Medium conveying device, control method of medium conveying device, and recording device

A medium conveying and control technology, applied in printing devices, transportation and packaging, thin material processing, etc., can solve problems such as recording medium wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

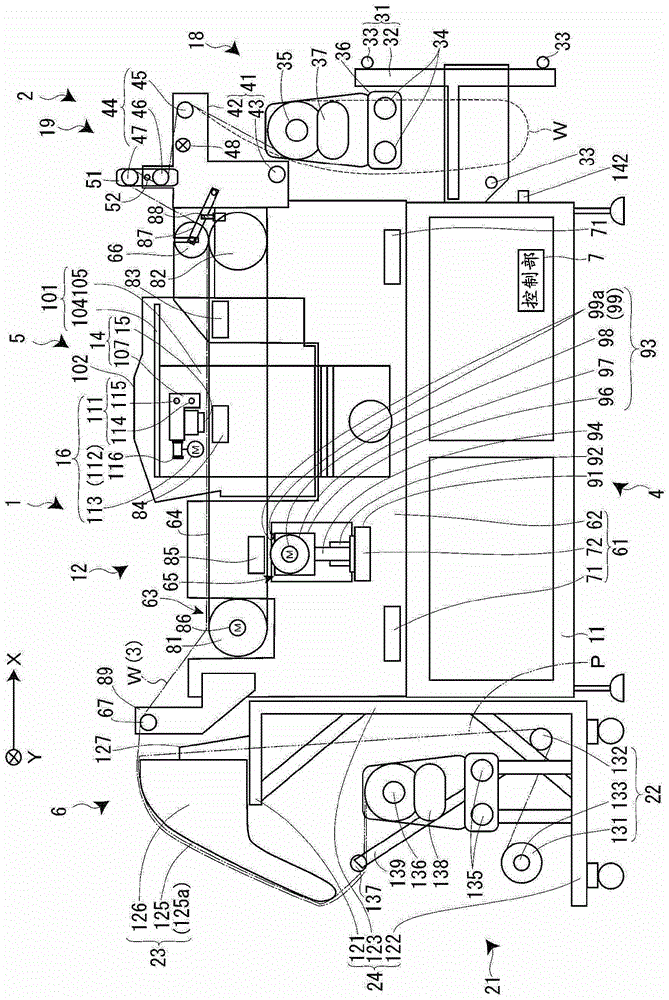

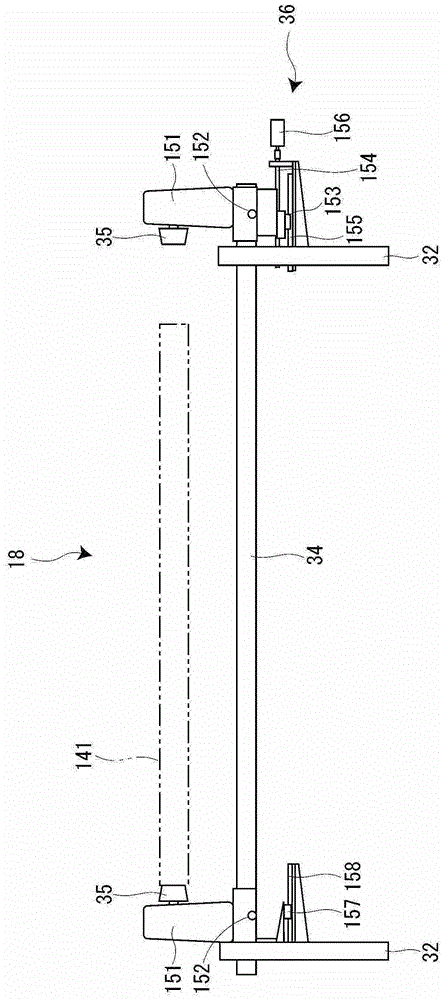

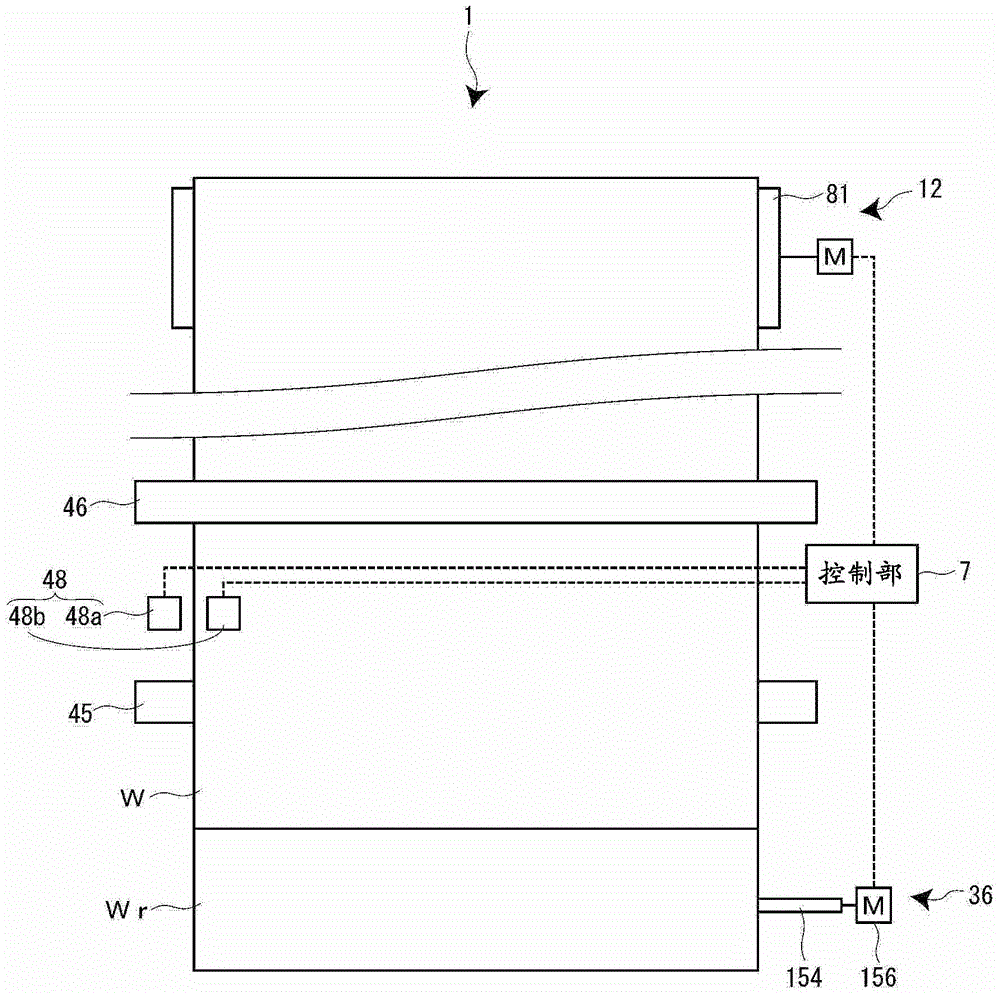

[0024] Hereinafter, an inkjet recording device 1 according to an embodiment of the present invention will be described with reference to the drawings. This inkjet recording device 1 inkjet-prints characters, patterns, etc. using a dedicated dye ink on a fabric that feeds and receives materials in a so-called reel-to-reel format (printing). In addition, in the following description, the forward and reverse conveyance direction of the recording medium W as a fabric is defined as the X-axis direction, the direction perpendicular to the X-axis direction is defined as the Y-axis direction, and the direction perpendicular to the X-axis direction and The direction of the Y-axis direction is defined as the Z-axis direction.

[0025] figure 1 is a cross-sectional configuration diagram of the inkjet recording device 1 . As shown in the figure, the inkjet recording apparatus 1 includes an ejection unit 2 that ejects and conveys a recording medium W wound in a roll shape, and an apparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com