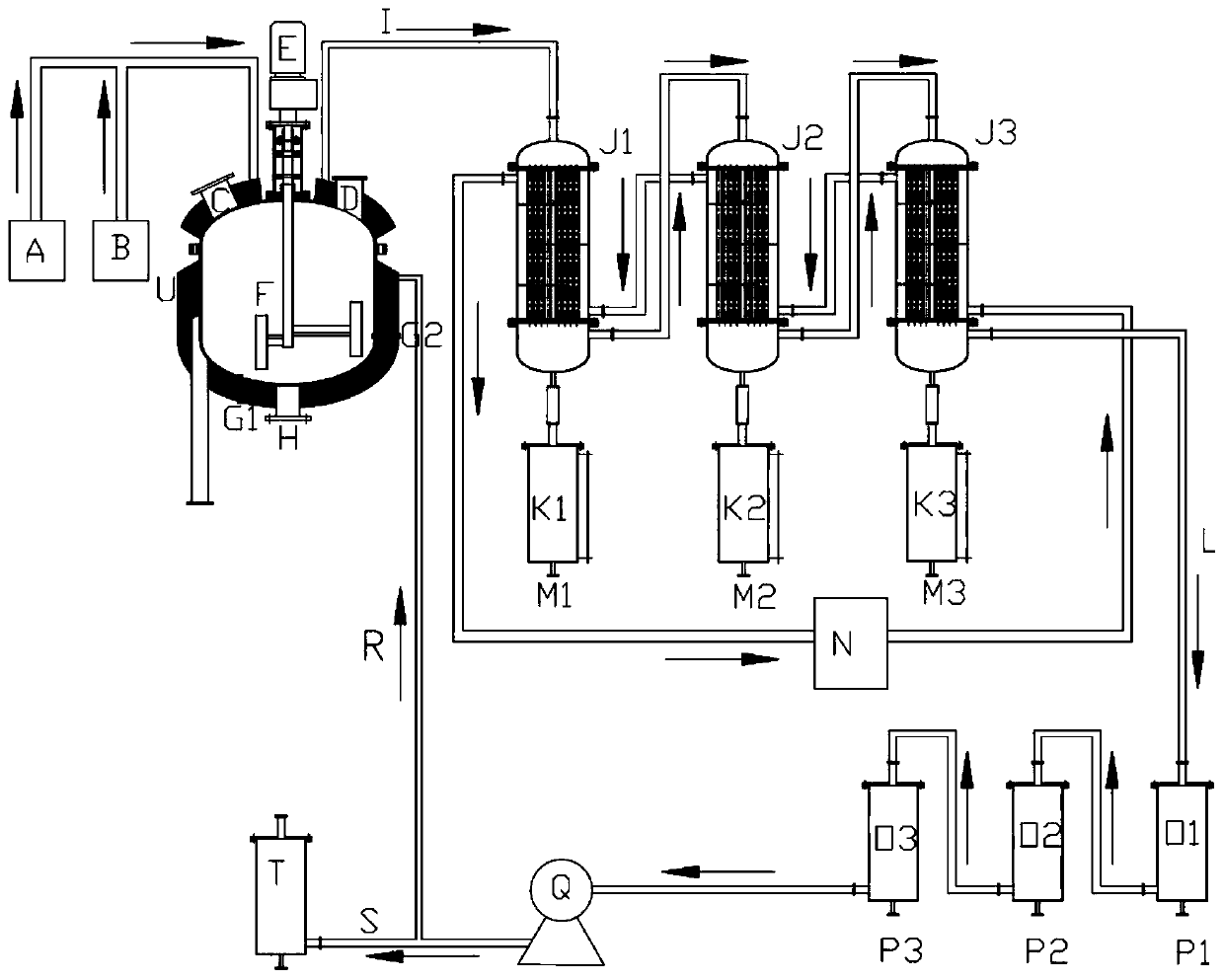

System for preparation of bio-oil, activated carbon and synthetic gas by microwave pyrolysis

A technology for synthesis gas and bio-oil, which is used in bio-fuel, petroleum industry, indirect heating and dry distillation, etc., can solve the problems of harsh particle size and moisture content of raw materials, no temperature detection system designed, and poor quality of pyrolysis products. Achieve good industrial value, sufficient and uniform pyrolysis reaction, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Before the reaction starts, feed material (50KG poplar wood particles) through the material inlet valve C, close the valve, open the nitrogen generator A, exhaust the whole system, close the nitrogen generator A, and turn on the microwave generator in the microwave reactor D (3 microwave generators, power of each microwave generator is 1500W) and helical gear motor E, so that the stirrer F can be used to stir while the system is heating, and it can be carried out by thermocouple temperature measuring tubes G1 and 2 The temperature measurement is fed back to the PLC controller to control the power of the microwave generator. When the temperature rises to 450°C, the channel I of the pyrolysis gas pipeline is opened to allow the pyrolysis gas to pass through the three-stage condenser J1, 2, and 3 (circulation in the condenser The water temperature is 5°C), so that the pyrolysis gas is condensed to generate bio-oil (bio-oil yield is 75%), which is then collected into bio-oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com