Fire regulating device

A technology of adjusting device and firepower, which is applied in the direction of valve device, regulating fuel supply, valve operation/release device, etc. It can solve the problems of opening degree and actual opening degree error, out of adjustment, non-detection of flow regulating mechanism opening, etc. , to achieve a reliable correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

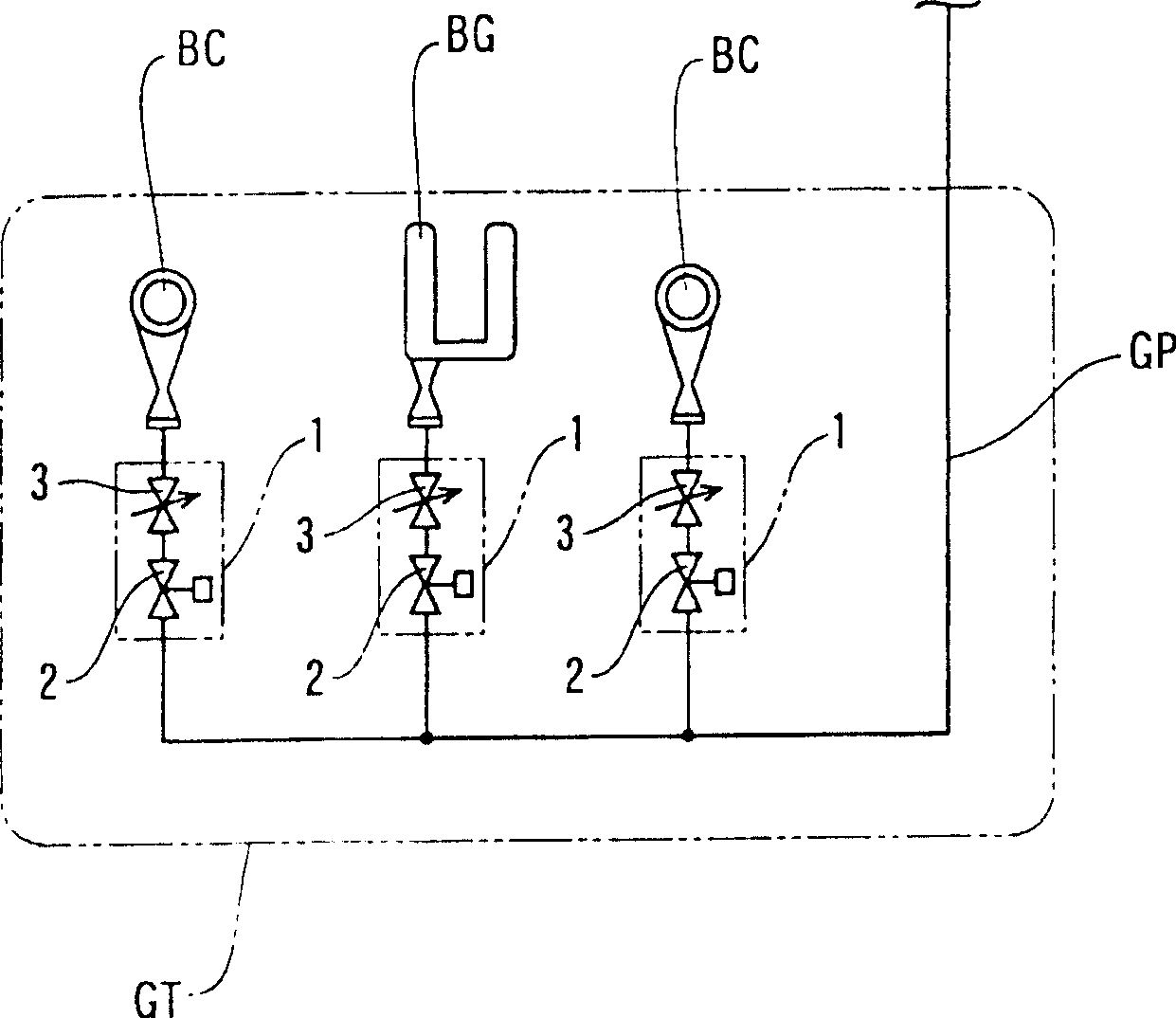

[0018] refer to figure 1 , GT is a gas bench with 2 furnace burners BC and 1 grill burner BG. These respective burners BC and BG can supply gas from the gas supply pipe GP. The valve assembly 1 for thermal power adjustment is connected in series to each burner BC, BG, respectively.

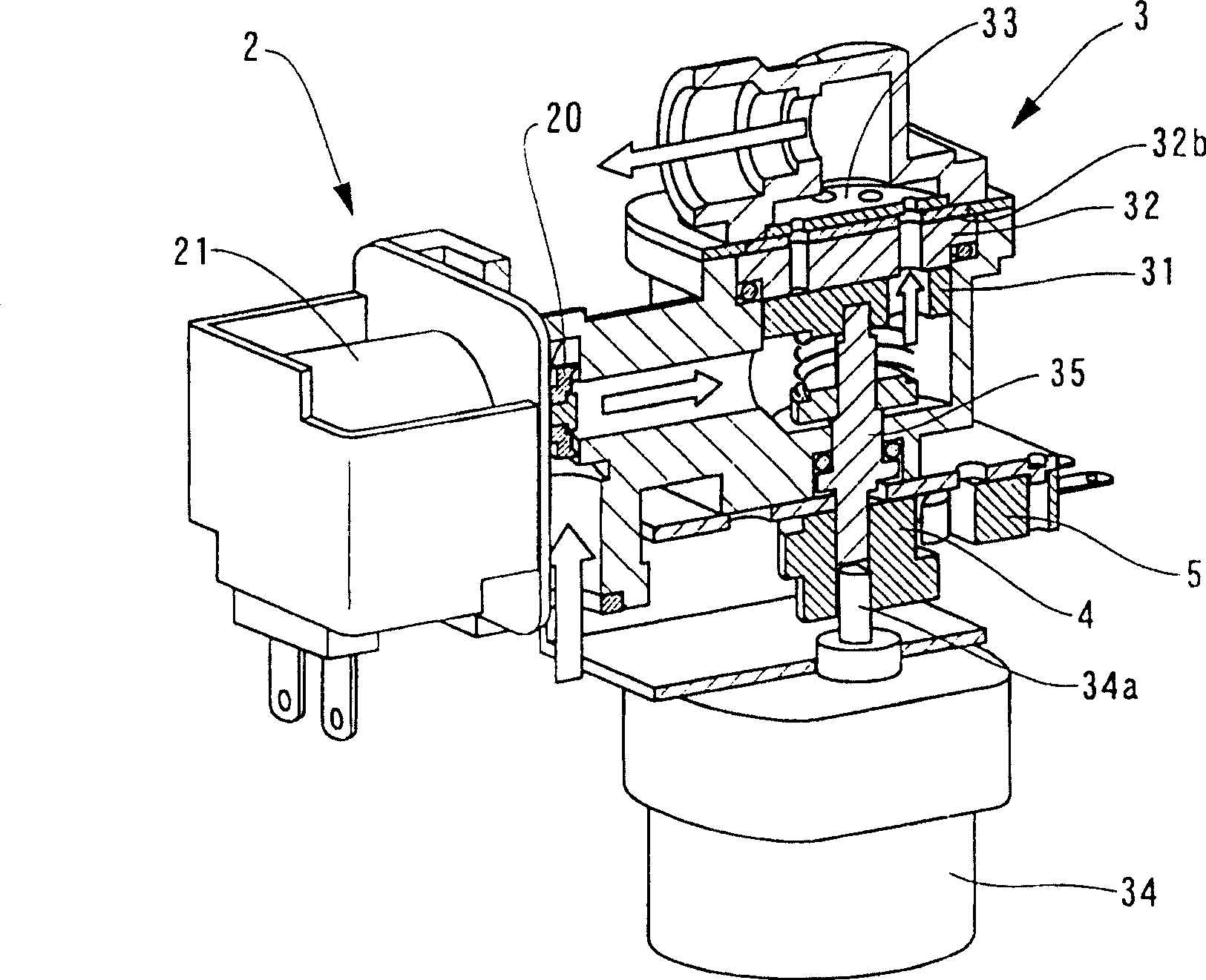

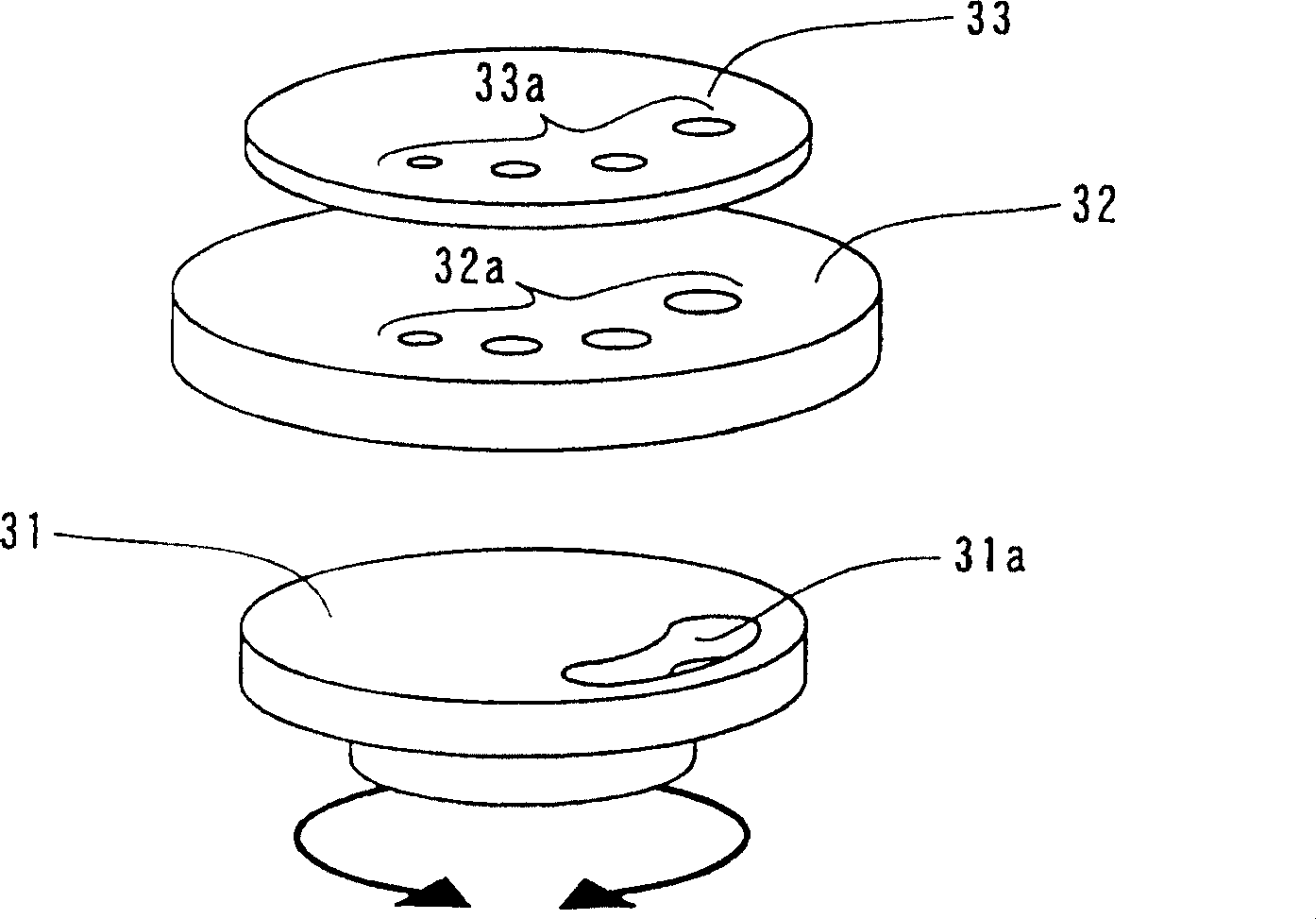

[0019] This valve assembly 1 is composed of an electromagnetic safety valve 2 and a flow regulating valve 3. The electromagnetic safety valve 2 opens and closes the gas supply passages to each burner BC, BG, and the flow regulating valve 3 opposite to each The gas flow rate supplied by the burners BC and BG is increased or decreased to adjust the firepower.

[0020] refer to figure 2 , The safety valve 2 incorporates an electromagnetic coil and a spring in the electromagnetic coil portion 21 . The valve body 20 is always exerted force in the valve closing direction by the spring, and once the electromagnetic coil is energized, the valve body 20 is driven in the valve opening direction against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com