Rotary pre-correction device for silicon wafer

A pre-correction and silicon wafer technology, which is applied to the exposure device of photolithography process, transportation and packaging, photoplate process of pattern surface, etc., can solve the problems of lithography machine stop alarm, affect work efficiency, inconsistency, etc., and achieve improvement Accuracy, simple structure, good correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific examples.

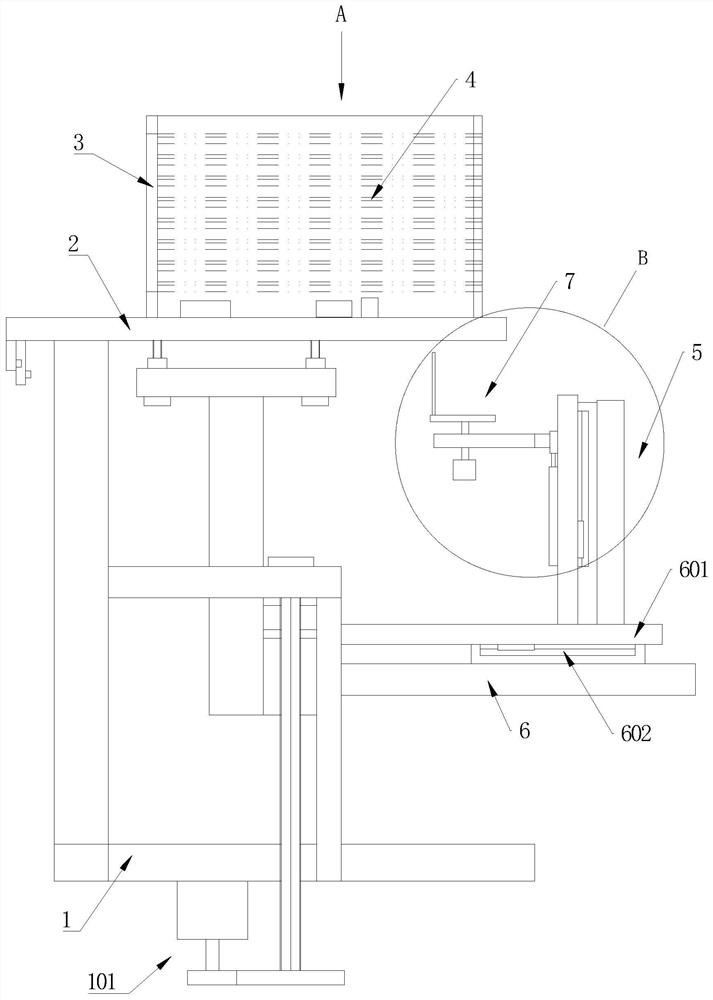

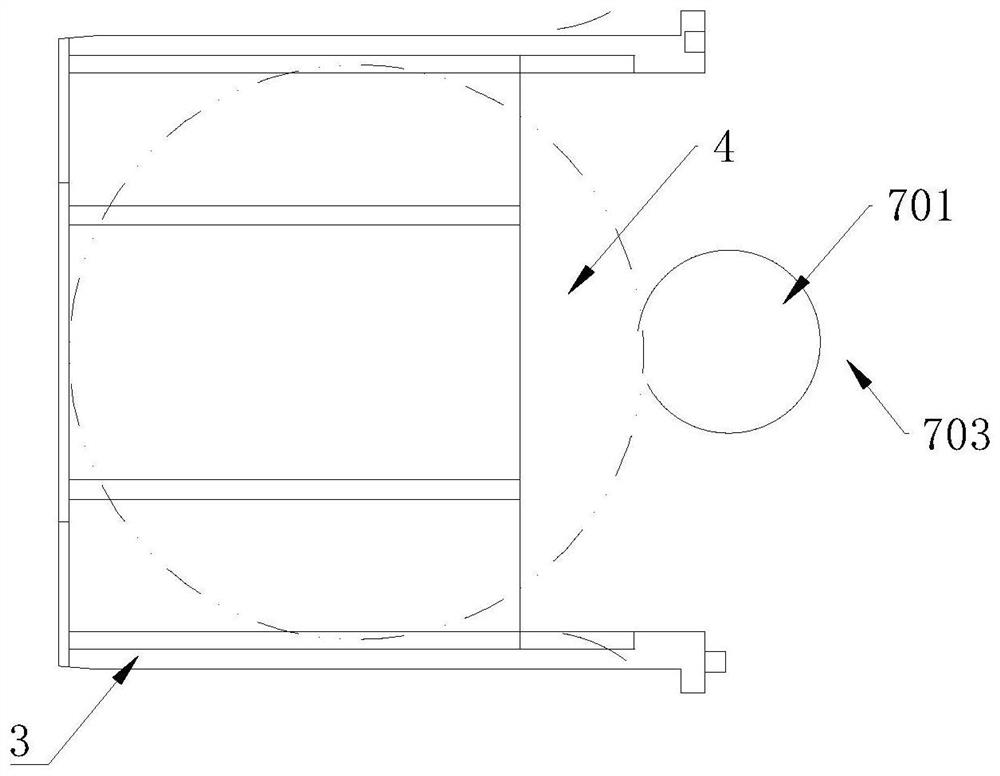

[0036] Such as figure 1 As shown, a rotating pre-correction device for silicon wafers includes a frame 1, and the frame 1 is provided with a placement platform 2 driven by a lifting drive device 101 (a lifting drive component such as a cylinder), and a silicon wafer is positioned on the placement platform 2. Chip holding box 3 (preventing many silicon wafers 4 in it), this frame 1 is also provided with horizontal support 6, and this horizontal support 6 is provided with vertical driving mechanism 5, drives on this vertical driving mechanism 5 There is a support base 500, on which a correcting mechanism 7 is rotatably installed, and the correcting mechanism 7 is arranged on the same side as the opening end of the silicon wafer storage box 3 (see figure 2 ).

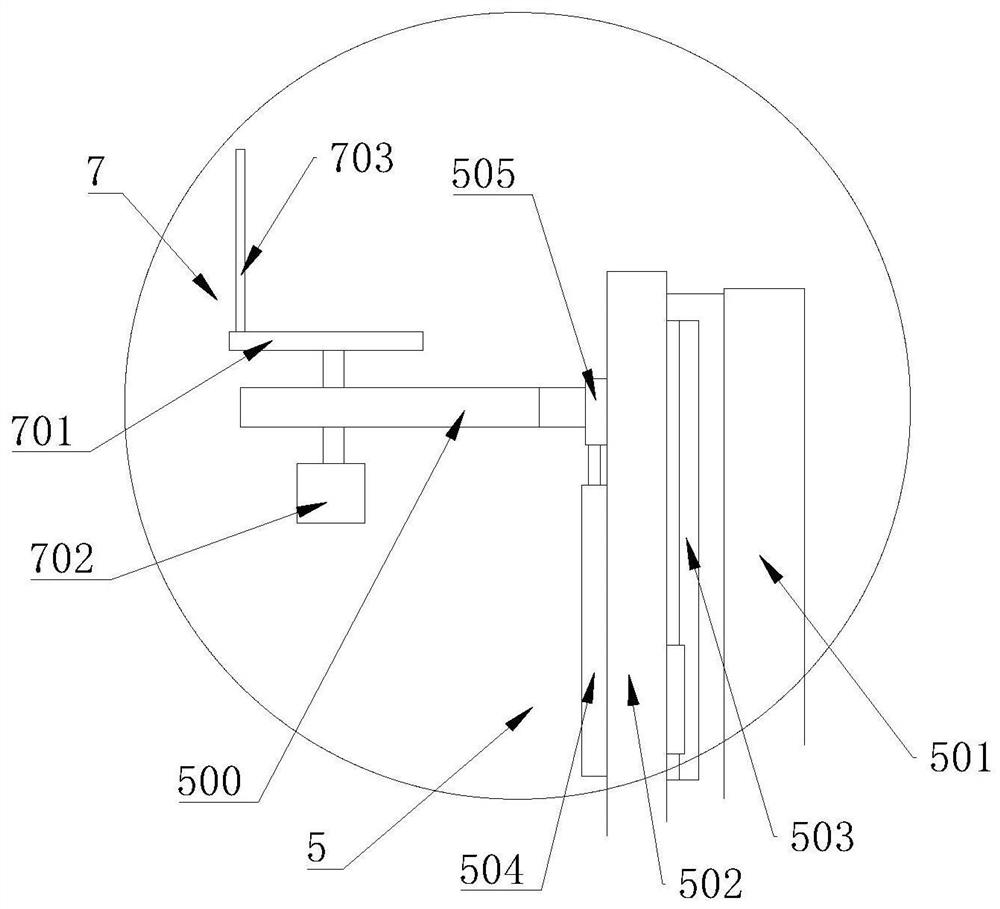

[0037] The correction mechanism 7 includes a turntable 701 that is rotatably installed on the support base 500 and arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com