Multi-layer structure unit and its manufacturing method

A multi-layer structure and component technology, applied in the direction of multi-layer circuit manufacturing, printed circuit components, semiconductor/solid-state device components, etc., can solve the problem of inability to form high-precision, low-yield multilayer structure components Problems such as the fixed division of the mother board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

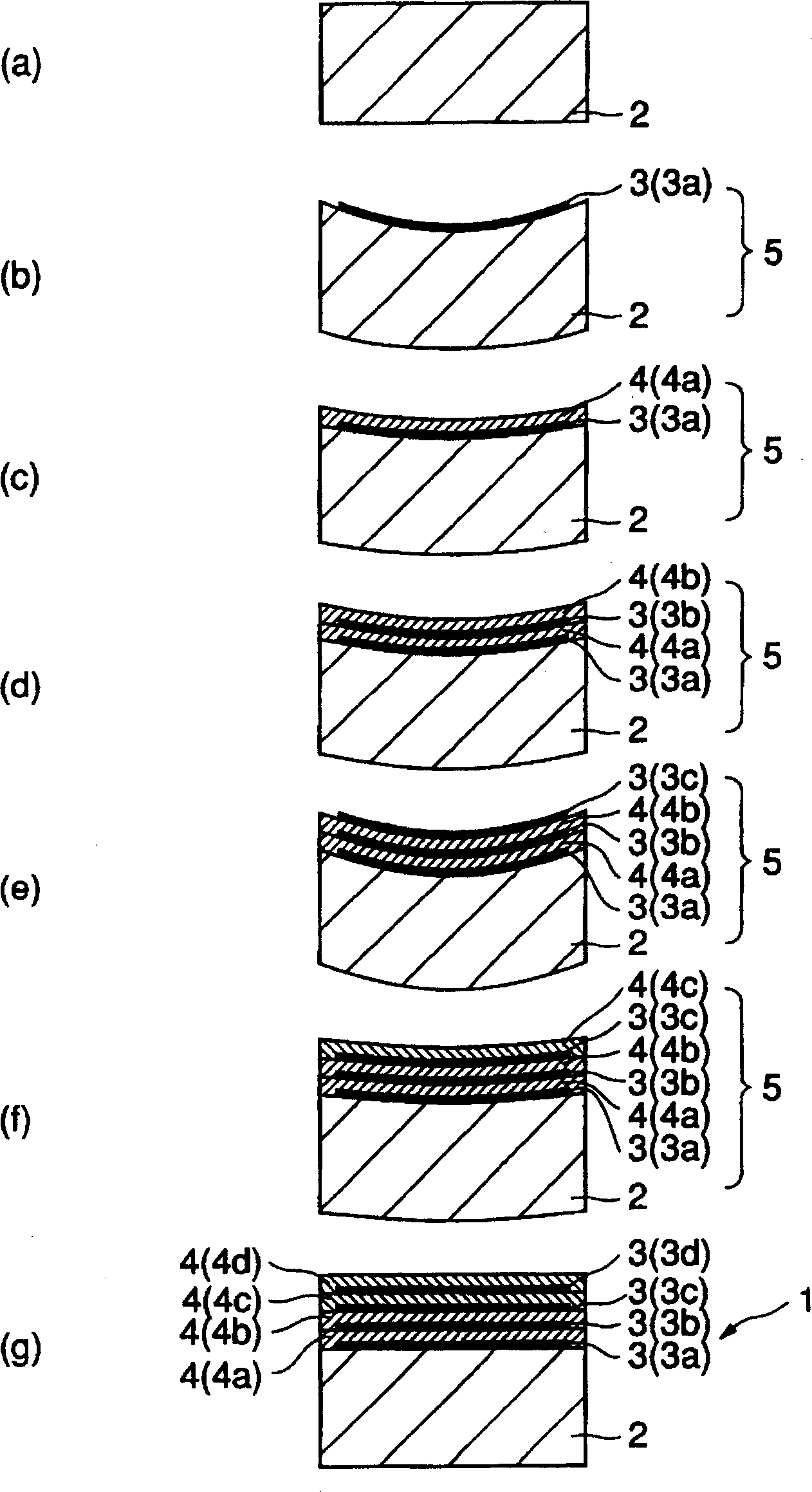

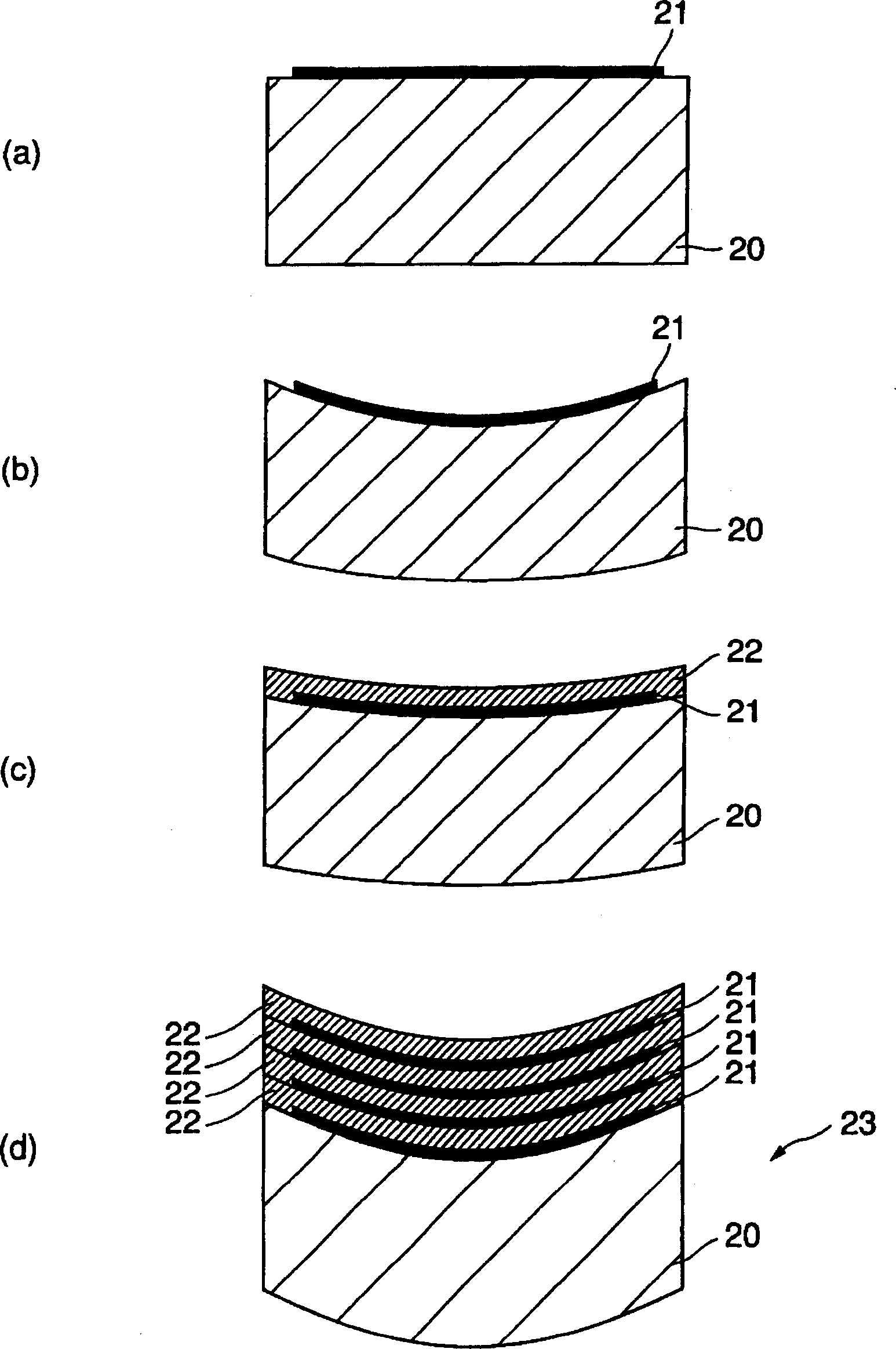

[0018] Such as figure 1 As shown in (g), the multilayer structural component 1 of this embodiment has a mode of alternately laminating the conductor pattern 3 and the insulating layer 4 on the surface side of the insulator substrate 2. The most important feature is that a plurality of insulating layers 4 ( At least one layer among 4a, 4b, 4c, and 4d) is made of an insulating material having a different thermal expansion ratio from the other insulating layers 4 .

[0019] Hereinafter, a specific configuration of the multilayer structure member 1 of this embodiment will be described together with an example of a manufacturing process. For example, first, prepare as figure 1 Insulator substrate 2 shown in (a). The insulating substrate 2 is made of, for example, an alumina substrate or a glass substrate. On the upper surface of the insulating substrate 2, a conductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com