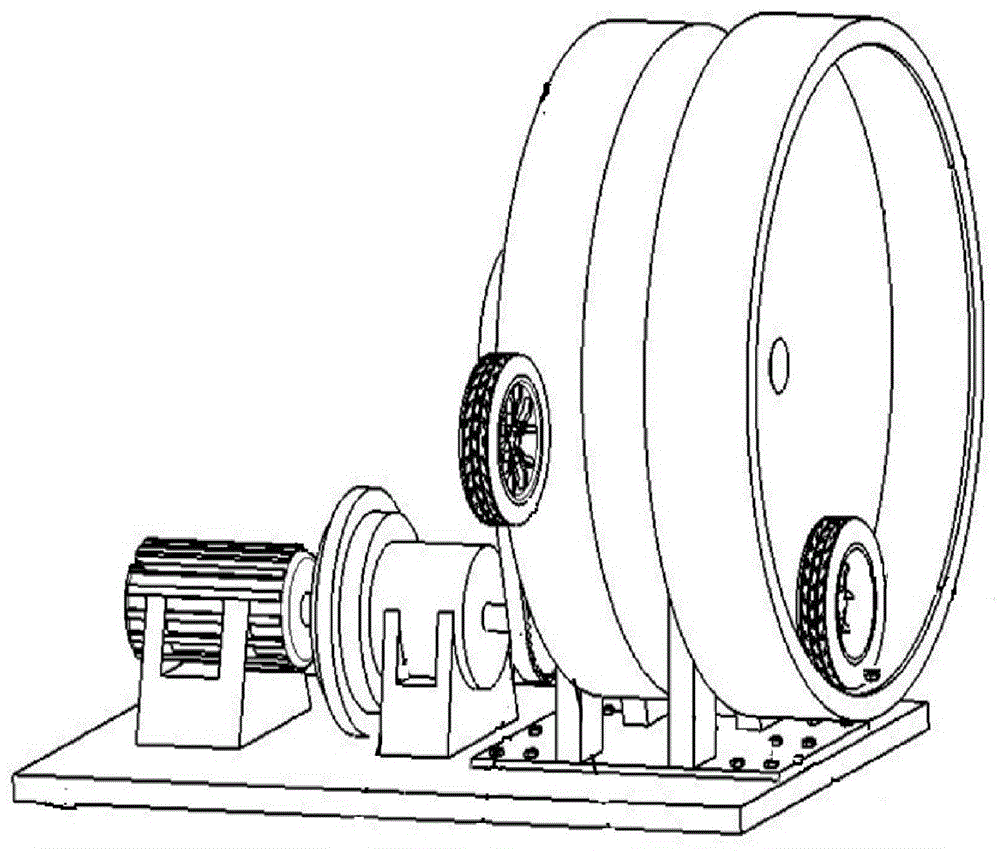

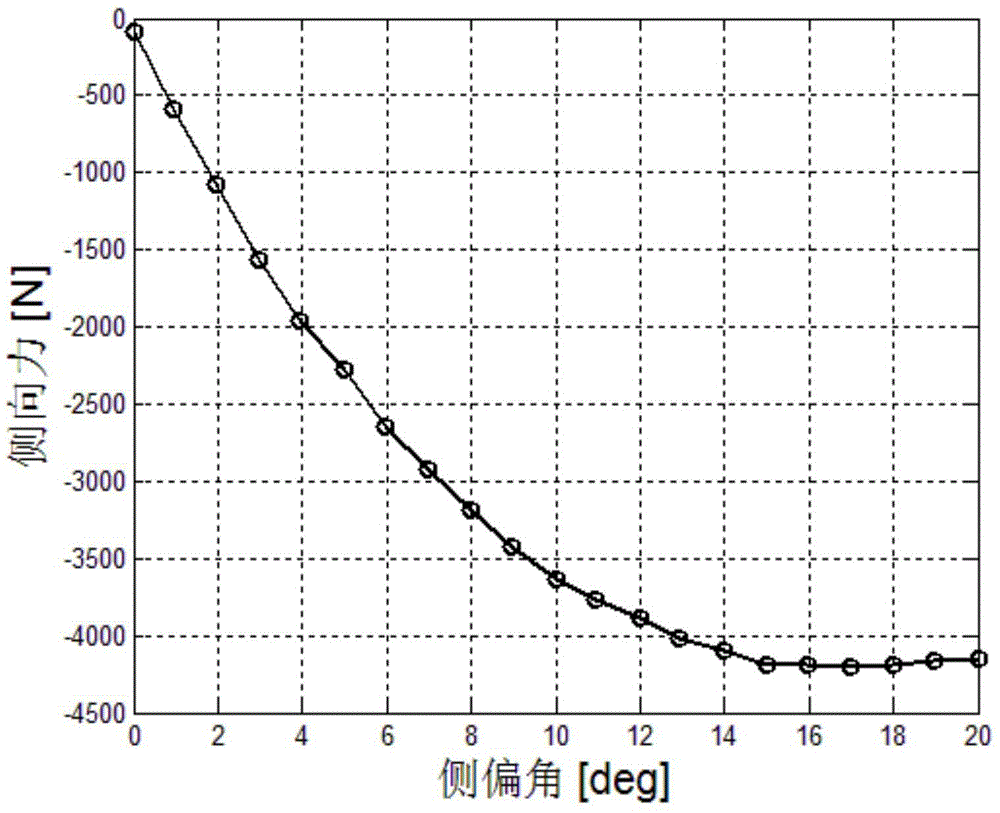

Method for Predicting Mechanical Properties of Tire on Flat Pavement Based on Drum Test Rig Test Data

ActiveCN104390794BReliable CorrectionThe mechanical properties of flat pavement are accurately obtainedVehicle tyre testingFinite element techniqueRoad surface

The invention discloses a method for predicating flat-pavement mechanical properties of a tyre based on test data of a rotary drum test bed. The method comprises the following steps of: setting load, tyre pressure, pavement rough state, rolling speed and movement working conditions (lateral deviation, lateral inclination, and the like) of the tested tyre, and implementing the tests and the simulations in the following steps under the conditions; establishing a model for the tested tyre by utilizing ABAQUS software, and respectively stimulating movement of the tyre on inner rotary drum pavement and outer rotary drum pavement; simultaneously correcting the tyre model by using the test data of the inner rotary drum test bed and the outer rotary drum test bed; simulating the tyre movement under the special condition on the flat pavement by using the corrected precise tyre model so as to precisely predicate the flat-pavement mechanical properties of the tyre. The method disclosed by the invention can be used for effectively eliminating influences of the pavement curvature by utilizing the tested data of the rotary drum test bed through a finite element technology to obtain the mechanical properties of the tyre on the flat pavement, has the advantages of simple needed test equipment and high predication precision. Meanwhile, the method is suitable for all tyres including large-load and high-rotation-speed aircraft tyres.

Owner:JILIN UNIV

Multi-layer structure unit and its manufacturing method

InactiveCN1331375CReliable CorrectionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

The purpose of the present invention is to correct the warpage of multilayer composite 5 in the process of alternatively forming conductor pattern 3 and insulation layer 4 on the insulation body substrate 2. In the process of alternatively forming conductor pattern 3 and insulation layer 4 on the insulation body substrate 2, the constituting material of the insulation layer is modified to be the other insulation material which can correct the warpage of the multilayer composite 5 according to the predetermined schedule, or in the forming step to constitute the multilayer composite 5 by the insulation substrate 2, conductor pattern 3 and insulation layer 4. Thus, the insulation layer 4 is formed, and thereby the warpage of the multilayer composite 5 can be corrected with high accuracy.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com