Graphene heating and dehumidification device for dehumidification of electrical equipment installation cabinets

A technology of graphene heating sheet and electrical equipment, applied in the field of power transmission and transformation equipment, can solve the problems of large hidden safety hazards and inconvenient installation of dehumidification devices, and achieve the effects of avoiding excessive local temperature, occupying small space and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

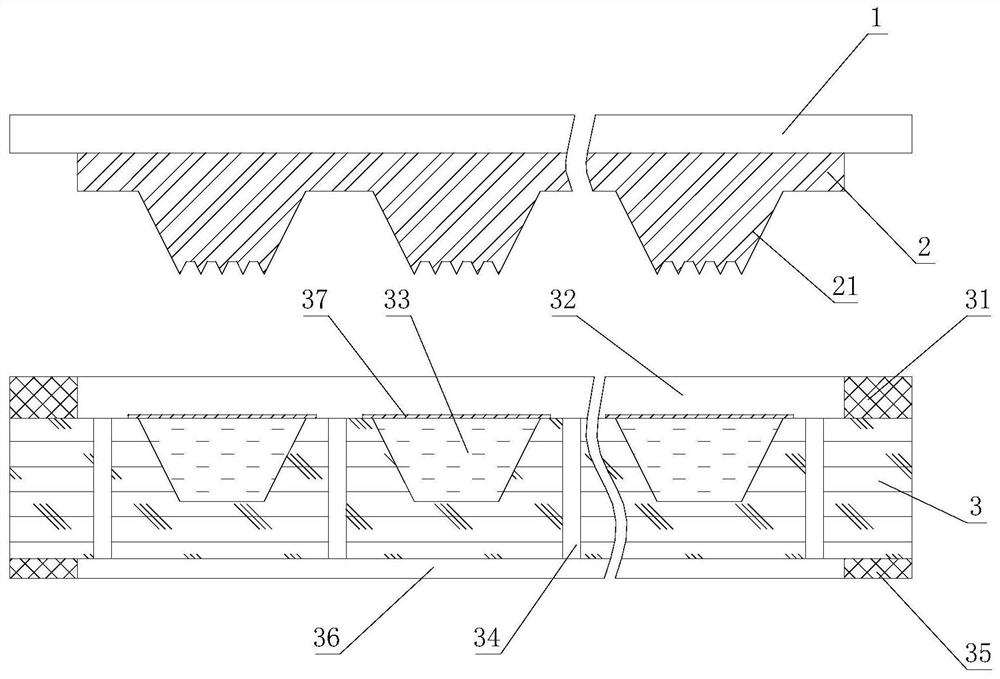

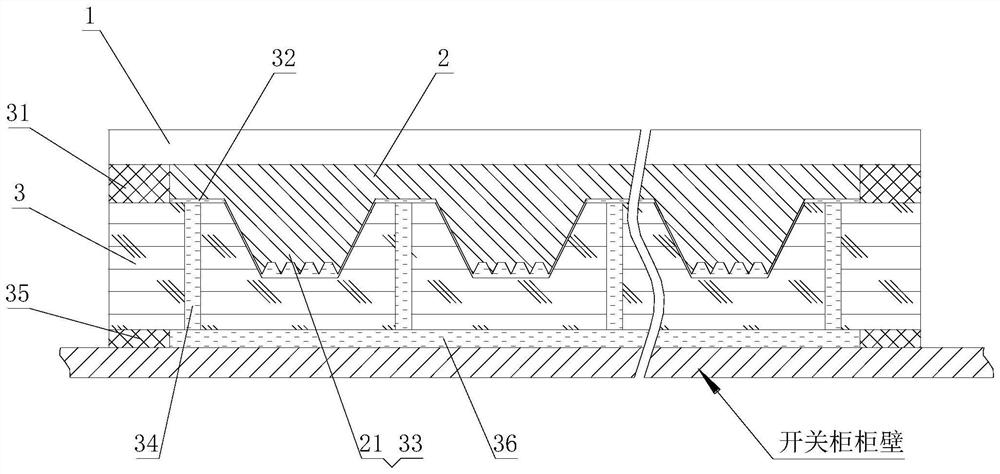

[0025] combine figure 1 , figure 2 , a graphene heating and dehumidifying device used for dehumidification of an electrical equipment installation cabinet, comprising a graphene heating sheet 1, the lower end surface of the graphene heating sheet 1 is provided with a lining 2; it can be understood that the lining 2 and graphite The alkene heating sheets 1 can be bonded together or fixedly connected together by screws. In this embodiment, in order to reduce the volume of the device, they are fixed together by bonding. The liner 2 can be made of plastic, but in order to ensure that the thickness of the liner 2 is as small as possible while having high rigidity, this embodiment is made of steel sheet. If the lining 2 is directly used as the base layer of the graphene coating of the graphene heating sheet 1, an insulating layer needs to be coated on the surface of the lining 2 in contact with the graphene coating. The middle part of the lower end of the lining 2 is provided wit...

Embodiment 2

[0031] Based on Embodiment 1, the groove 33 is used to hold the adhesive. The adhesive usually adopts quick-drying glue and instant adhesive. Of course, other adhesives can be used, but the longer the curing time of the adhesive, the corresponding The longer the time required to press the lining 2, the longer the installation efficiency will be affected. It should be noted that, during installation, it should be ensured that the adhesive in the groove 33 will not overflow, and the notch of the groove 33 is preferably sealed with a packaging film 37, that is, the notch of the groove 33 is covered with a packaging film 37.

[0032] Preferably, the cross-section of the groove 33 is a trapezoid with a large top and a small bottom. Correspondingly, the cross-section of the protrusion 21 is also a trapezoid with a large top and a small bottom, which can increase the rigidity of the lining 2 . The ends of the protrusions 21 are serrated, and can also be set in other sharp shapes, so a...

Embodiment 3

[0037] Based on the above embodiments, the graphene heating sheet 1 includes a waterproof layer and a base layer, and a graphene nano-coating is coated between the waterproof layer and the base layer. The waterproof layer is usually made of a flexible film, such as PE, PVC, waterproof and breathable film, etc.; by setting the waterproof layer, the graphene heating sheet 1 can be prevented from getting damp and affecting the service life. The graphene coating is electrically connected with a control circuit, and the control circuit is provided with a graphene coating power supply interface, which can control the voltage (such as a step-down circuit) supplied to the graphene coating through the control circuit.

[0038] The control circuit is also provided with an uplink communication interface for communicating with an upper computer (such as a single-chip microcomputer, PLC, or a control terminal in a LAN through a communication module), and an external environment temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com