Immersion objective lens for microscope

A microscope and liquid immersion technology, applied in the field of liquid immersion objective lenses for microscopes, can solve the problems of frequent maintenance rate, high manufacturing cost, increase and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

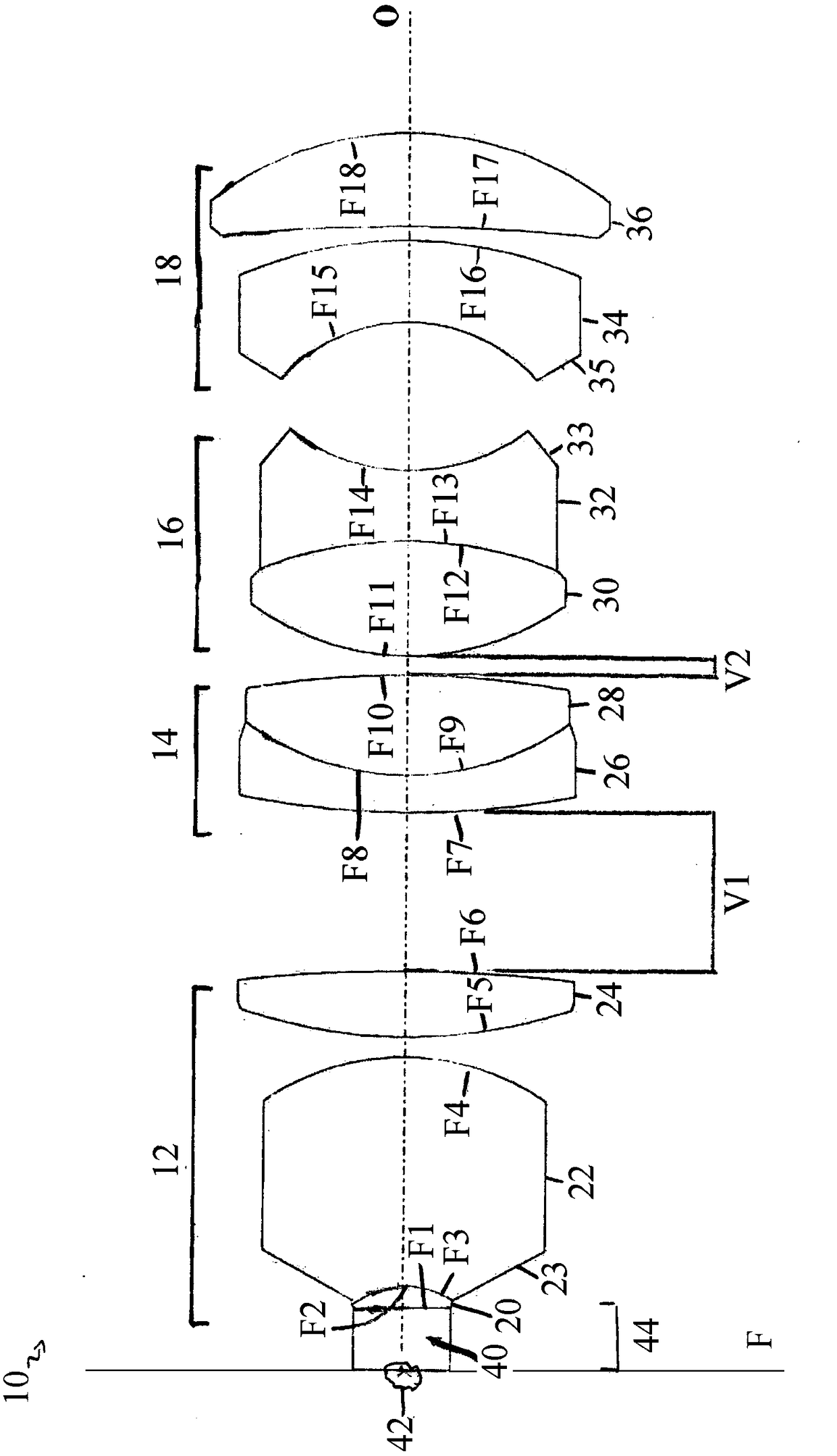

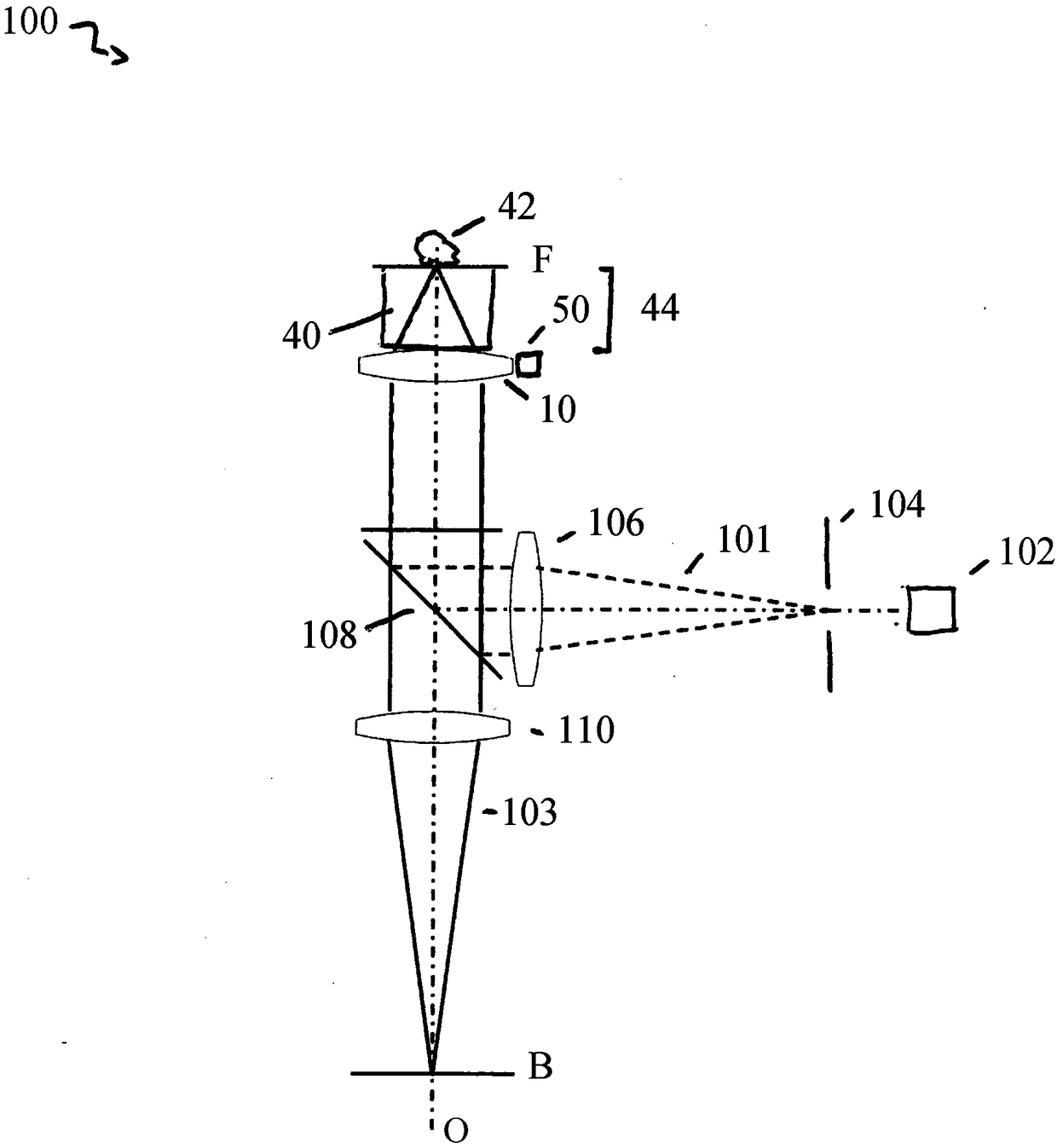

[0026] figure 1 The immersion objective 10 is shown in a sectional view along the optical axis O as a possible embodiment.

[0027] The immersion objective 10 faces the sample space 44 in which the sample 42 is arranged. An immersion liquid 40 such as water, glycerin or a special immersion oil is located in the sample space 44 .

[0028] The liquid immersion objective lens 10 comprises the first lens group 12 of positive refractive power, the second lens group 14 of positive refractive power, the third lens group 16 of negative refractive power and the fourth lens group 28 of positive refractive power, and these lens groups are obtained from sample 42 from the sample side , Arrange in this order. Only the second lens group 14 is designed to be movable for correcting spherical aberration, that is to say, the first lens group 12 , the third lens group 16 and the fourth lens group 18 are fixed.

[0029] Viewed from the object sample side, the first lens group 12 includes: a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com