A method for controlling the concentricity between the deep hole and the outer circle of a deep hole piston rod

A control method and piston rod technology, which can be applied to instruments, measuring devices, mechanical measuring devices, etc., can solve the problems of high production cost, low efficiency, and difficulty in guaranteeing the pass rate, and achieve a feasible correction process and improve the accuracy of coaxiality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

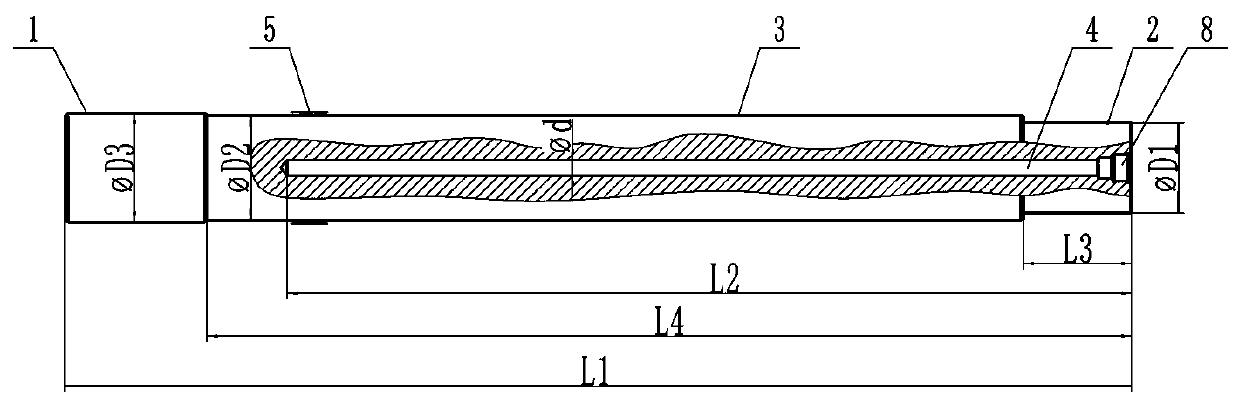

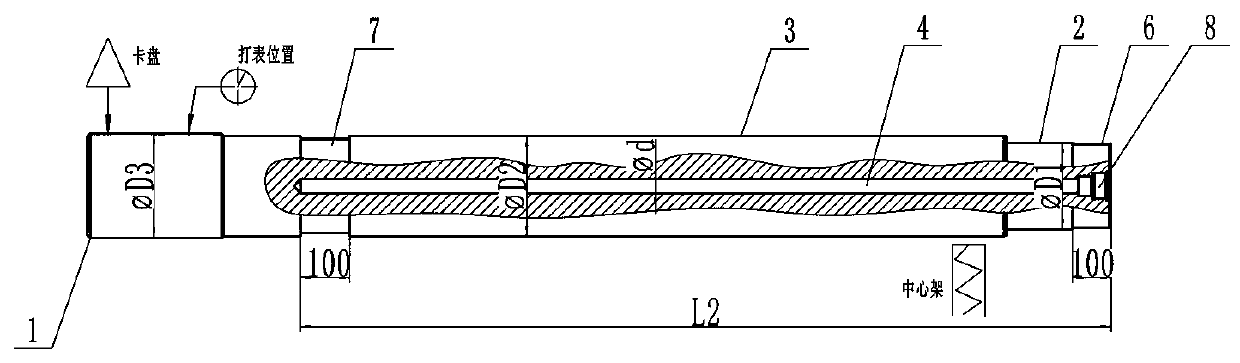

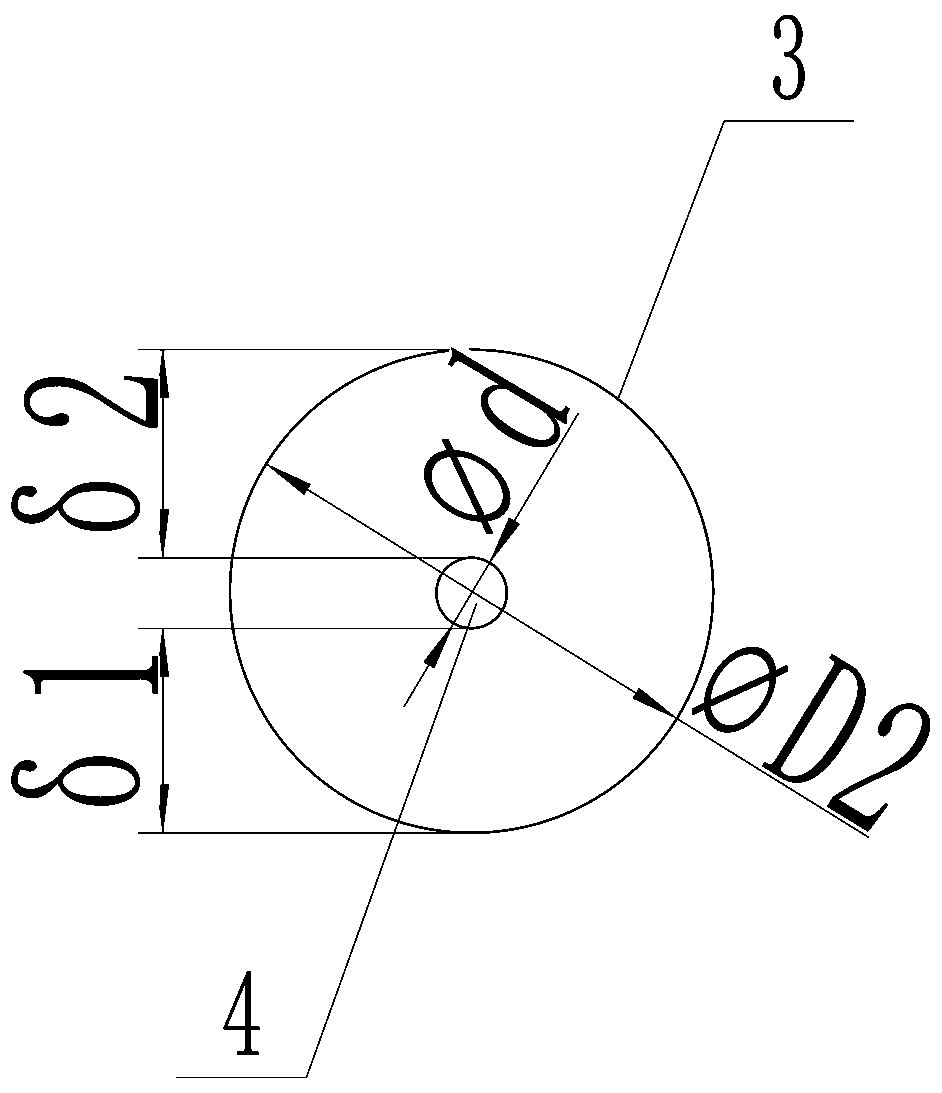

[0041] Such as Figure 1-3 As shown, take a commonly used piston rod as an example: set the diameter of the outer circle of the orifice end 2 as ΦD1, the diameter of the middle outer circle 3 as ΦD2, the diameter of the outer circle of the big end 1 as ΦD3, the diameter of the blind hole 4 as Φd, and the total length of the piston rod L1, the depth of the blind hole 4 is L2, the length of the orifice end 2 is L3, the sum of the lengths of the orifice end 2 and the middle outer circle 3 is L4, where ΦD1=Φ110mm, ΦD2=Φ120mm, ΦD3=Φ130mm, Φd =Φ20.5mm, L1=1572mm, L2=1315mm, L3=141mm, L4=1387mm, the method for controlling the coaxiality between the deep hole and the outer circle of the deep hole piston rod of the present invention includes the following steps:

[0042] The first step is to prepare materials. The raw material size of the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com