Electronic device and housing manufacture method thereof

A technology for electronic equipment and casings, which is applied in the production field of electronic equipment and casings, can solve the problems of affecting the service life of electronic equipment with protection performance, unable to provide users with metal touch, low thermal conductivity and strength, etc., and achieves good appearance. effect, ensuring stable installation, material compactness and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

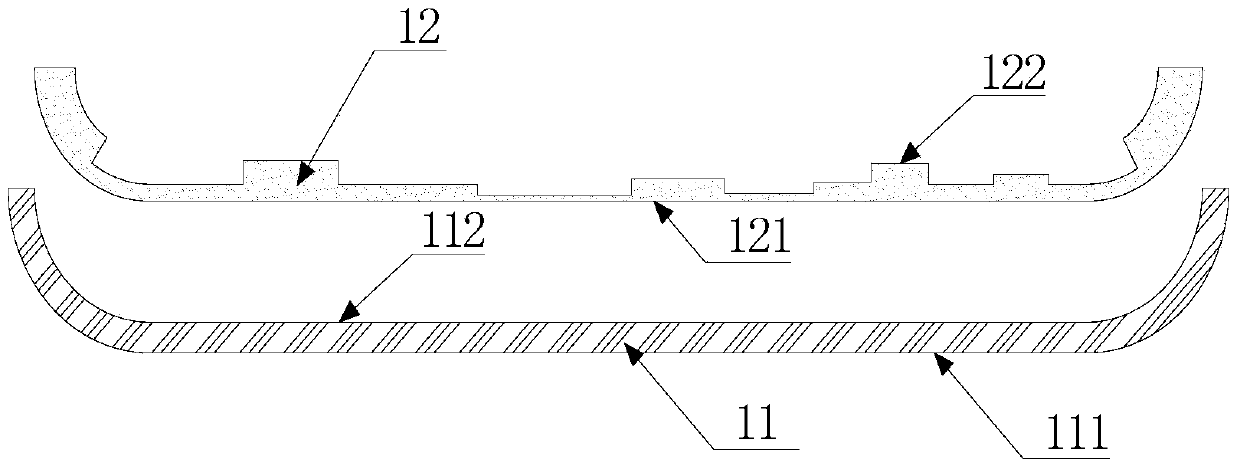

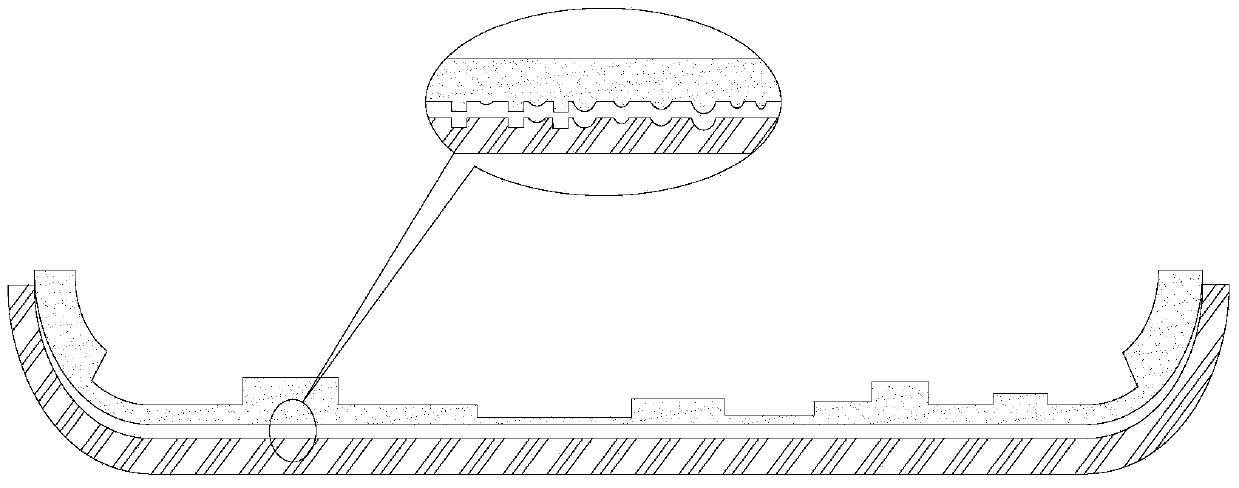

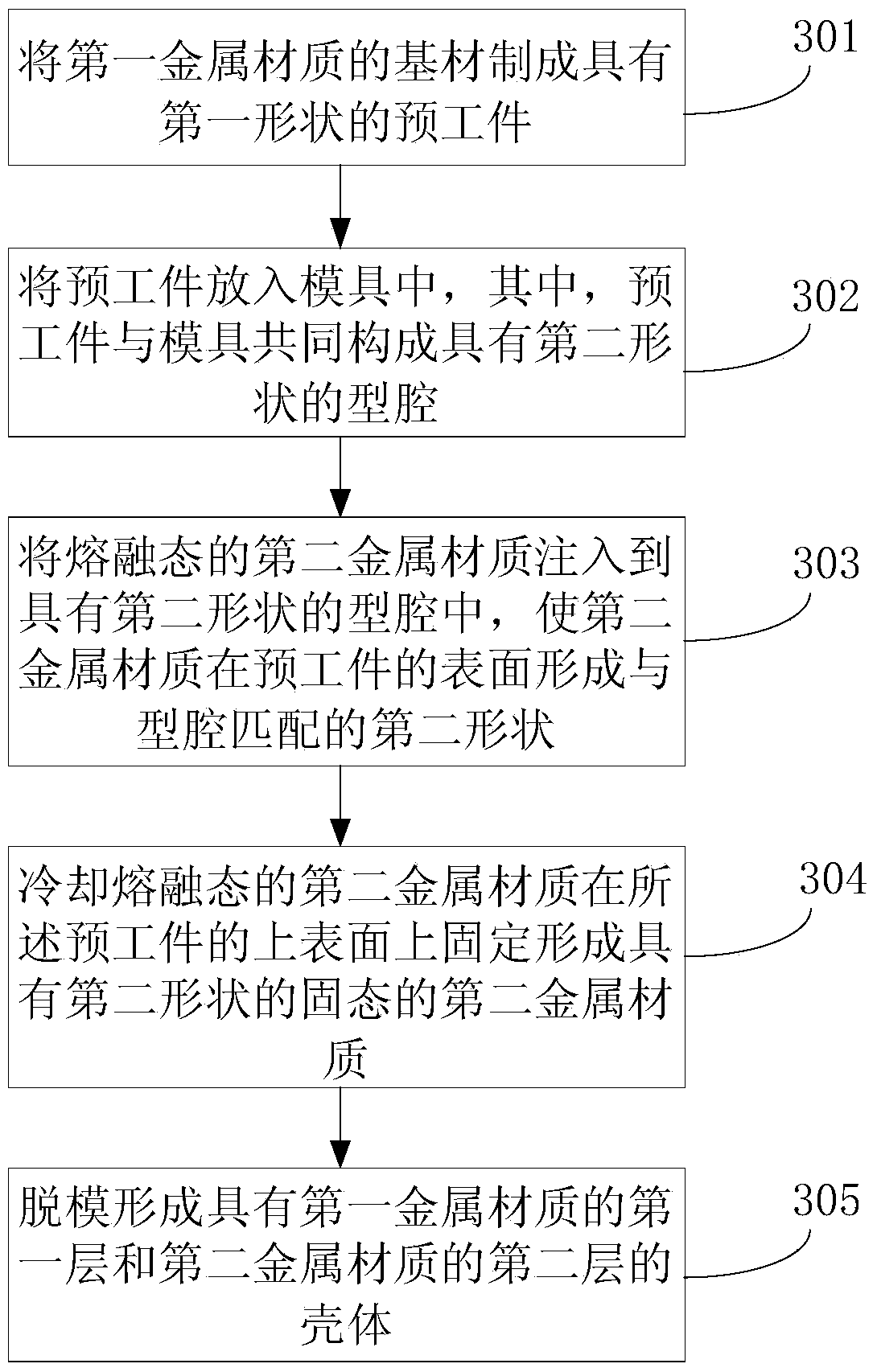

[0026] In order to further explain the technical means and effects adopted by the present invention, the specific implementation, structure, characteristics and methods of manufacturing an electronic device and its casing according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Its efficacy is described in detail as follows:

[0027] An embodiment of the present invention provides an electronic device, such as figure 1 shown, the electronic equipment includes at least:

[0028] M components, M is a positive integer greater than or equal to 1, and the components are, for example, batteries, circuit boards, display screens, and various chips on the circuit board, etc. These components are the core components of electronic equipment. The application environments of electronic equipment are different. In order to protect the components in the electronic equipment, special treatments such as waterproof, dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com