Button sewing method and sewing machine

A sewing machine and button technology, which is applied to sewing machine components, needle holders for sewing machines, control devices for sewing machines, etc., can solve the problems of unstable placement posture, poor appearance and touch feeling of finished products, and skewed button threads. To achieve the effect of good appearance, good touch feeling, and reliable correction of skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

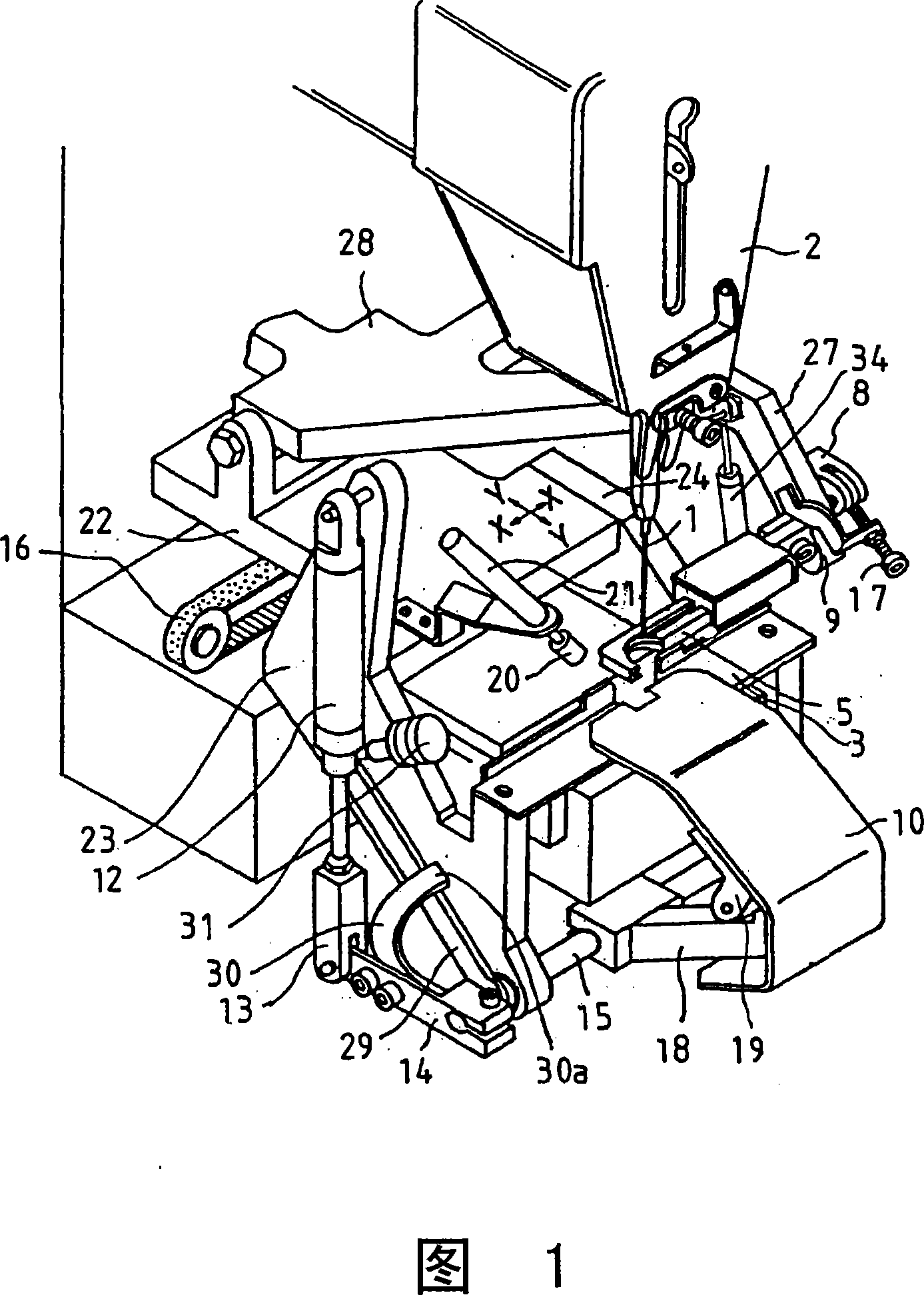

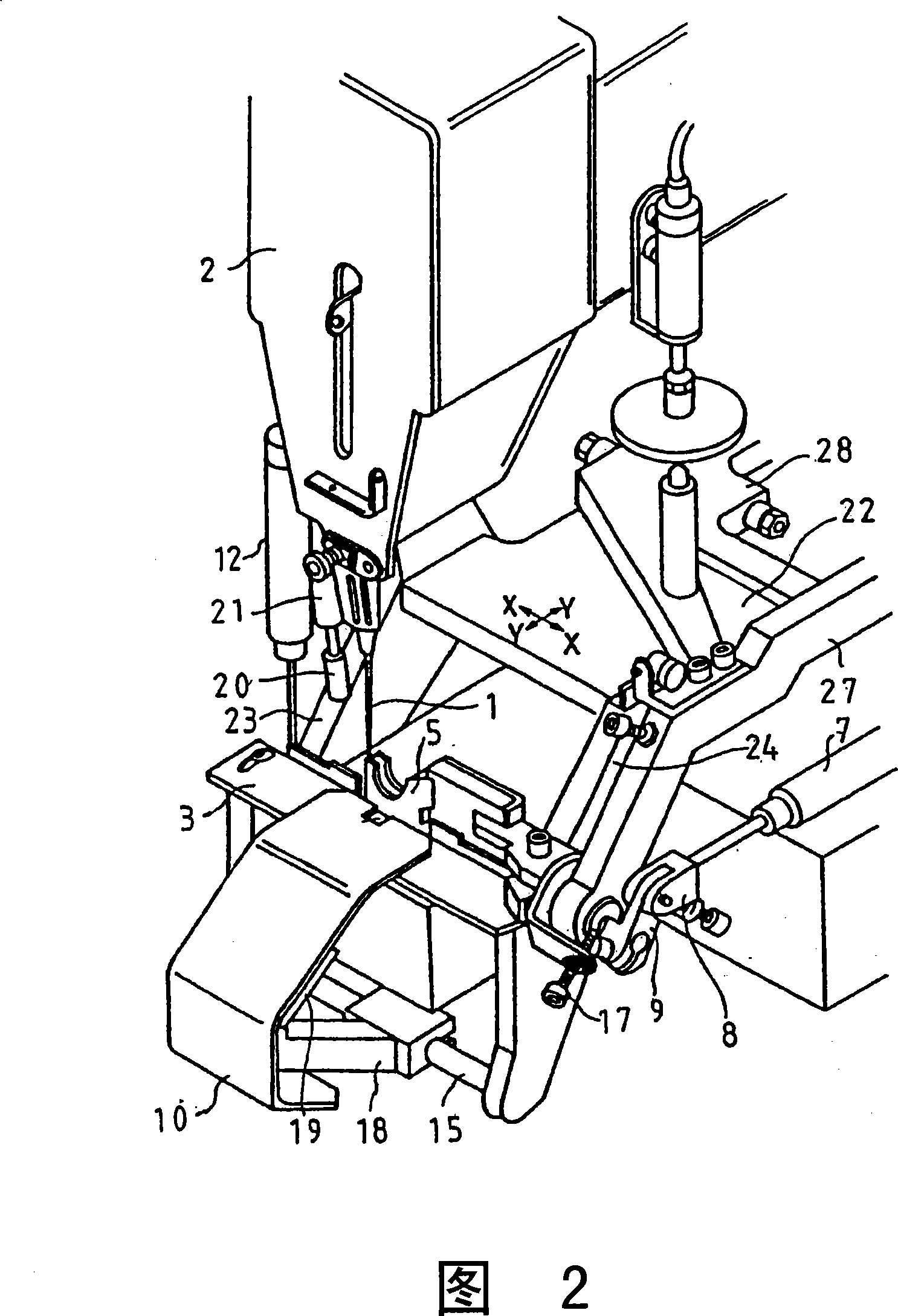

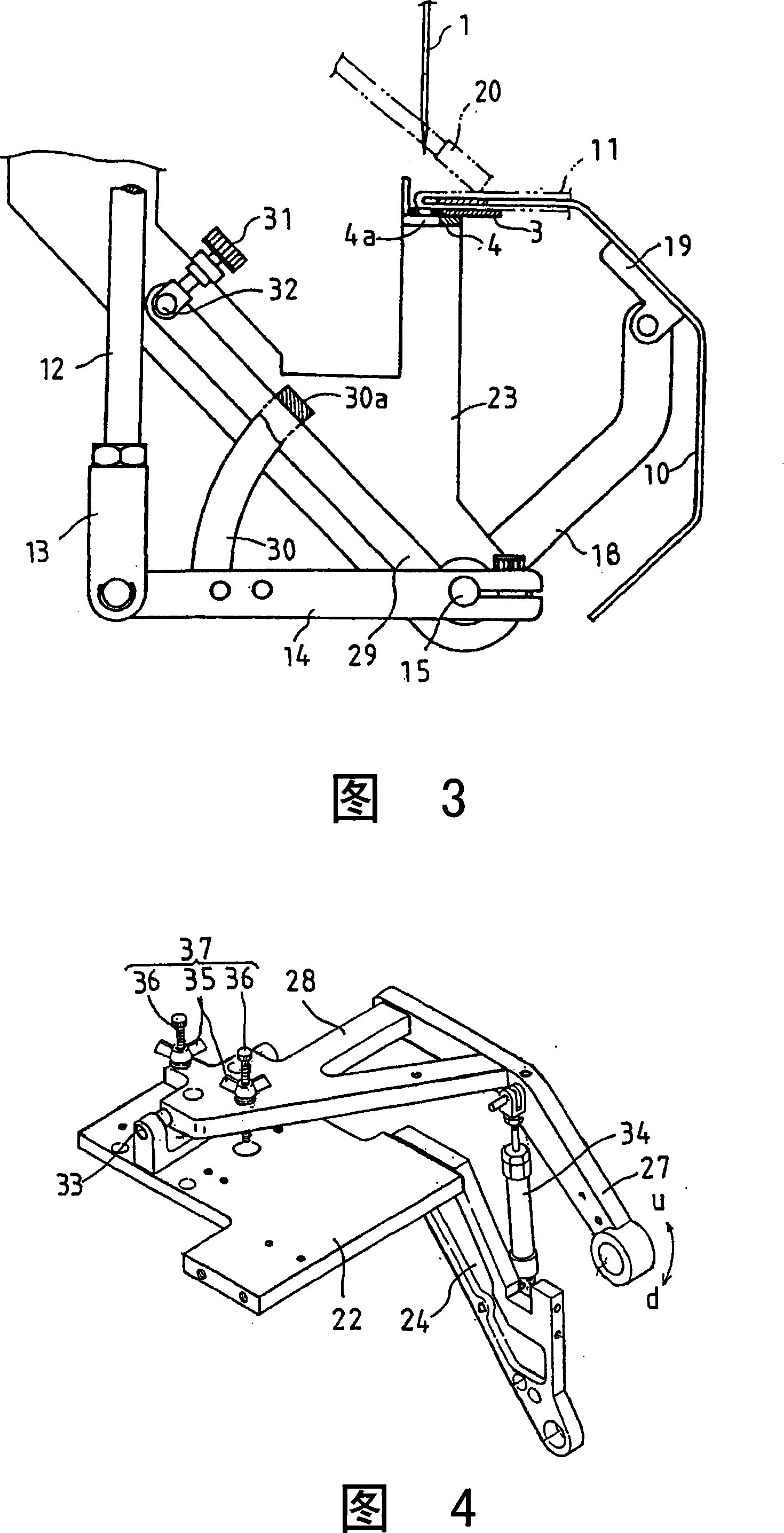

[0021] FIGS. 1 and 2 are schematic perspective views of main parts of a button attaching sewing machine according to the present invention, and FIG. 3 is an enlarged side view of the main parts. In these FIGS. 1 to 3 , 1 is a needle, which reciprocates up and down in conjunction with a sewing machine main shaft (not shown) provided in a sewing machine casing 2 . 3 is a cloth guide, on the lower side of the cloth guide 3, a needle plate 4 is arranged and fixed in a close contact state, and the needle plate 4 has a needle drop hole for the needle 1 to move up and down. 5 is a button holder, which is made to elastically hold the button from both sides of the outer peripheral portion of the four-eye button 6 (referring to Fig. 5, Fig. 6 and Fig. 8 ). In action, the connecting rods 8 and 9 can be freely rotatably switched between the fastening posture shown in FIG. 1 and the knotting posture shown in FIG. 2 .

[0022] 10 is a cloth holder, and the cloth 11 (refer to FIG. 3 ) for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com