Patents

Literature

108results about How to "Avoid high local temperatures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

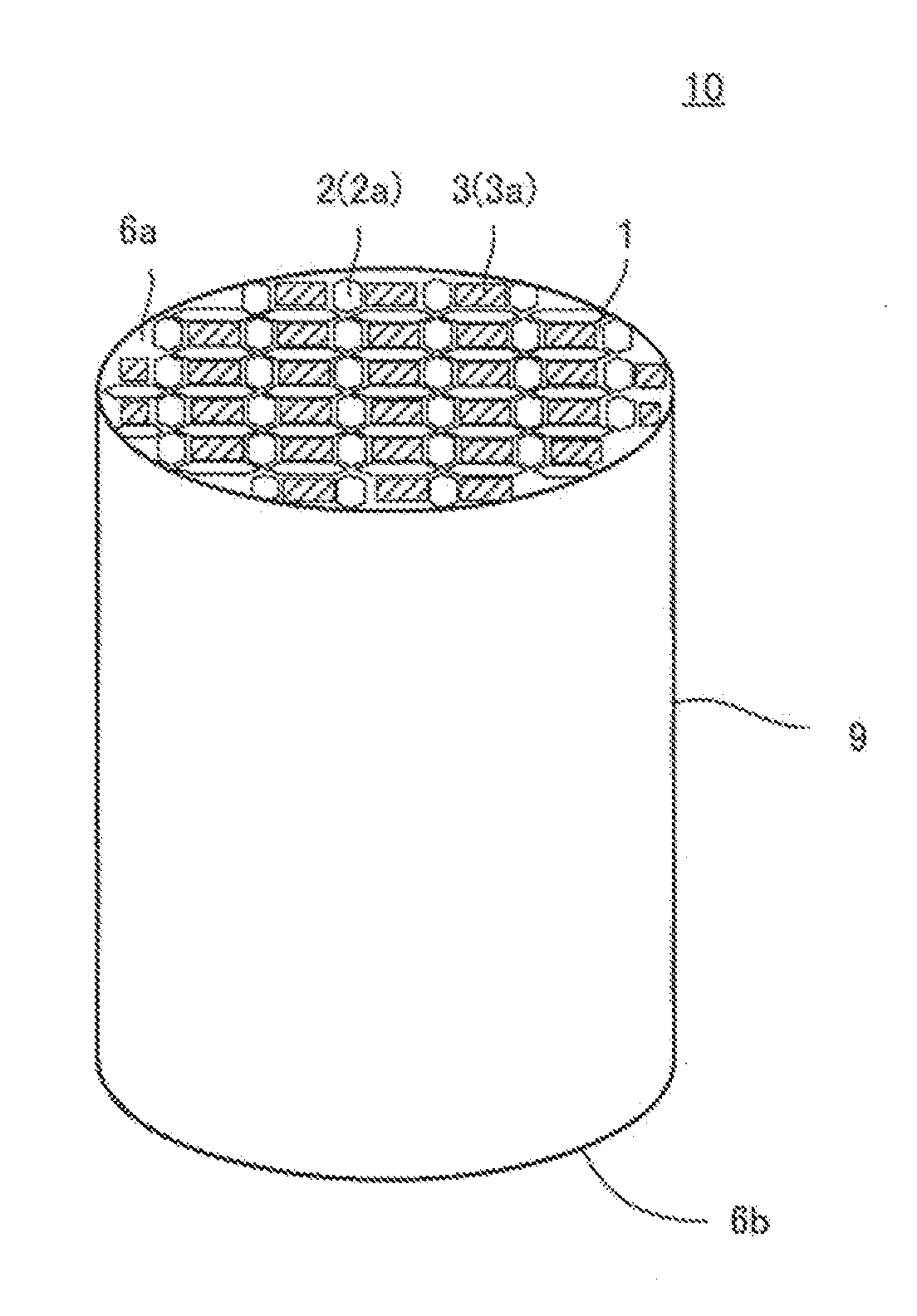

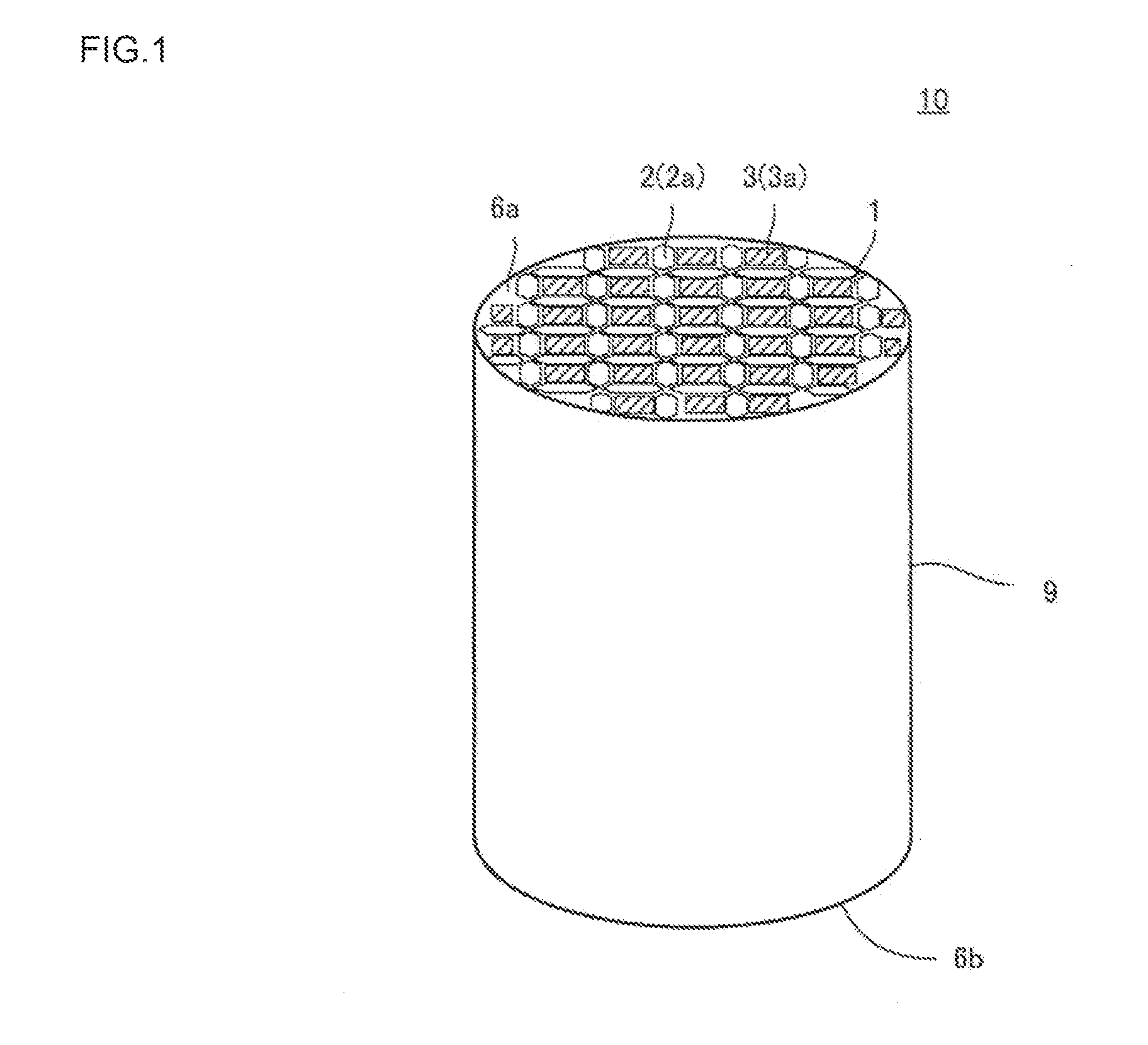

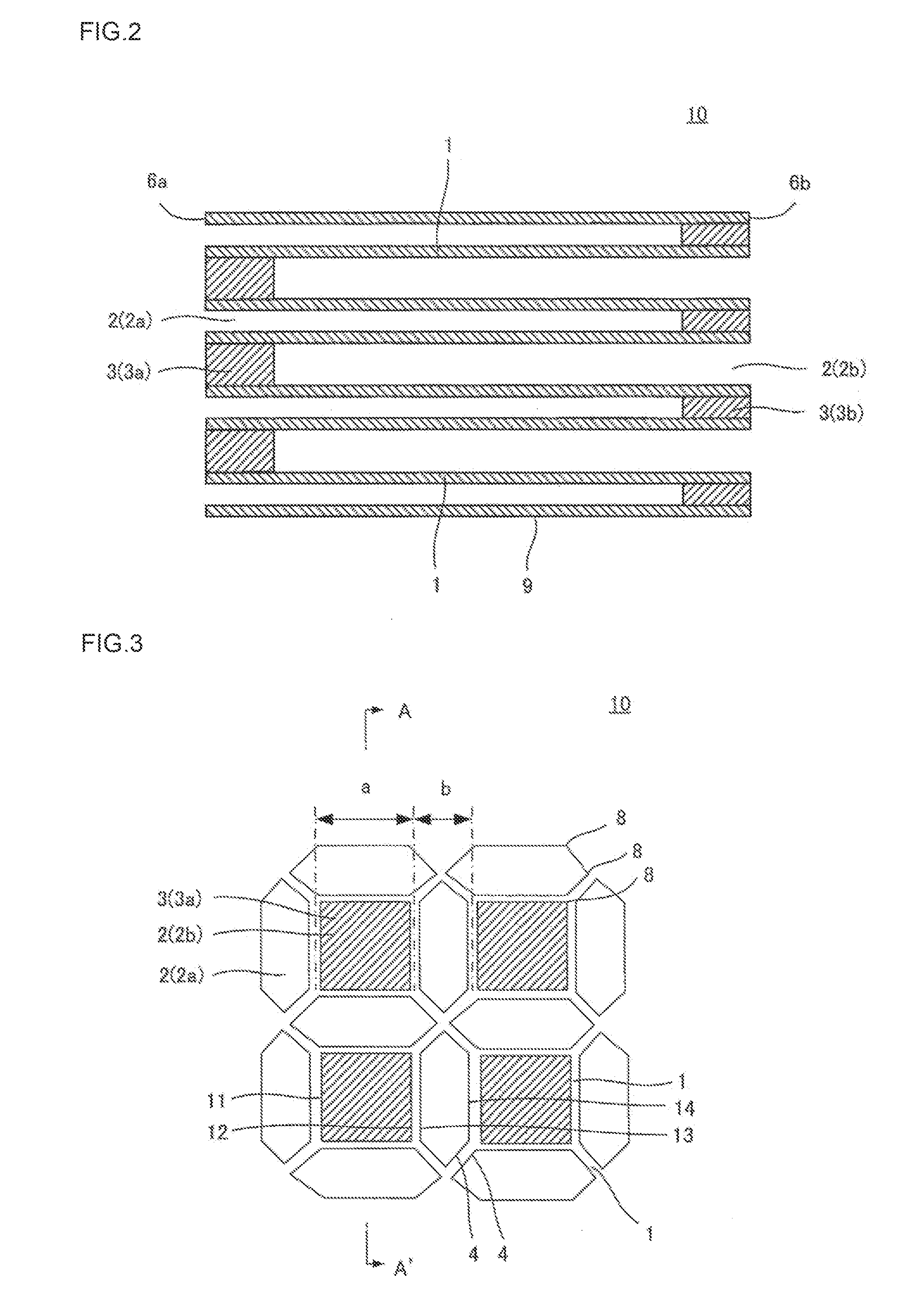

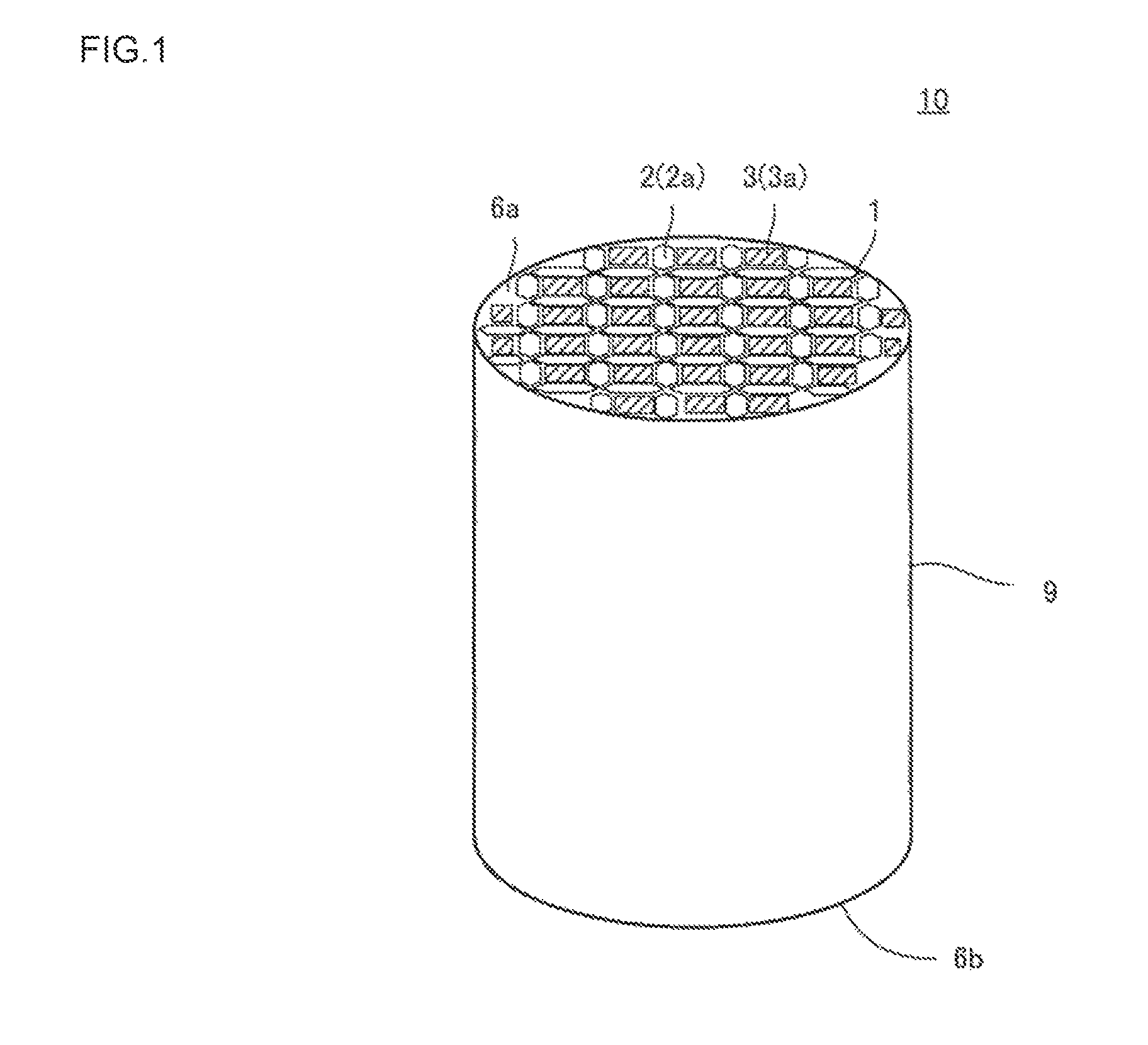

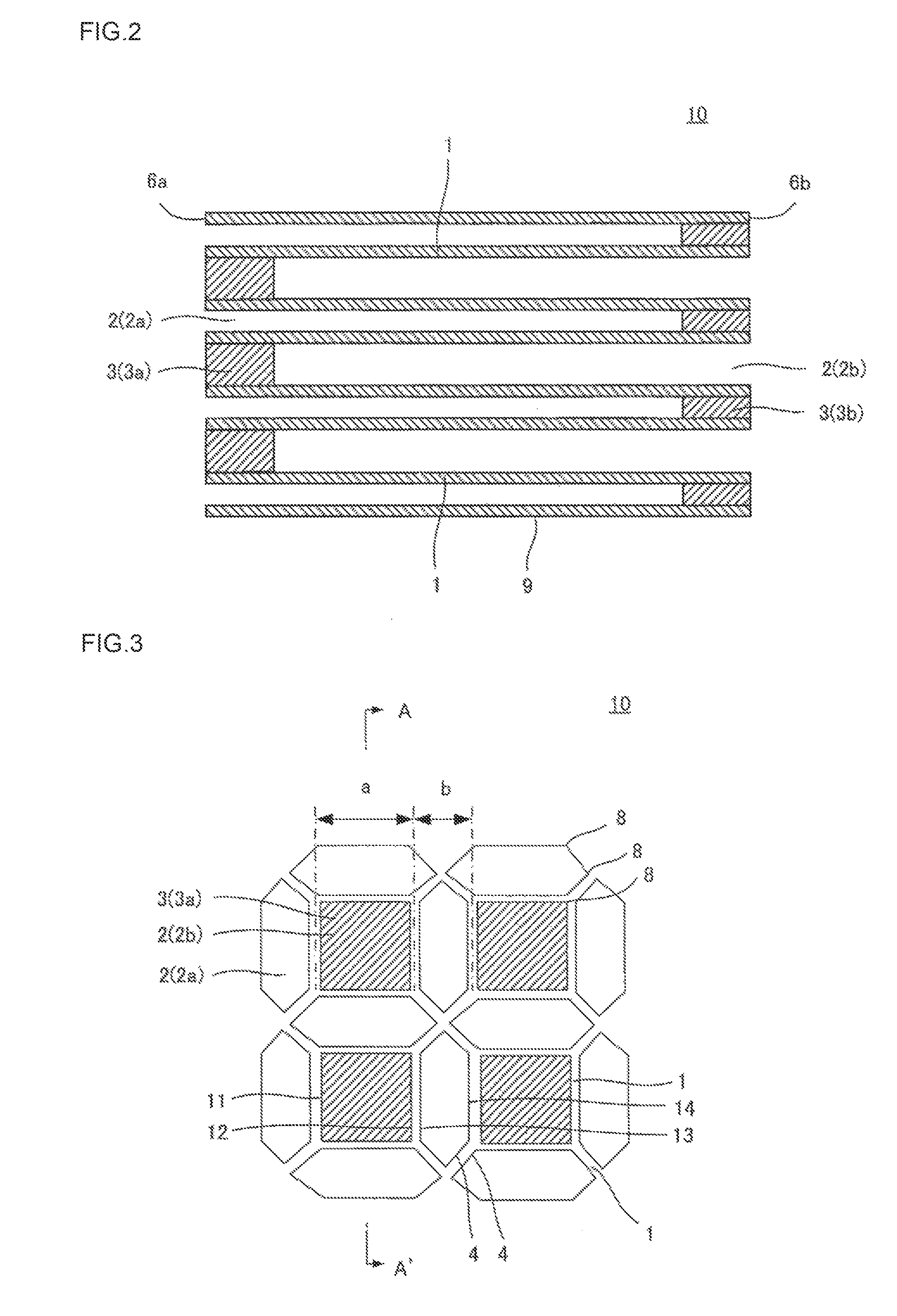

Wall flow type exhaust gas purification filter

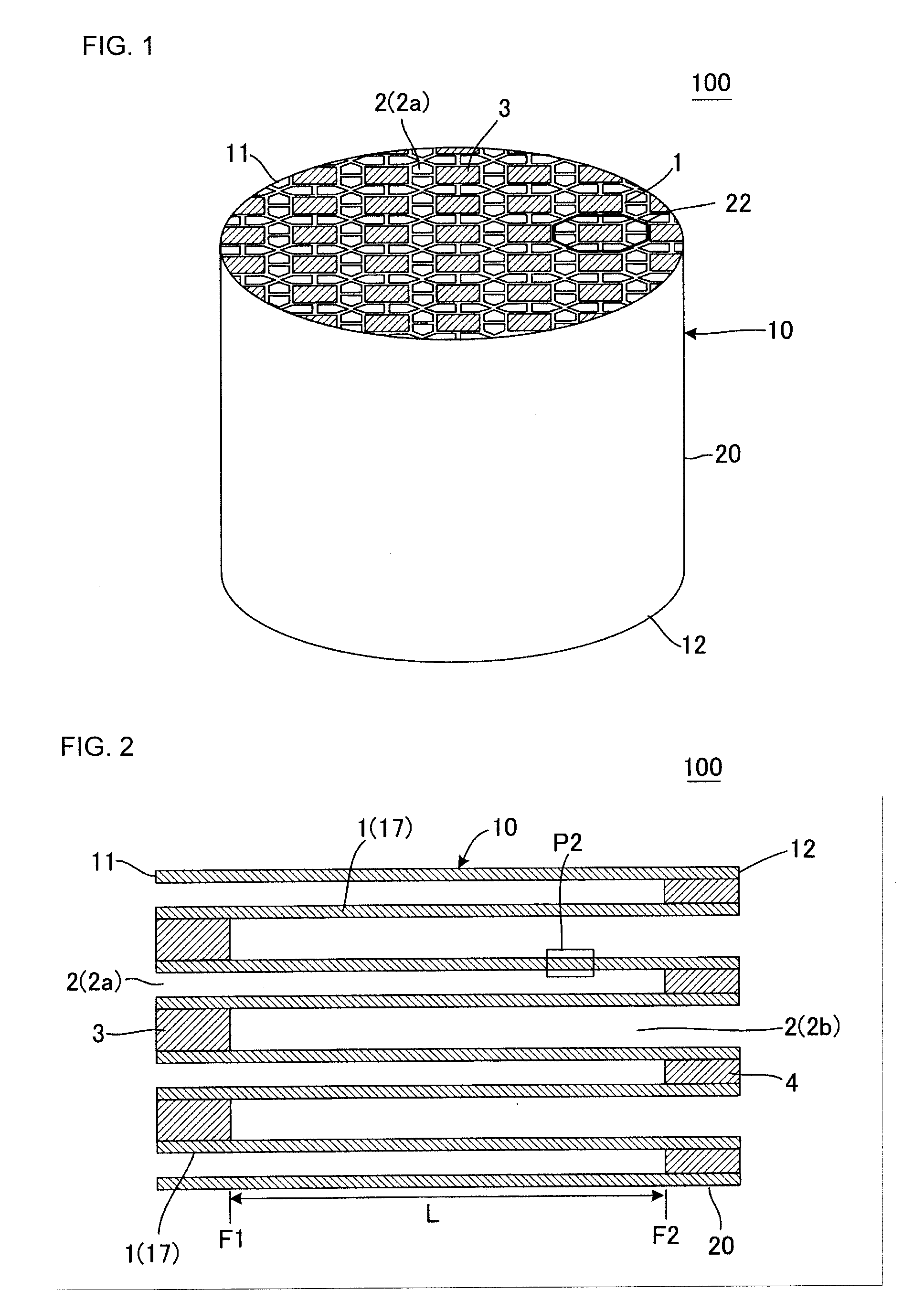

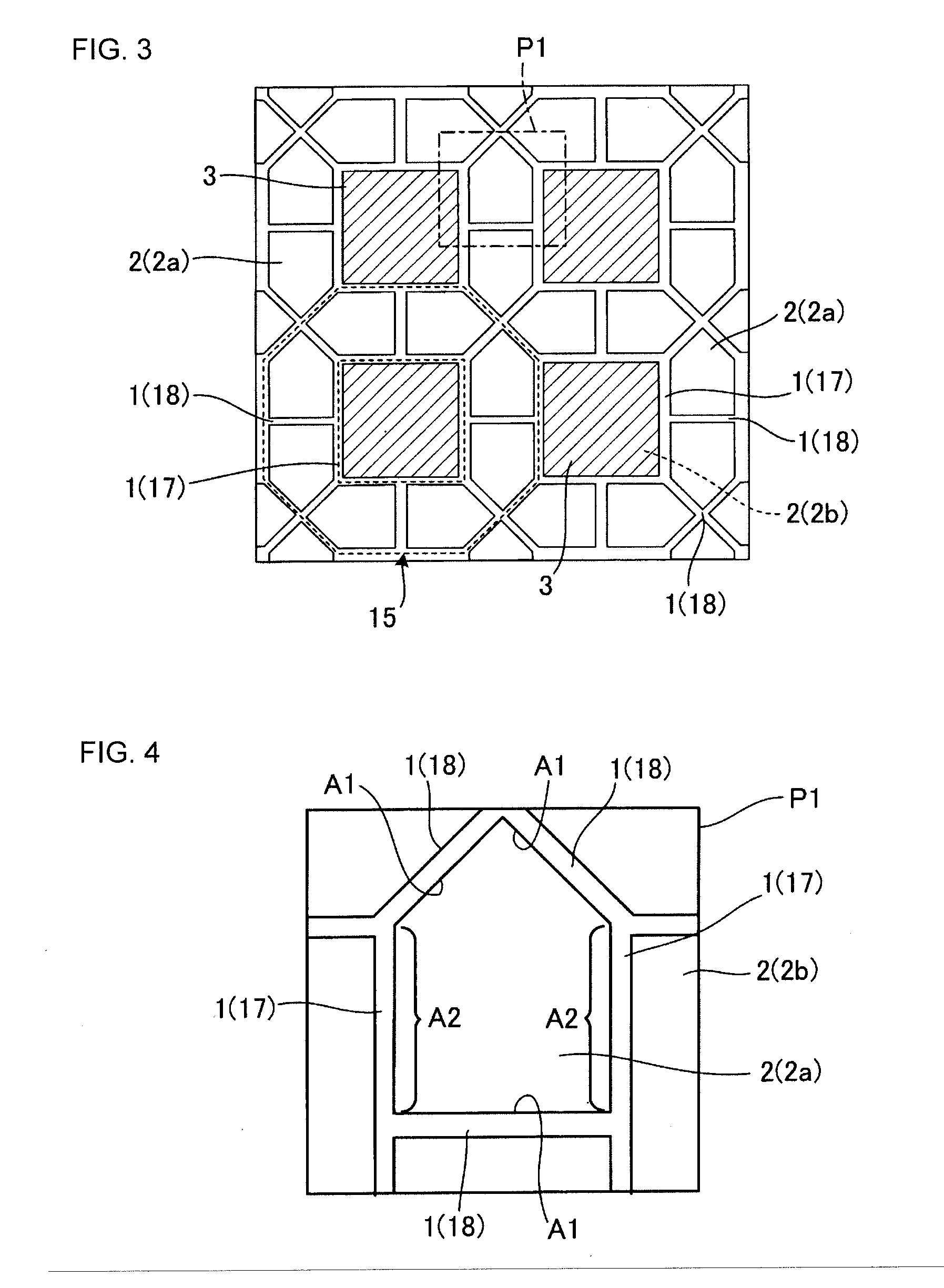

ActiveUS20140298779A1Efficient collectionLess pressure lossSilencing apparatusMachines/enginesEngineeringHoneycomb structure

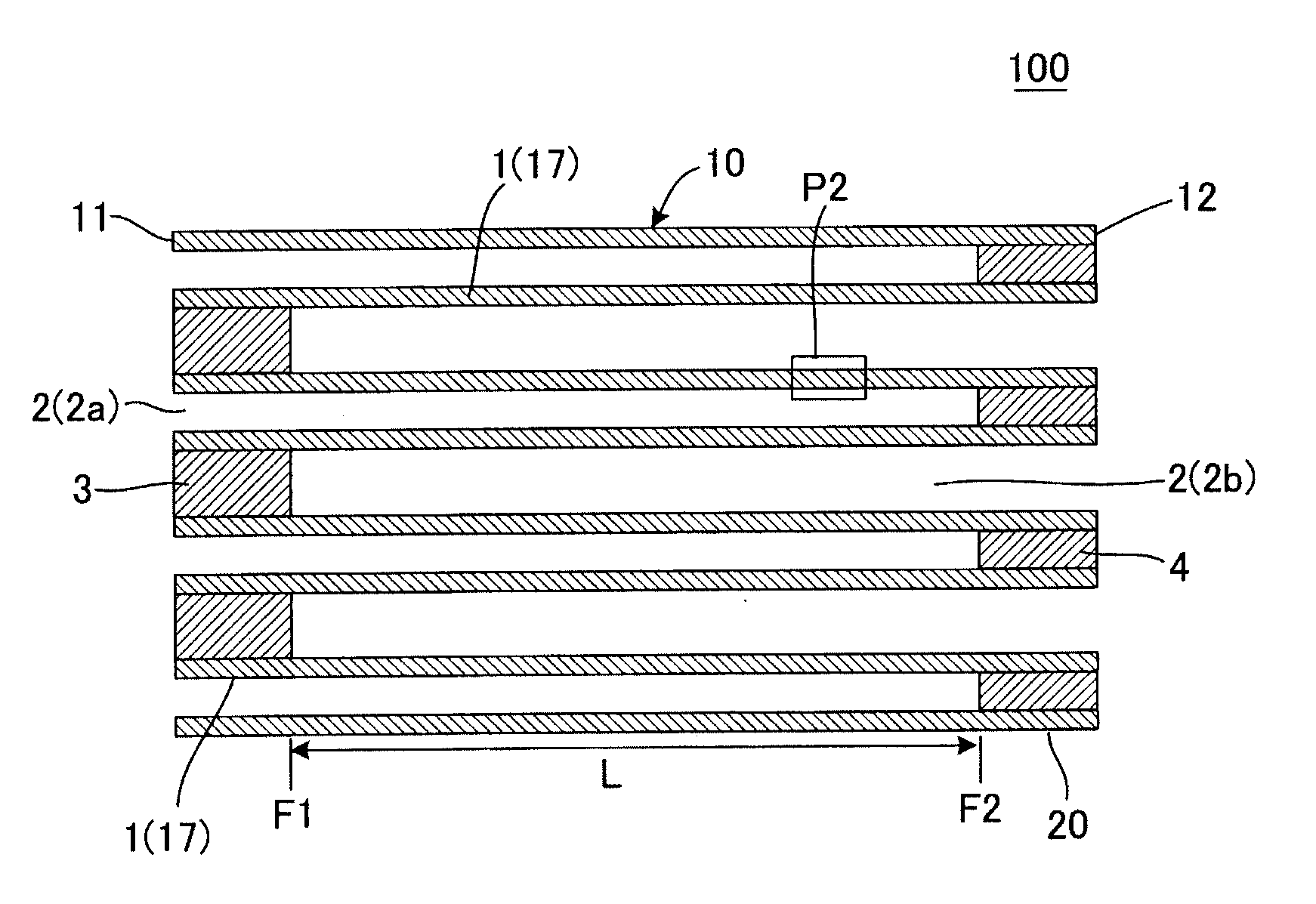

A wall flow type exhaust gas purification filter includes a honeycomb structure body and plugging portions. Four inlet opening cells having a substantially hexagonal shape in cross section surround one outlet opening cell having a substantially square shape in cross section, where one side of an inlet opening cell and one side of the outlet opening cell have a substantially same length and are substantially parallel and adjacent to each other. Distance a between the partition wall defining a first side of the outlet opening cell and the partition wall defining an opposed second side is in a range of exceeding 0.8 mm and less than 2.4 mm, and distance b between the partition wall defining a third side of the inlet opening cell and the partition wall defining an opposed fourth side has a ratio to the distance a in a range exceeding 0.4 and less than 1.1.

Owner:NGK INSULATORS LTD

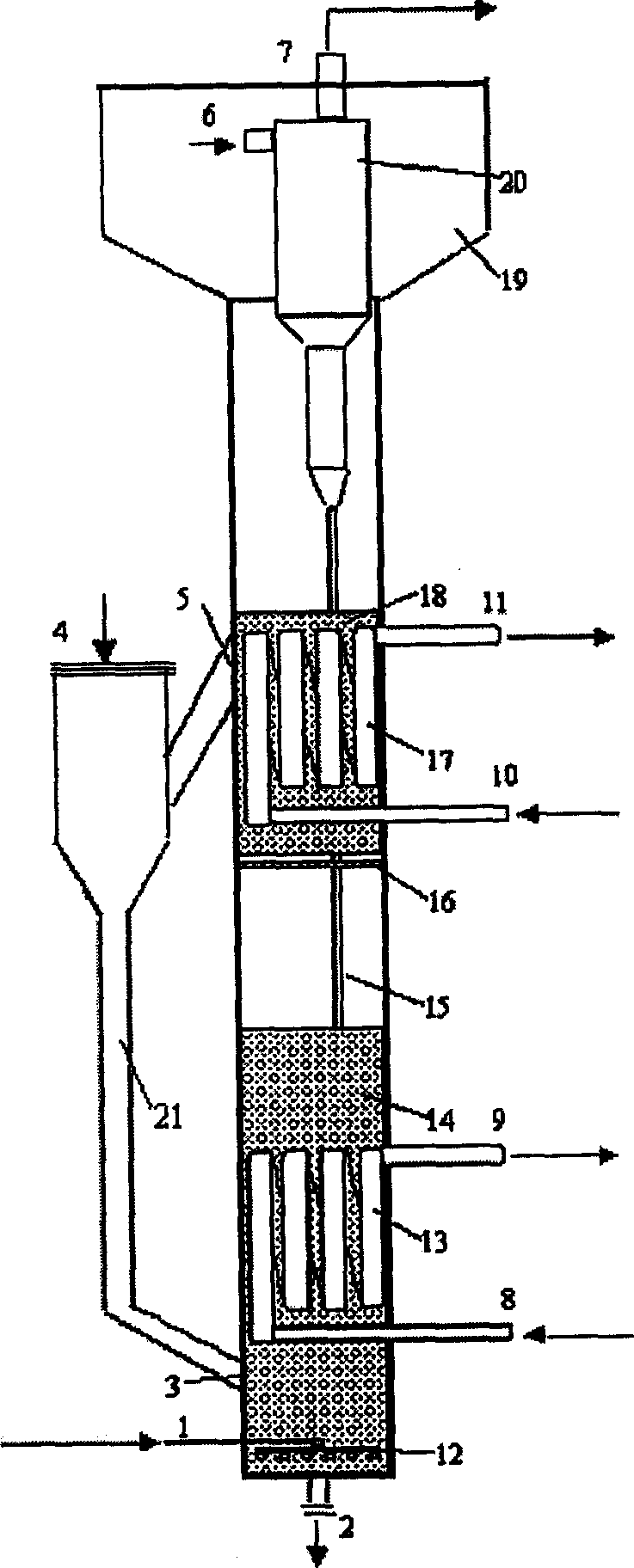

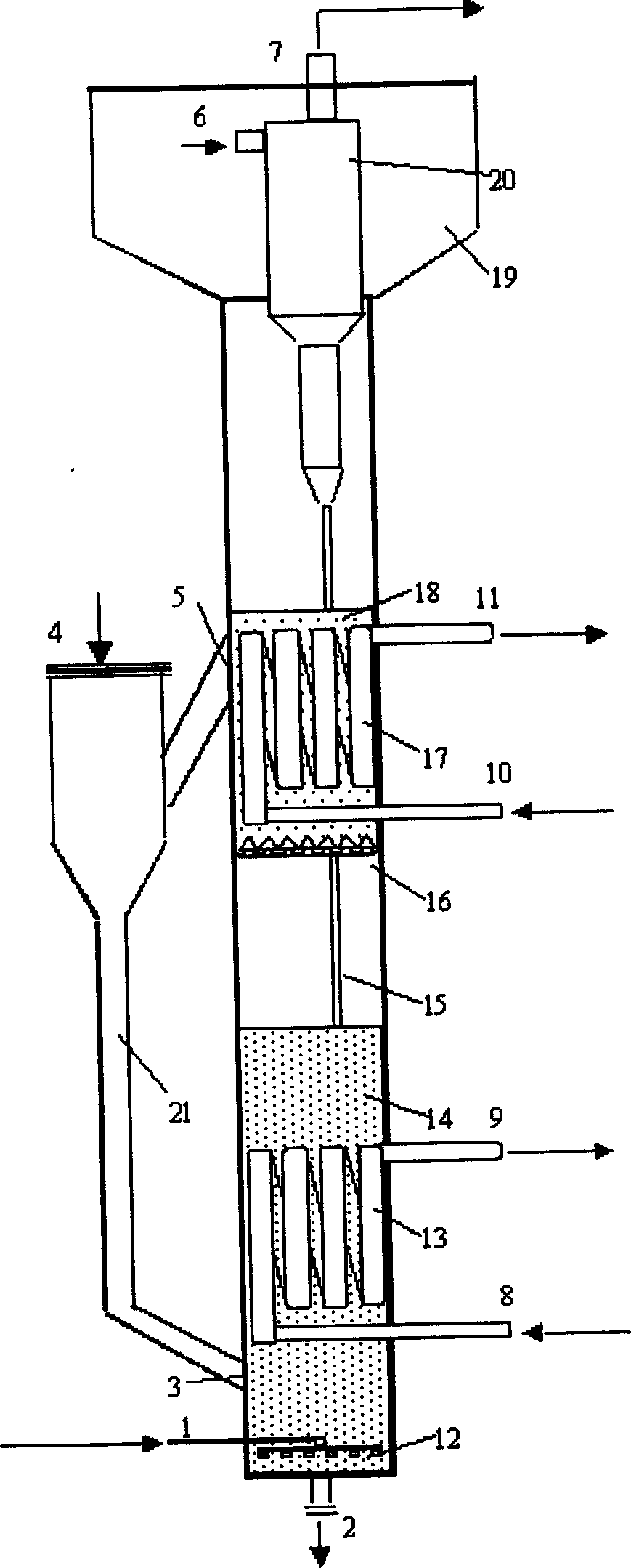

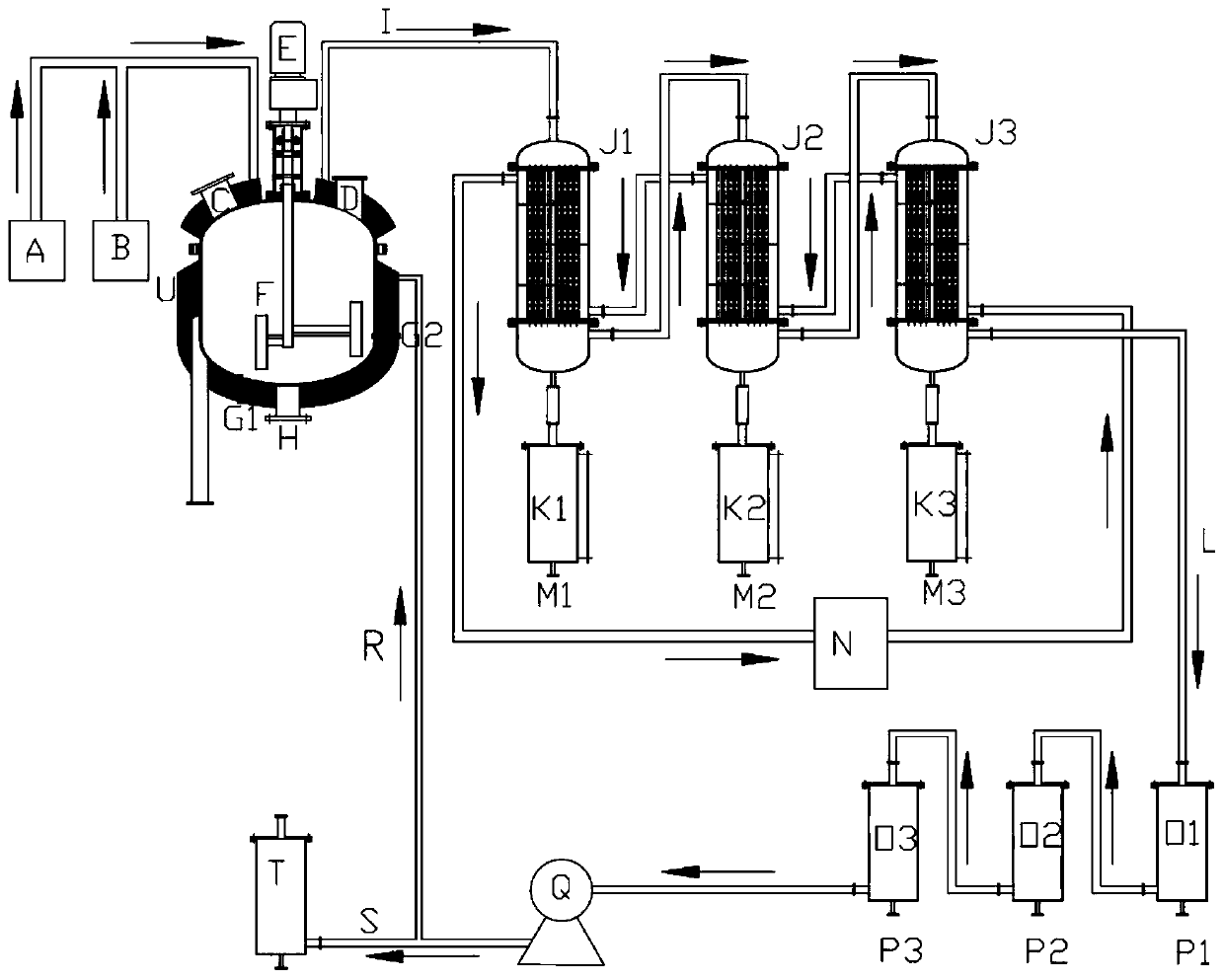

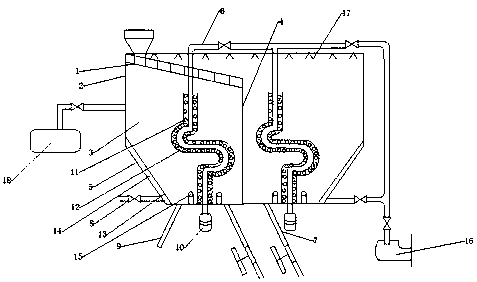

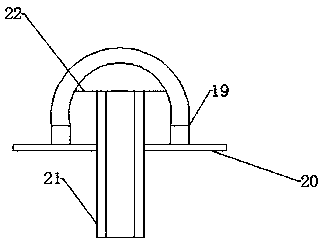

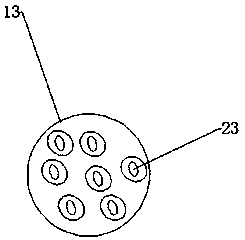

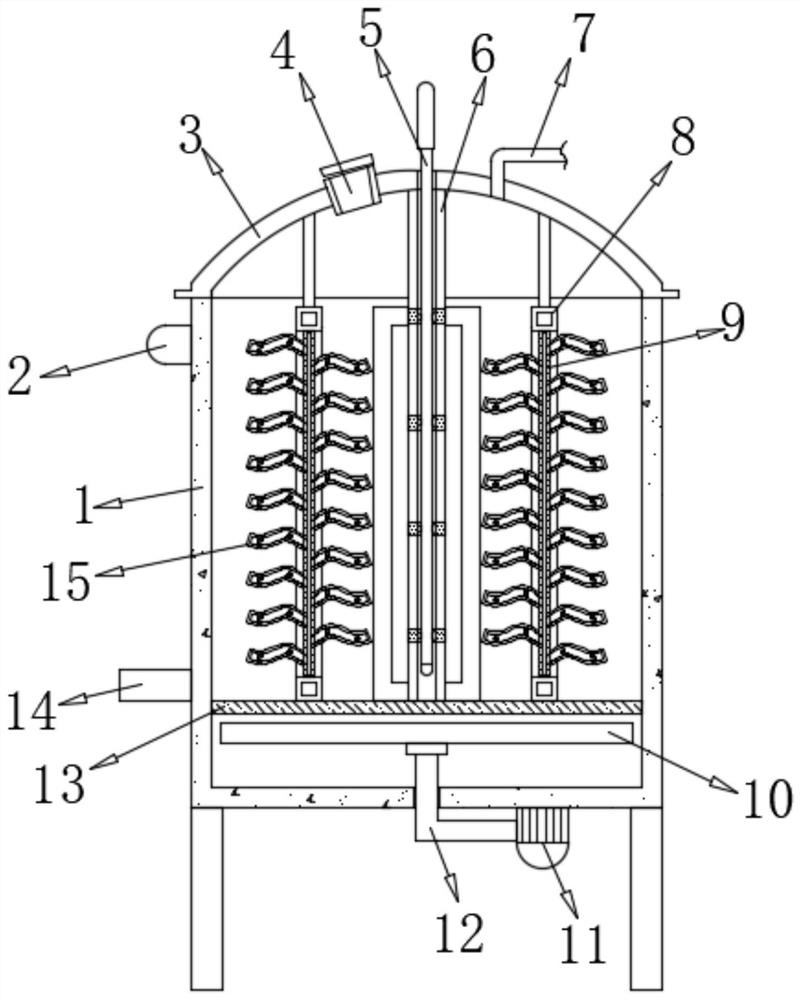

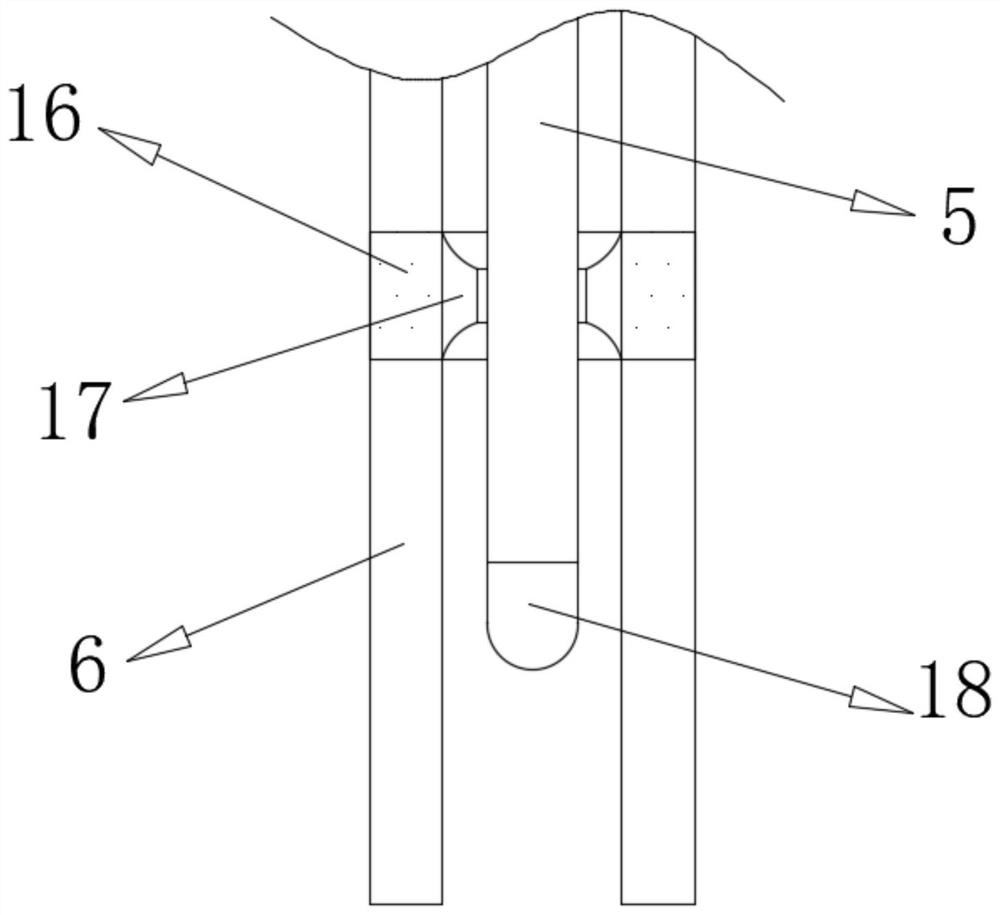

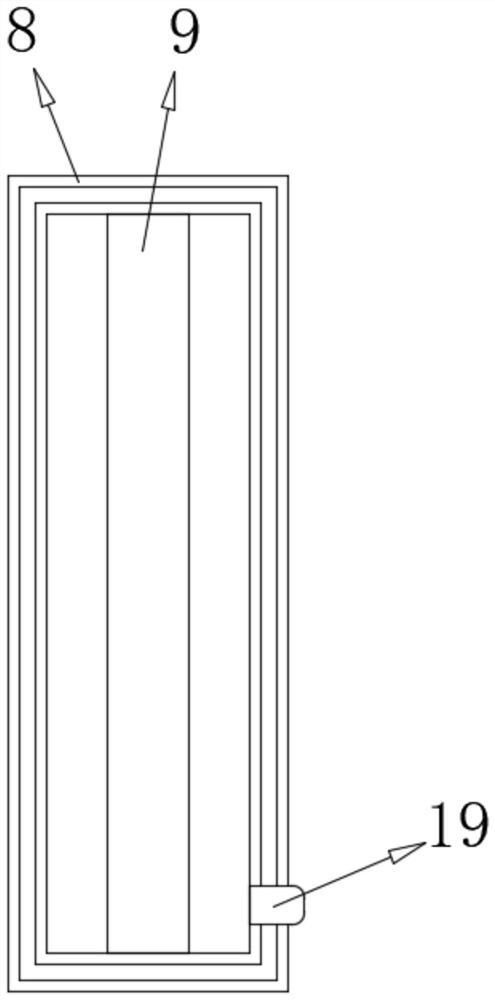

Apparatus and method for preparing aminobenzene by nitrobenzene gas-phase hydrogenation

ActiveCN1528737AImprove conversion rateReduce dosageOrganic compound preparationAmino compound preparationNitrobenzeneChemistry

The invention discloses a device and method to prepare aniline by the nitrobenzene gas phase hydrogenization, and the device mainly includes a fluidized bed reactor set at the raw material gas inlet at the bottom of the reactor, a first gas distributor on the top of the gas inlet, a second gas distributor separating the reactor in the middle of axial height of the reactor into two catalyst dense phase regions, and heat exchangers in two catalyst dense phase regions; catalyst overflow device connected with two catalyst dense phase regions and gas-solid separator. It also discloses a method to prepare aniline by the device, mainly including: the steps of controlling the mol ratio of hydrogen gas to nitrobenzene, controlling the temperature in two catalyst dense phase regions, etc. It has advantages of large reactor operation flexibility, high nitrobenzene conversion, high aniline production selectivity, high product purity, etc.

Owner:TSINGHUA UNIV

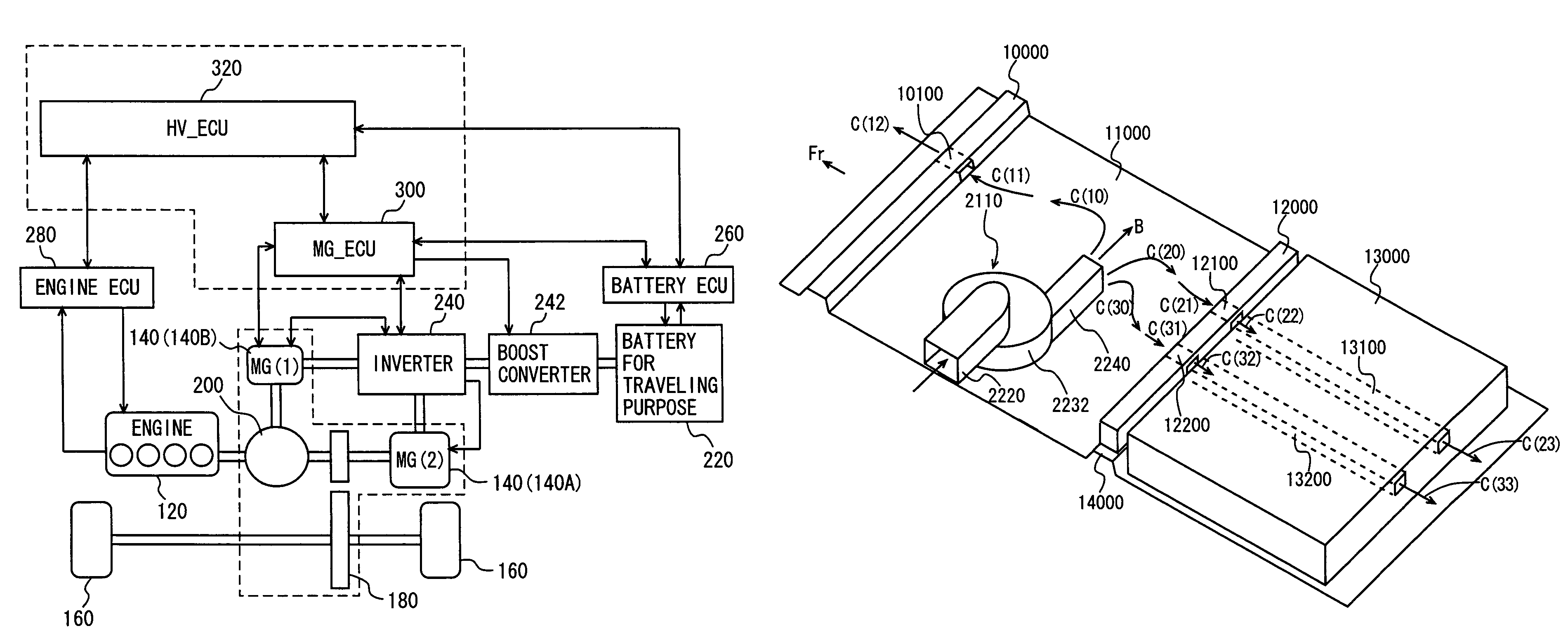

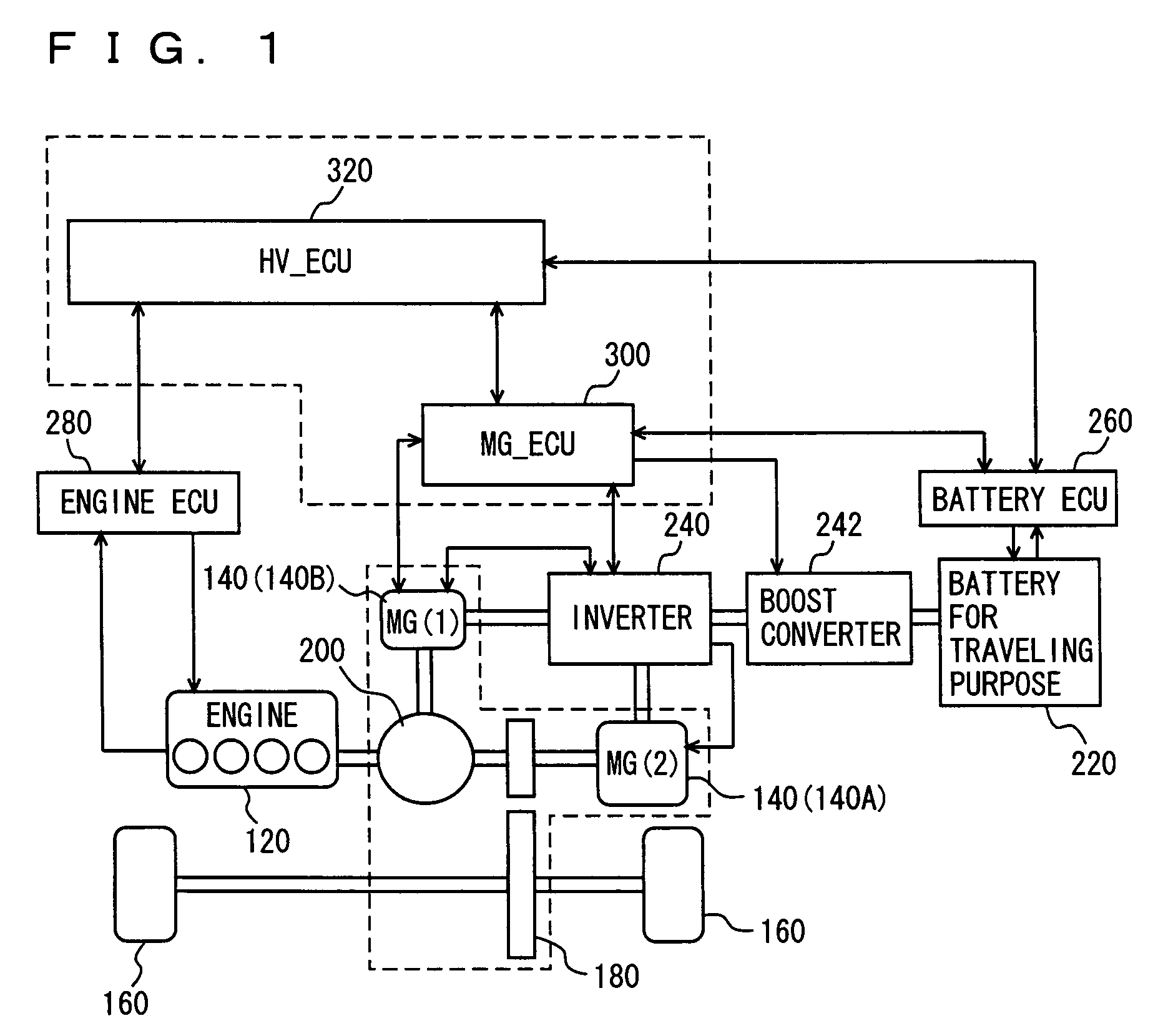

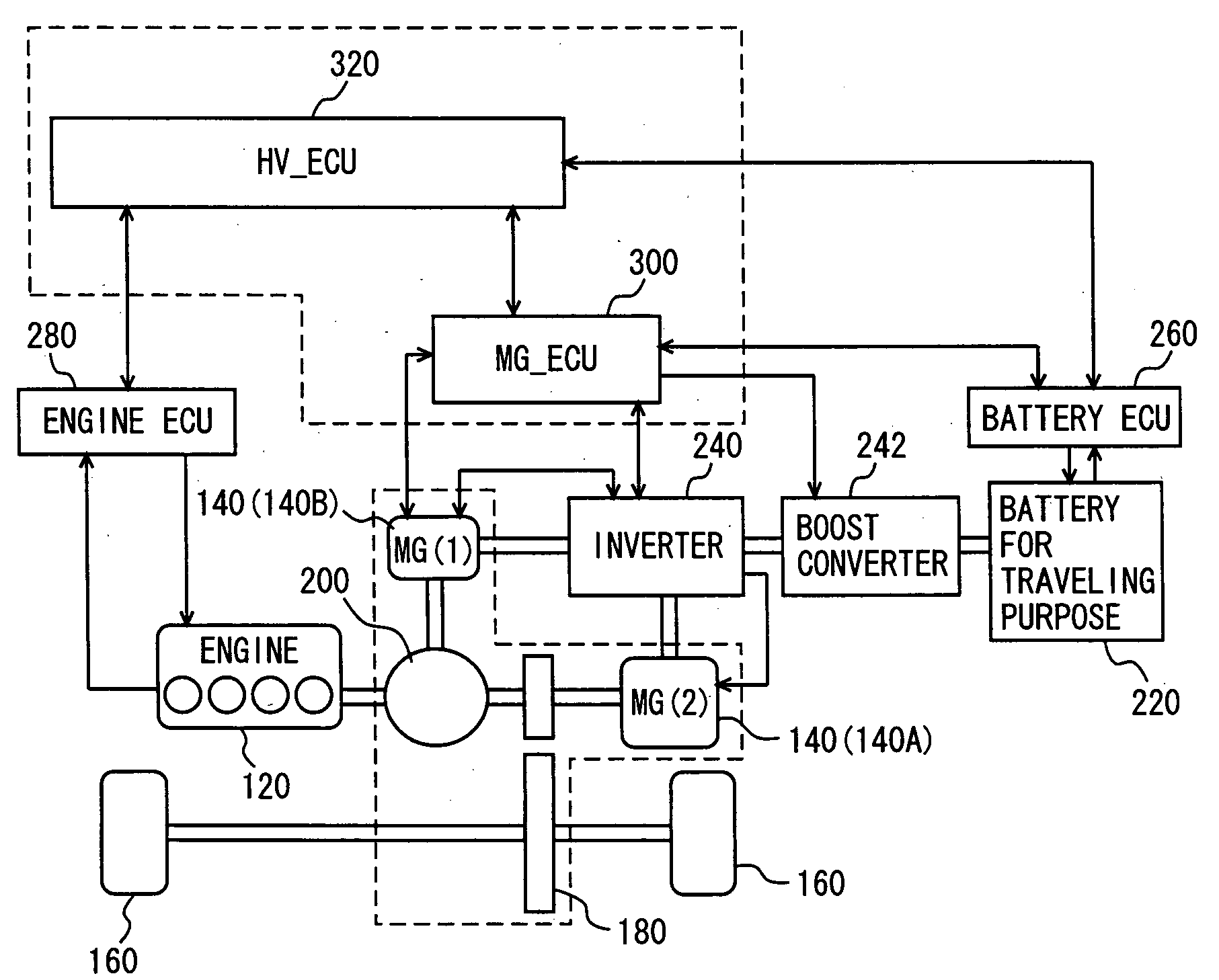

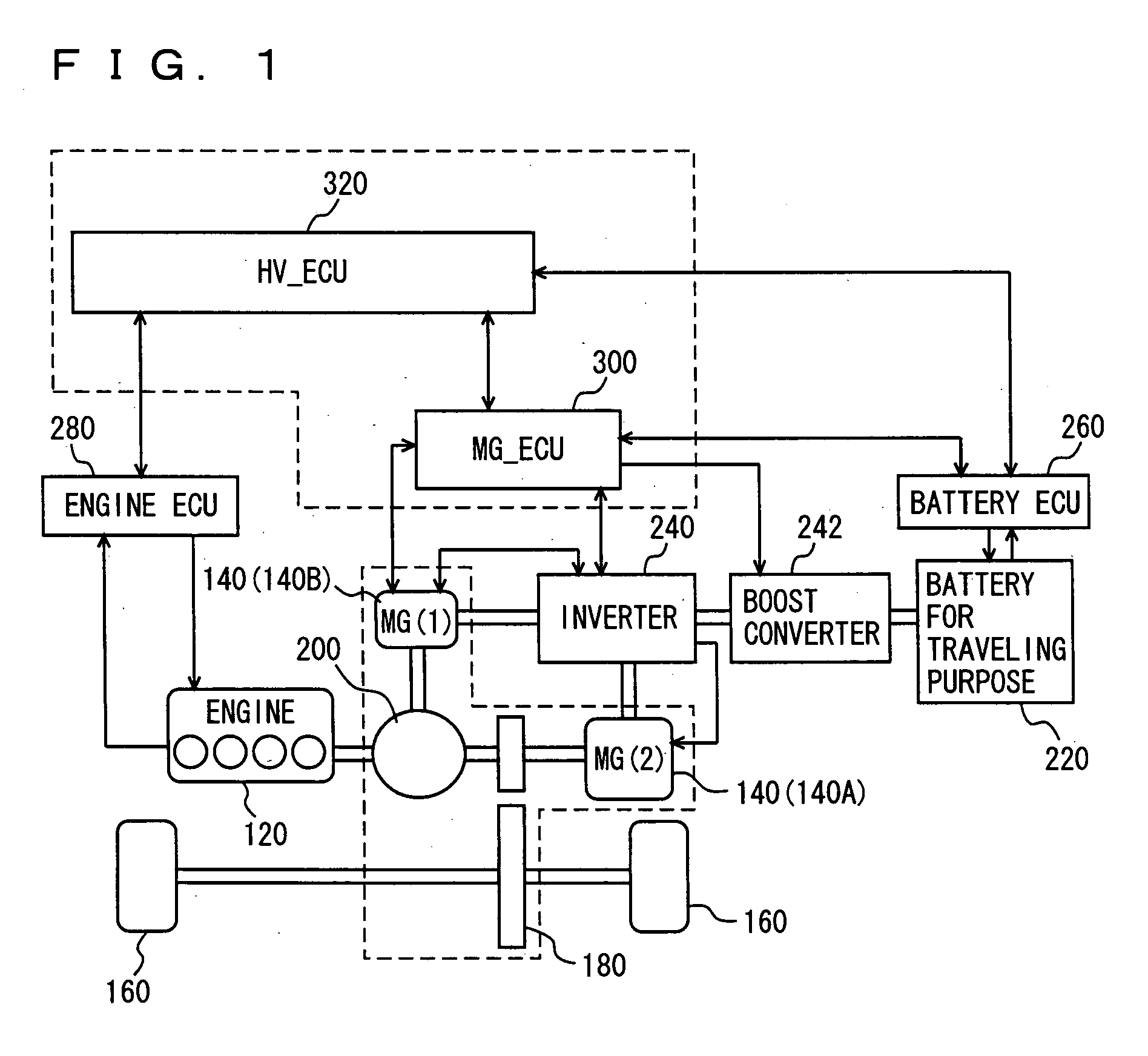

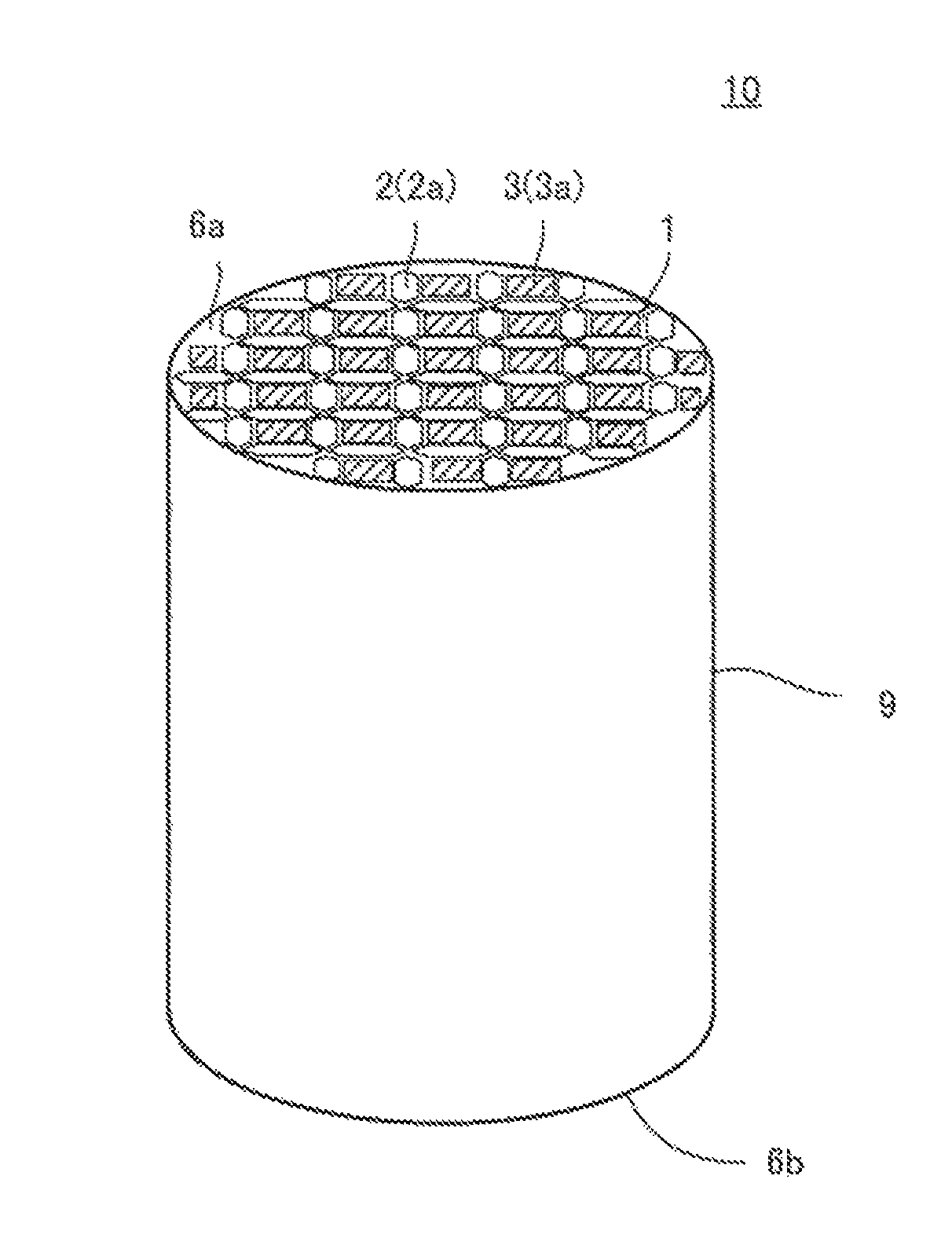

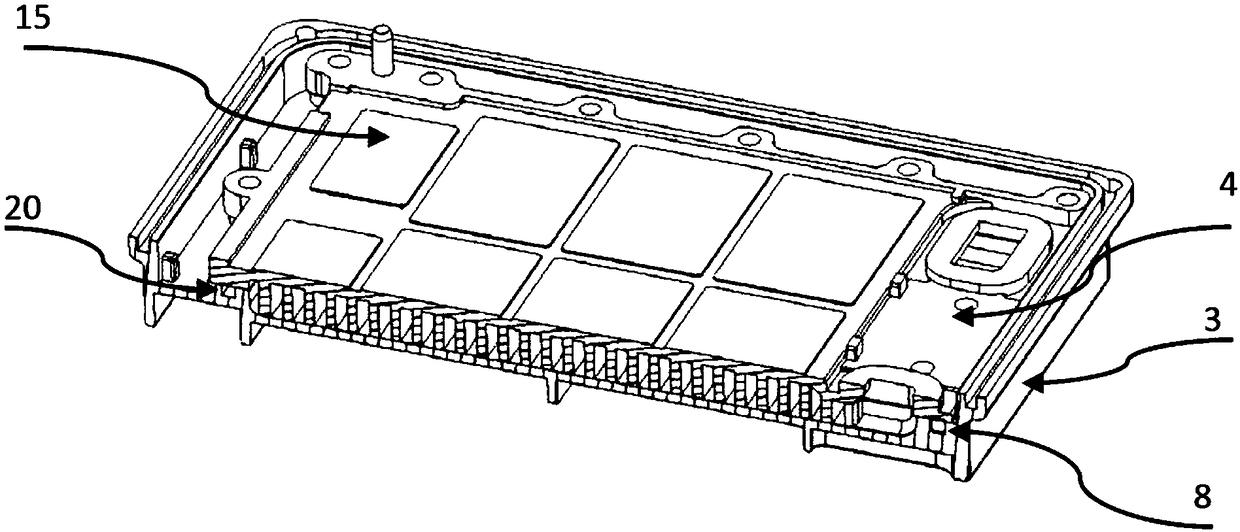

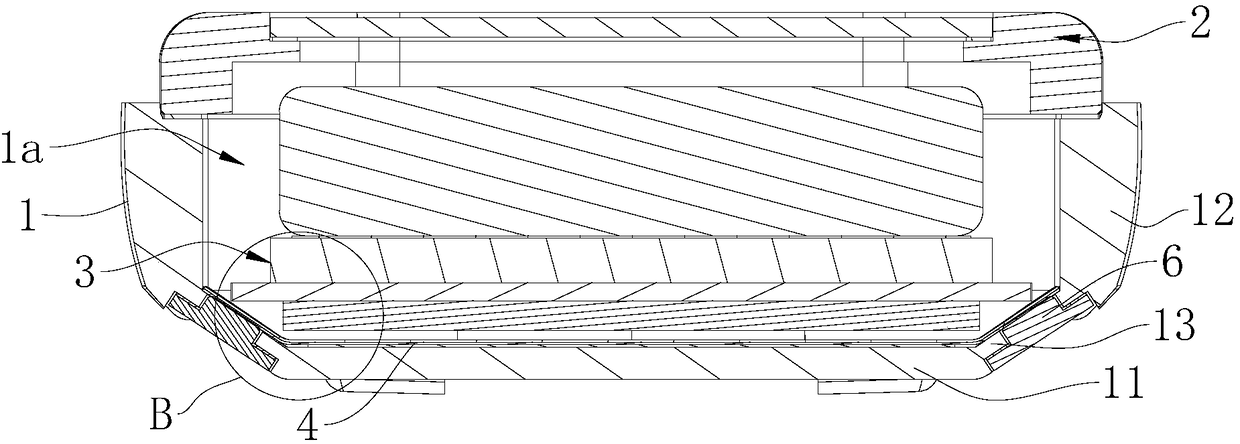

Cooling device for electric apparatus mounted on vehicle

InactiveUS7631711B2Avoid high local temperaturesBig spaceCell temperature controlSuperstructure subunitsCushioningElectrical devices

Exhaust air from an electric-powered battery cooling fan which draws in an exhaust airflow from a battery for traveling purpose is diffused in a direction to a ventilating opening provided in a first cross member, as shown by an arrow C (10), an arrow C (11), and an arrow C (12), in a direction to a first ventilating opening provided in a cushioning material and a first ventilating duct provided in a cushioning material, as shown by an arrow C (20), an arrow C (21), an arrow C (22), and an arrow C (23), and in a direction to a second ventilating opening provided in the cushioning material and a second ventilating duct provided in the cushioning material, as shown by an arrow C (30), an arrow C (31), an arrow C (32), and an arrow C (33). With such a configuration, a local temperature rise in a vehicle interior is avoided even though the exhaust airflow flows from the battery for traveling purpose, without the need of a large space.

Owner:TOYOTA JIDOSHA KK

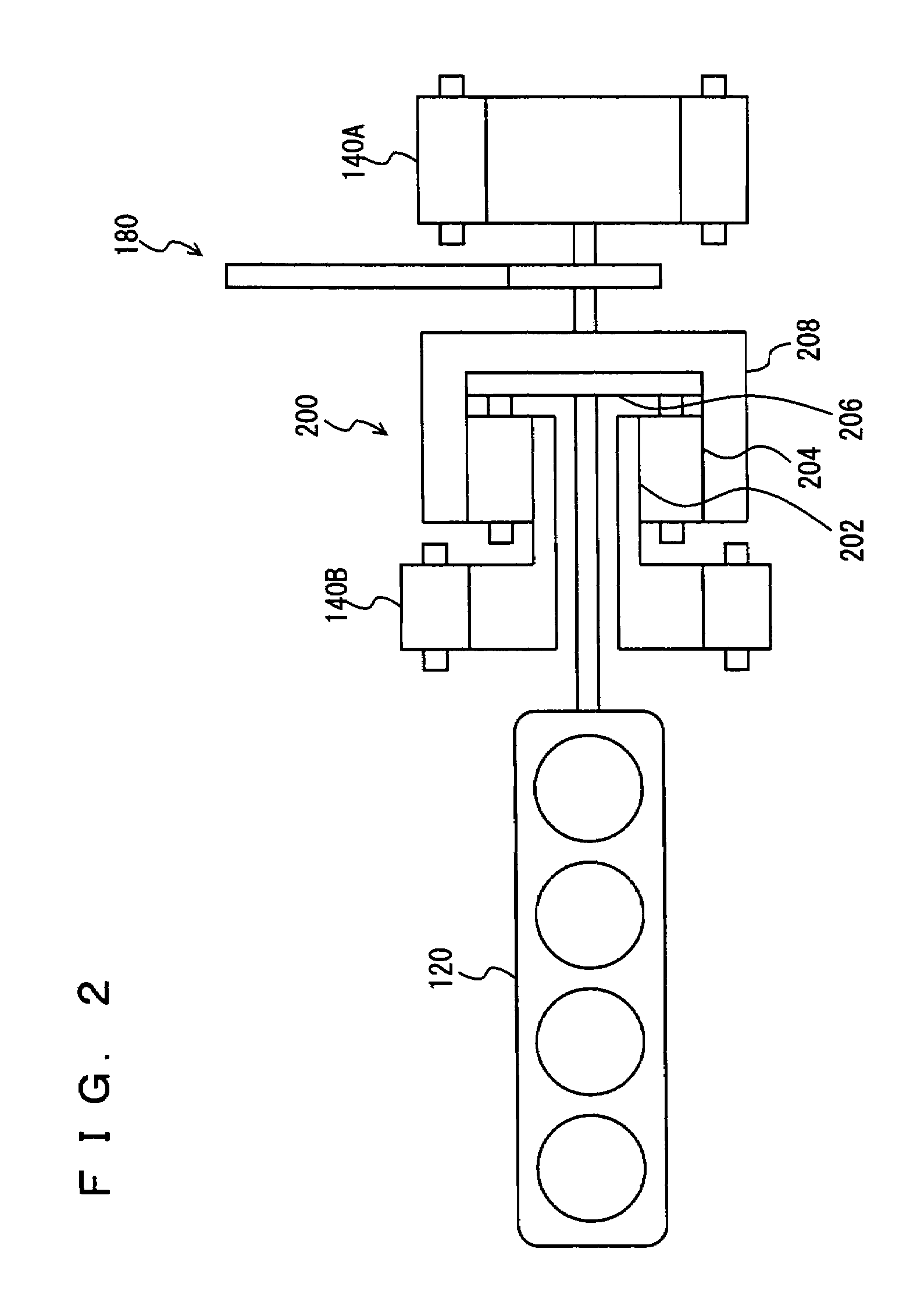

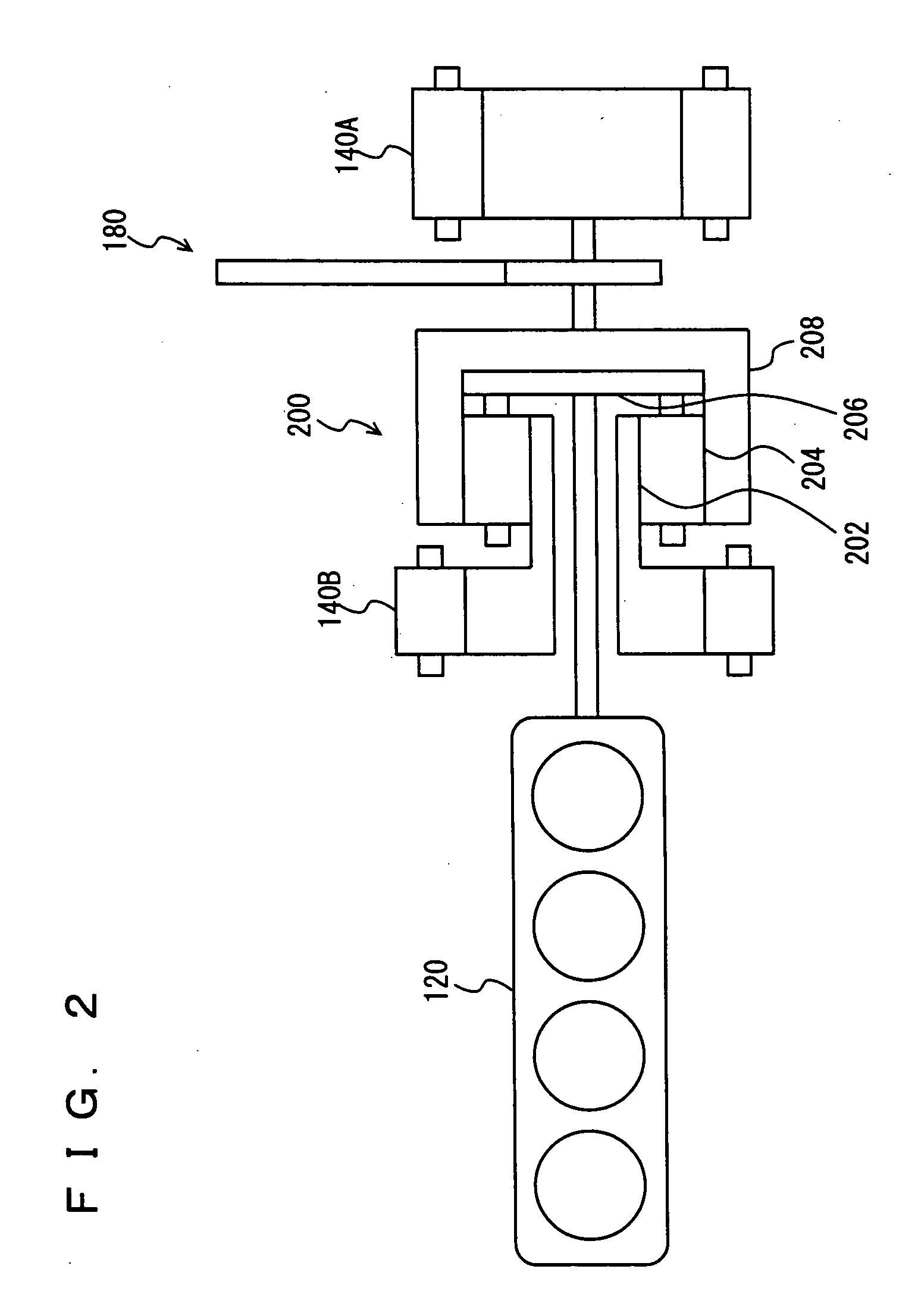

Cooling device for electric apparatus mounted on vehicle

InactiveUS20080257624A1Avoid high local temperaturesBig spaceCell temperature controlPlural diverse prime-mover propulsion mountingCushioningElectrical devices

Exhaust air from an electric-powered battery cooling fan which draws in an exhaust airflow from a battery for traveling purpose is diffused in a direction to a ventilating opening provided in a first cross member, as shown by an arrow C (10), an arrow C (11), and an arrow C (12), in a direction to a first ventilating opening provided in a cushioning material and a first ventilating duct provided in a cushioning material, as shown by an arrow C (20), an arrow C (21), an arrow C (22), and an arrow C (23), and in a direction to a second ventilating opening provided in the cushioning material and a second ventilating duct provided in the cushioning material, as shown by an arrow C (30), an arrow C (31), an arrow C (32), and an arrow C (33). With such a configuration, a local temperature rise in a vehicle interior is avoided even though the exhaust airflow flows from the battery for traveling purpose, without the need of a large space.

Owner:TOYOTA JIDOSHA KK

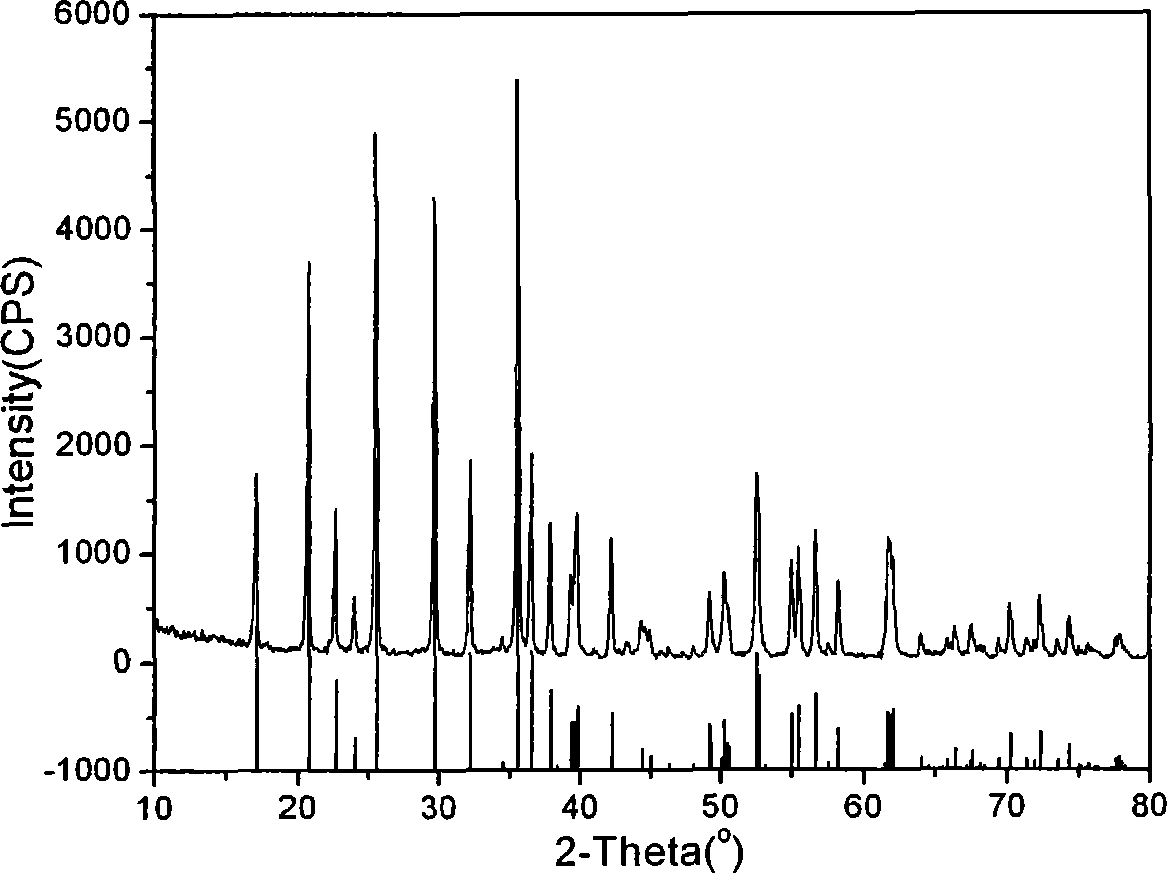

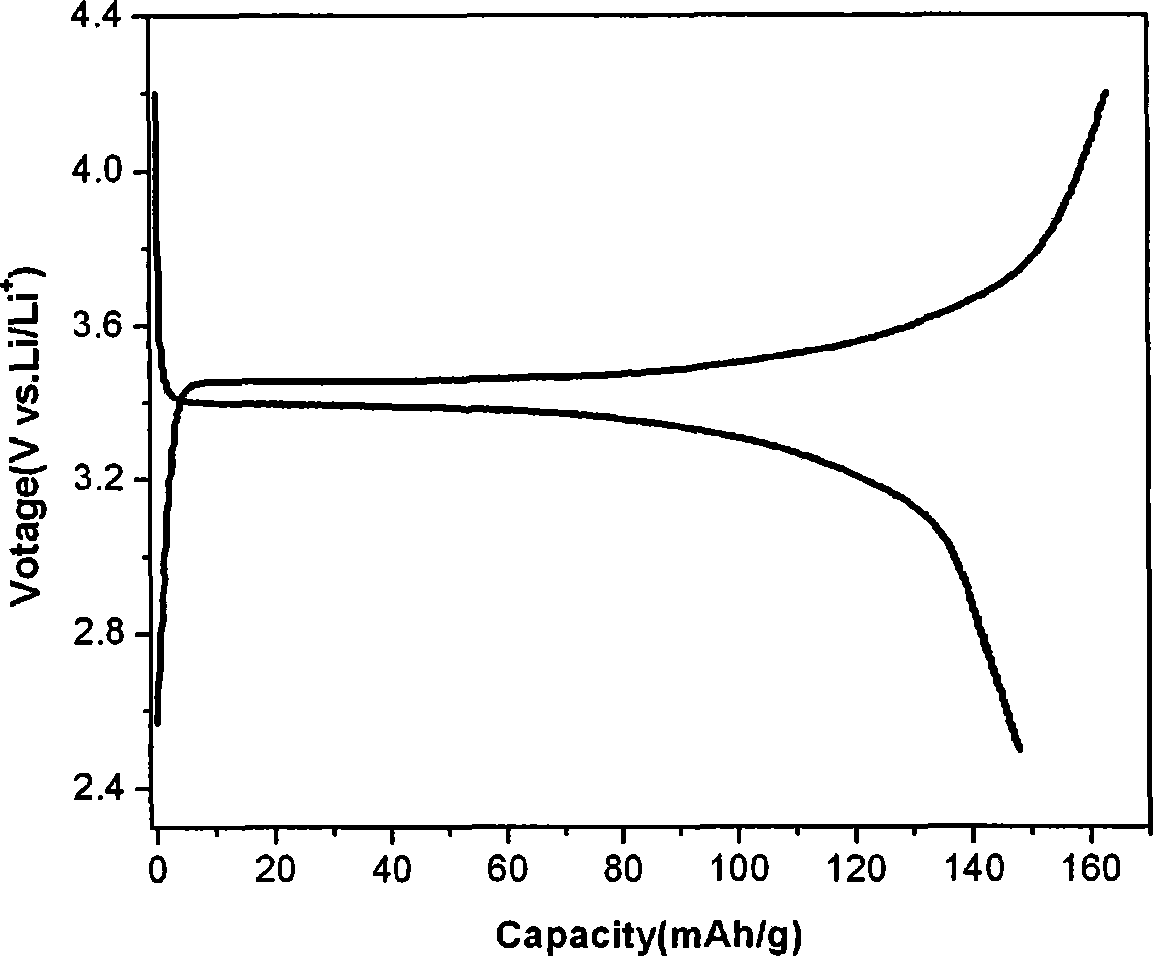

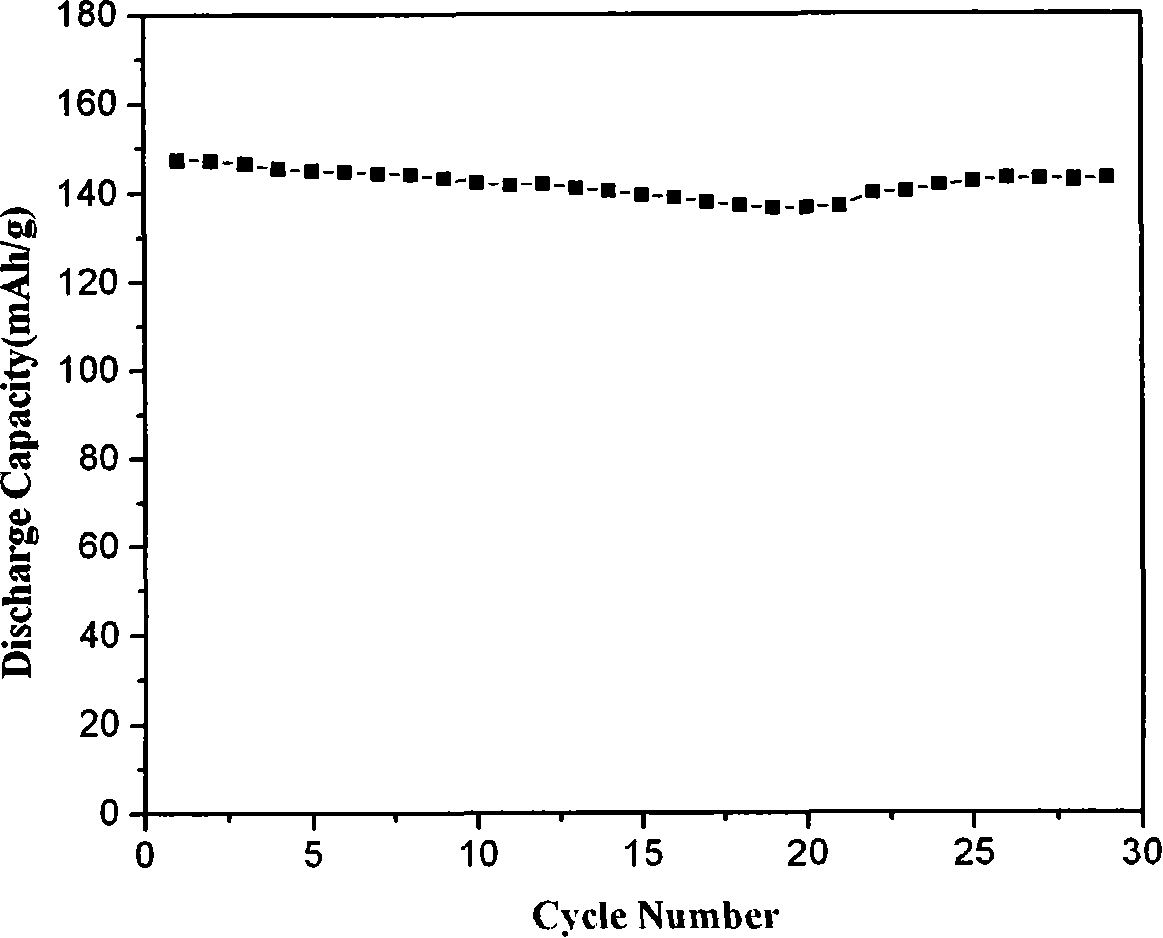

LiFePO4/C nano composite positive pole material and preparation method thereof

InactiveCN101159328AAchieve hybridControl chemical compositionElectrode manufacturing processesChemical industryPhosphateLithium-ion battery

The invention discloses a nano-composite positive material LiFePO4 / C and a fabrication method, relating to a fabrication method of positive material of a lithium-ion battery. The invention uses the method of liquid-phase coprecipitation, the certain amount of lithium resource, iron resource and phosphate resource is weighted as the quality mol ratio of Li:Fe:P = (3.0-3.3):(1.0-1.1):(1.0-1.1), and the appropriate amount of carbon-doped material and organic surfactant is added in the reaction vessel; by controlling the reaction conditions like concentration, temperature etc. of the reaction solution, precursor gels are fabricated, and the precursor gels are separated, cleaned, filtered and dried to obtain precursor powder; the precursor powder is tableted and put into the crucible with microwave absorbent, and then the crucible is placed in the microwave oven, with the microwave power controlled between 100 to 600W and heated for 30 min, to obtain nano-sized composite positive material LiFePO4 / C. The technique method in the invention has the advantages of short periods, saved energy consumption, ease to control the process, suitability for industrialization and so on. The composite positive material LiFePO4 / C fabricated in the invention is characterized by high purity, small particle size lower than 100 nm, and good electrochemical properties.

Owner:上海微纳科技有限公司

Wall flow type exhaust gas purification filter

ActiveUS9080484B2Avoid high local temperaturesSuppress pressure lossSilencing apparatusMachines/enginesEngineeringMechanical engineering

Owner:NGK INSULATORS LTD

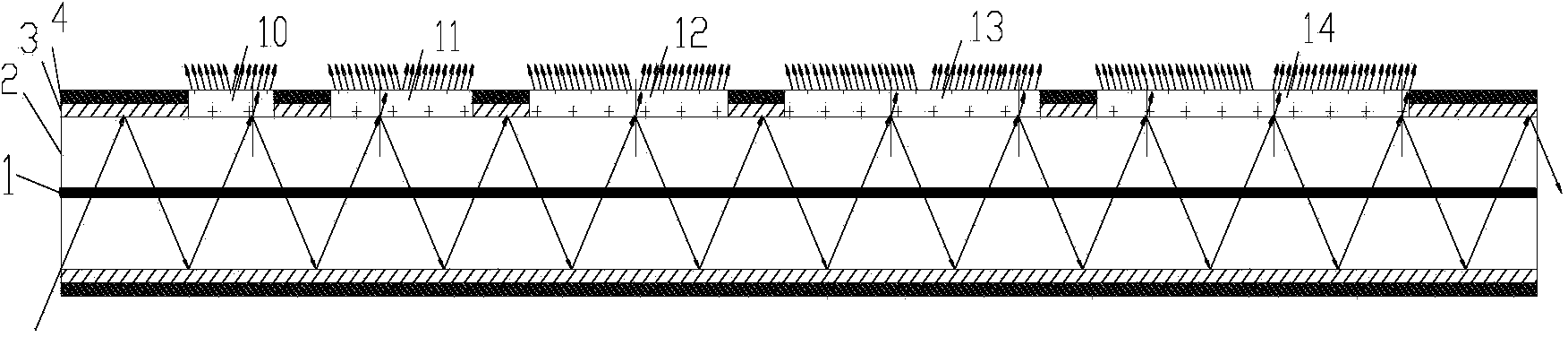

Cladding light filtering device for high-power optical fiber laser

ActiveCN103904535AGuarantee structureAvoid damageOptical fibre with multilayer core/claddingActive medium shape and constructionDouble-clad fiberSystem stability

The invention discloses a cladding light filtering device for a high-power fiber laser. The device comprises one or more sections of double-cladding optical fibers. The double-cladding optical fibers can partially strip a protection layer and an external cladding in the laser output direction from the small stripping area to the large stripping area at intervals to enable an internal cladding to be exposed, the exposed internal cladding is coated with filtering materials, and the light filtering device is fixed to a heat dissipation metal material or a water cooling plate. According to the cladding light filtering device, the damage to an optical fiber structure is small, light filtering is even, the phenomenon that the temperature of some filtering points is excessively high in the non-even filtering process is avoided, and system stability is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

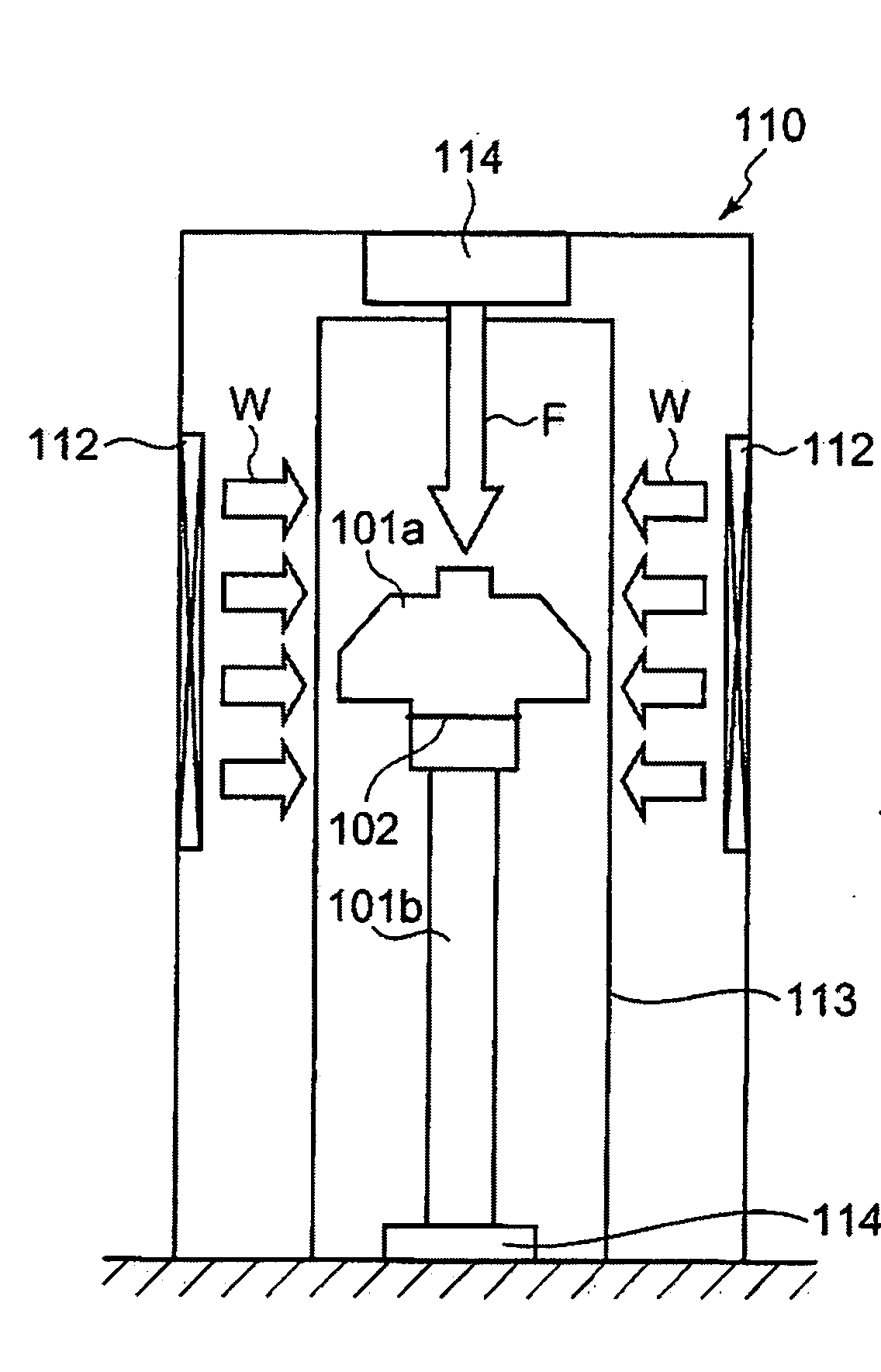

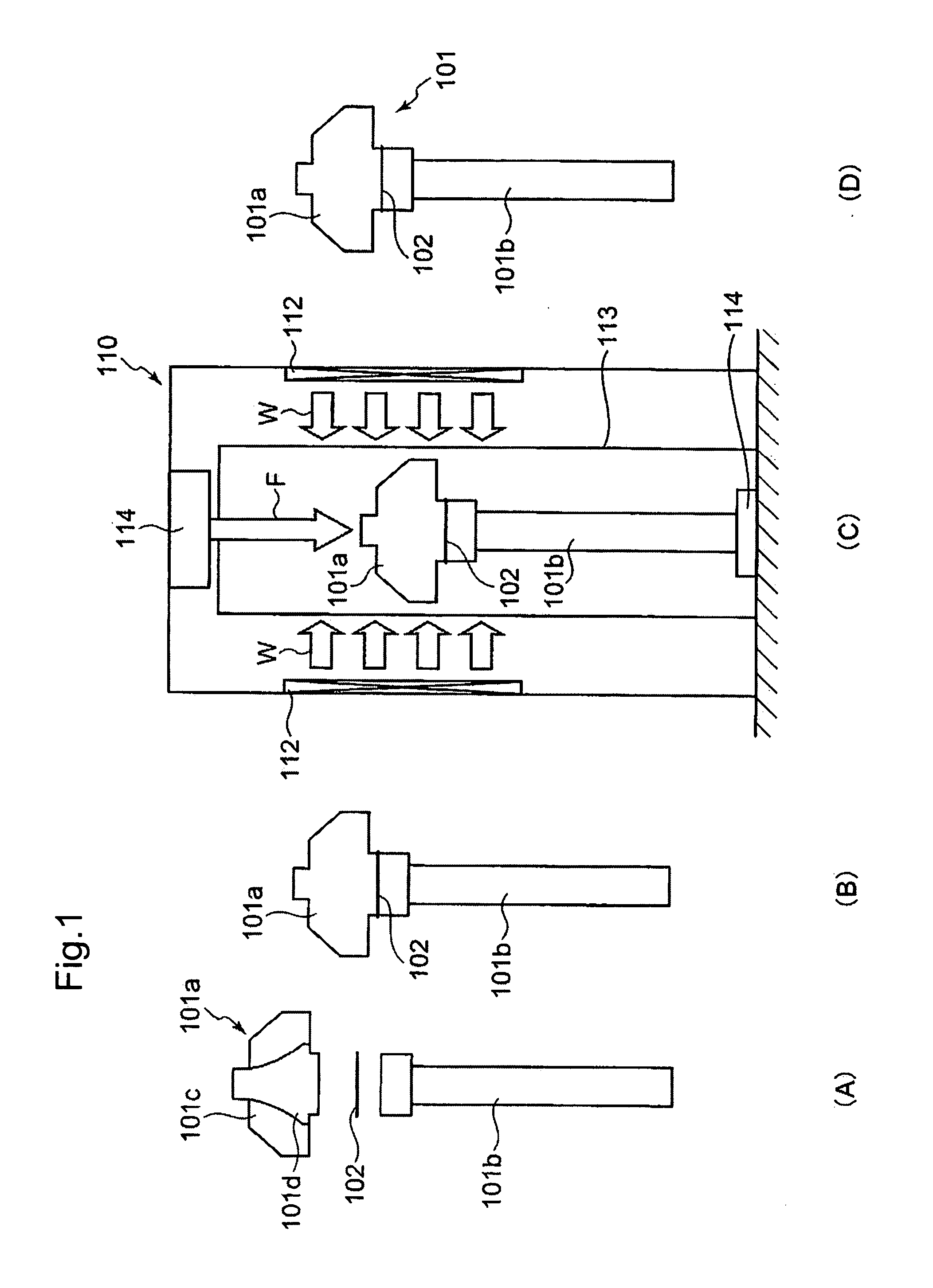

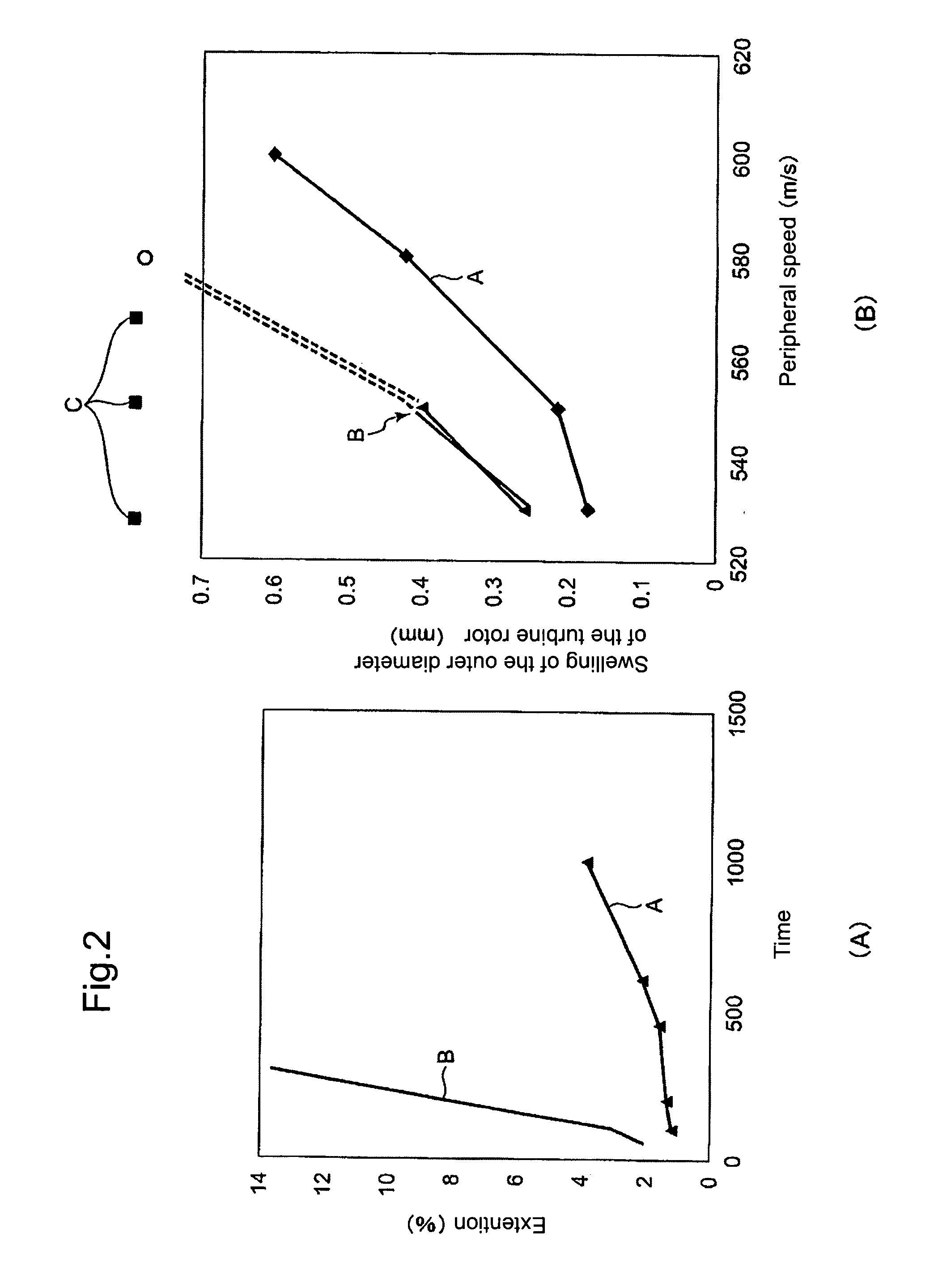

Method of manufacturing rotor and exhaust turbo-supercharge incorporating the rotor

InactiveUS20080199313A1High strengthInhibition strengthPropellersPump componentsCircular discTurbocharger

Provided are a method of manufacturing a brazed rotor composed of a wheel and a shaft joined to the former by brazing, having a durability and a reliability which can be enhanced without increasing the manufacturing man hours, and a turbine rotor for an exhaust turbo-supercharger. The wheel having a disc portion formed at its outer periphery with blades, and a rod-like shaft are arranged in a furnace, being opposed to each other at their surfaces to be joined with a brazing solder being interposed therebetween, and infrared radiation is irradiated onto a side part of the wheel so as to heat the surfaces to be joined up to a temperature in a range from 1,000 to 1,080 deg. C. in order to melt the brazing solder, thereby the wheel and the shaft are joined by brazing to each other at their surfaces to be joined.

Owner:MITSUBISHI HEAVY IND LTD

Functional ceramic coating diaphragm for lithium ion battery and preparation method for functional ceramic coating diaphragm

ActiveCN108717965AGood dispersionAvoid breakingSecondary cellsCell component detailsCeramic coatingMetallurgy

The invention discloses a functional ceramic coating diaphragm for a lithium ion battery. The diaphragm is characterized by consisting of a porous polymer film layer and a functional ceramic coating with which the porous polymer film layer is coated, wherein the functional ceramic coating comprises ceramic nanoparticles, modified polymeric nanoparticles, a plasticizer, a catalyst, a dispersant andan adhesive. The functional ceramic coating diaphragm has the advantages that, when the battery is excessively heated and the local temperature exceeds 150 DEG C, the modified polymeric nanoparticlesin the functional ceramic coating are molten and plasticized under the action of the plasticizer, the molten modified polymeric nanoparticles rapidly react with ethylene carbonate around under the action of the catalyst to form a high-temperature-resistant solid film layer on the surface of the diaphragm, and by the solid film layer, the diaphragm can be protected and prevented from being brokenby high temperature on one hand and, on the other hand, ion transportation is blocked to prevent the local temperature of the battery from keeping increasing and ensure the safety of the battery.

Owner:JIANGSU QINGTAO ENERGY TECH

Making process for kirschwasser

InactiveCN103468465AGuaranteed qualityAchieve sterile hygieneAlcoholic beverage preparationYeastTrace element

The invention relates to a making process for kirschwasser. The process includes the steps of: 1) subjecting cherries to peduncle removing, washing, drying, disinfection and crushing; 2) letting cherry juice and peels contact, adding a distiller's yeast according to a proportion to make them ferment together; 3) in the fermentation process, making the pigment and aroma in the peels dissolved in wine; 4) after the fermentation, carrying out peel pomace separation to separate the original wine from the peel pomace and wine sediment, and then performing cylinder pouring to make the wine liquid clear and transparent; 5) fermenting the separated original wine; 6) ageing the separated original wine liquid; 7) carrying out clarification and gelatin charging at the end of ageing to make a gel net generated in the wine liquid, and filtering out the peels; 8) performing freezing treatment after the clarification treatment; 9) conducting heat treatment after the freezing treatment; 10) performing deployment after the heat treatment to deploy various trace elements of the kirschwasser; 11) then removing sediment and floating matters to make the wine liquid clear and stable; and 12) canning the filtered wine juice by a stainless steel canning machine, performing packaging by an aseptic packaging machine, and conducting sealing by a cork stopper.

Owner:王战乐

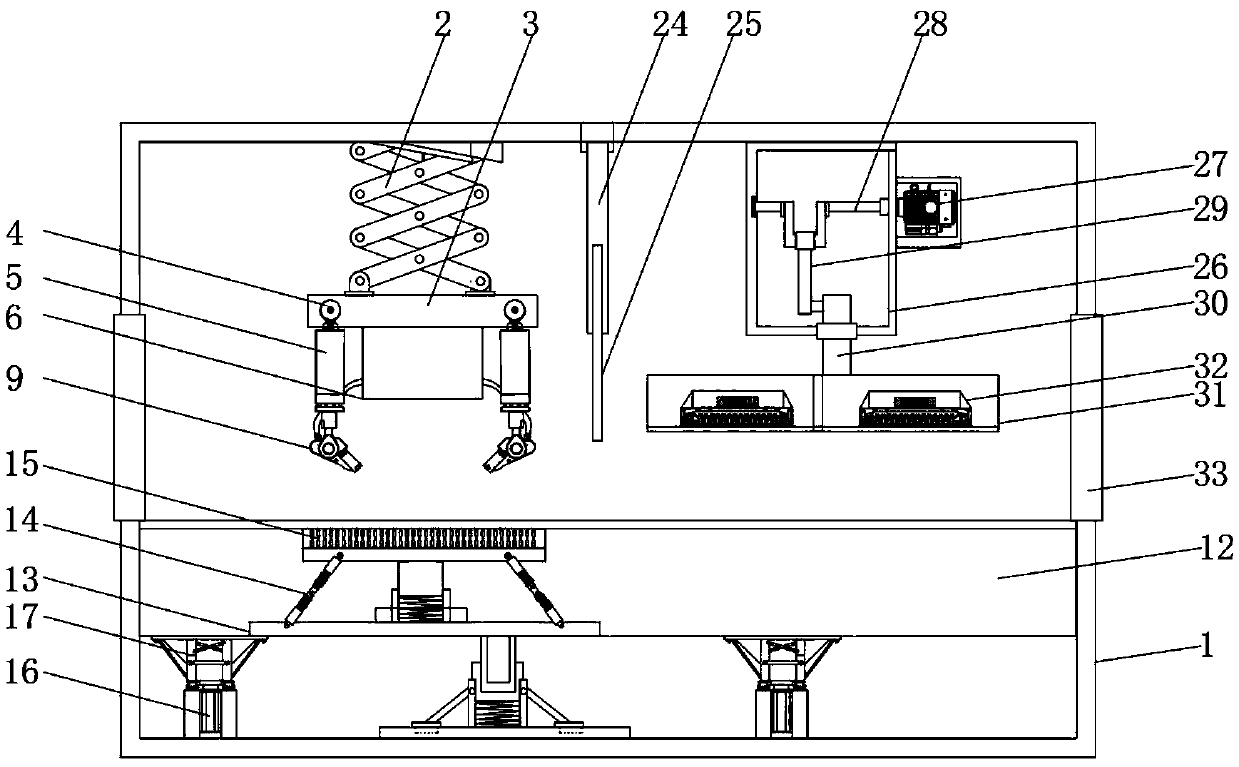

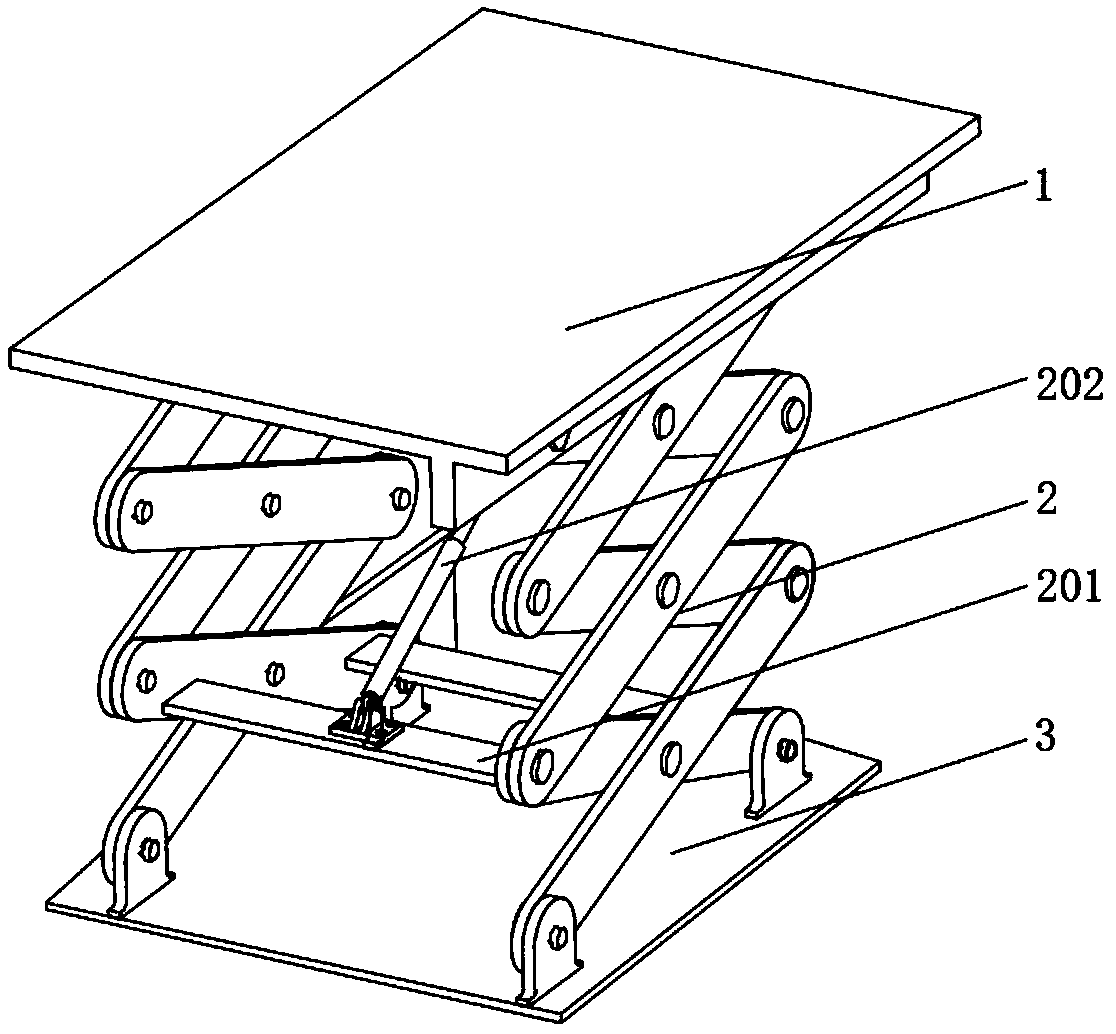

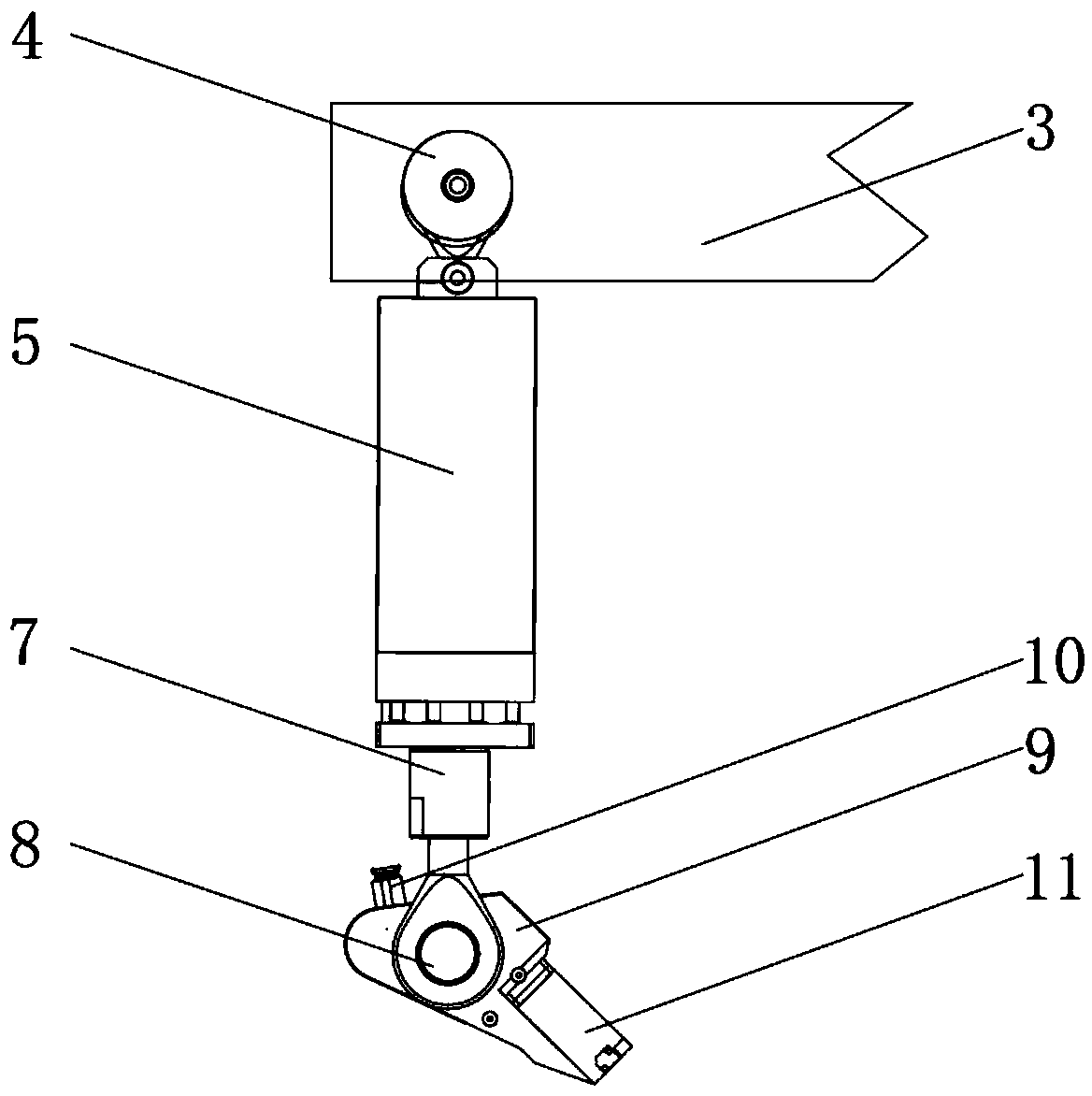

Full-automatic spraying assembly line

InactiveCN109513547AEasy to collectReduce usageSpraying apparatusPretreated surfacesAgricultural engineeringSpray nozzle

The invention discloses a full-automatic spraying assembly line. The full-automatic spraying assembly line comprises a work outer rack. The top of the inner wall of the work outer rack is fixedly connected with a shear fork lifting module. The bottom of the shear fork lifting module is fixedly connected with a mounting rack. The two sides of the bottom of the mounting rack are fixedly connected with electric telescopic rods through adjusting mounting seats. The middle position of the bottom of the mounting rack is fixedly connected with a spraying loading box. An adjustable mounting head is mounted at the bottom of each electric telescopic rod through a telescopic rod. The inner side of each adjustable mounting head is fixedly connected with an adjustable spray head. A liquid injection mounting opening is formed above each adjustable spray head. The invention relates to the technical field of spraying machining. According to the full-automatic spraying assembly line, the aim of freelycontrolling the spraying position and the nozzle requirement during spraying is achieved, multi-directional free spraying can be suitable for machining of most materials, use of work equipment can bereduced, the labor amount of workers can be reduced by means of the integrated work process, and a collection cavity is formed in a supporting table and can collect waste conveniently.

Owner:滁州市朝友精密制造有限公司

Process for producing nitrogen trifluoride and use thereof

InactiveUS20030017098A1Improve securityImprove efficiencyNitrogen-metal/silicon/boron binary compoundsHydrogen fluorideGas phaseOrganic chemistry

Owner:SHOWA DENKO KK

Honeycomb filter

ActiveUS20170014747A1Excellent regenerationLow pressure lossDispersed particle filtrationExhaust apparatusHoneycomb structurePore diameter

A honeycomb filter includes a honeycomb structure body having porous partition walls defining a plurality of cells, inflow side plugging portions, and outflow side plugging portions, and in a cross section perpendicular to a cell extending direction, the whole periphery of each of outflow cells is surrounded by an inflow cell group, inflow cells are defined by inflow / outflow partition walls which are the partition walls defining the outflow cell and inflow / inflow partition walls which are the partition walls intersecting the inflow / outflow partition walls, a surface area A1 of the inflow / outflow partition wall of the inflow cell and a surface area A2 of the inflow / inflow partition wall of the inflow cell satisfy a relation of 1.2≦A1 / A2≦2, and in the partition wall, an average pore diameter of a surface region is from 4 to 60% of an average pore diameter of a central region.

Owner:NGK INSULATORS LTD

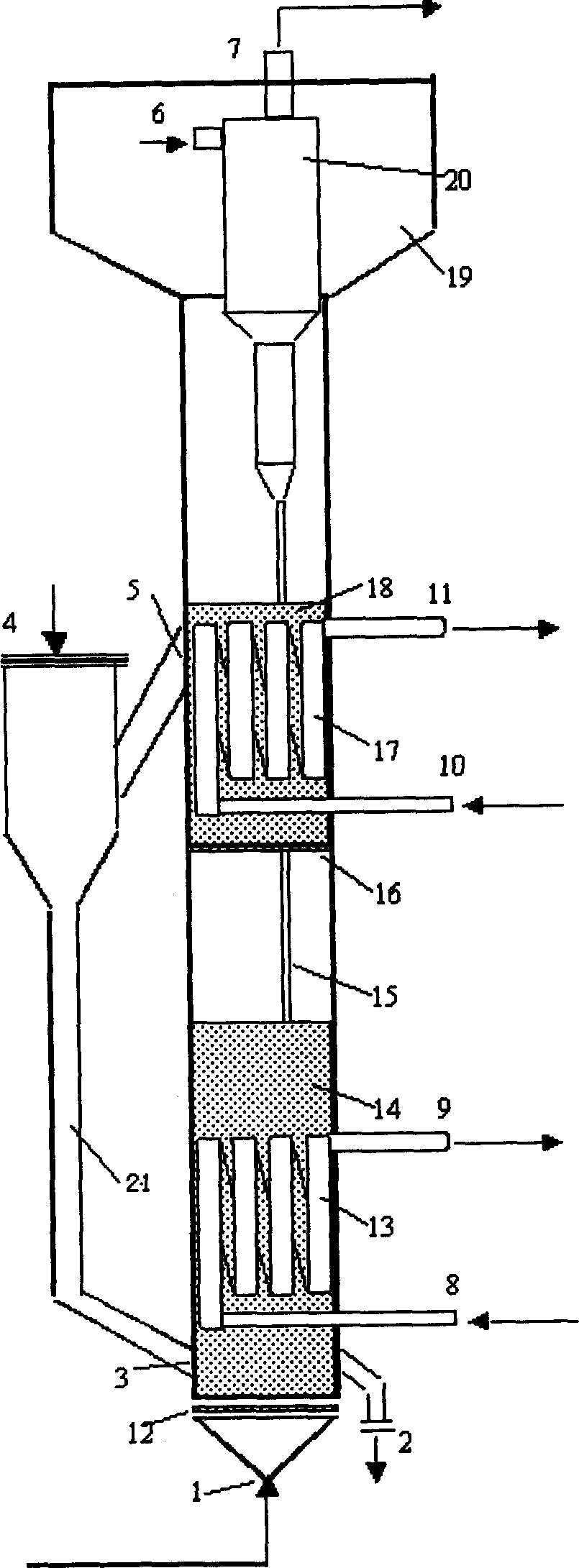

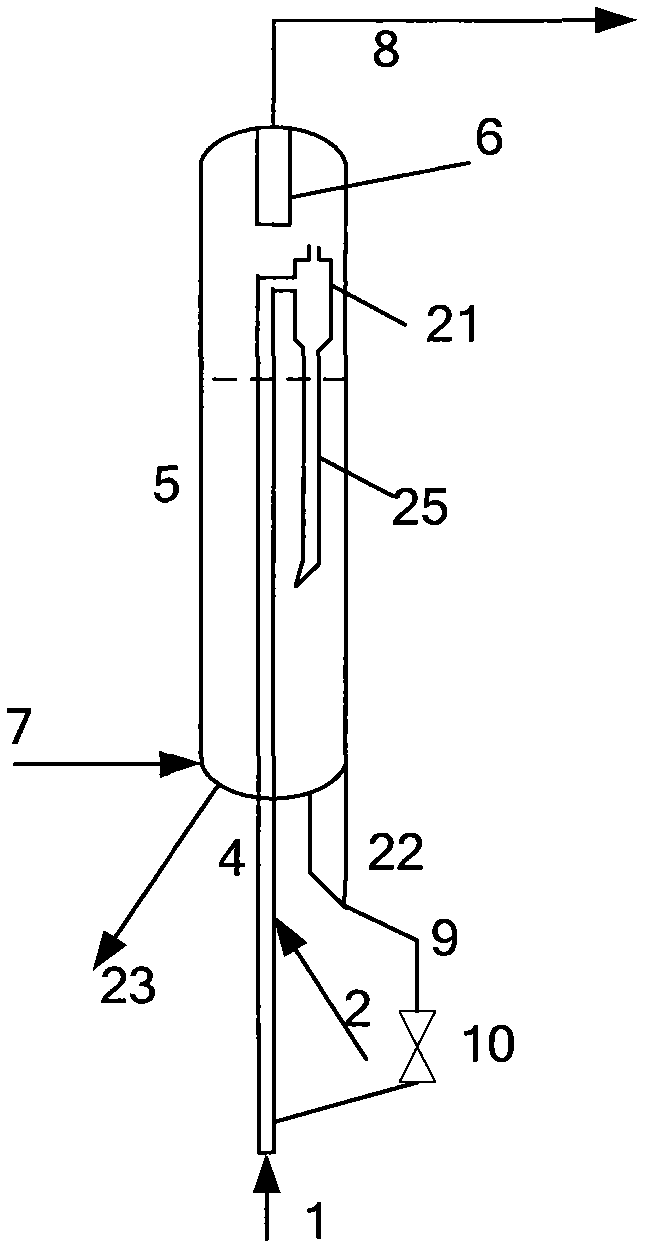

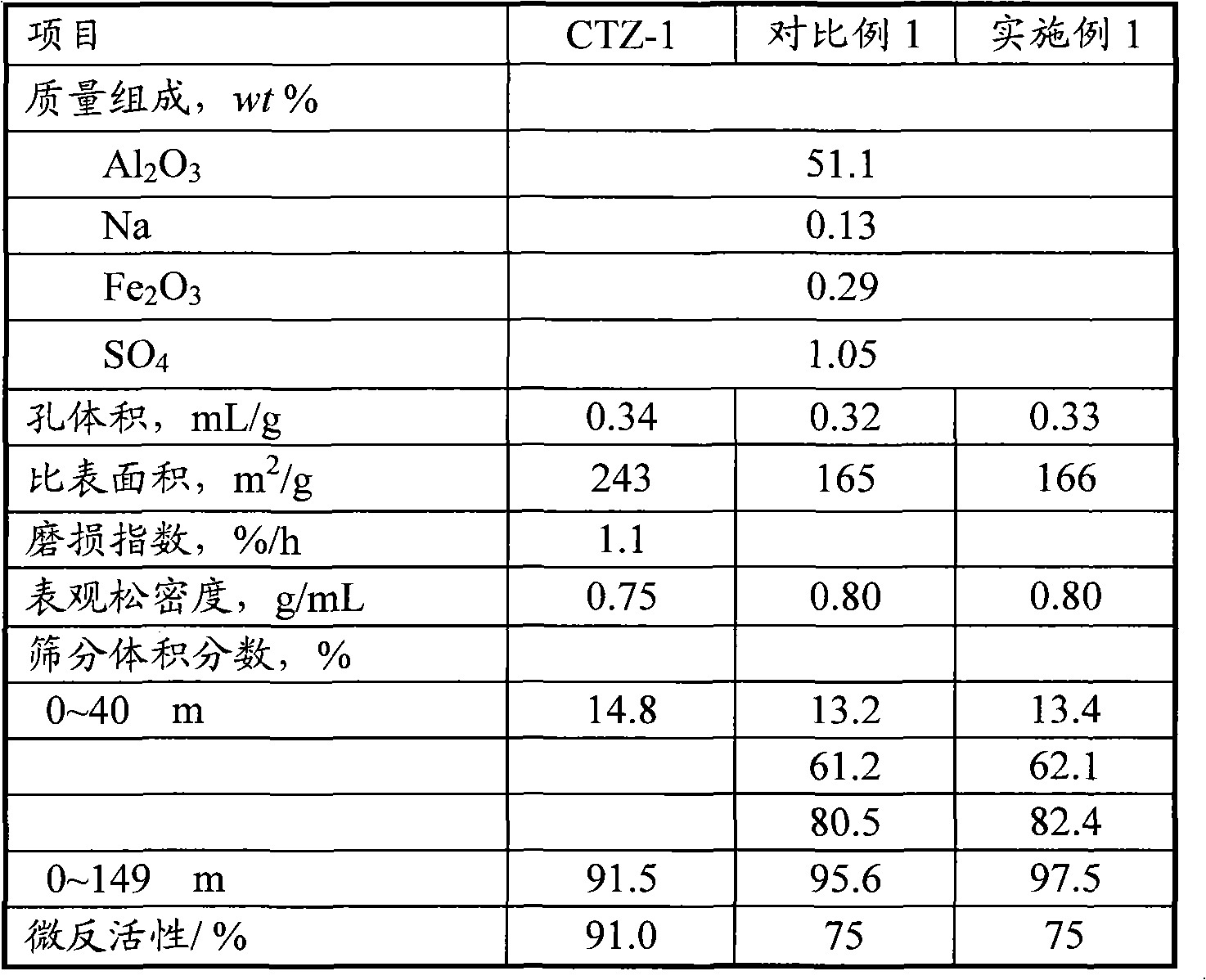

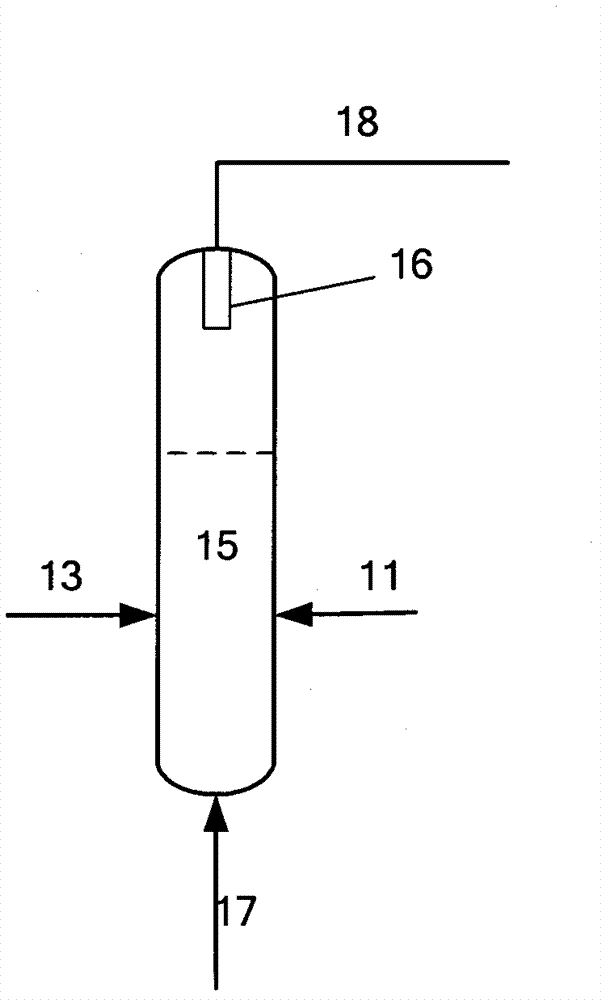

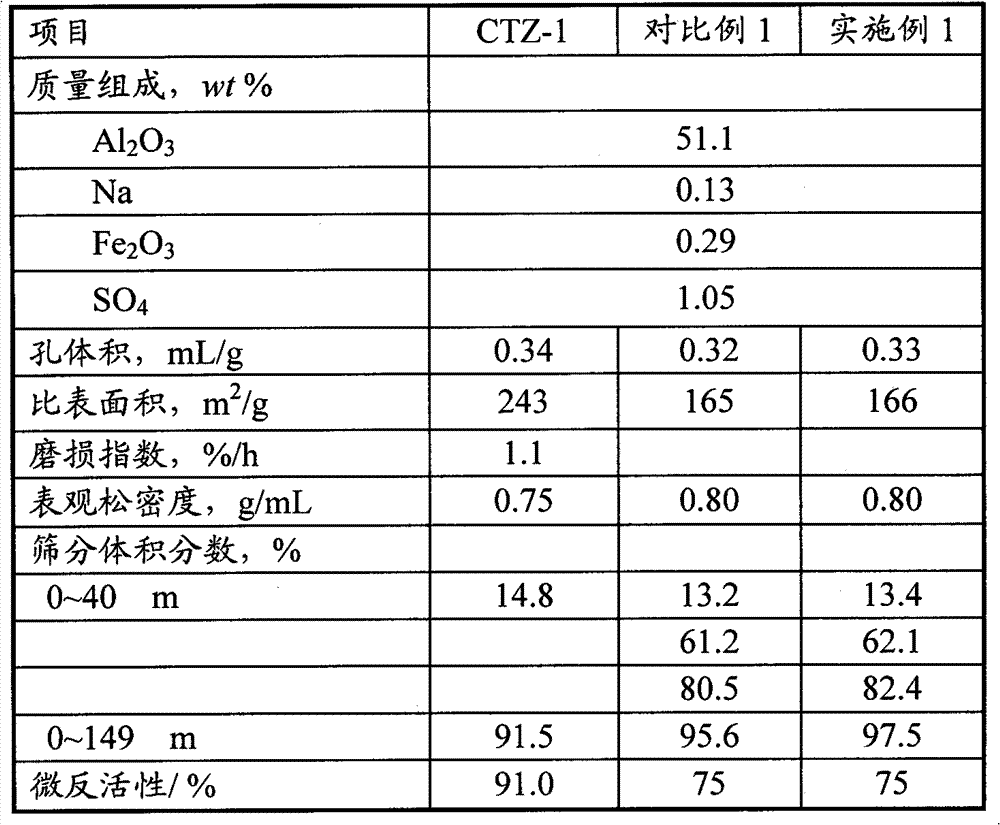

Catalytic cracking catalyst continuous aging method and device

The invention relates to a catalytic cracking catalyst continuous aging method and a catalytic cracking catalyst continuous aging device. The method comprises the steps that: a catalyst enters a bottom of a dilute-phase combustion tube, and then mixed with oxygen-containing gas and a fuel; the mixture is combusted and flows upward; gas-solid separation is carried out at the port of the dilute-phase combustion tube; catalyst obtained by separation enters a fluidized-bed reactor; the catalyst is subjected to a reaction with steam, such that activity is reduced; gas-solid separation is carried out at the top of the fluidized-bed reactor, and gas is discharged out of the device; the catalyst enters a catalyst buffering tank from the bottom of fluidized-bed reactor, and is circulated back to the bottom of the dilute-phase combustion tube through a control valve; when aging is finished, the catalyst is unloaded; material level in the catalyst buffering tank is maintained, and the catalyst continues to participate in circulation reaction in the dilute-phase combustion tube and the fluidized-bed reactor. The invention also relates to a device used for realizing the aging method. With the aging method and device provided by the invention, combustion reaction and hydro-thermal reaction operation conditions can be respectively controlled; and activity of aged catalyst is uniformly distributed. When the catalyst is used in hydrocarbon oil catalytic cracking reactions, product distribution can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

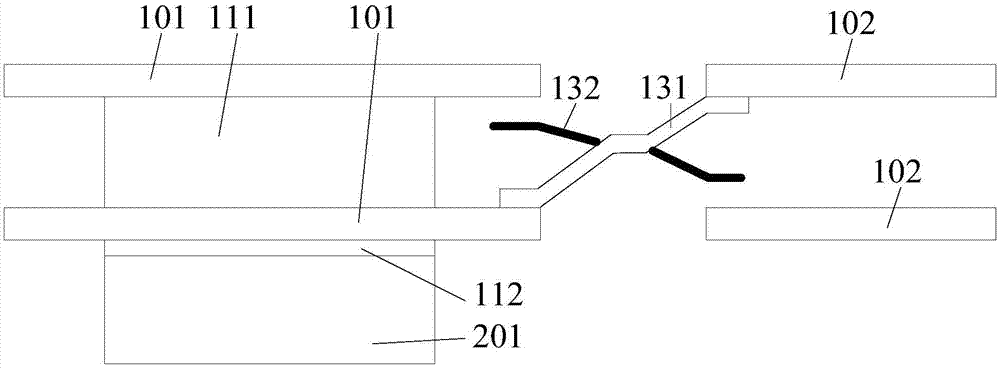

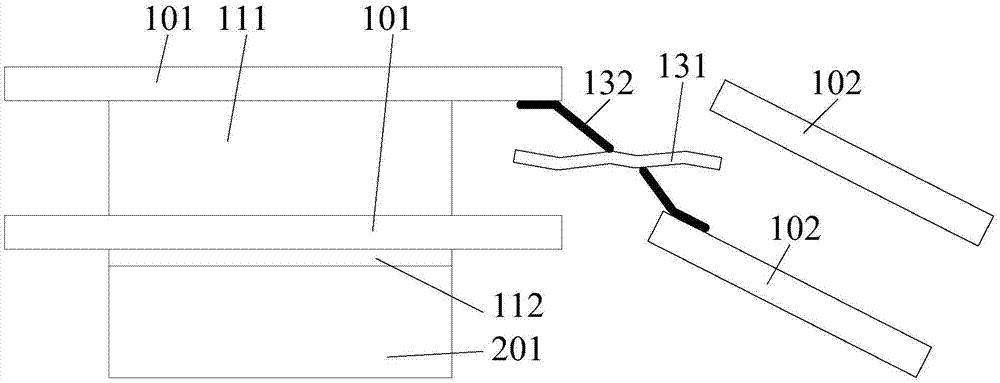

Heat dissipation device and electronic equipment

ActiveCN106922103AImprove cooling effectRapid and effective heat dissipationModifications by conduction heat transferFully developedEngineering

The invention discloses a heat dissipation device used for electronic equipment. The heat dissipation device comprises a first heat sink, a second heat sink and a heat transfer connection piece, wherein the first heat sink is used for being in closely contact with a heat generation component of the electronic equipment, the second heat sink is used for being arranged with the heat generation component in a staggered way, and the heat transfer connection piece is arranged between the first heat sink and the second heat sink and is connected with the first heat sink and the second heat sink. In the heat dissipation device, the first heat sink can be used for directly dissipating heat of the heat generation component, the heat can be also transferred to the second heat dissipation component far away from the heat generation component by the heat transfer connection piece and is dissipated, so that the heat of the heat generation component is fully and effectively dissipated, the frequency of the electronic equipment is prevented from being reduced, the performance of the electronic equipment can be fully developed, a local temperature of a position, corresponding to the heat generation component, on the electronic equipment is also prevented from being excessively high, and a user is convenient to wear the electronic equipment. The invention also provides the electronic equipment employing the heat dissipation device. The performance of the electronic equipment can be developed to the greatest extent, no problem of excessively high local temperature is generated, and the user is convenient to wear.

Owner:LENOVO (BEIJING) CO LTD

Heavy oil suspended bed hydrogenation method under near clinical water condition

InactiveCN101735852AImprove conversion rateDisperse in timeHydrocarbon oil crackingHydrogenReaction temperature

The invention provides a heavy oil suspended bed hydrogenation method under a near clinical water condition. The method comprises the following steps of: making a mixture of heavy oil raw materials and water contacted with a hydrogenation catalyst in the presence of hydrogen gas to perform a hydrogenated reaction, wherein the reaction temperature is between 300 and 450 DEG C, and the reaction pressure is 6 to 20 MPa; and separating the reaction products to obtain the liquid distillates. In the method, the special action of the near clinical water integrates the hydrogenation characteristics of the catalyst, and on a basis of keeping a higher residue-to-oil conversion rate, the coke formation is inhibited to a maximum degree, and the yield of light oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

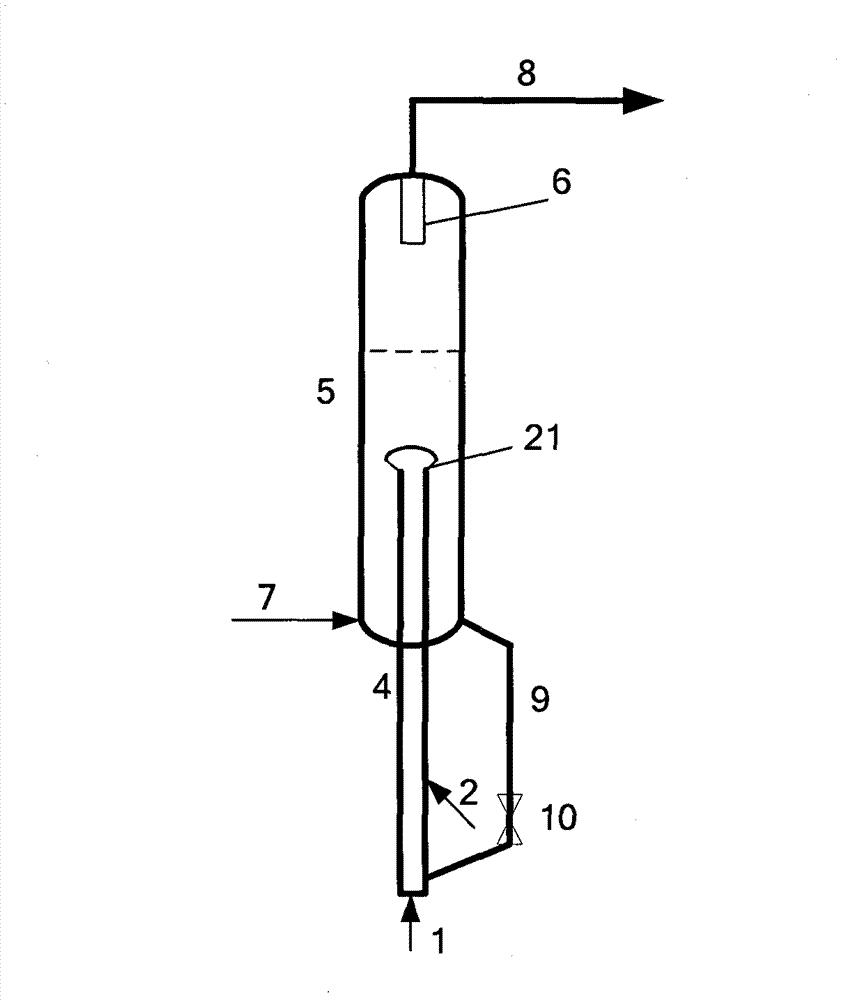

Method and equipment for quickly stabilizing activity of catalytic cracking catalyst

ActiveCN102950031ASmall sizeFast combustion reactionCatalytic crackingCatalyst protectionChemistryGas separation

The invention provides a method and equipment for quickly stabilizing the activity of a catalytic cracking catalyst. The method comprises the following steps that: (1) the catalyst enters the bottom of a dilute phase combustion tube via a fluidized bed reactor, is mixed with an oxygen-containing gas and fuels and then is combusted and flows upward, and the gas and the catalyst enter the fluidized bed reactor via a distributor at the outlet of the dilute phase combustion tube; (2) water vapor is injected into the fluidized bed reactor and is contacted with the high-temperature catalyst to carry out hydrothermal reaction to reduce the activity of the catalyst, the catalyst and the gas are separated at the top of the fluidized bed reactor, the separated gas is exhausted from the device and the separated catalyst returns to the fluidized bed reactor; and (3) operation is stopped and the catalyst is unloaded when the activity of the catalyst is reduced to the appropriate level. The invention also provides a catalyst ager implementing the aging method. By adopting the aging method and equipment provided by the invention, the operating conditions of the combustion reaction and the hydrothermal reaction can be controlled respectively, the activity of the aged catalyst is distributed uniformly and distribution of the products used for catalytic cracking reaction of hydrocarbon oil is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

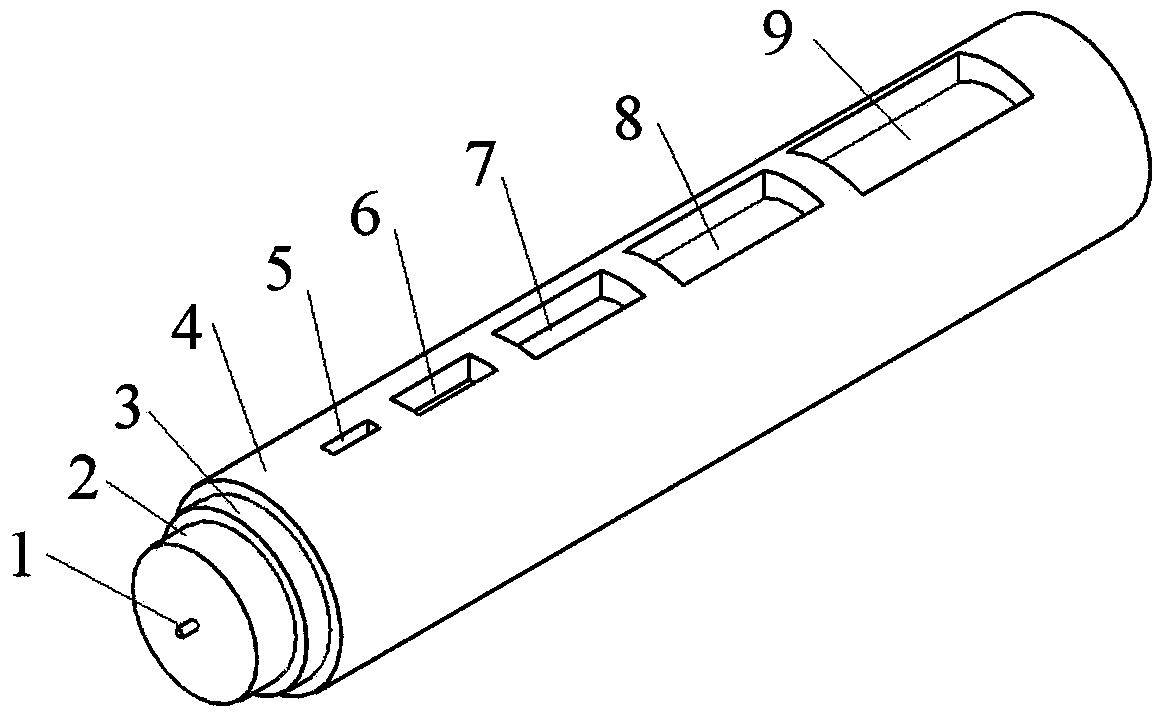

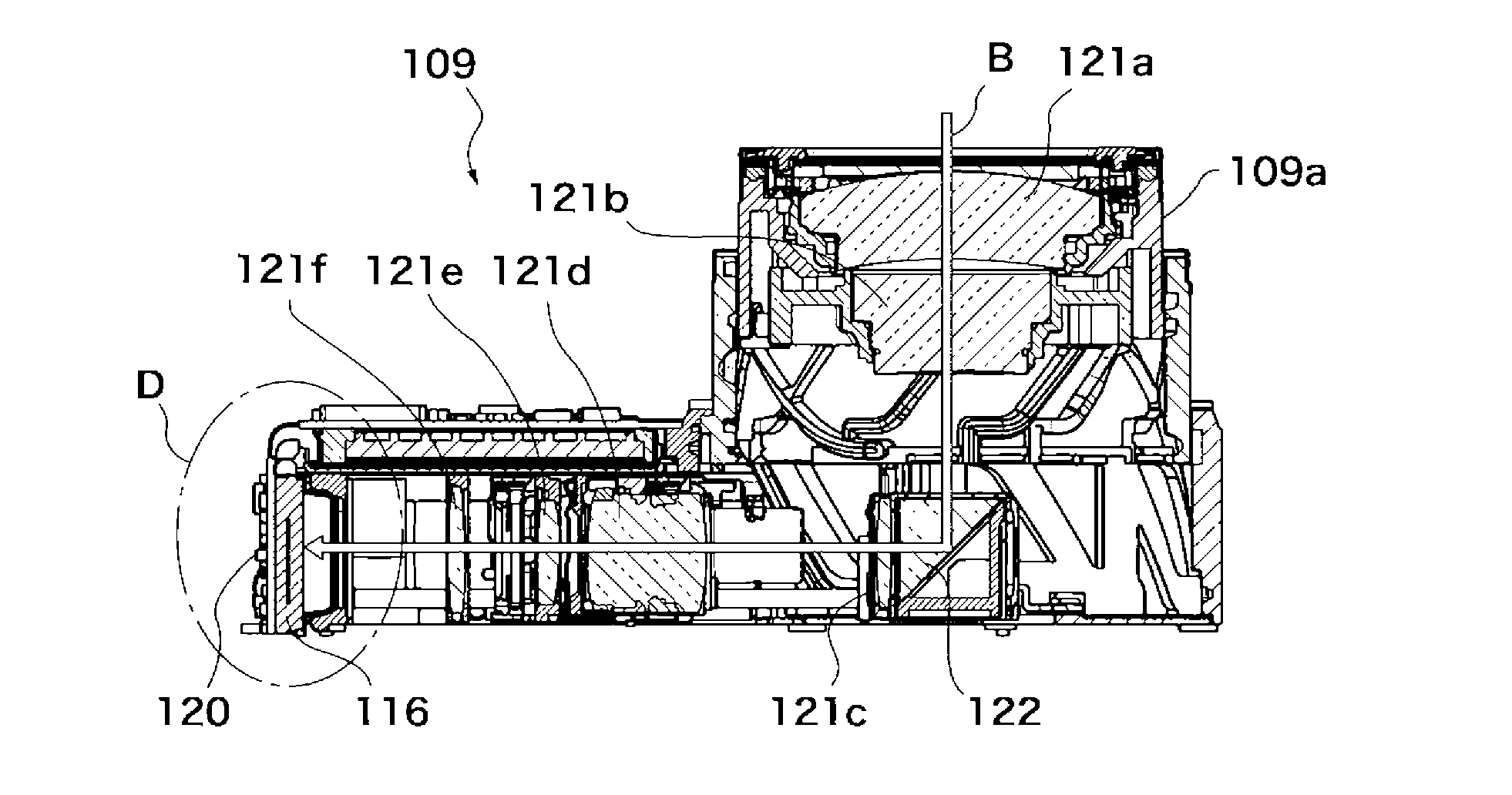

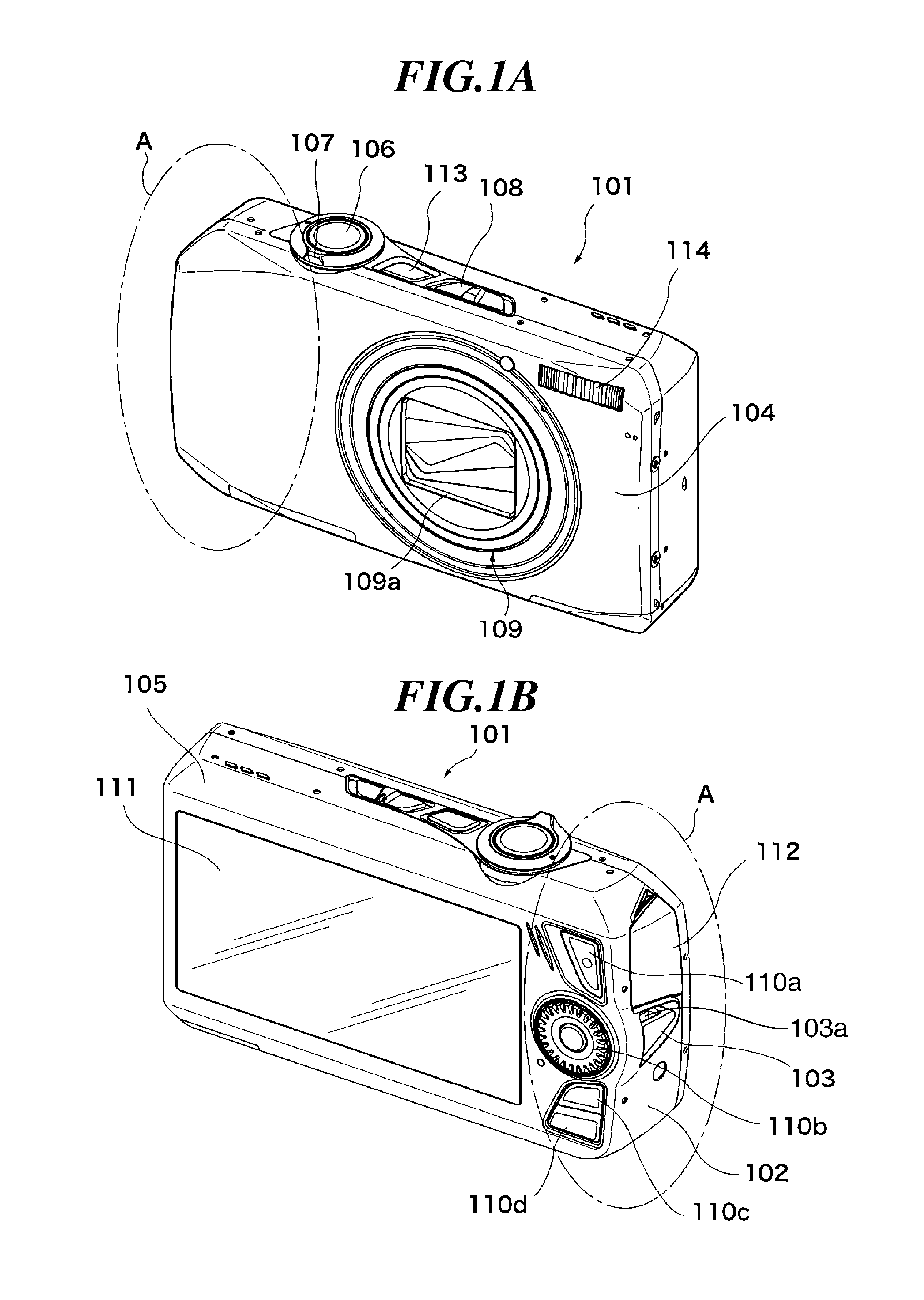

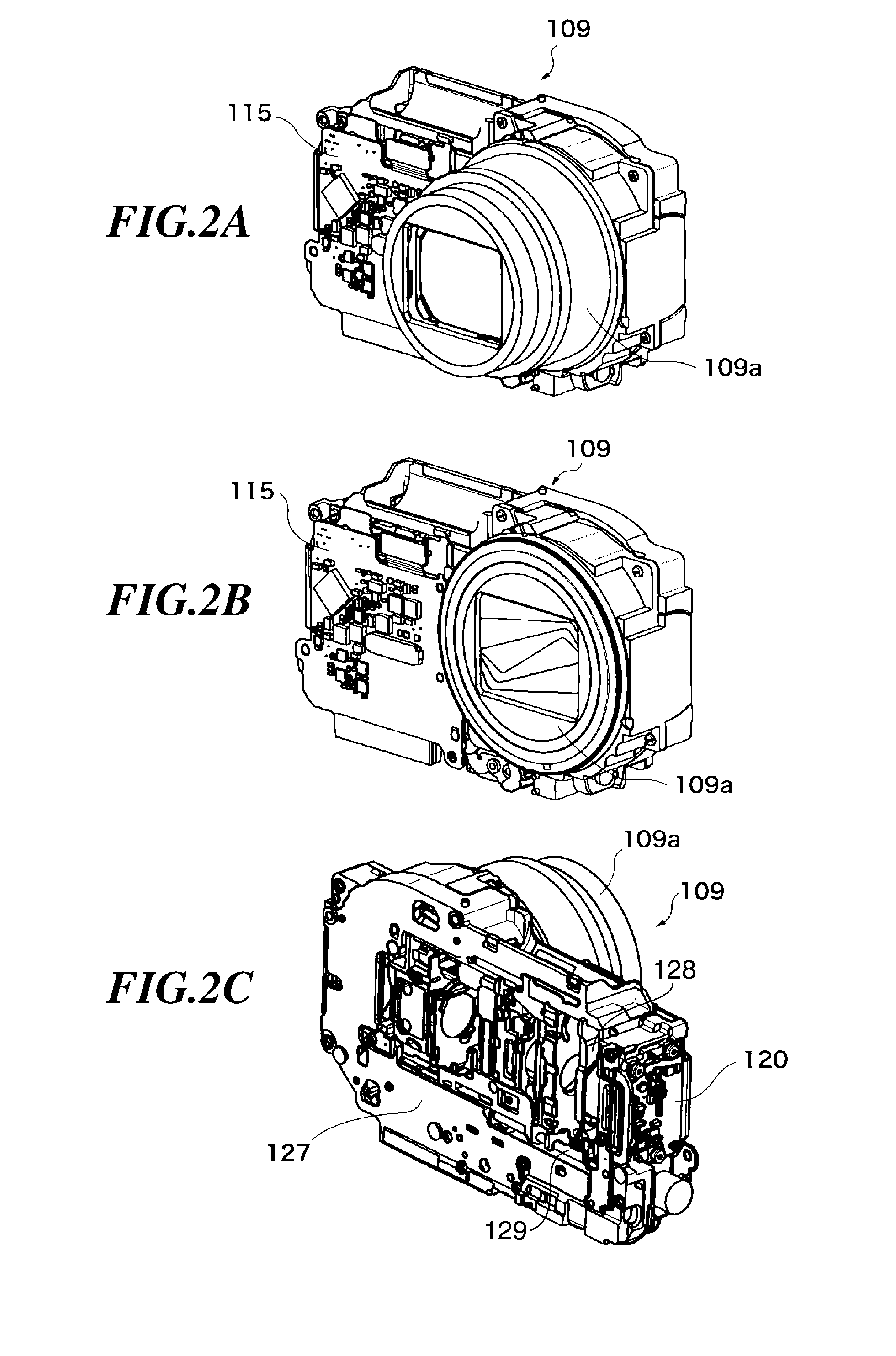

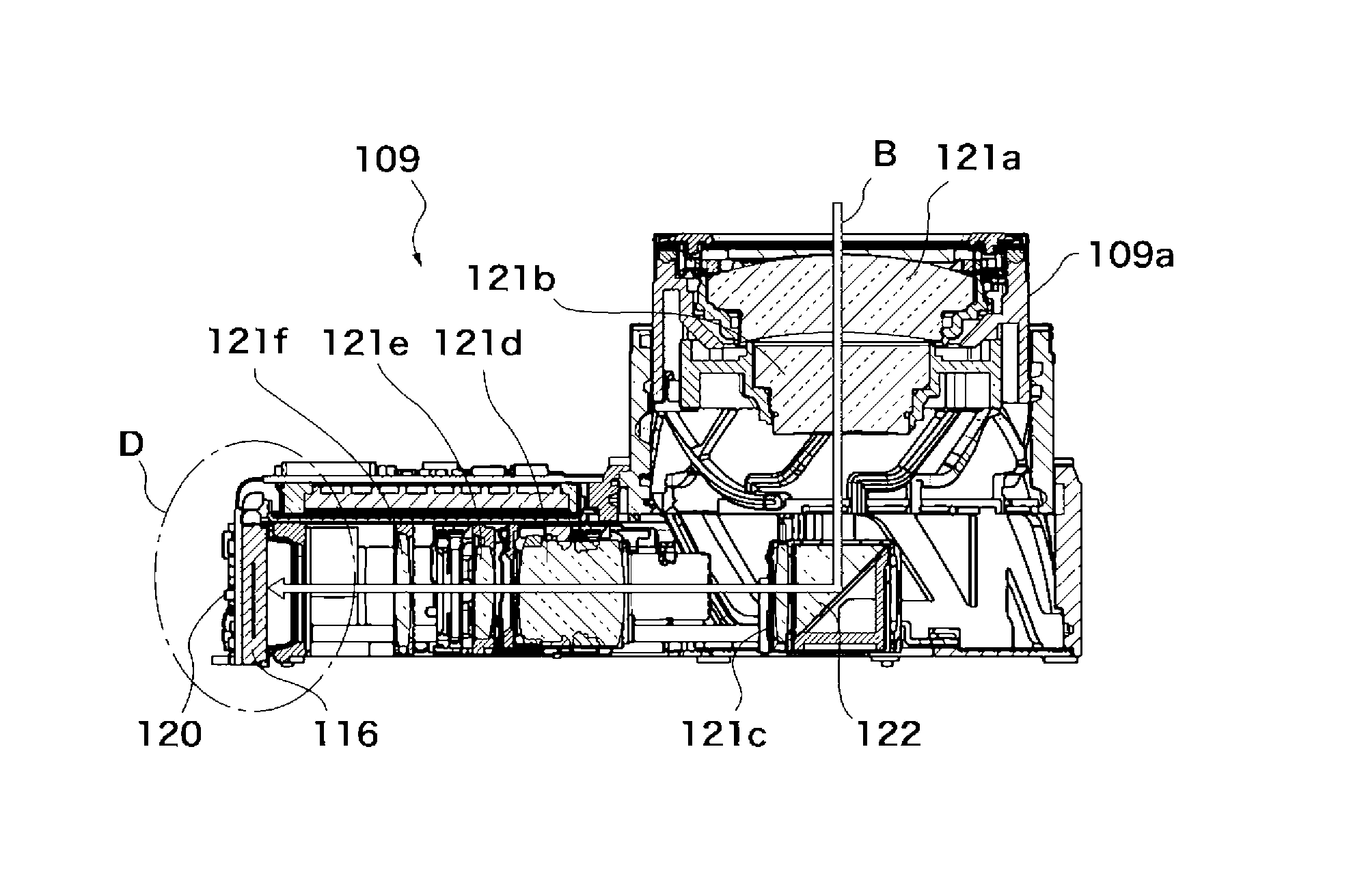

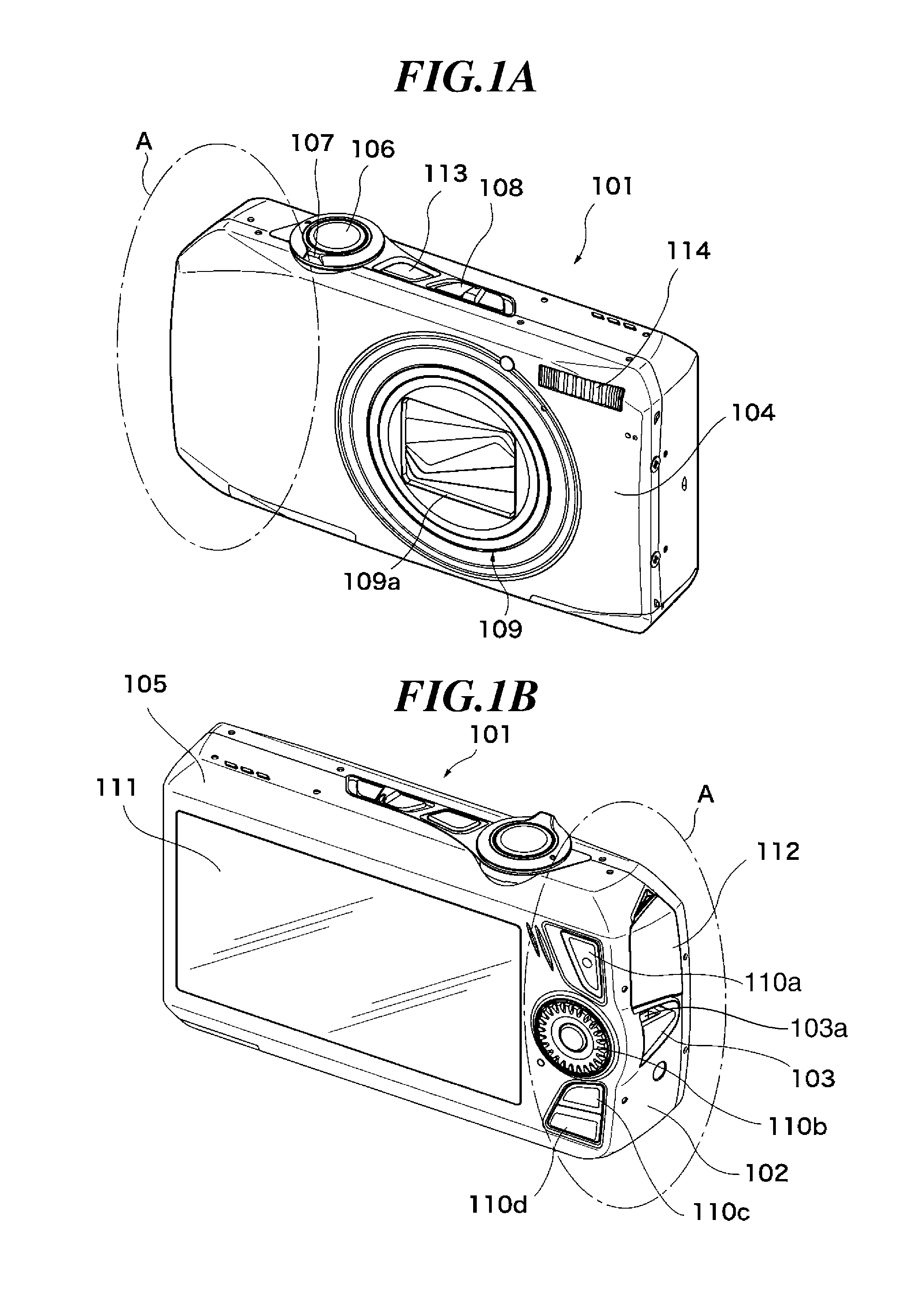

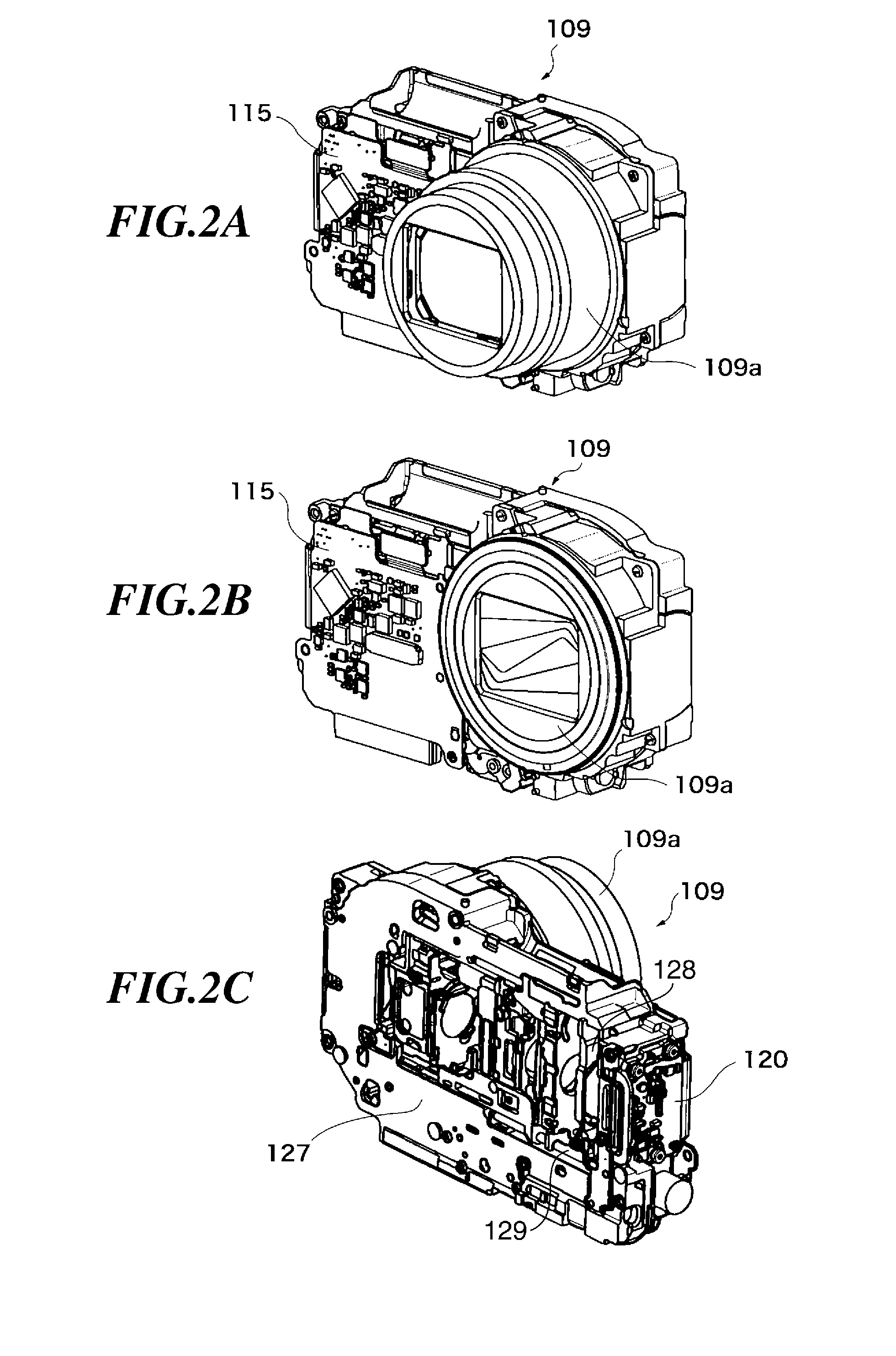

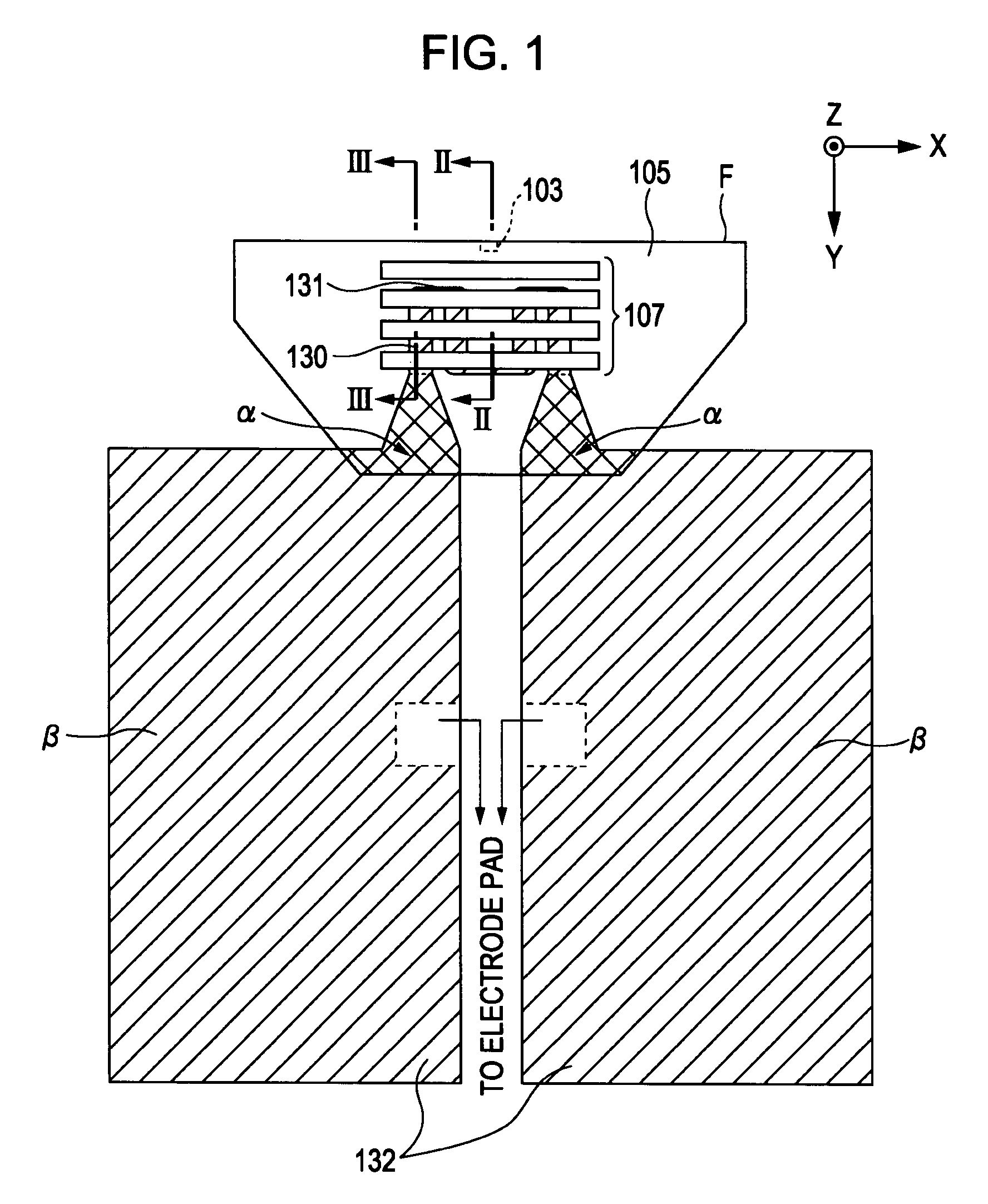

Image pickup apparatus capable of releasing heat efficiently

ActiveUS20120026383A1Efficient heat dissipationAvoid high local temperaturesTelevision system detailsColor television detailsThermal conductivityLight flux

An image pickup apparatus capable of efficiently releasing heat generated by an image pickup element disposed close to an exterior of a grip portion, and thereby prevent a local temperature rise in the grip portion. A lens barrel bends a light flux incident from an object by a prism to guide the light flux toward the grip portion. The lens barrel is fixed to a chassis member. A front cover covers a portion of the lens barrel and is disposed such that the lens barrel is positioned between the chassis member and the front cover. An image pickup element is disposed toward the grip side. A heat conductive member is coupled to the chassis member and the front cover. Side covers cover the heat conductive member. The thermal conductivity of the side covers is smaller than that of the front cover.

Owner:CANON KK

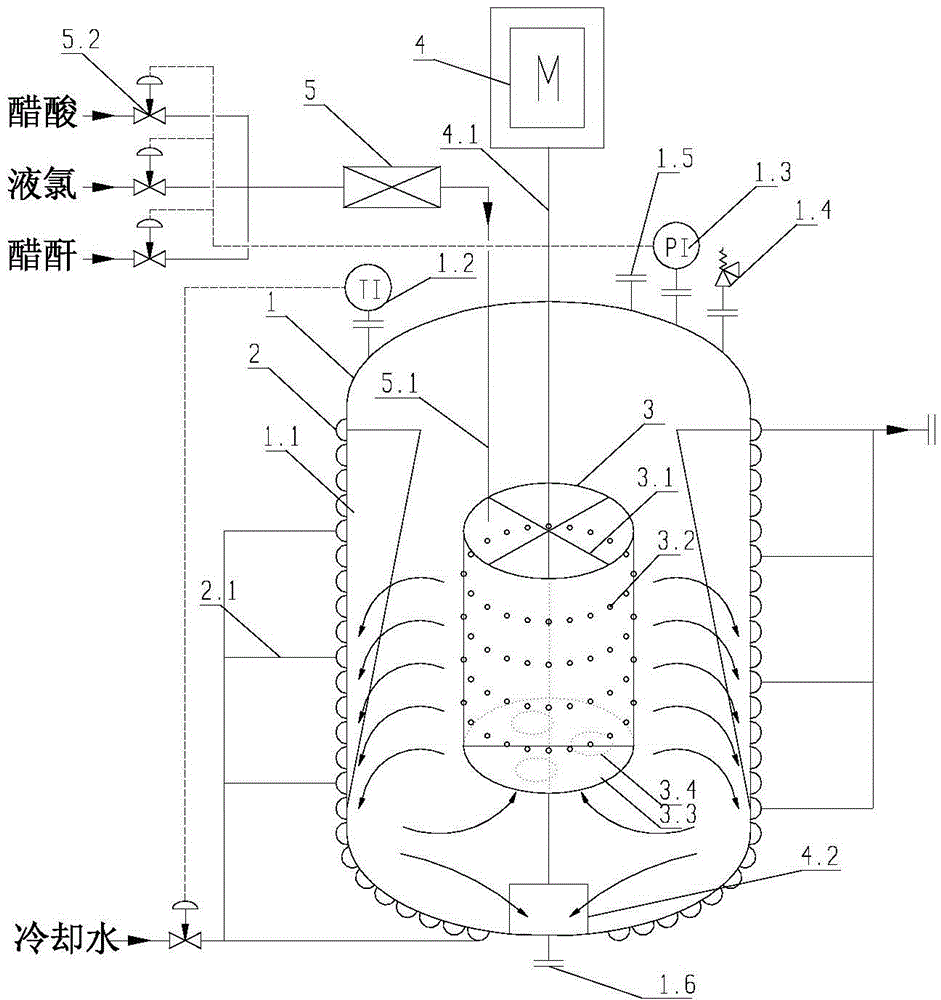

Chloroacetic acid production method and chlorination reactor

ActiveCN104387258AImprove macro and micro distributionLess side effectsOrganic compound preparationChemical/physical/physico-chemical stationary reactorsAcetic anhydrideChloroacetic acids

The invention provides a chloroacetic acid production method and a chlorination reactor. The chloroacetic acid production method comprises the following steps: primarily mixing acetic acid, liquid chlorine and acetic anhydride according to a ratio, feeding a mixture obtained from the former step into the chlorination reactor, keeping a certain reaction temperature and a certain reaction pressure, completing chlorination reaction in a gravity field of 100-1000g, and performing separation purification on the product by using a continuous method production process after the reaction is completed, thereby obtaining a product finally. The chlorination reactor mainly comprises a reaction kettle, a cooling half-tube, a supergravity bucket, a driving motor and a mixer. By adopting the chloroacetic acid production method and the chlorination reactor provided by the invention, the macroscopic and microcosmic distribution of components in a reaction system can be improved, the side effect is reduced, the internal mass transfer velocity of the liquid phase is reduced, the separation of the gas phase and the liquid phase is improved, the chlorination reaction velocity is increased, the reaction retention time is shortened, the heat radiation effect is improved, and the treatment capacity is much higher than that of a conventional method, and the chloroacetic acid production method is particularly applicable to a large-size chloroacetic acid device.

Owner:CHINA TIANCHEN ENG +1

Image pickup apparatus capable of releasing heat efficiently

ActiveUS8537275B2Efficient heat dissipationAvoid high local temperaturesTelevision system detailsColor television detailsLight fluxLight beam

An image pickup apparatus capable of efficiently releasing heat generated by an image pickup element disposed close to an exterior of a grip portion, and thereby prevent a local temperature rise in the grip portion. A lens barrel bends a light flux incident from an object by a prism to guide the light flux toward the grip portion. The lens barrel is fixed to a chassis member. A front cover covers a portion of the lens barrel and is disposed such that the lens barrel is positioned between the chassis member and the front cover. An image pickup element is disposed toward the grip side. A heat conductive member is coupled to the chassis member and the front cover. Side covers cover the heat conductive member. The thermal conductivity of the side covers is smaller than that of the front cover.

Owner:CANON KK

Preparation process of cherry wine

InactiveCN105132238AGuaranteed qualityAchieve sterile hygieneAlcoholic beverage preparationYeastAdditive ingredient

The invention discloses a preparation process of cherry wine, wherein the preparation process comprises the following steps: 1) removing stems of cherries, cleaning and drying the cherries in the air, disinfecting and crushing the cherries; (2) making cherry juice contact with peels, and adding a distiller's yeast in proportion for fermentation together; 3) during fermenting, dissolving pigment and aroma in the peels into wine; 4) after fermentation, separating peel dregs, separating raw wine from the peel dregs and wine sediment, and pouring the wine into a jar so that the wine liquid is clear and transparent; 5) after separation, fermenting the raw wine; 6) aging the raw wine liquid obtained from the separation; 7) clarifying and fining after aging so that a colloidal net-shaped substance is generated in the wine liquid, filtering and removing peels; 8) implementing freezing treatment after clarifying; 9) implementing heat treatment after freezing treatment; 10) after heat treatment, blending various trace ingredients of the cherry wine; 11) after blending, removing sediment and suspension, so that the wine liquid is clear and stable; and 12) canning the filtered wine juice by virtue of a stainless steel canning machine, packaging by virtue of a sterile packaging machine and sealing with a cork.

Owner:王战乐

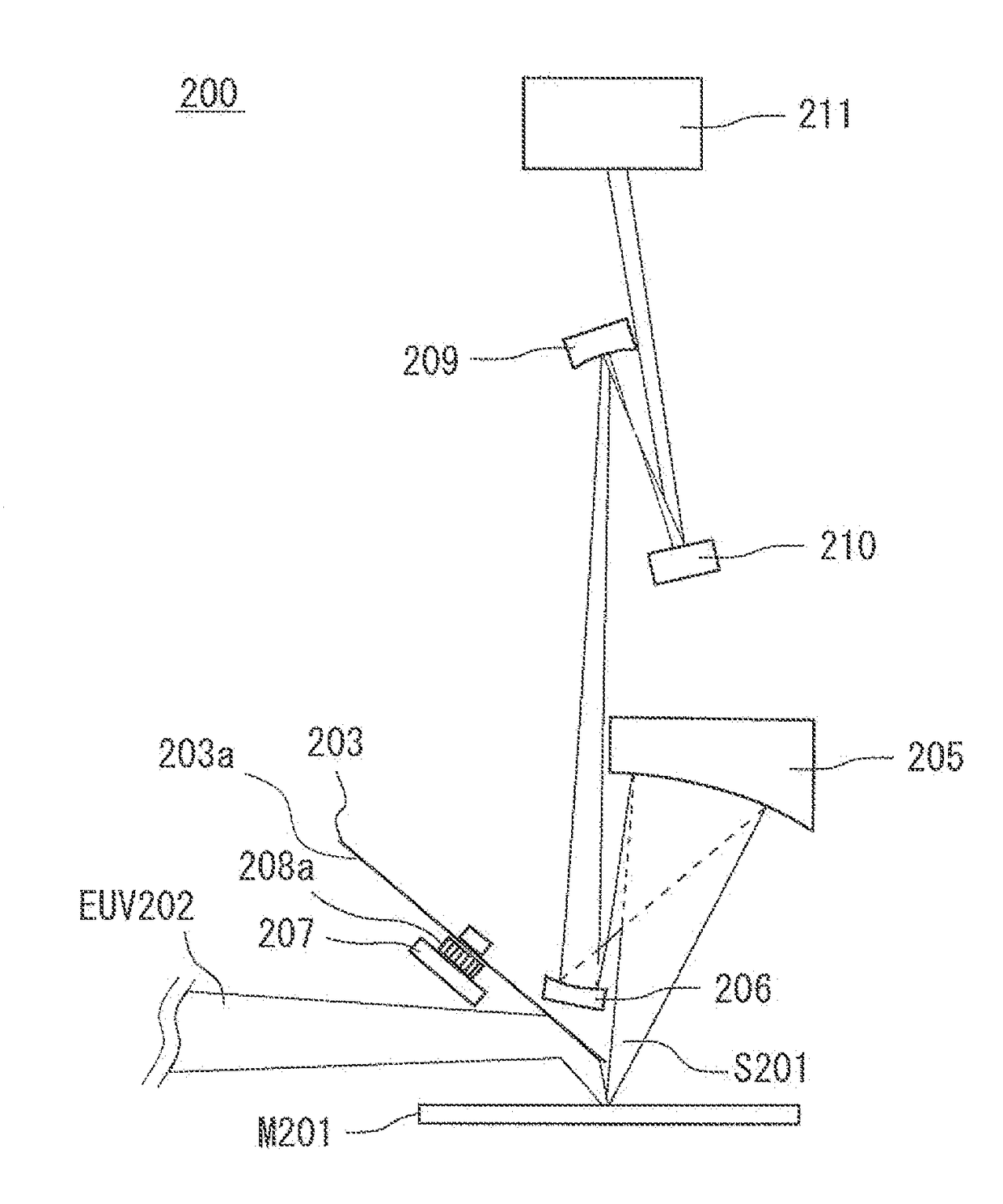

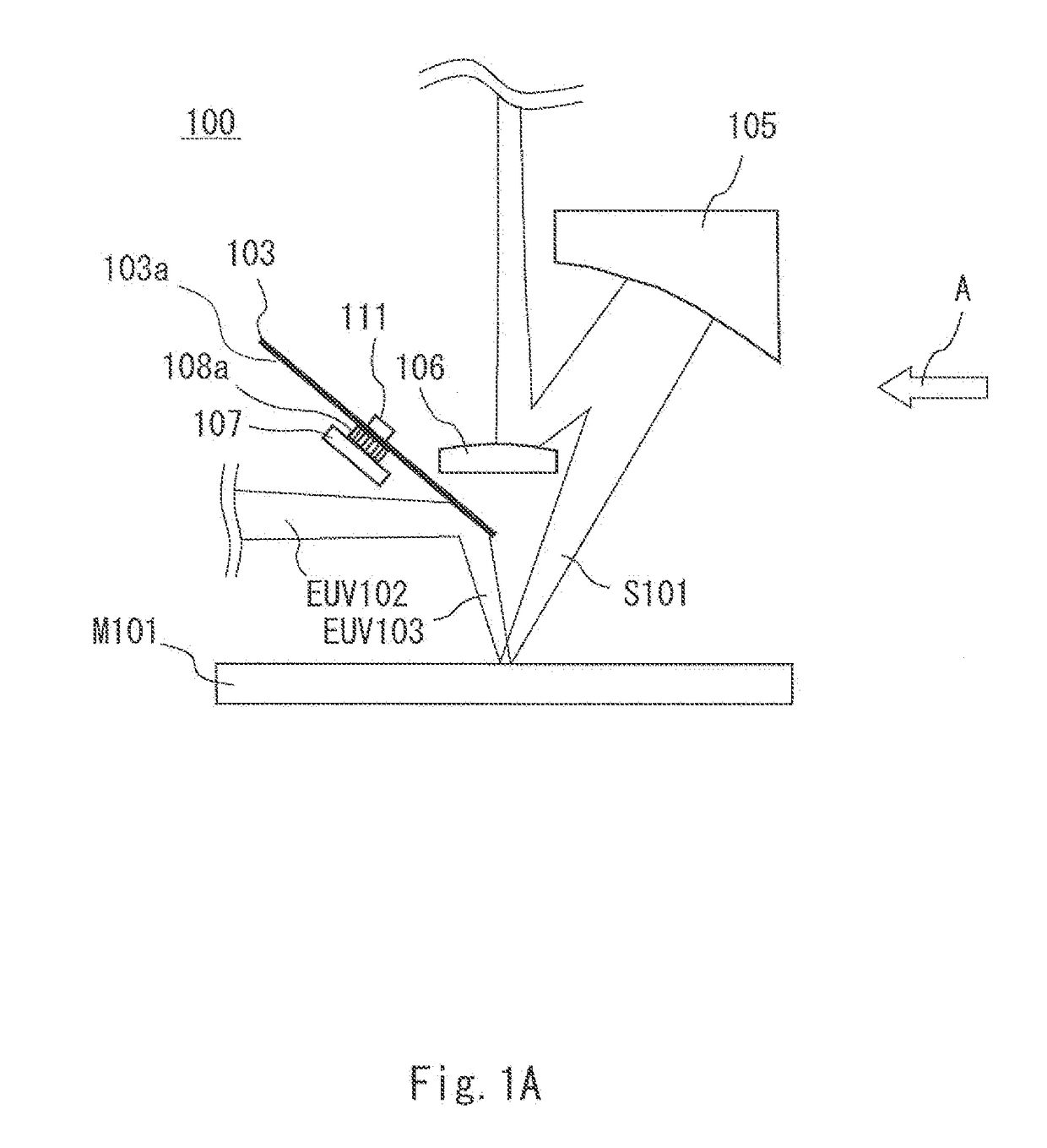

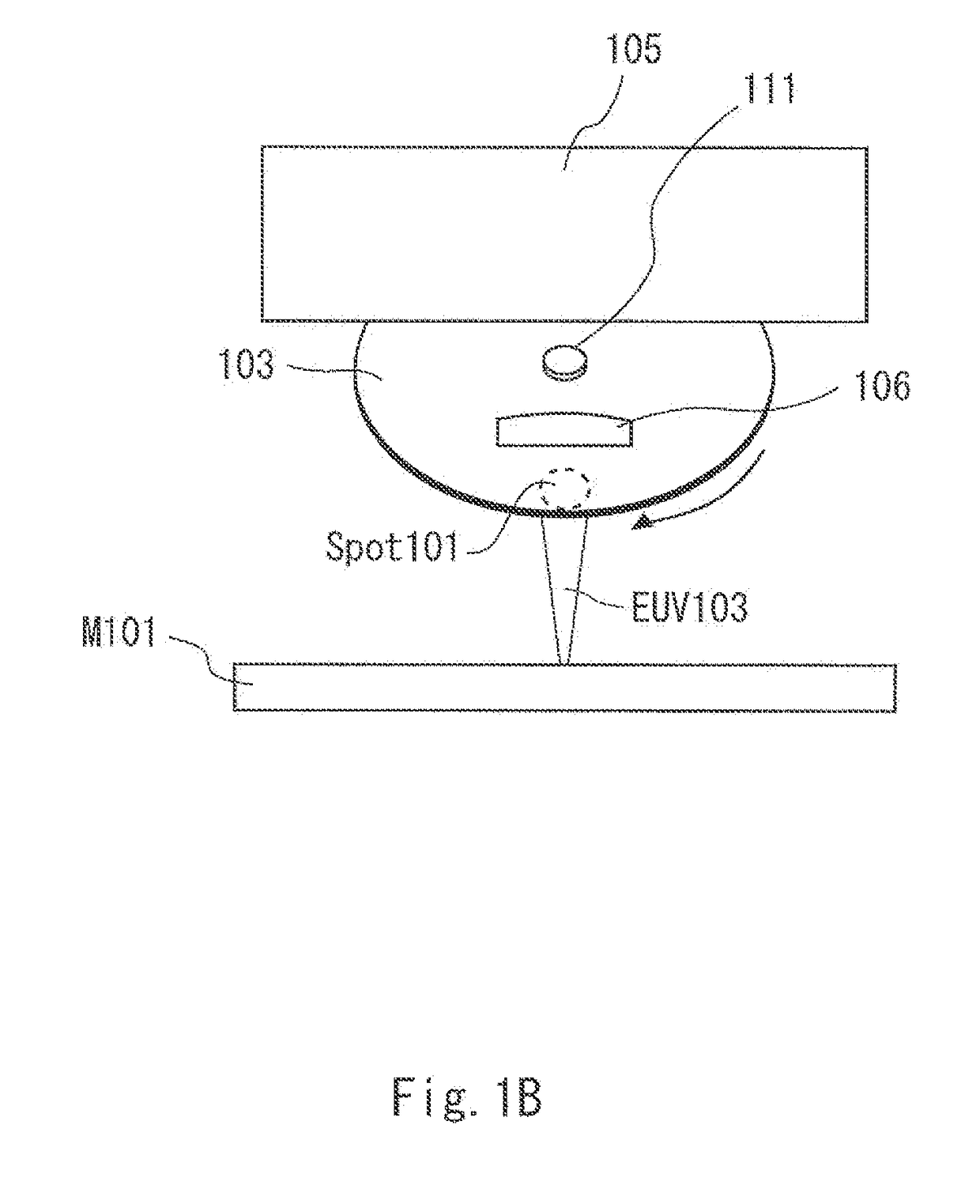

Mask inspection apparatus and mask inspection method

ActiveUS20170235031A1Prevent reduction reflectanceIncrease the areaMirrorsDiffraction gratingsMask inspectionReflectivity

Provided are a mask inspection apparatus and a mask inspection method that can prevent a reduction in a reflectance of a drop-in mirror, which is caused by carbon contaminants. A mask inspection apparatus according to the present invention includes a drop-in mirror including multi-layer film and a reflective surface. The drop-in mirror is configured to reflect illumination light incident on the reflective surface and illuminate the mask. An area of the reflective surface is configured to be greater than an area of an illuminated spot irradiated with the illumination light on the reflective surface. The drop-in mirror is configured to be movable. A position of the illuminated spot on the reflective surface is configured to be moved when the drop-in mirror is moved.

Owner:LASERTEC CORP

System for preparation of bio-oil, activated carbon and synthetic gas by microwave pyrolysis

InactiveCN110194959AEasy to cleanSimple designBiofuelsIndirect heating destructive distillationNitrogen generatorWater vapor

The invention relates to a system for preparation of bio-oil, activated carbon and synthetic gas by microwave pyrolysis. The system consists of a nitrogen generator, a water vapor generator, a microwave pyrolysis reactor, condensers, bio-oil storage tanks, synthetic gas buffer tanks, a suction fan and a synthetic gas storage tank. The nitrogen generator and the water vapor generator are connectedto an air inlet at the top of a microwave generator through a pipeline, an air outlet at the top of the microwave generator is connected to the condensers through a pyrolysis gas pipeline, the bottomsof the condensers are connected to the bio-oil storage tanks, the air outlets of the condensers are connected to the synthetic gas buffer tanks through a pipeline, circulating water cools in a circulating water refrigerating machine and then flows through the condensers through a pipeline for circulating cooling, the suction fan is connected to the synthetic gas buffer tanks and the synthetic gasstorage tank, one part of the synthetic gas is stored by the storage tank, and the other part of the synthetic gas is returned as the gas for activating biochar to the microwave pyrolysis reactor through a pipeline to convert biochar into activated carbon.

Owner:JIANGSU UNIV

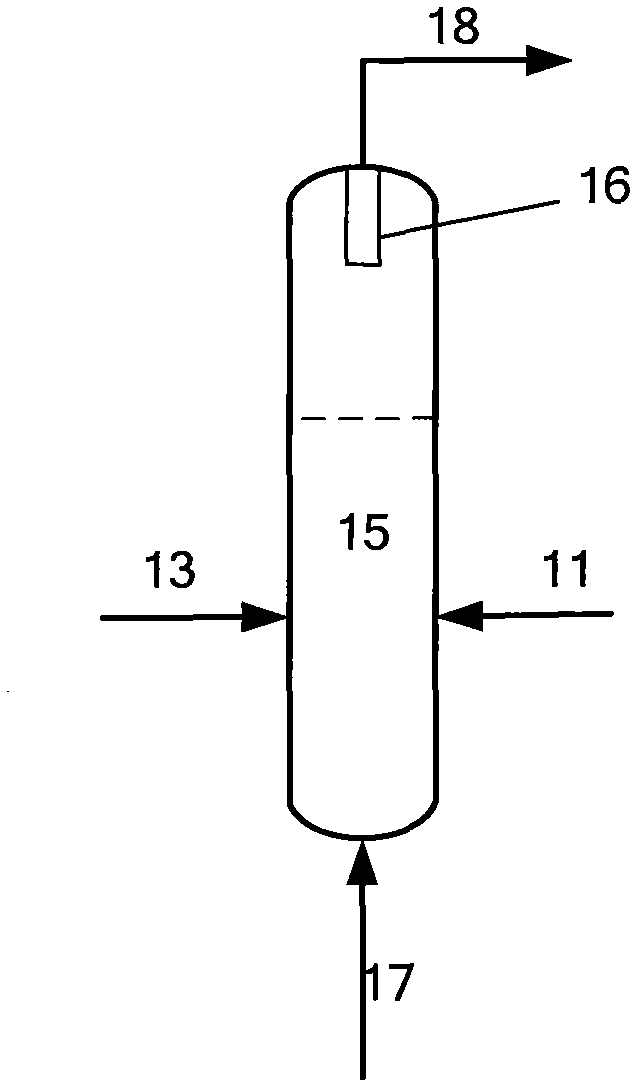

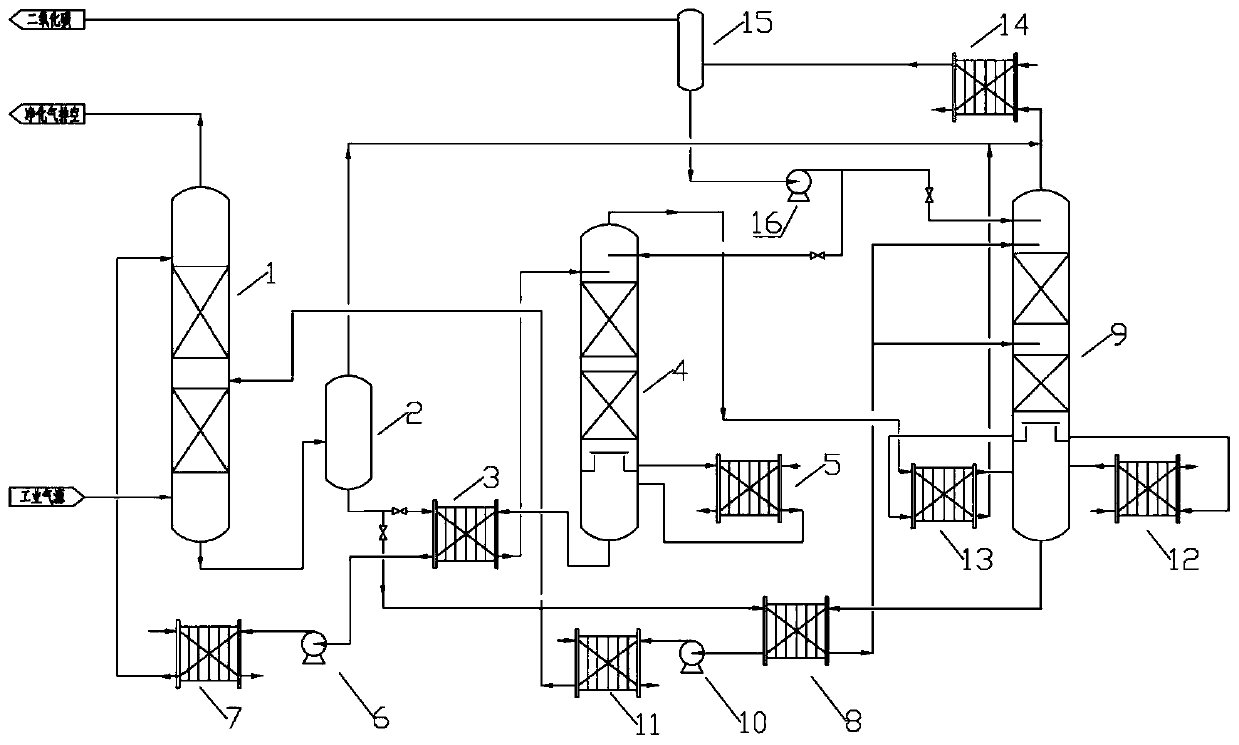

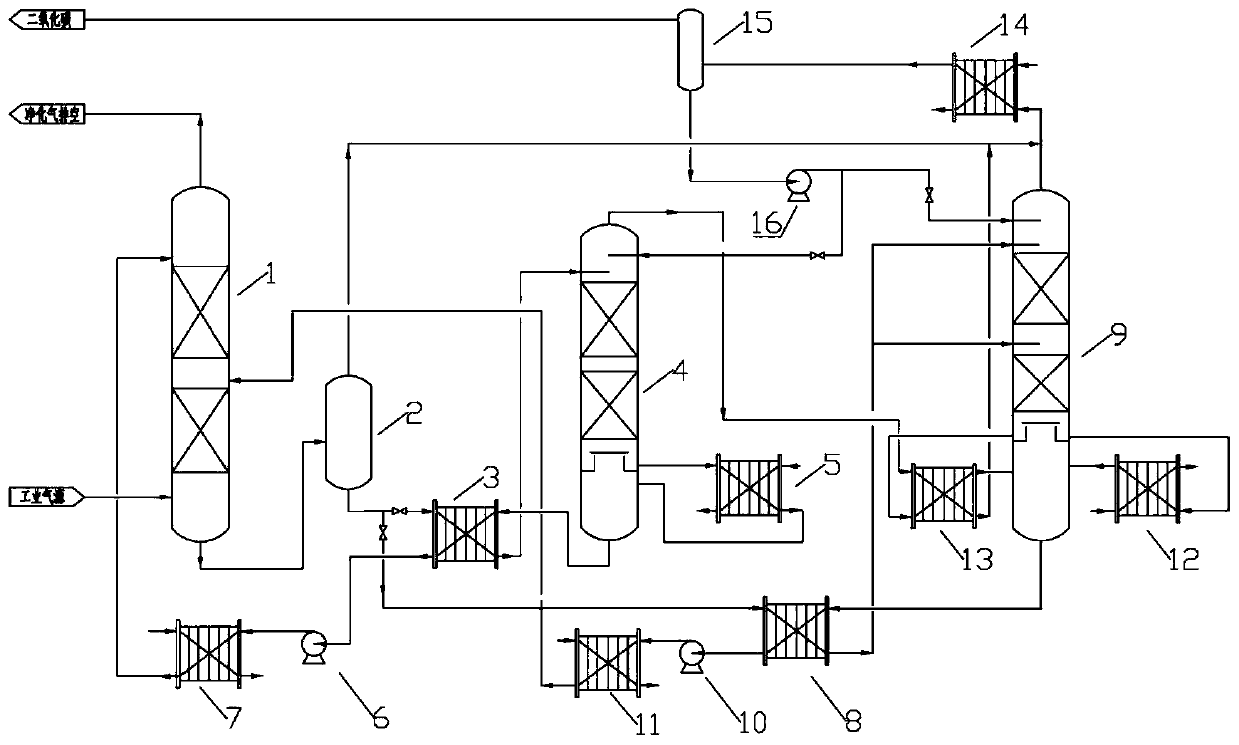

Separation system and method for carbon dioxide in medium-high pressure air source

PendingCN109999618AReduce inputMeet energy consumptionDispersed particle separationDesorptionReaction temperature

The invention provides a separation system and method for carbon dioxide in a medium-high pressure air source. CO2 rich liquor from an absorption tower is subjected to pressure reduction and regenerated step by step in modes such as flash evaporation, high-pressure desorption and low-pressure desorption, the high-pressure characteristic of a CO2 air source is fully used, and input of external heatconsumption is reduced; the low-energy-consumption and low-cost requirements are met; high-temperature desorbed air of the tower top of a high-pressure desorption tower is introduced into a reboilerof a low-pressure desorption tower and used for a heating desorption heat source, external heat consumption required by the low-pressure desorption tower is reduced, and meanwhile the cooling-water consumption of a desorbed air cooler is reduced; barren liquor and semi-barren liquor from the high-pressure desorption tower and the low-pressure desorption tower enter from an upper-section filler anda lower-section filler of the absorption tower respectively, reaction temperatures at all portions of a tower body can be kept uniform, it is avoided that the local temperature is over high, and degradation and loss of an absorbent are reduced. According to the separation system and method for carbon dioxide in the medium-high pressure air source, the high-pressure characteristic of the CO2 air source is fully used, the input of the external heat consumption is reduced, and the low-energy-consumption and low-cost requirements are met.

Owner:HUANENG POWER INTERNATIONAL +1

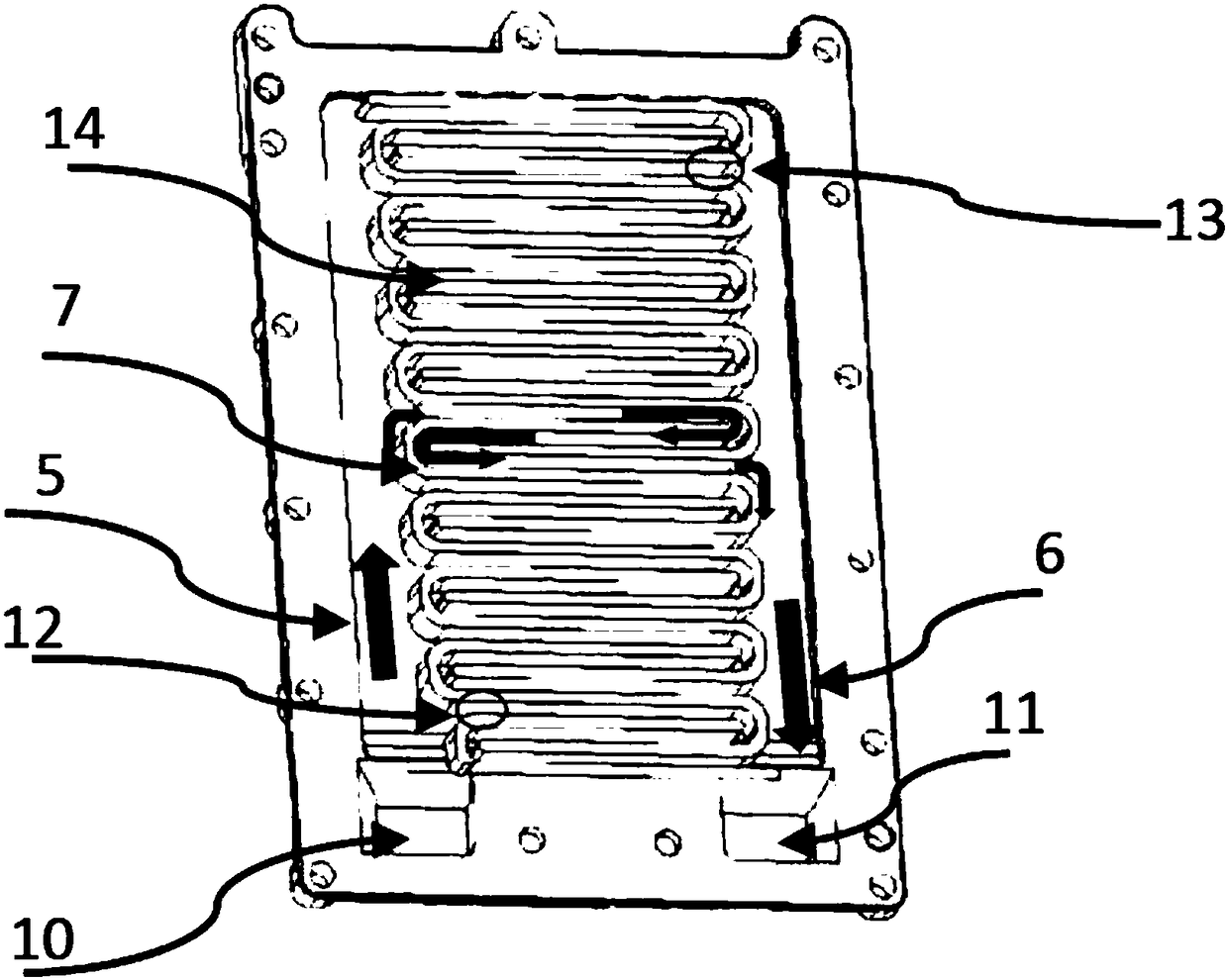

Runner layer structure of PTC electric heating device

PendingCN108534347AOptimize layout structureAvoid local overheatingWater heatersElectric heatingHeating element

The invention discloses a runner layer structure of a PTC electric heating device. Medium flow speed can be balanced, cooling is more uniform, too high local temperature is avoided, heat exchange is more sufficient, meanwhile, mounting is convenient, flow resistance is low, and heat exchange efficiency is high. The structure comprises a lower shell, an upper shell and a seal element, at least oneof the lower shell and the upper shell is attached to a PTC heating element, the lower shell or upper shell is provided with a groove used for mounting of the seal element, the lower shell and the upper shell are subject to press fitting through the seal element to form an assembling body with an inlet and an outlet outwards, branch runners composed of an inlet main runner, an outlet main runner and multiple heat exchange fins are arranged in the assembling body, and are in S shapes, the multiple branch runners are in parallel connection so as to enable flowing media in the inlet main runner to be introduced into the outlet main runner, the inlet communicates with the inlet main runner, and the outlet communicates with the outlet main runner.

Owner:SHANGHAI FENGTIAN ELECTRONICS

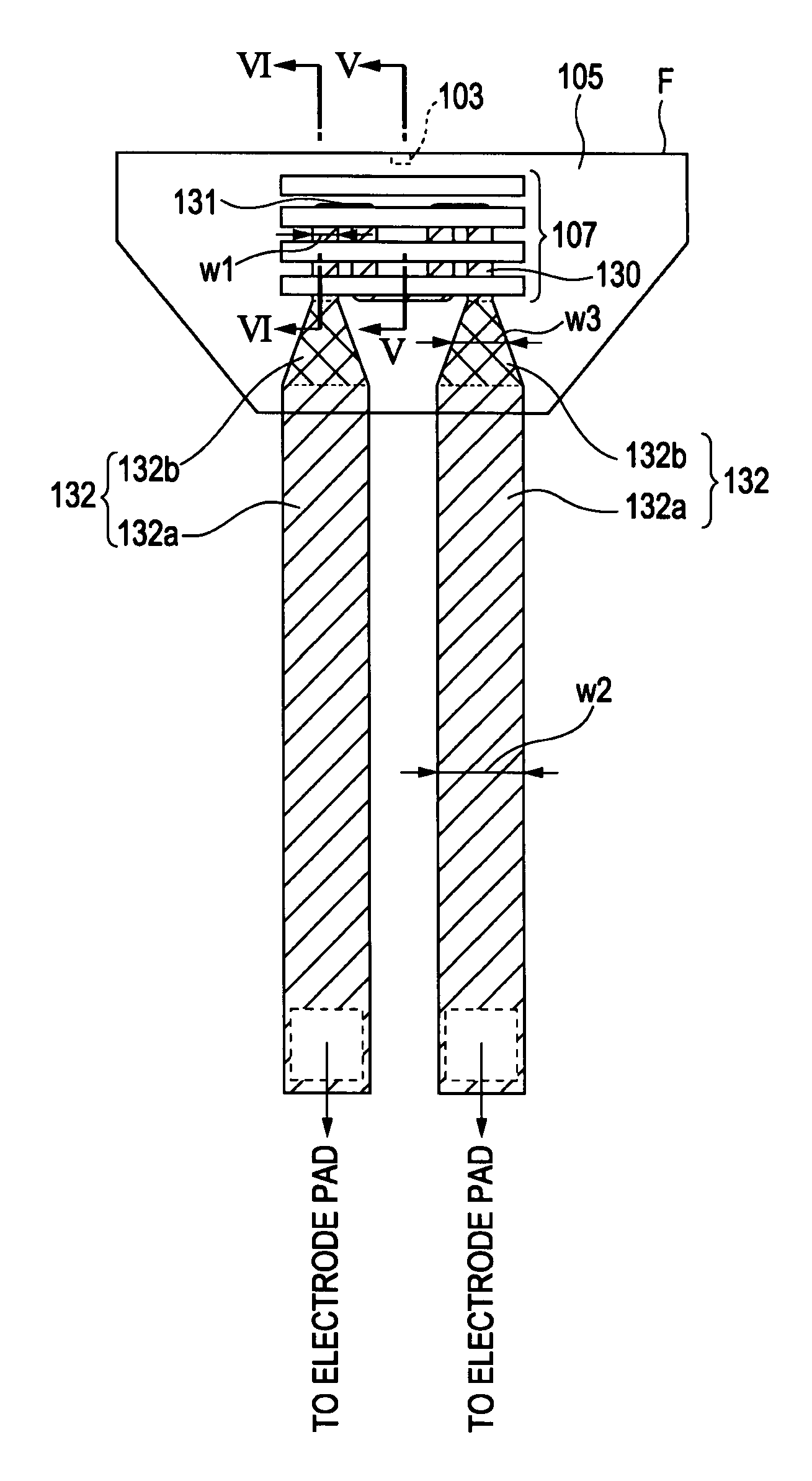

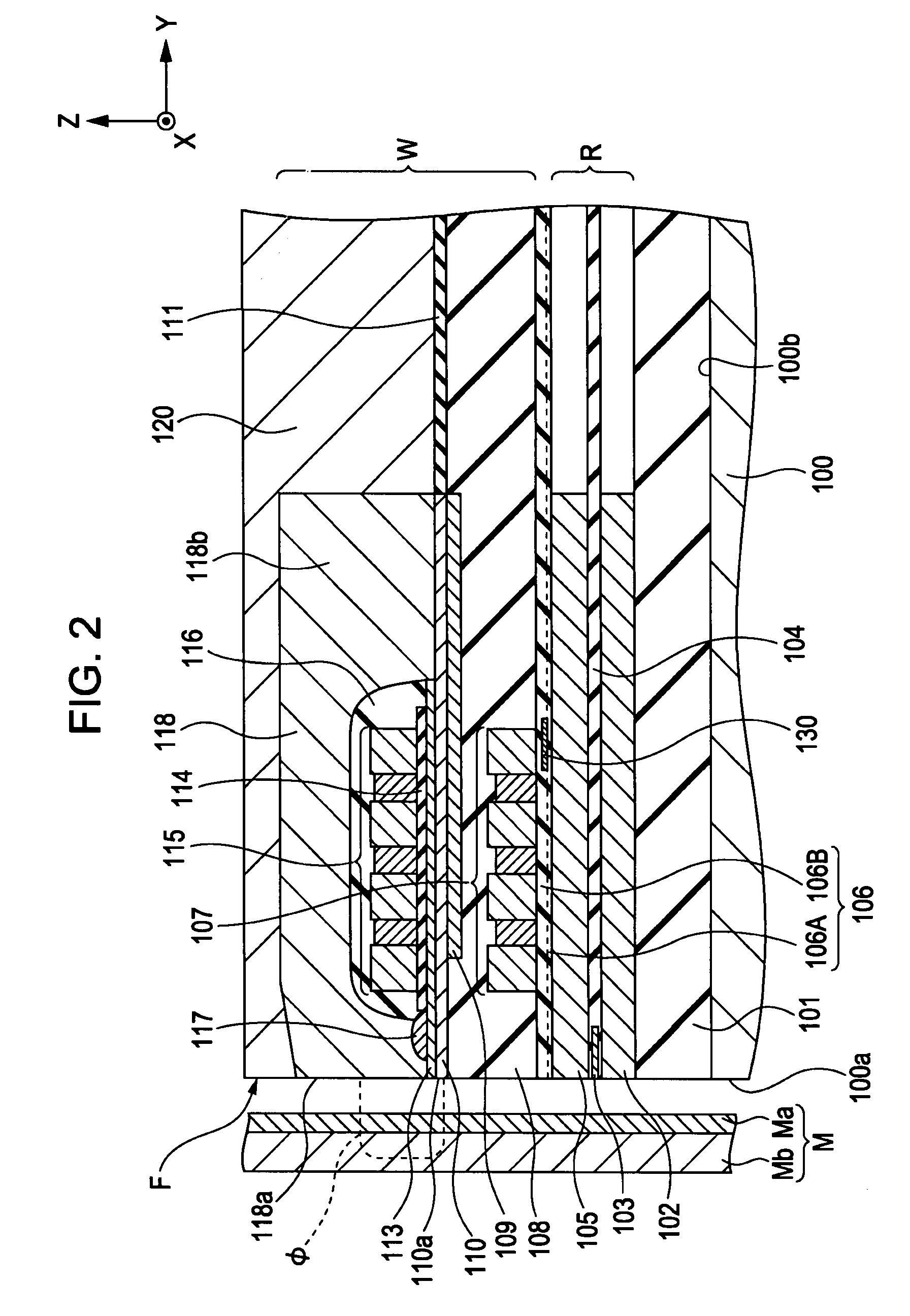

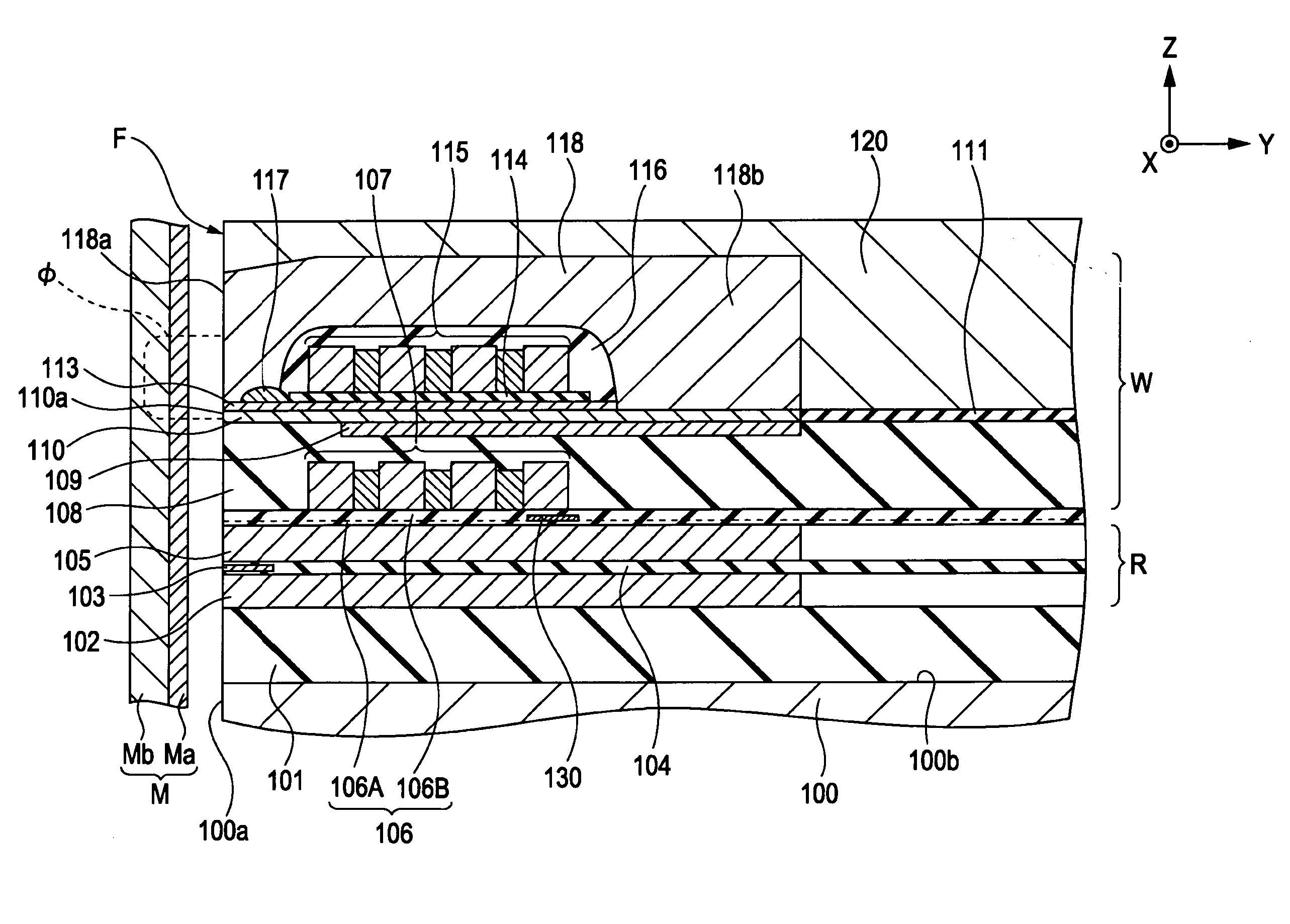

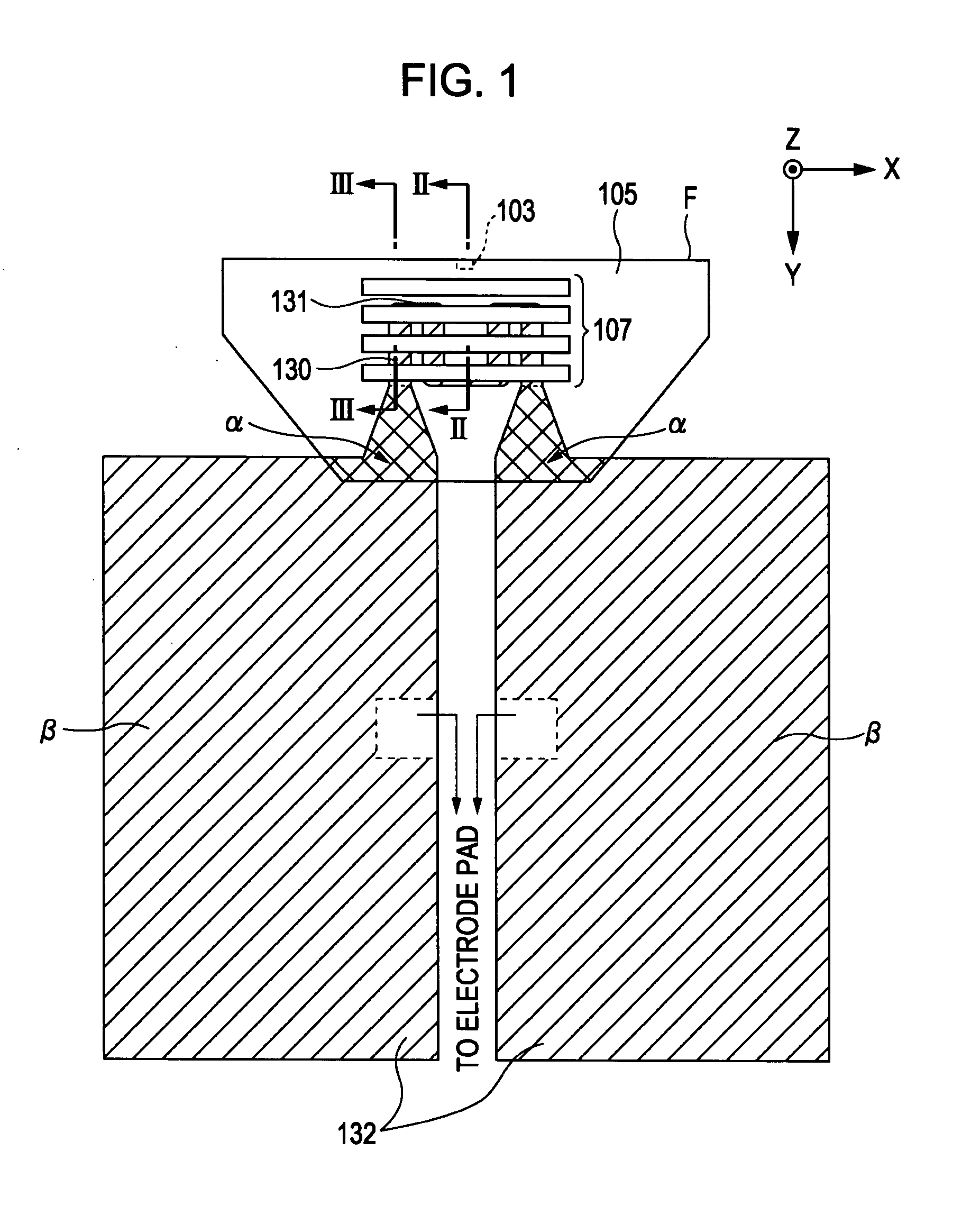

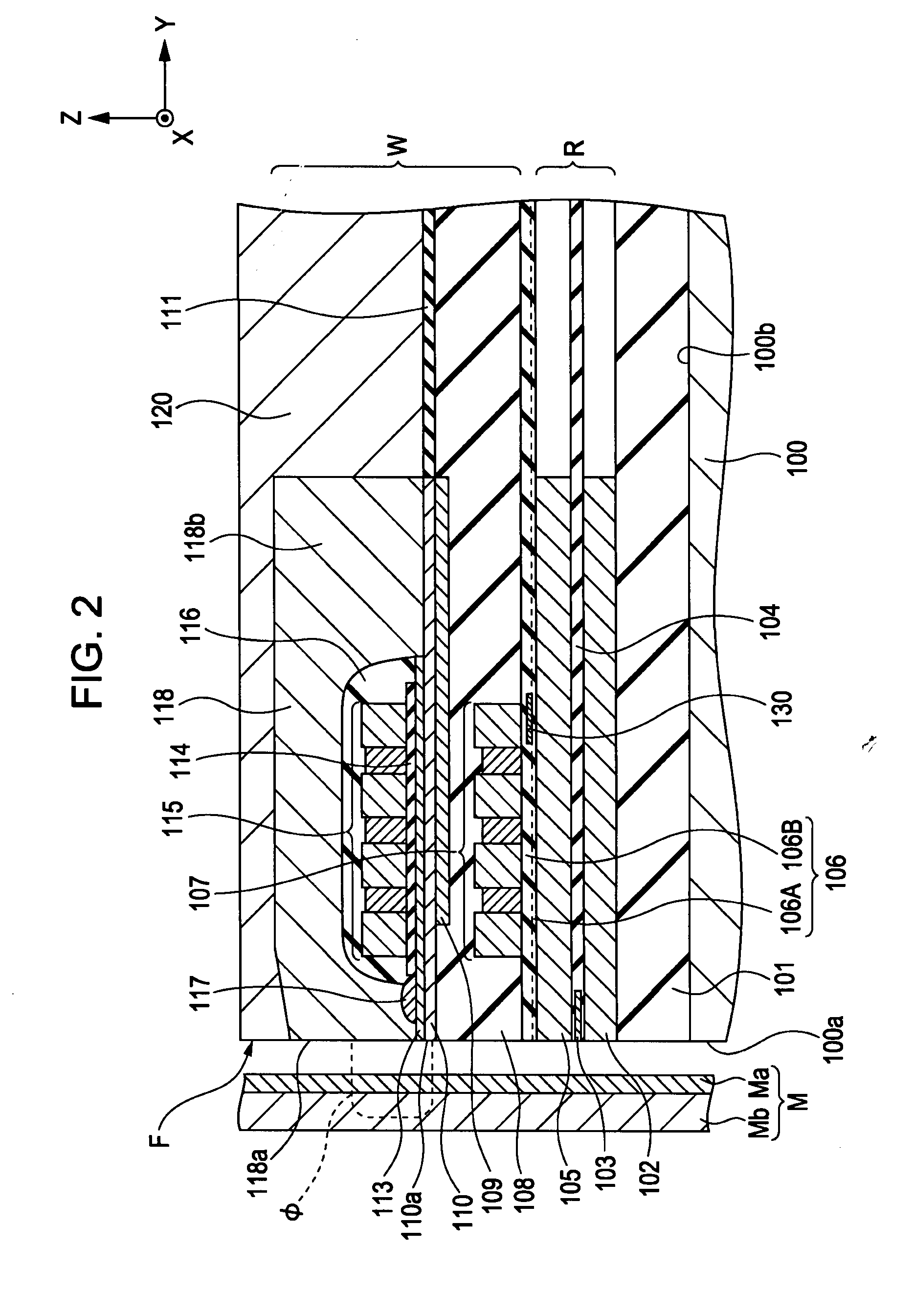

Thin film magnetic head having heating element

ActiveUS7903373B2Reduce protrusionAvoid high local temperaturesHeads using thin filmsRecord information storageEngineeringThermal expansion

A thin film magnetic head is provided, in which the amount of protrusion in the periphery of an element portion can be reduced or a local temperature increase of electrode leads of a heating element can be prevented. The thin film magnetic head includes a playback element disposed between lower and upper shield layers, a recording element laminated on the upper shield layer, a heating element which is disposed below a coil layer and which generates heat to allow the playback element to protrude toward the recording medium side through thermal expansion, and a pair of electrode leads including overlapping regions, which are in contact with rear ends of the heating element and which overlap with the upper shield layer, and heat dissipation regions. Furthermore, connection wiring portions of the pair of electrode leads are disposed in a region sandwiched between the upper shield layer and a magnetic layer.

Owner:TDK CORPARATION

Wheat steeping device with classifying function

InactiveCN107711484AHierarchical implementationControl soaking timeSievingScreeningSteepingEngineering

The invention discloses a wheat steeping device with a classifying function, comprising a classifying screen and a wheat steeping slot, wherein the classifying screen is arranged at the top of the wheat steeping slot and is obliquely arranged, the wheat steeping slot is divided into two wheat steeping chambers; the lower part of the cylinder of the wheat steeping slot is a circular truncated conebottom, the circular truncated cone bottom is in a funnel shape and the bottom is in a circular arc shape, ventilation pipes are arranged in the two wheat steeping chamber, each ventilation pipe is formed by two straight pipes and a flat S-shaped pipe, the two ends of the flat S-shaped pipe are connected with the straight pipes, the two straight pipes respectively penetrate through the top and thebottom of the wheat steeping slot, the flat S-shaped pipe is positioned in the middle of the circular truncated cone bottom, and the bottom of the wheat steeping slot is fixedly connected with a discharge pipe, an exhaust pipe and a drain pipe. The wheat steeping device with a classifying function, disclosed by the invention, can steep wheat of different sizes separately, so that the two kinds ofwheat both achieve a good steeping quality, and further the overall growth quality of the wheat can be improved; and meanwhile, uniform ventilation of the wheat steeping slot is realized, and waste gas such as CO2 can be exhausted timely.

Owner:黄林海

Thin film magnetic head having heating element

ActiveUS20070274004A1Easy to manufactureEasy to carryRecord information storageManufacture of flux-sensitive headsEngineeringThermal expansion

A thin film magnetic head is provided, in which the amount of protrusion in the periphery of an element portion can be reduced or a local temperature increase of electrode leads of a heating element can be prevented. The thin film magnetic head includes a playback element disposed between lower and upper shield layers, a recording element laminated on the upper shield layer, a heating element which is disposed below a coil layer and which generates heat to allow the playback element to protrude toward the recording medium side through thermal expansion, and a pair of electrode leads including overlapping regions, which are in contact with rear ends of the heating element and which overlap with the upper shield layer, and heat dissipation regions. Furthermore, connection wiring portions of the pair of electrode leads are disposed in a region sandwiched between the upper shield layer and a magnetic layer.

Owner:TDK CORPARATION

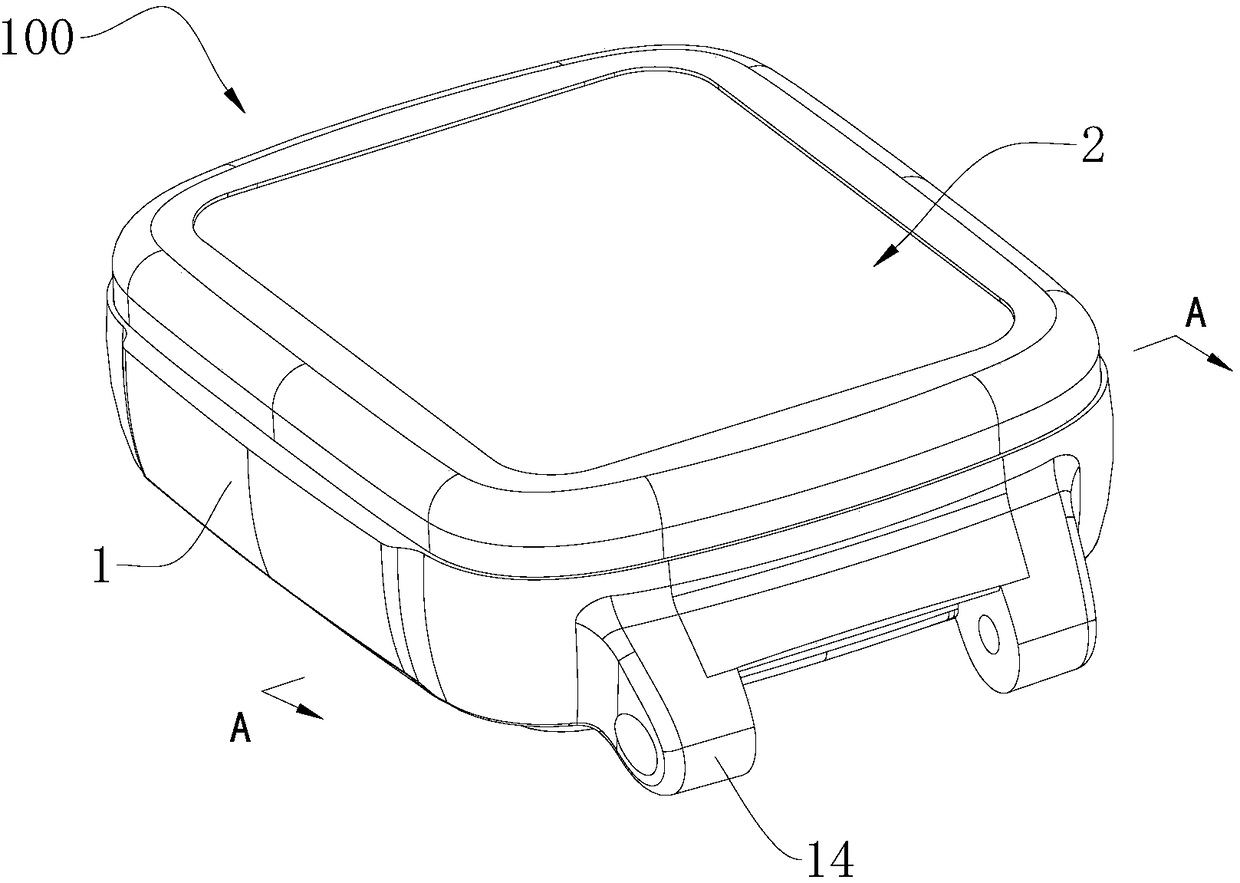

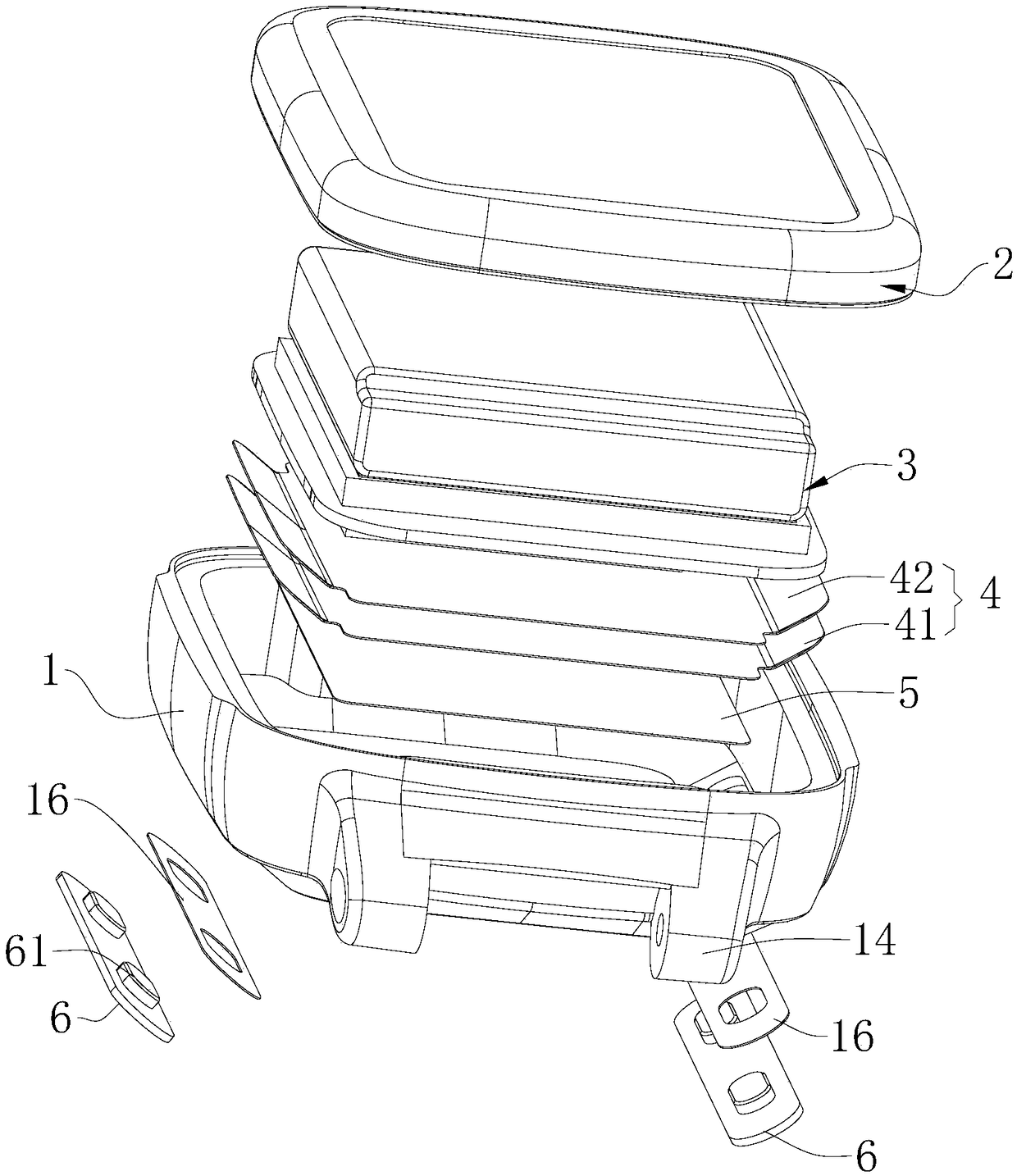

Heat dissipation structure of smart watch

PendingCN108093611AEfficient deliveryEvenly distributedClockwork casesCooling/ventilation/heating modificationsSkin contactMetal foil

The invention relates to the technical field of a smart watch, and provides a heat dissipation structure of a smart watch. The heat dissipation structure comprises a bottom shell, and a screen assembly and a main board assembly connected with the bottom shell; the bottom shell and the screen assembly are in enclosure to form an internal space for accommodating the main board assembly, wherein theheat dissipation structure also comprises a heat conducting sheet, a thermal insulating sheet and at least one metal heat dissipation sheet; the metal heat dissipation sheet is arranged on the outer surface of the bottom shell; the thermal insulating sheet is arranged between the heat conducting sheet and the bottom shell; the heat conducting sheet is used for transferring heat generated by the main board assembly to the metal heat dissipation sheet to guide the heat to the outside of the bottom shell; the heat conducting sheet is arranged in the internal space and comprises a metal foil and athermal diffusion film arranged on one side surface, towards the main board assembly, of the metal foil; and at least one metal heat dissipation sheet props against one side, far from the thermal diffusion film, of the metal foil. Compared with the prior art, heat dissipation efficiency can be improved and the temperature in a position in contact with skin can be lowered, thereby improving user experience of the product.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

Small soy sauce fermentation tank

InactiveCN111876322AImprove accuracyFast heat conductionBioreactor/fermenter combinationsBiological substance pretreatmentsStructural engineeringManufacturing engineering

The invention discloses a small soy sauce fermentation tank. The small soy sauce fermentation tank comprises a tank body, wherein a top cover is arranged at the top of the tank body, a sieve plate isarranged at the bottom of the circumferential inner wall of the tank body, a distributor is arranged at the bottom of the sieve plate, an air inlet pipe is arranged at the bottom of the distributor, and a residue outlet is inserted into the outer wall of one side of the tank body; a feeding opening is formed in one side of the outer wall of the top of the top cover, an air outlet pipe is insertedinto the outer wall of the top of the top cover, and two fixing rods are arranged on the inner wall of the top of the top cover. The height of a temperature sensor is adjusted by pulling an extensionrod to measure the temperature of materials at different horizontal positions, and when the extension rod is pulled, the circumferential inner wall of a material scraping ring makes contact with the extension rod and the circumference of the temperature sensor to conduct scraping. Therefore, inaccurate temperature detection caused by the fact that a large number of materials at original positionsare adhered to the outer wall of the temperature sensor and move to a to-be-detected position when the temperature sensor moves is avoided, and temperature detection accuracy is improved.

Owner:冯步迎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com